Adjustable steering drag link assembly

A technology of steering straight tie rods and straight tie rods, which is applied in the field of auto parts and can solve problems such as inability to adjust, inconvenient loading, and inability to adjust the rod body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

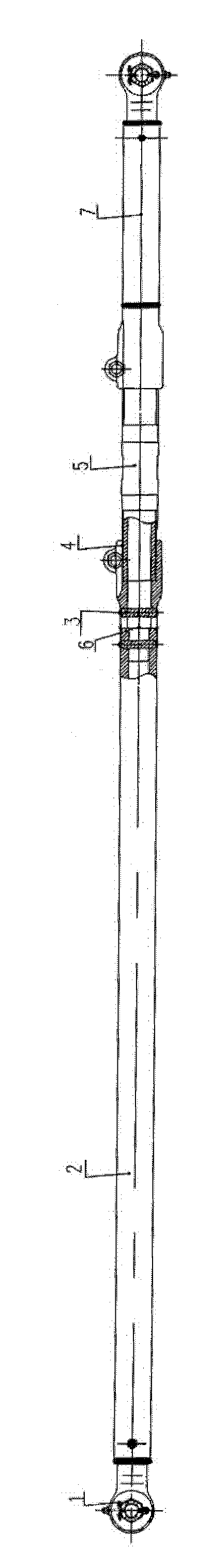

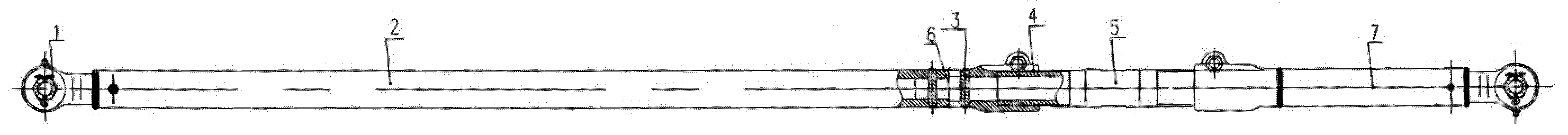

[0009] Such as figure 1 As shown, the present invention is welded with a joint assembly 1 at one end of the first straight rod 2, at the other end of the first straight rod 2 through the tie rod fixing pin 6 and the positioning sleeve 3, and at both ends of the connecting bolt 5 are respectively provided with The connecting sleeve 4 is fitted together with the positioning sleeve 3 and fastened with bolts, and the second straight rod 7 is connected with the other positioning sleeve 3 therein. Through the above settings, the length of the present invention can be adjusted by adjusting the depth of the connecting sleeve 4 inserted into the positioning sleeve 3, which facilitates loading and better meets the requirements of users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com