Copper pipe processing method adopting scanning flaring

A processing method and copper tube technology, which is applied in the processing field of copper tubes that adopt scanning expansion, can solve the problems of slow expansion process, low processing efficiency, long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

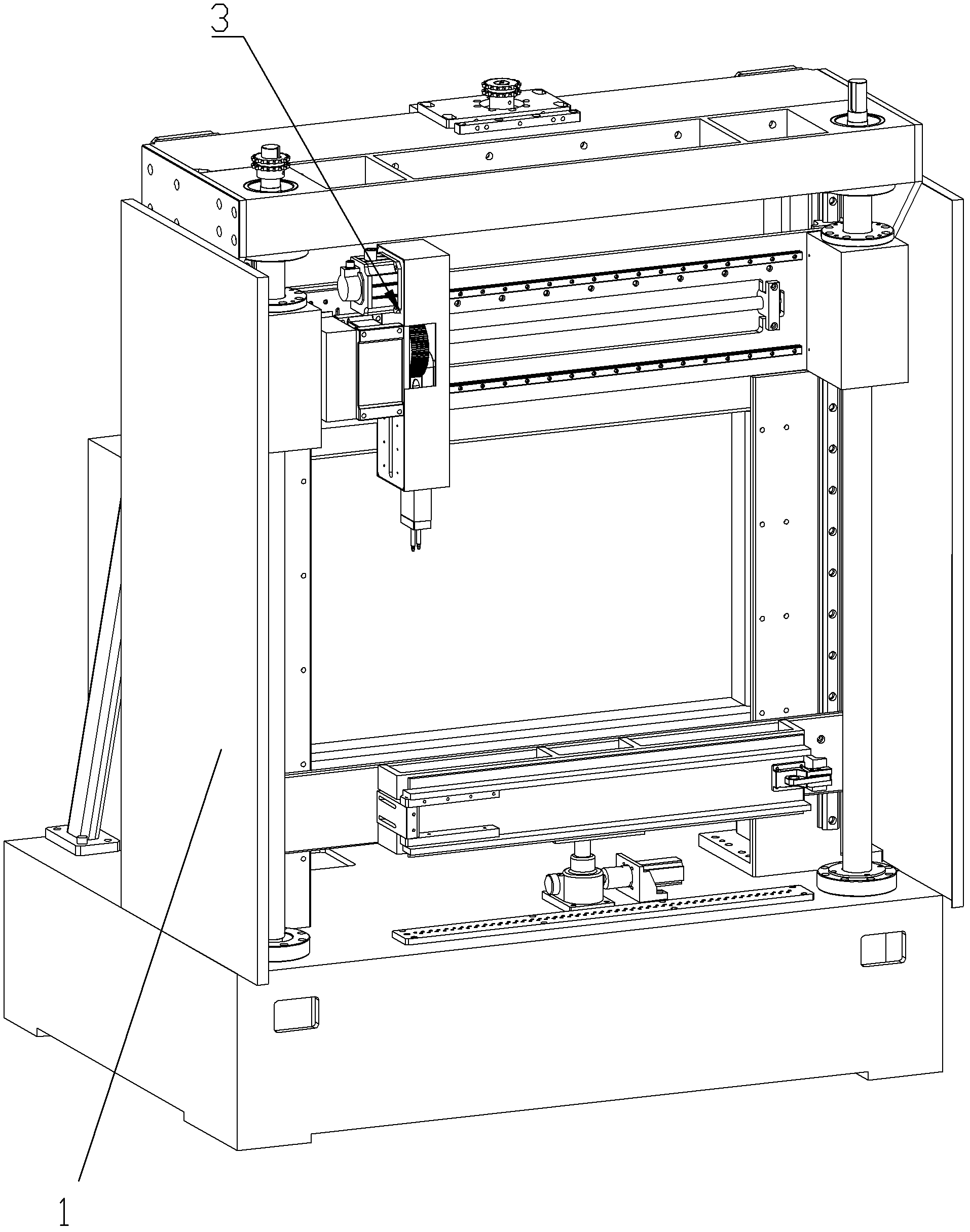

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

[0020] The processing method of scanning flared copper tube includes the following steps:

[0021] A: Fix the copper pipe, fix the copper pipe assembly on the frame 1, make the nozzles of each copper pipe face the same direction, and provide a prerequisite for the copper pipe expansion later.

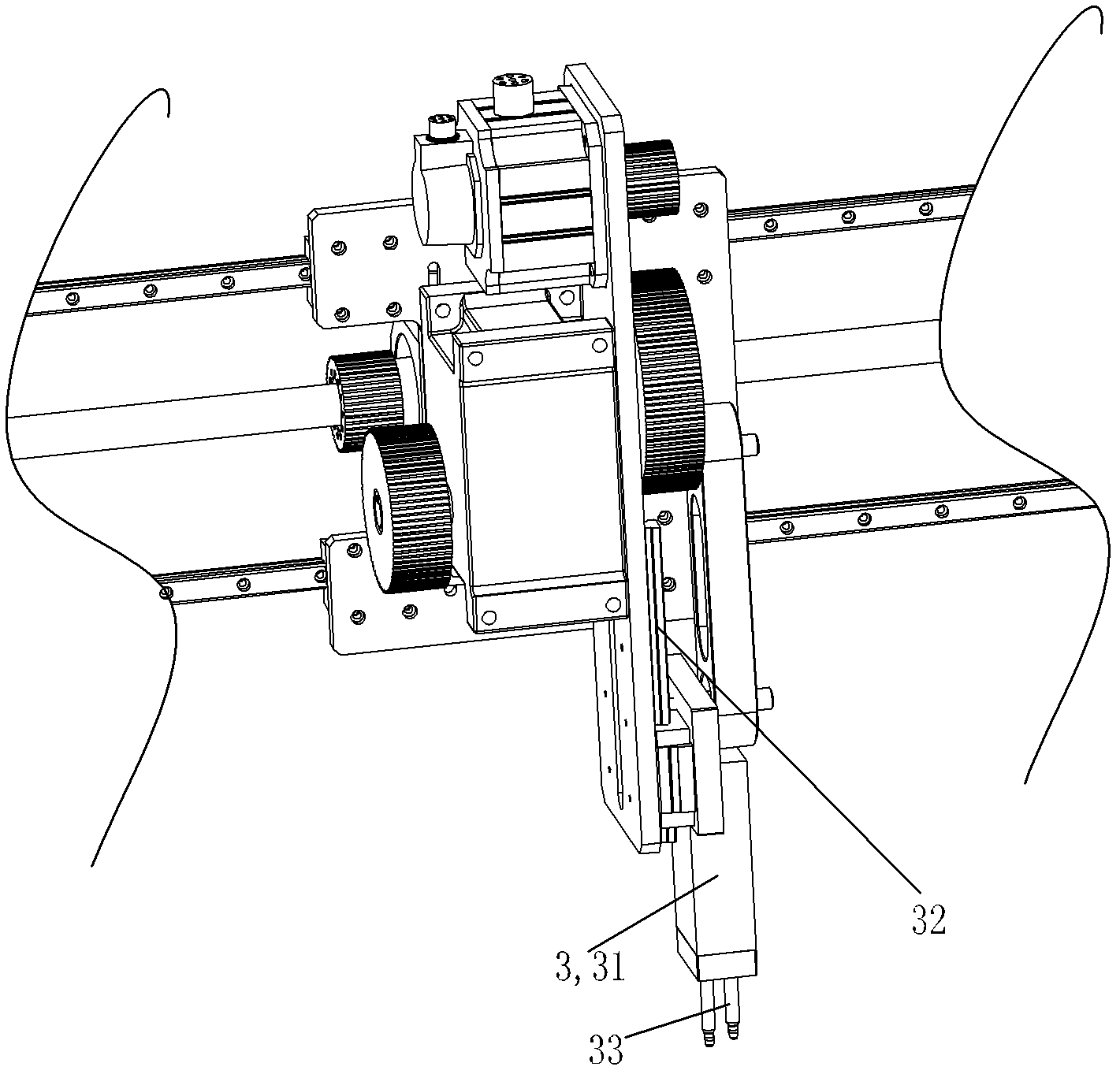

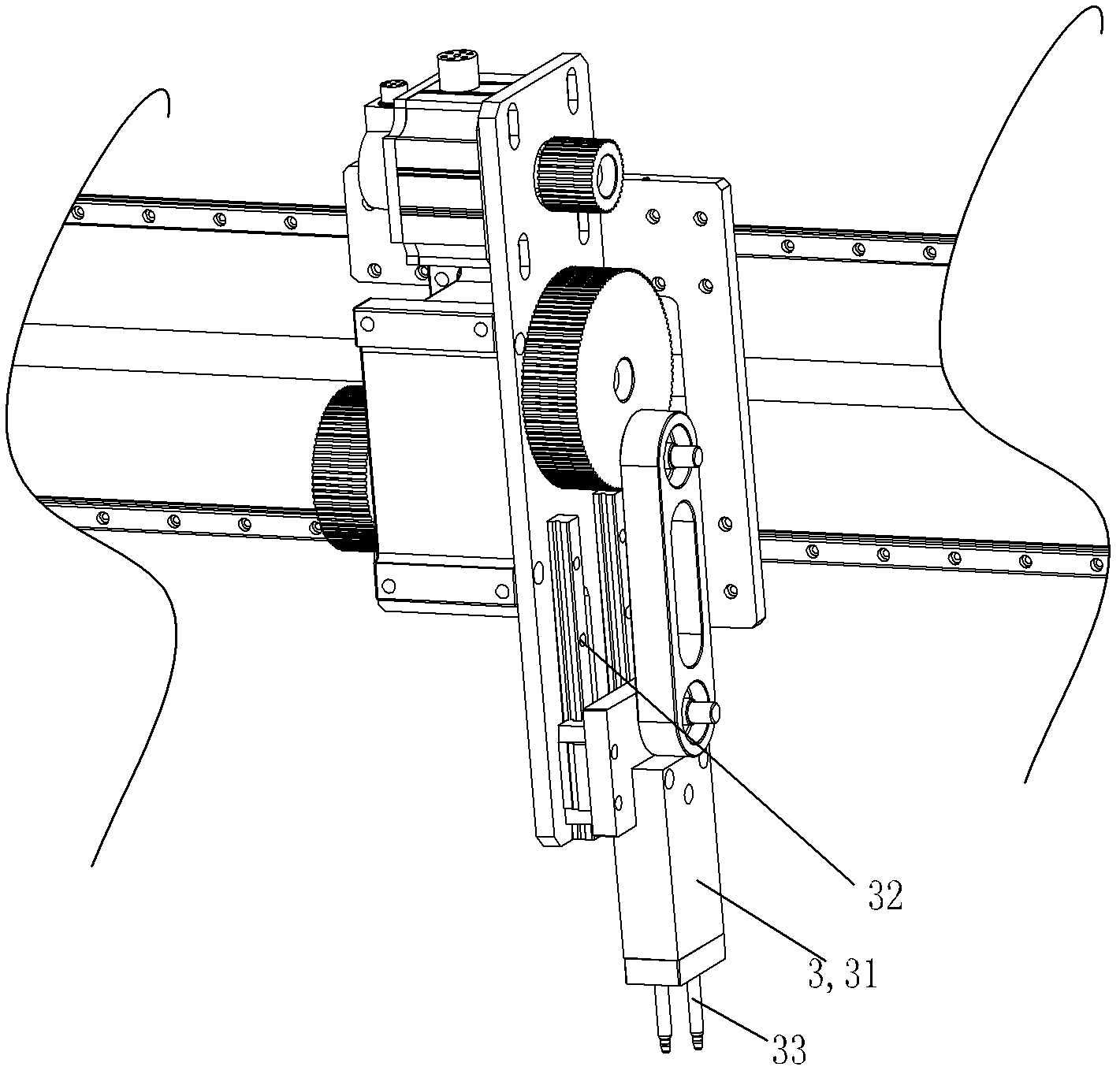

[0022] B: Scanning the expansion, first make the expansion head of the expansion head assembly 3 face the copper pipe opening on the copper pipe assembly, and then drive the expansion head assembly 3 to move down quickly, so that the expansion head can carry out the copper pipe on the copper pipe assembly Expand the mouth, then the expanding head assembly 3 quickly moves up and back, the expanding head assembly 3 realizes a pulse movement, and the up and down movement of the expanding head assembly 3 is a pulse movement.

[0023] Afterwards, the expanding head assembly 3 moves linearly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap