Enamel coating, coated article and method of coating an article

A technology of ceramic coating and enamel, applied in the field of coated articles and coated articles, enamel coating, to achieve the effect of allowing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

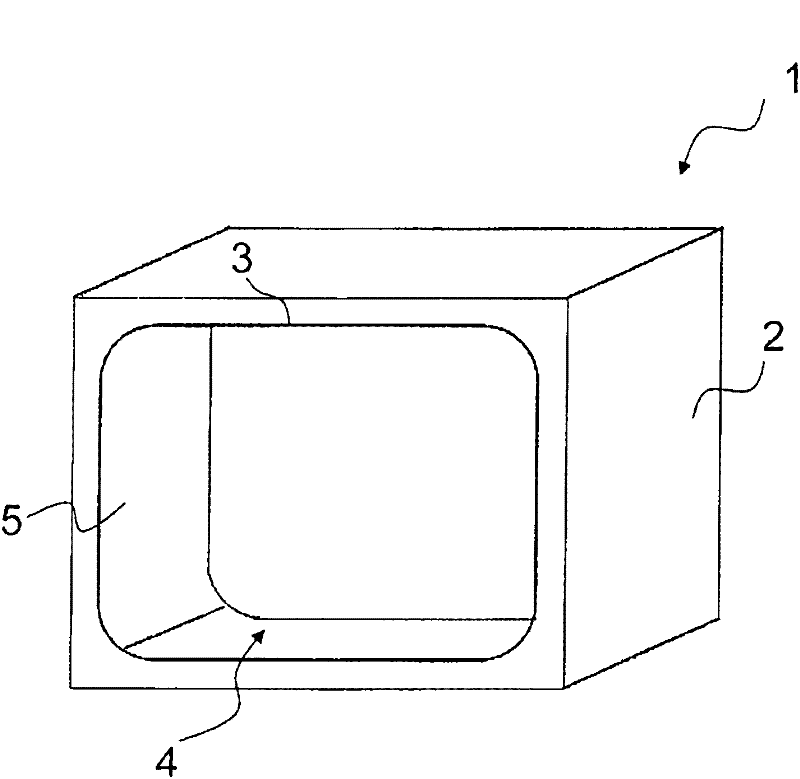

[0033] figure 1 Part 1 of a domestic oven is shown. Details of the oven that are not necessary for a complete understanding of the invention, such as parts of the oven door and manual operating elements, have been omitted. However, this does not limit the scope of the invention.

[0034] Said part 1 comprises an enclosure 2 surrounding a muffle 3 of the oven. The muffle 3 constitutes a cavity for receiving via the front opening 4 food products to be baked or roasted. Often, the inner surfaces 5 of the side, bottom, top and rear walls of the muffle furnace become soiled during baking or toasting of food due to steam, liquid splashes, food residues and the like.

[0035] The relatively high temperatures prevailing during the baking process cause sticky dirt to stick to the inner surface 5 of the muffle furnace 3 . Cleaning the inner surface 5 is therefore troublesome, all the more troublesome since the inner surface 5 of the muffle furnace 3 is generally inaccessible. It is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com