Three-dimensional line printing device

A three-dimensional, light-cured material technology, applied in the direction of manufacturing auxiliary devices, manufacturing tools, processing materials handling, etc., can solve the problems of reducing printing fineness, printing platform tilt and not level, low fluidity, etc., to weaken buoyancy , Improve the effect of fineness reduction and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

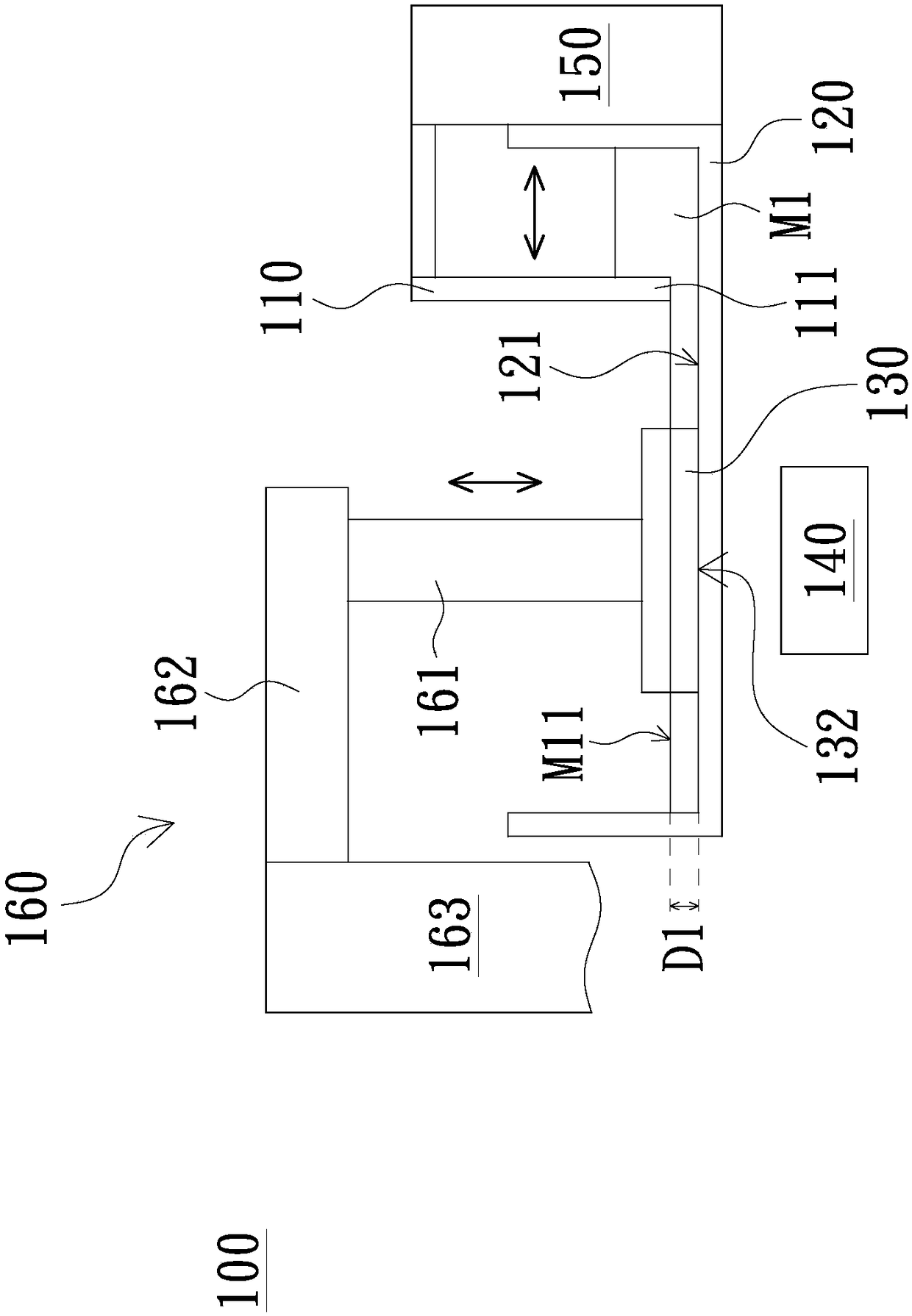

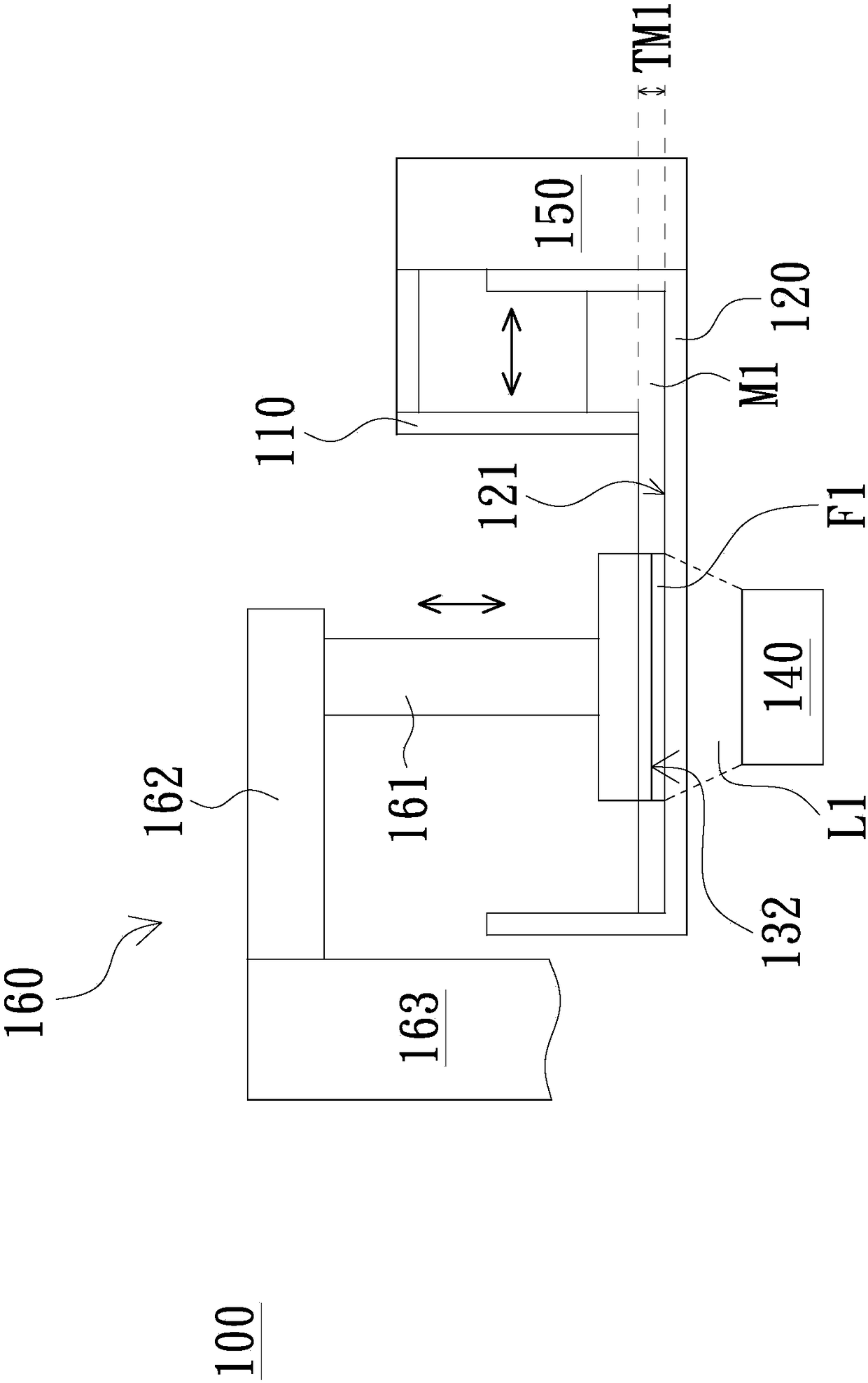

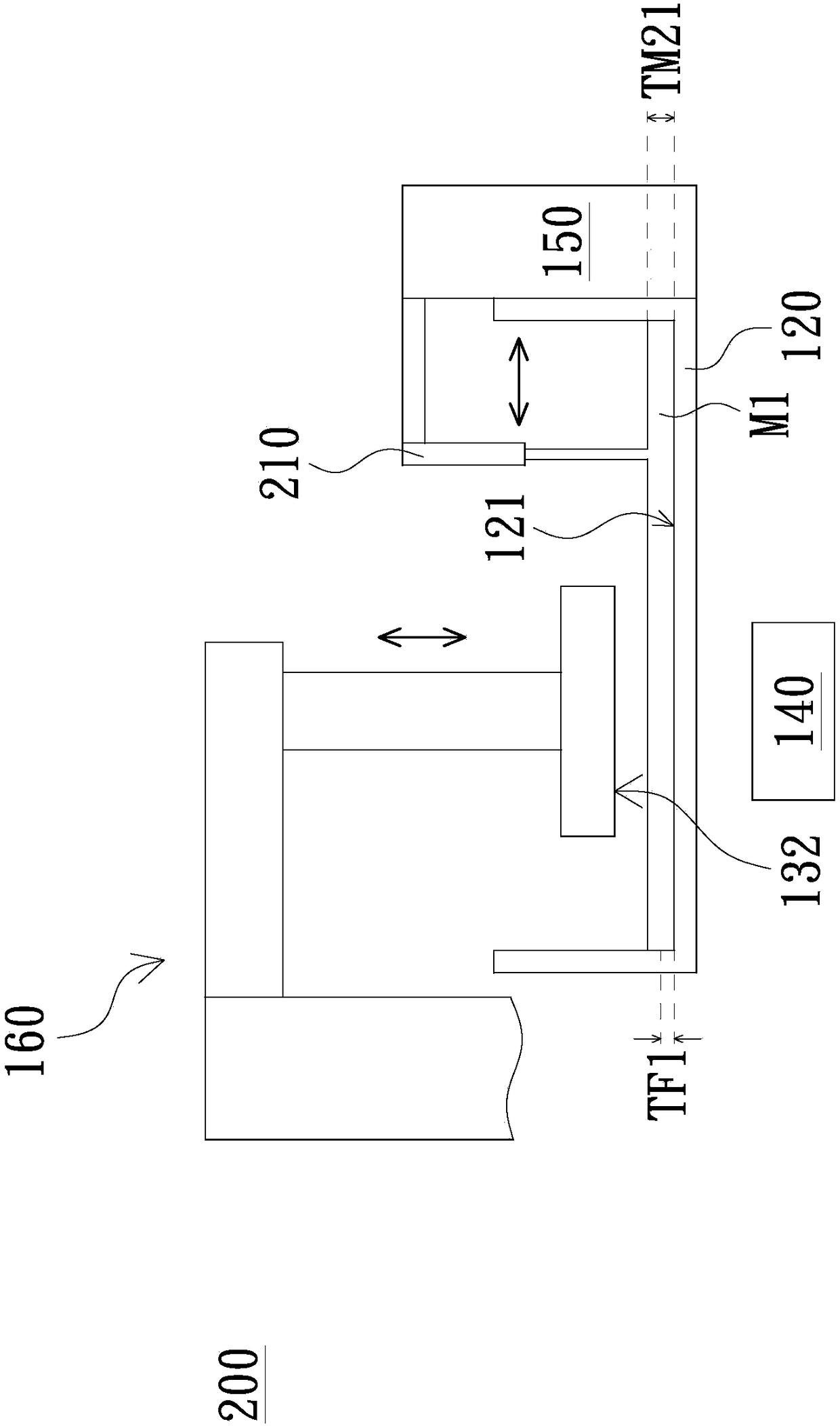

[0009] see Figure 1A and Figure 1B , the 3D printing device 100 includes a removing mechanism 110 , a putting base 120 , a printing platform 130 , a projector 140 and a driving mechanism 150 . The accommodating seat 120 can accommodate the photocurable material M1, and has a plane 121, which can be used to place the photocurable material M1. The photocurable material M1 can be a liquid with good fluidity or a fluid that is not easy to flow. for the limit.

[0010] The removal mechanism 110 has a contact end 111 located above the plane 121 for contacting and removing a part of the photo-curable material M1, wherein the removal mechanism 110 is, for example, a scraper. The driving mechanism 150 is connected to the removal mechanism 110, and drives the removal mechanism 110 to move on the plane 121, so that the contact end 111 of the removal mechanism 110 can remove part of the light-curable material M1, so that the light on the plane 121 The thickness of the cured material M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com