High-pressure fuel injection tube having connection head and method for producing the same

A technology for high-pressure fuel and a manufacturing method, which is applied to fuel injection devices, fuel injection devices, special fuel injection devices, etc. with stress reduction measures, can solve problems such as tensile stress rise, circumferential cracks, cavitation, etc. The effect of eliminating the increase of the inner diameter and the elimination of valley cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

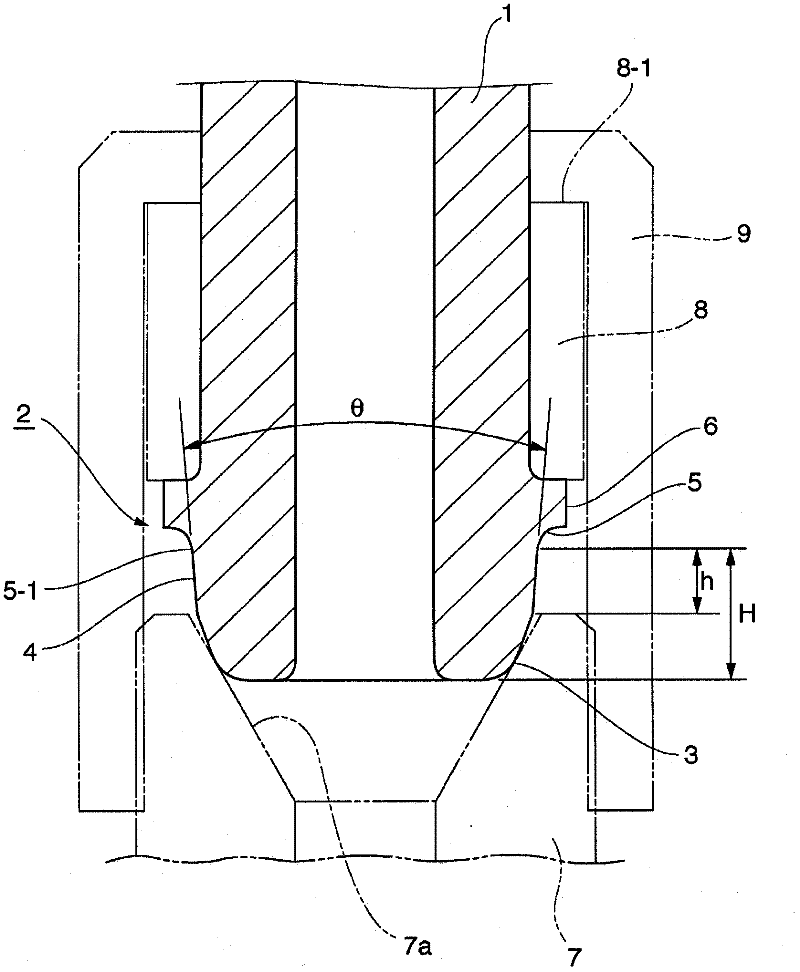

[0058] Using a thick-walled thin-diameter steel pipe (t / D=0.27) with a pipe diameter D of 9.0mm, an inner diameter Din of 4.0mm, and a wall thickness t of 2.5mm (material: equivalent to DIN ST52), the use is basically the same as Figure 7 The stamped components shown are the same stamped components, using and Figure 8 The same molding method as shown in the head molding method, manufacturing Figure 11 Shown is a high pressure fuel injection tube with a connecting head.

[0059] Regarding the pipe diameter D and wall thickness t of the thick-walled thin-diameter steel pipe in this example, the distance L in the axial direction from the end of the connection head obtained to the back of the annular flange part, the cylindrical shape The rear side opening angle θ of the face, the length h of the cylindrical face in the tube axis direction, the length H in the tube axis direction from the end of the connection head to the end of the rounded part on the side of the annular flan...

Embodiment 2

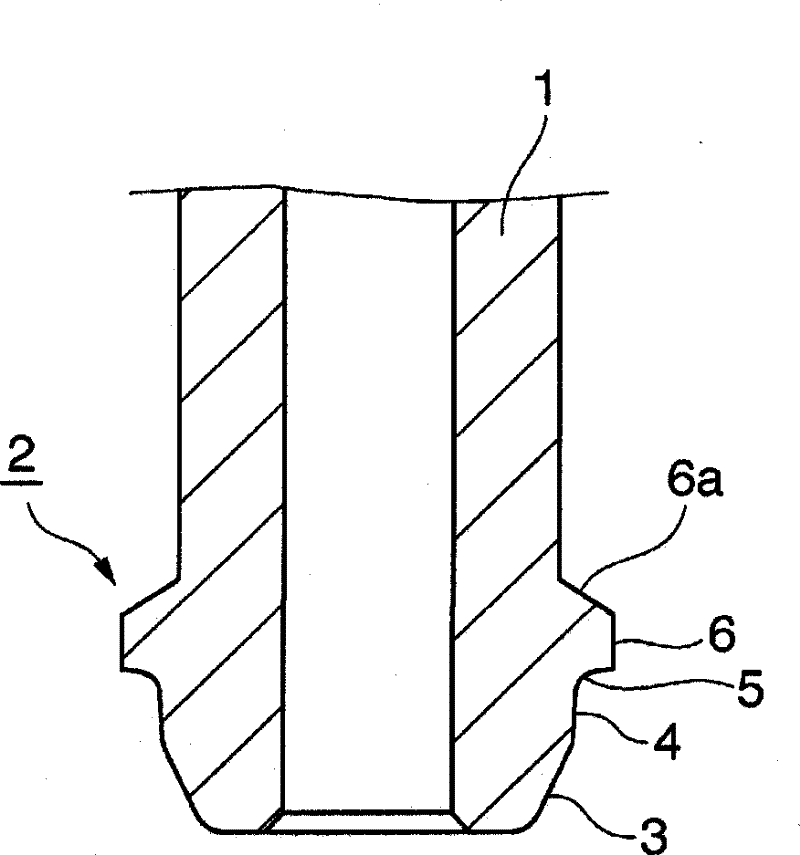

[0062] Using a thick-walled thin-diameter steel pipe (t / D=0.27) with a pipe diameter D of 9.0mm, an inner diameter Din of 4.0mm, and a wall thickness t of 2.5mm (material: equivalent to DIN ST52), the use is basically the same as Figure 7 The stamped components shown are the same stamped components, using and Figure 8 The same molding method as shown in the head molding method, manufacturing Figure 12 Shown is a high pressure fuel injection tube with a connecting head.

[0063] Regarding the pipe diameter D and wall thickness t of the thick-walled thin-diameter steel pipe in this example, the distance L in the axial direction from the end of the connection head obtained to the back of the annular flange part, the cylindrical shape The rear side opening angle θ of the face, the length h of the cylindrical face in the tube axis direction, the length H in the tube axis direction from the end of the connection head to the end of the rounded part on the side of the annular flan...

Embodiment 3

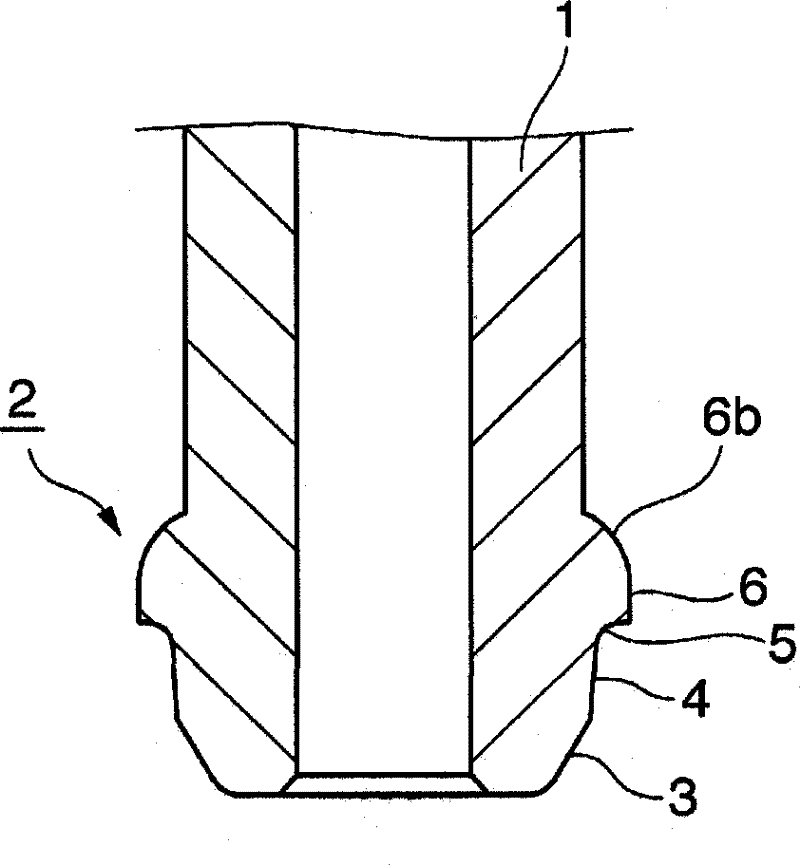

[0066] Using a thick-walled thin-diameter steel pipe (t / D=0.27) with a pipe diameter D of 9.0mm, an inner diameter Din of 4.0mm, and a wall thickness t of 2.5mm (material: equivalent to DIN ST52), the use is basically the same as Figure 7 The stamped components shown are the same stamped components, using and Figure 8 A high-pressure fuel injection pipe (omitted in the figure) having a connecting head is produced by the same forming method as the head forming method shown.

[0067] Regarding the pipe diameter D and wall thickness t of the thick-walled thin-diameter steel pipe in this example, the distance L in the axial direction from the end of the connection head obtained to the back of the annular flange part, the cylindrical shape The rear side opening angle θ of the face, the length h of the cylindrical face in the tube axis direction, the length H in the tube axis direction from the end of the connection head to the end of the rounded part on the side of the annular fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com