Cutting unit for cutting sheet material

A technology for cutting units and thin slices, which is applied in metal processing and other directions, and can solve the problems of complex configuration and structure of disk blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

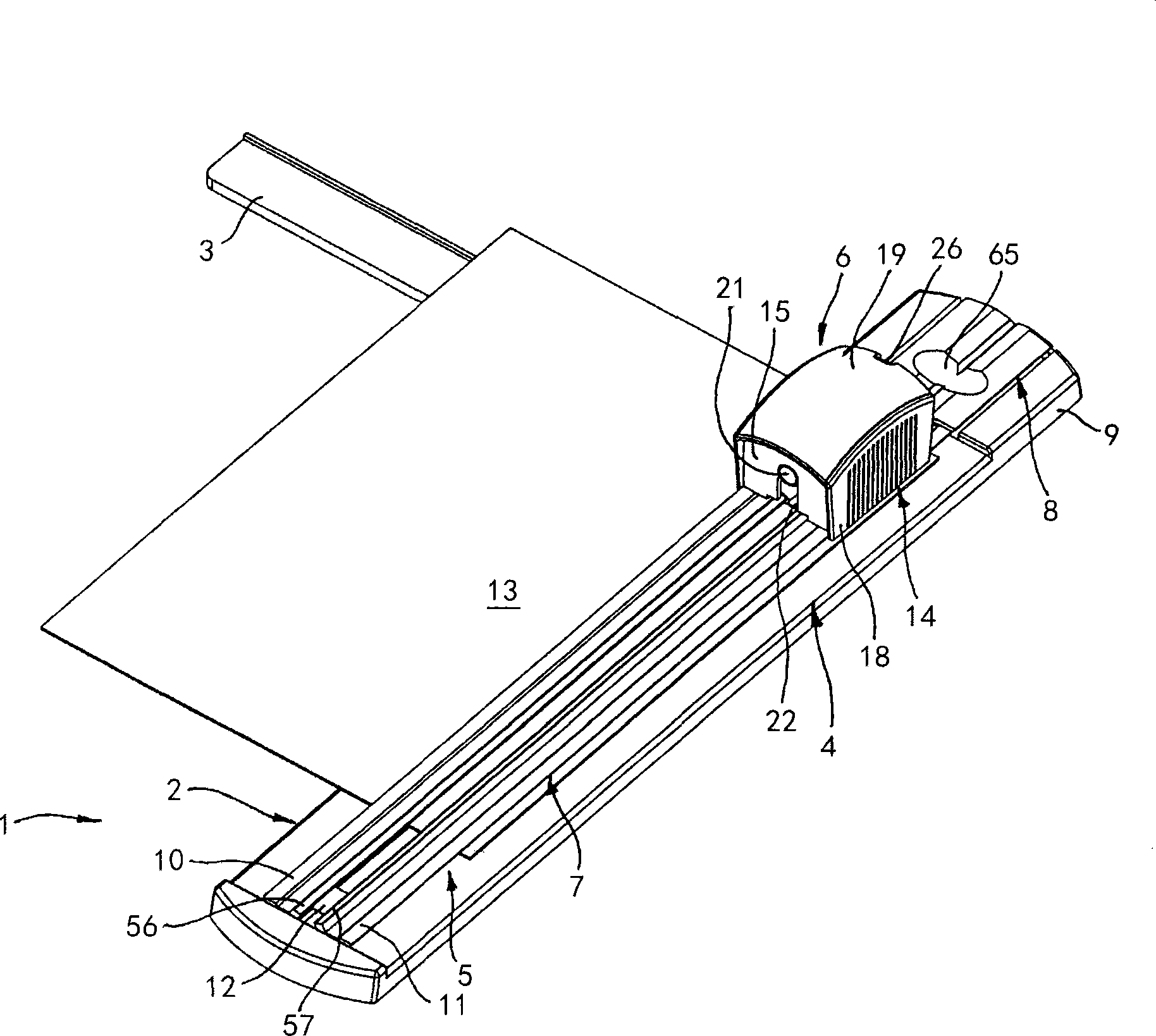

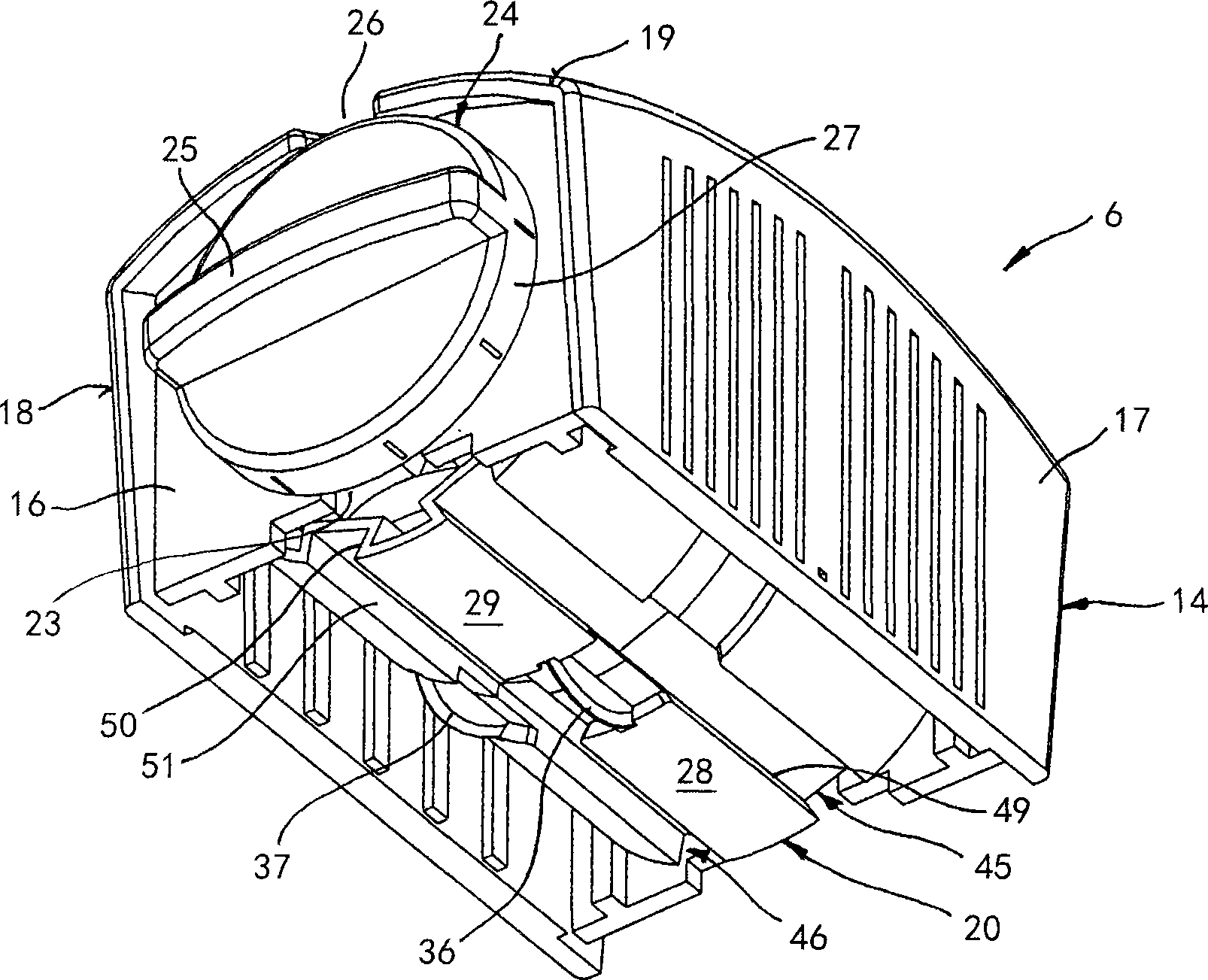

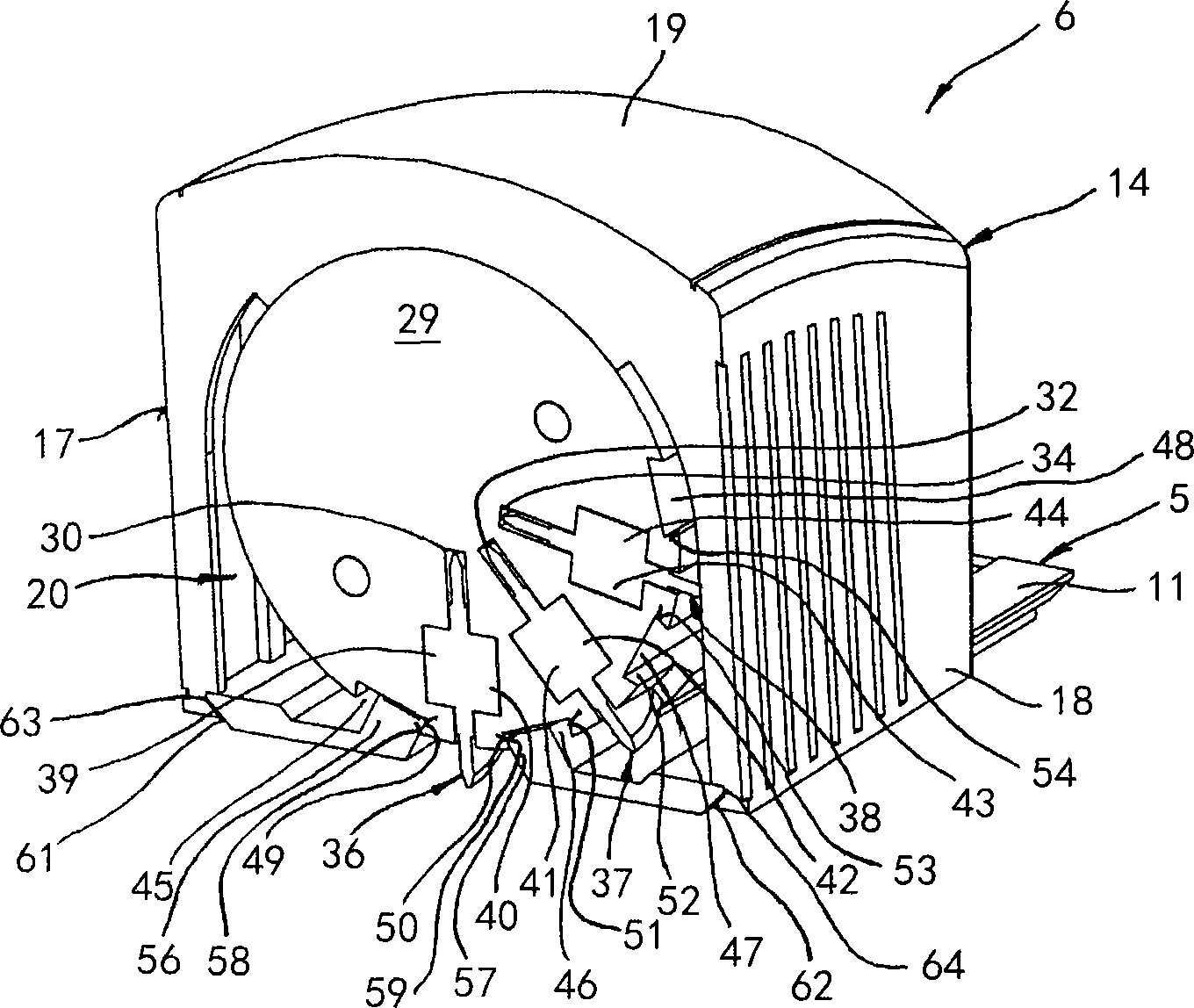

[0061] The cutting unit 1 shown in the drawing comprises a short beam-shaped foil support 2, wherein the contact rods 3 are folded out at right angles from the rear side of the foil support 2 facing away from the viewer. At a distance above the sheet support 2 there is a roll cutting device 4 which essentially comprises a support rail 5 and a cutting carrier 6 , which is movably supported on the support rail 5 . The support rail 5 is divided into a first rail assembly 7 and an adjacent second rail assembly, the first rail assembly 7 extends above the sheet support 2 with an offset (Offset), and the second rail assembly is formed into the sheet support. In the front end assembly 9 of the seat 2.

[0062] Both ends of the first rail assembly 7 are supported on the sheet support 2 by vertical coil springs (not shown), so that the first rail assembly 7 can be moved from the shown starting position (wherein the first rail assembly 7 There is an offset from the upper side of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com