Robot for automatically deicing for power transmission line

A transmission line and robot technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of failure to overcome obstacles, increased weight, and unreliable obstacles, and achieve the effect of easy remote control, convenient and reliable obstacle surmounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

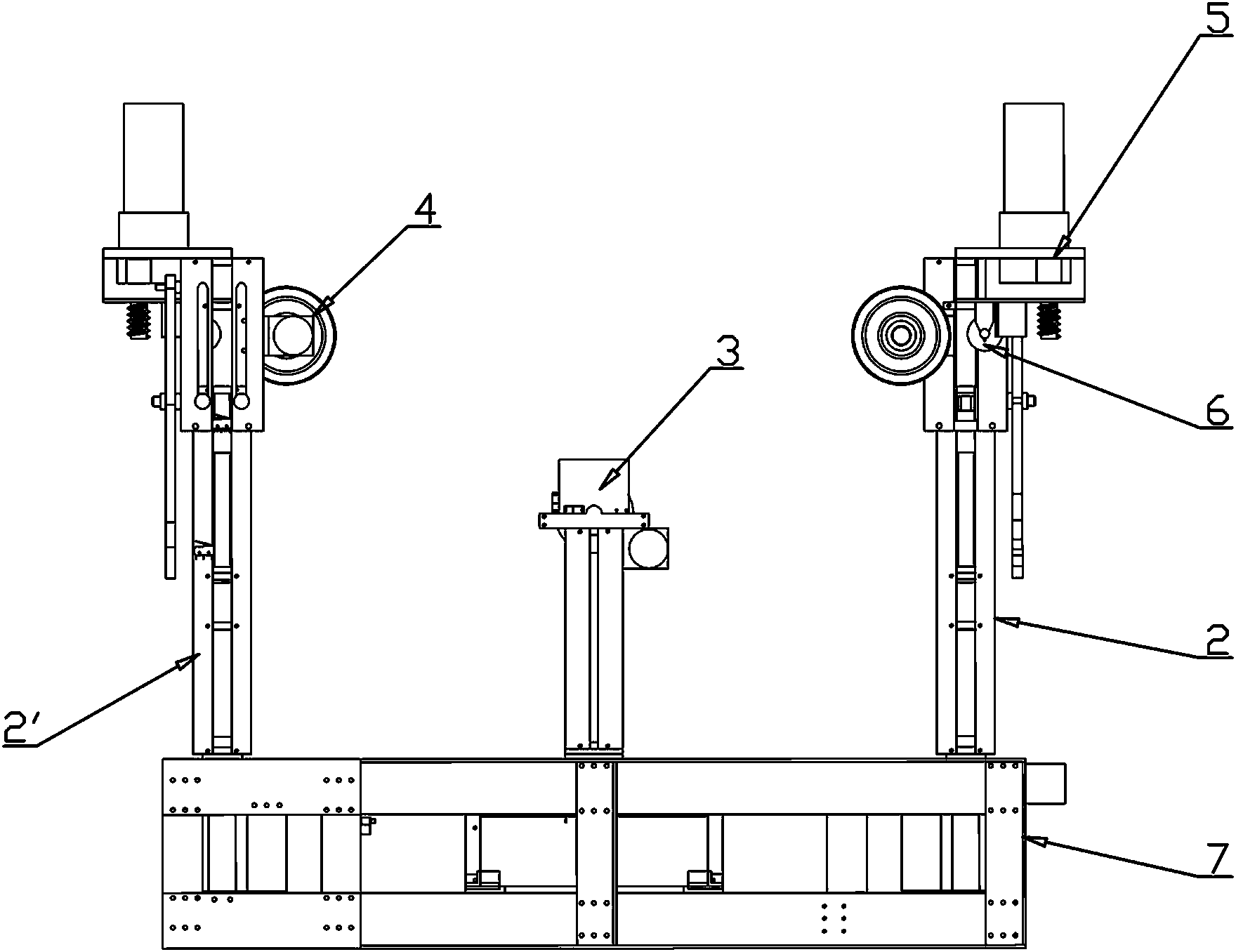

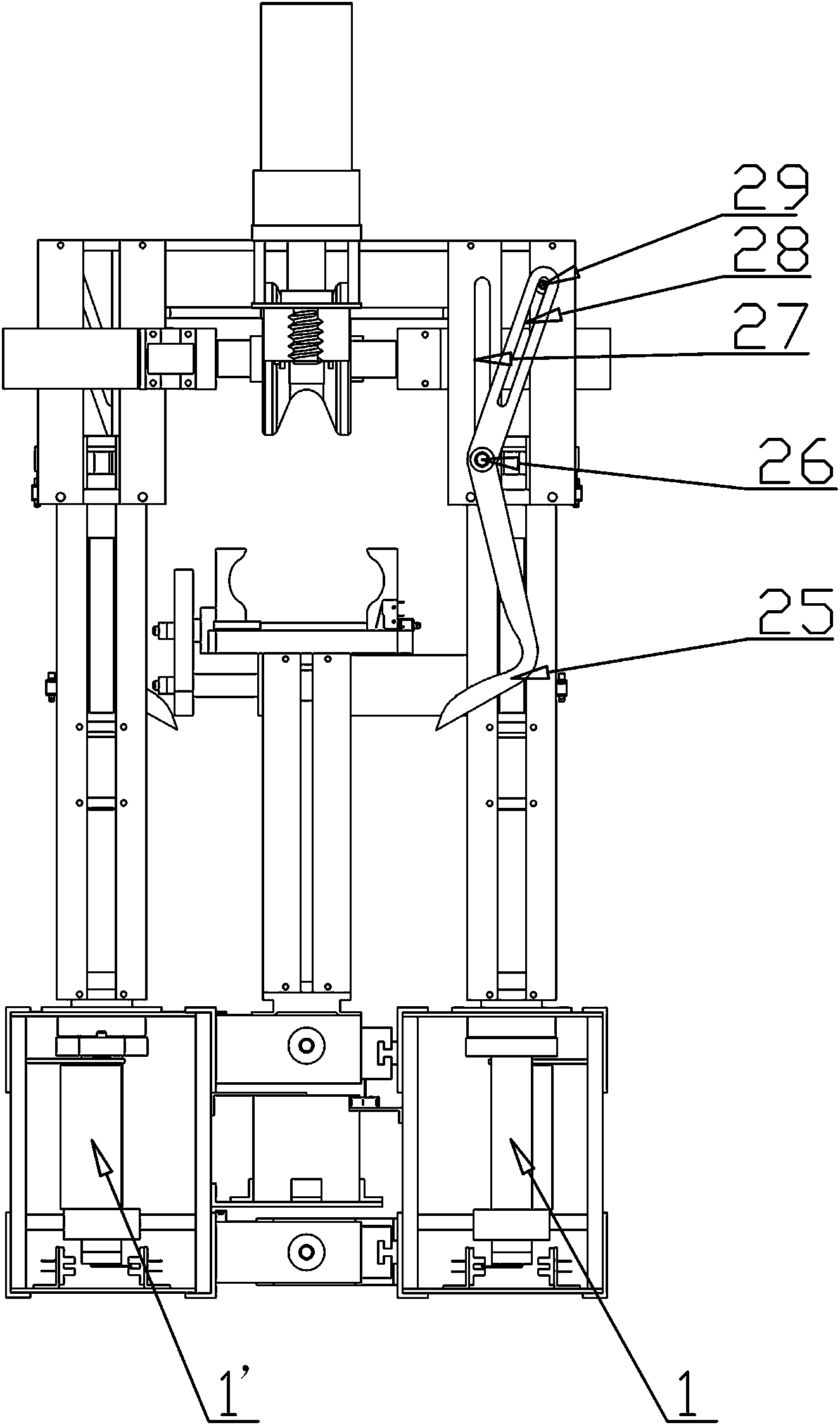

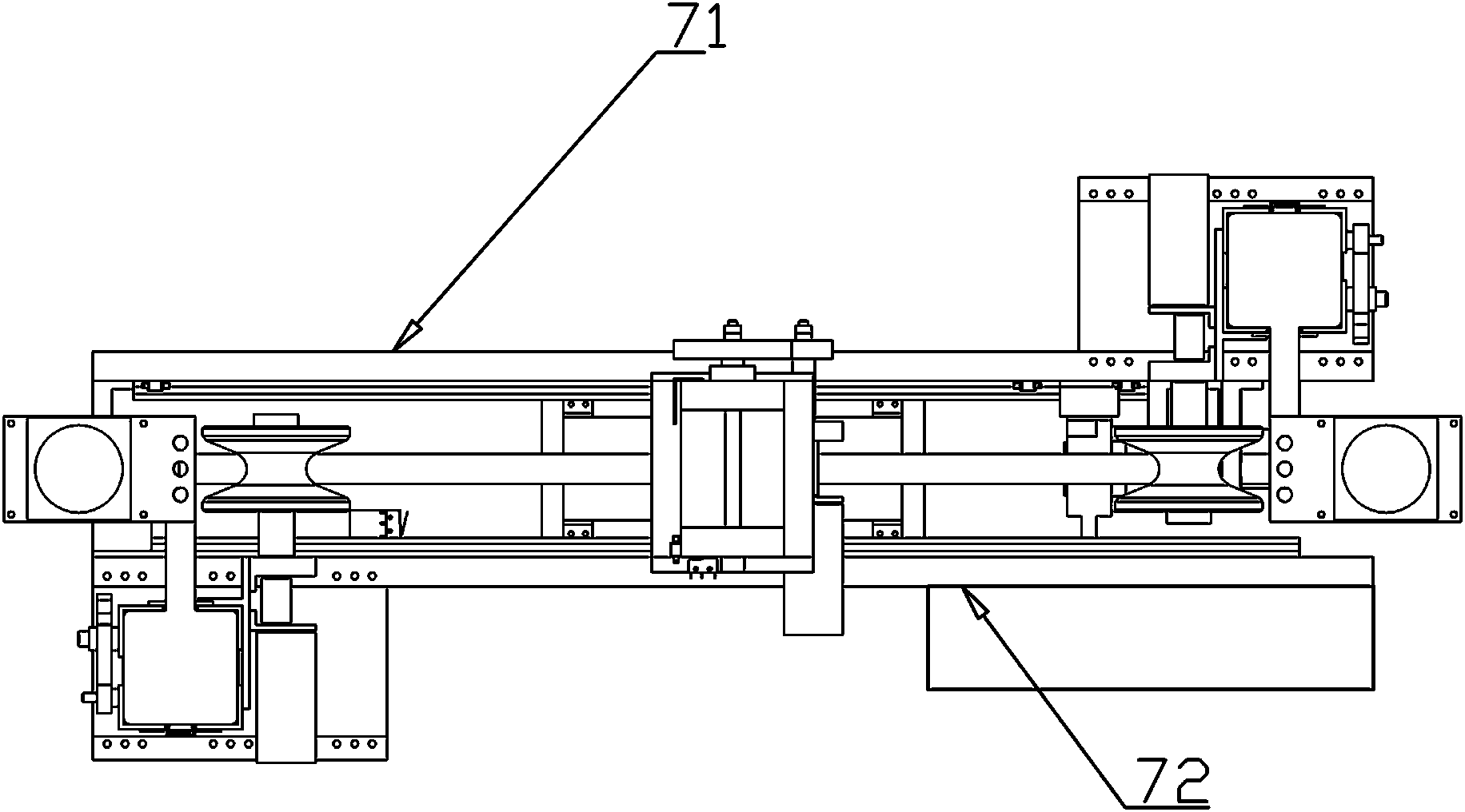

[0036] like figure 1 In -3, an automatic deicing robot for transmission lines, the first traveling case 71 and the second traveling case 72 are connected by a second screw and nut mechanism 74, and the screw in the second screw and nut mechanism 74 is installed on the first traveling case 71. , a first screw nut mechanism 73 is also provided above the second screw nut mechanism 74, and the lower end of the clamping device 3 is connected with the first screw nut mechanism 73 through threads; in this example, in order to reduce friction, part of the screw nut mechanism adopts Ball screw nut mechanism.

[0037] The first traveling box 71 is connected to the first lifting arm device 2 through the rotating device 1 that can rotate the device mounted on it to a certain angle, and the second traveling box 72 is connected to the rotating device that can rotate the device mounted on it through a certain angle. 1' is connected with the second lifting arm device 2';

[0038] The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com