Optical information record medium

A recording medium, optical information technology, used in optical record carriers, data recording, information storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

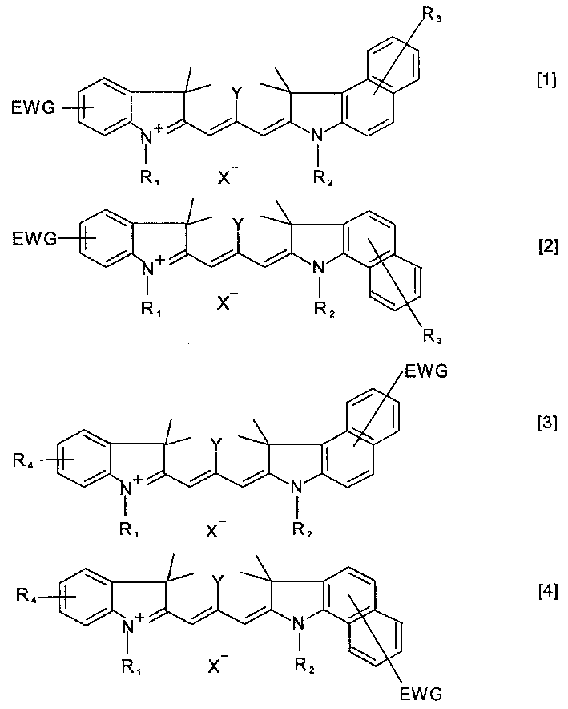

[0172] Example UV Spectrum Write Wavelength Reflectance Push-Pull Value I14 / I14H Vibration

[0173] (nm) (650nm)

[0174] CH 3 CN%%%

[0175] 1 577 for 66.4 0.29 0.45 8.2

[0176] 2 577 for 55.3 0.60 0.60 5.7

[0177] 3 577 for 47.5 0.43 0.61 6.5

Embodiment 1

[0181] Firstly, a transparent substrate is provided, which is an optical disc made of polycarbonate, and the optical disc has a threaded groove, the track pitch is 0.74 μm, the outer diameter of the optical disc is 120 mm, and the thickness is 0.6 mm.

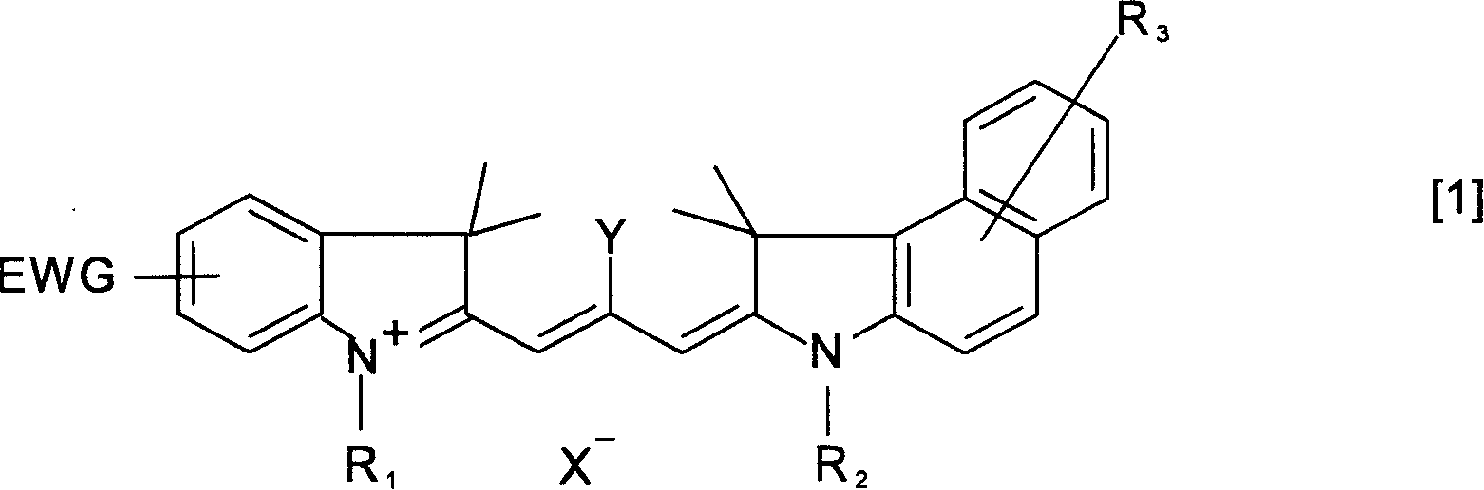

[0182] Next, 5.0 g of the compound of molecular formula [1-19] was dissolved in 100 ml of 2,2,3,3-tetrafluoro-1-propanol (TFP), stirred at room temperature for 5 hours, and passed through a 0.2 μm After filtering with polytetrafluoroethylene (PTFE) membrane, it is prepared into a dye solution.

[0183] By means of spin coating, the rotational speed was set at 3000 rpm, a layer of dye was coated on the substrate, and then dried at 70° C. for 20 minutes to form a recording layer with a thickness of 100 nm.

[0184] Then, in the mode of sputtering on the recording layer, a reflective layer of gold or silver is plated, wherein, argon is used as the gas required for sputtering, and the electric power required for sputtering is 1.5kw...

Embodiment 2

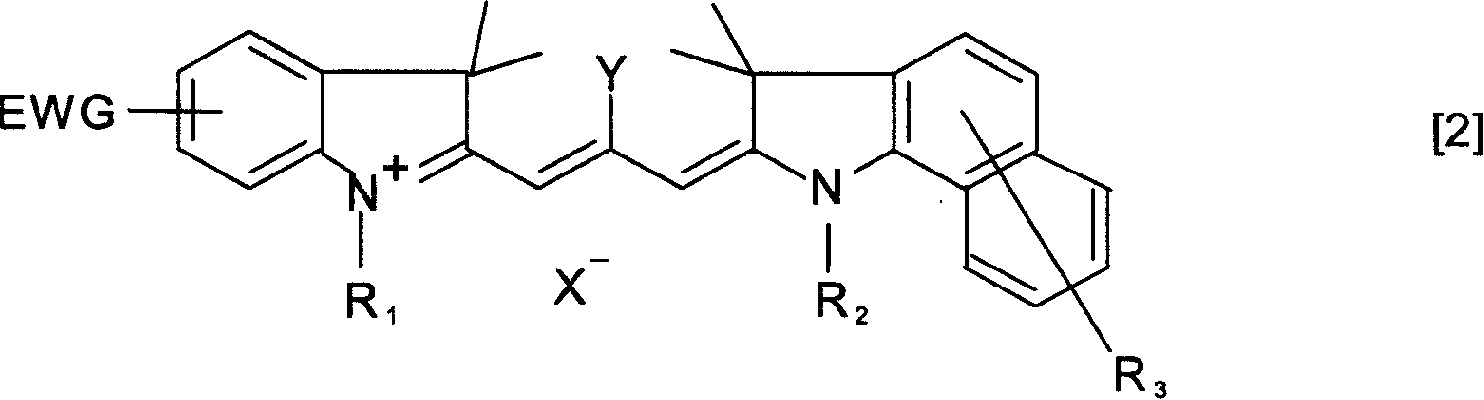

[0188] In this embodiment, the optical disc is prepared according to the method of embodiment 1, except that the dye substance of the molecular formula [1-21] is replaced in the embodiment 1. In this embodiment, the optical parameters of the recording layer are measured using the instrument used in Embodiment 1, and the measured results are recorded in Table 1. In this embodiment, the values of reflectivity, push-pull value and modulation degree are quite high, however, the vibration value is very low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com