Cross-winding bobbin replacement mechanism and its operating method

A technology for cross-winding bobbins and parts is applied in the field of replacing parts of cross-winding bobbins, which can solve the problems of cumbersome, time-consuming, complex structure and the like, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

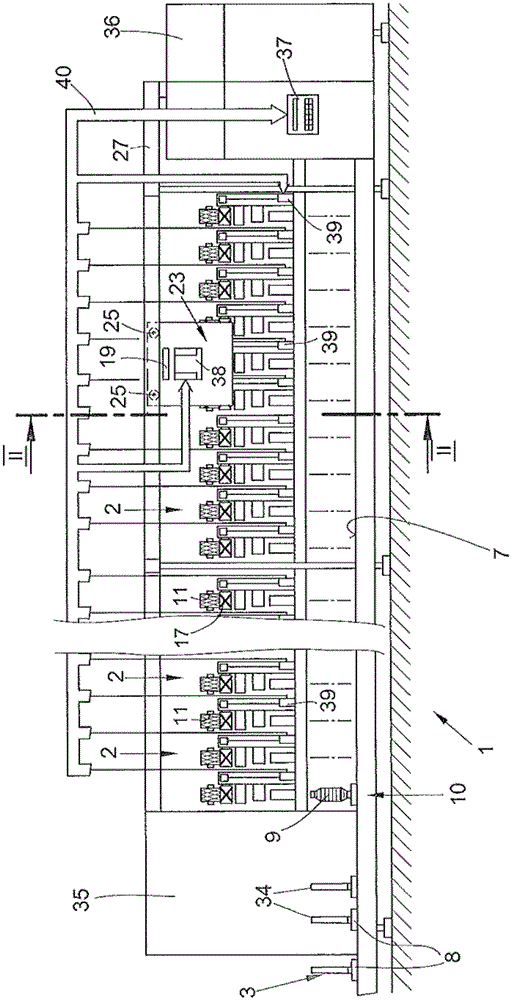

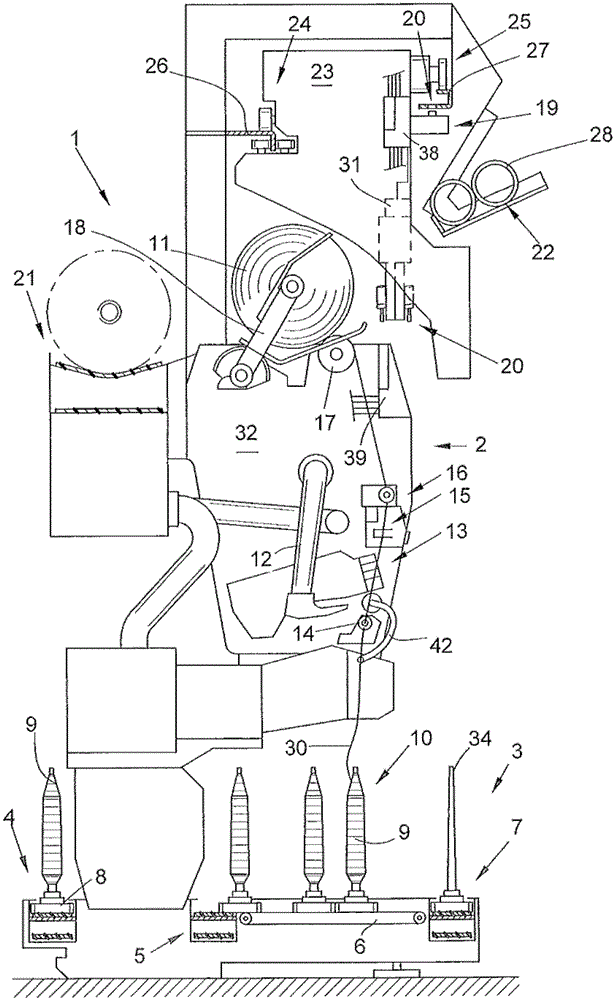

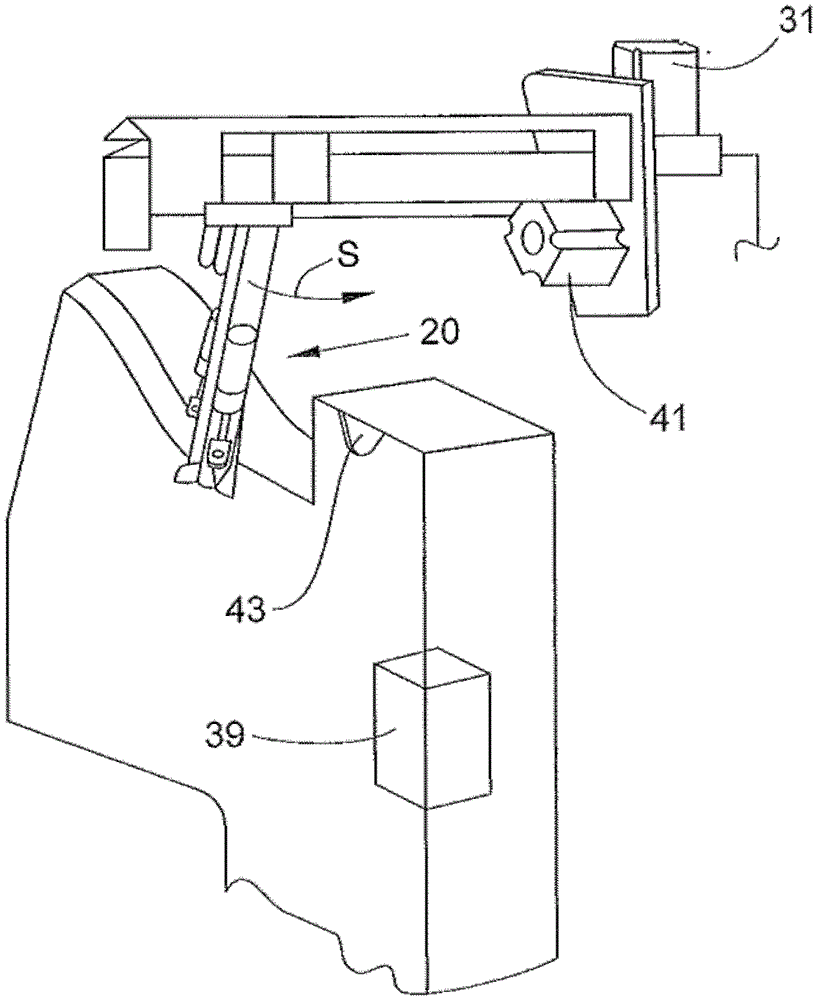

[0024] figure 1The front view schematically shows a textile machine for producing cross-wound bobbins, in this embodiment an automatic cross-winder 1 . Such an automatic cross-winding winder usually has a number of identical stations 2 between its end frames 35, 36, at which station a ring spinning machine (not shown) upstream of the production process The bobbin 9 produced is rewound into a cross-wound bobbin 11 of a large package. The prepared cross-wound bobbin 11 is then transferred to the cross-wound bobbin transport mechanism 21 of the textile machine itself by means of an automatically operating cross-wound bobbin changer 23 and then sent to the bobbin loading and unloading station ( not shown), etc. like figure 2 As shown, such an automatic cross-winding winder 1 generally has a logistics device in the form of a bobbin conveying system 3 in which bobbins 9 or empty bobbin bobbins 34 are transported by means of a conveying circle Disc 8 circulates. figure 2 The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com