Mechanical seal device

A mechanical seal device and mounting piece technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of low pumping ring slinging efficiency, slow cooling liquid circulation, etc., to reduce the working temperature, accelerate the circulation, Increases the effect of the water throwing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

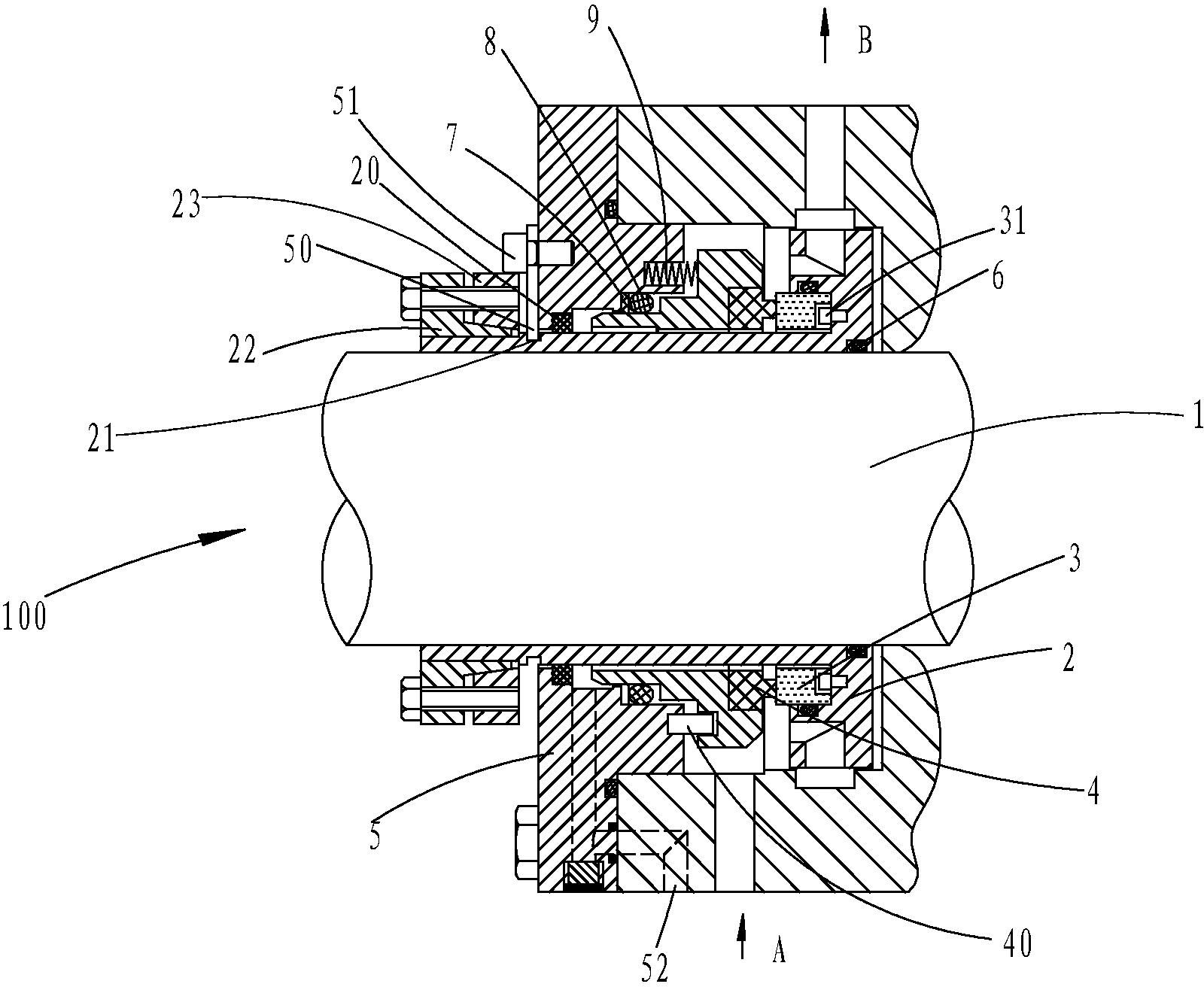

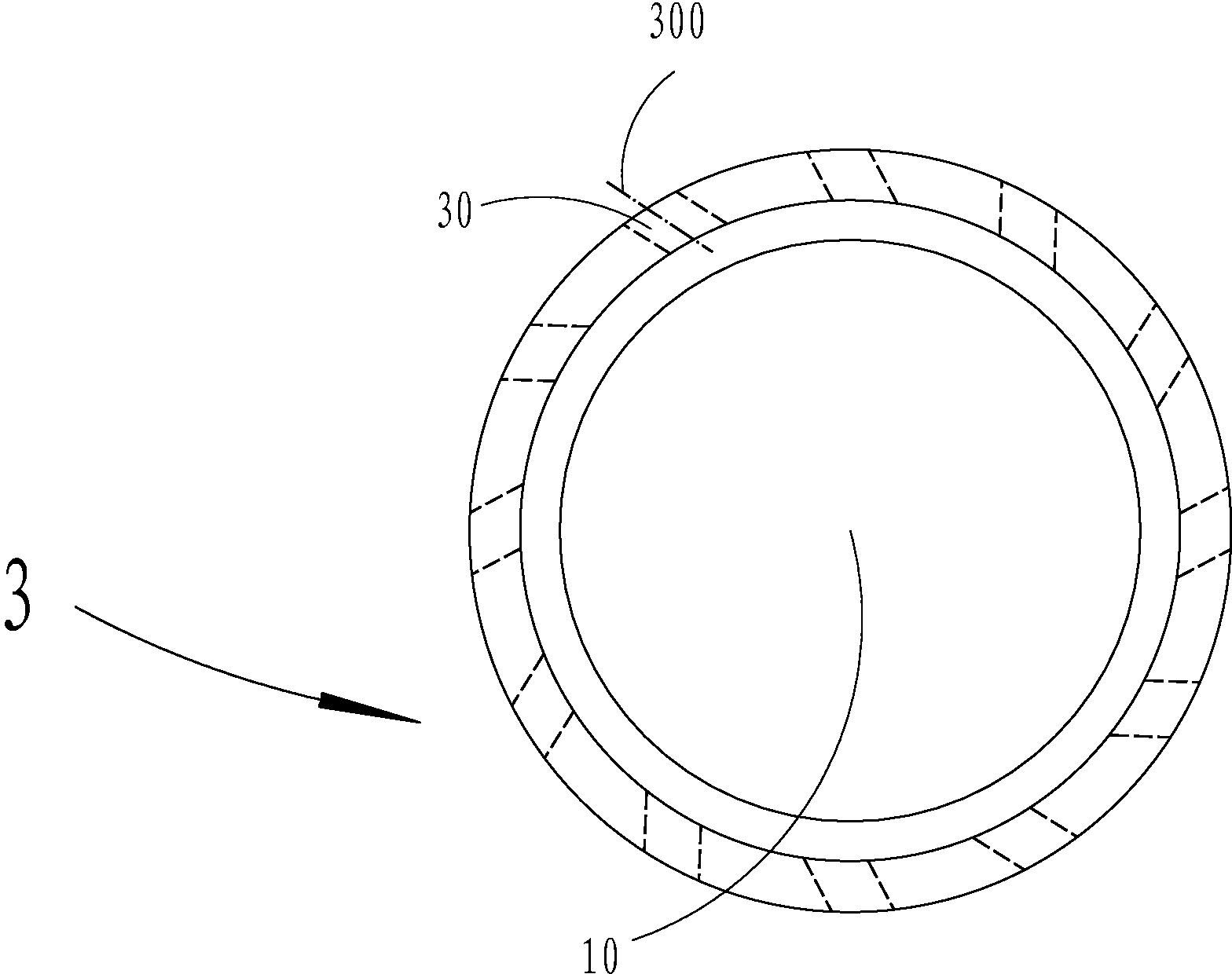

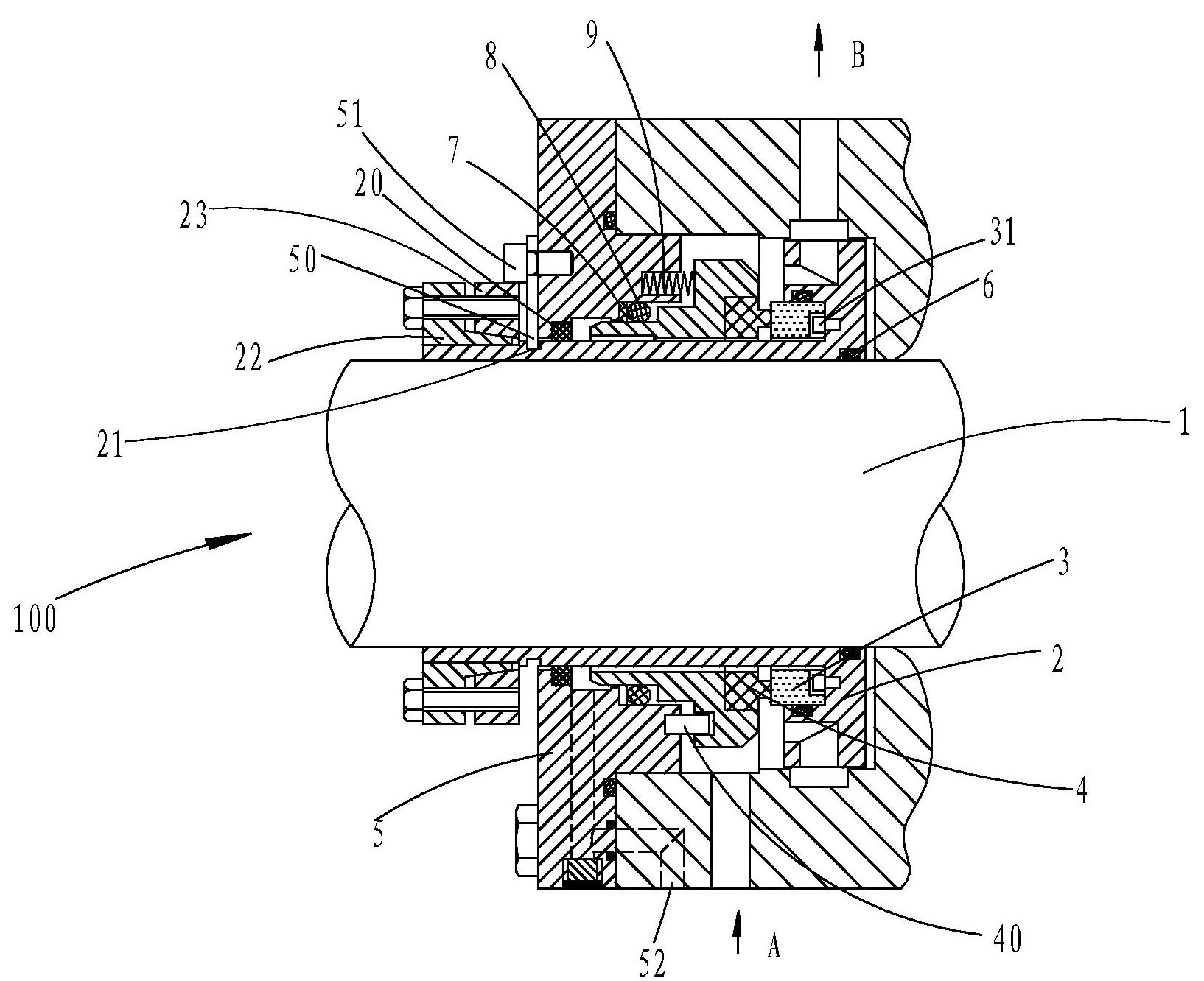

[0010] see figure 1 and figure 2 , a mechanical seal device 100, which includes: a rotating shaft 1, a shaft sleeve 2 installed on the rotating shaft 1, a pumping ring 3 integrally formed with the shaft sleeve, a static ring 4 frictionally fitted with the pumping ring 3, and a static ring mounted on the static ring The gland 5 on 4, the sleeve O-ring 6 is arranged between the shaft sleeve 2 and the rotating shaft 1, the gasket 7 and the static ring O-ring 8 are arranged between the gland 5 and the static ring 4, so A spring 9 is provided between the gland 5 and the static ring 4, and an anti-rotation pin 40 is provided between the gland 5 and the static ring 4, thereby preventing the gland 5 from rotating relative to the static ring 4. The gland 5 A cut-off ring 20 is provided between the shaft sleeve 2, and a mounting piece 50 is provided on one side of the gland 5, and the mounting piece 50 is fixed to the gland 5 by a hexagon socket head set screw 51, and the shaft The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com