Lift device for opening and closing of oil tank hatchcover

A lifting device and oil tank technology, which is applied in door/window fittings, buildings, wing leaf operating mechanisms, etc., can solve the problems of excessive use of materials, seizure of the joint between the screw shaft and the nut, and easy accumulation of water in the cylindrical hole. , to achieve the effect of reducing the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

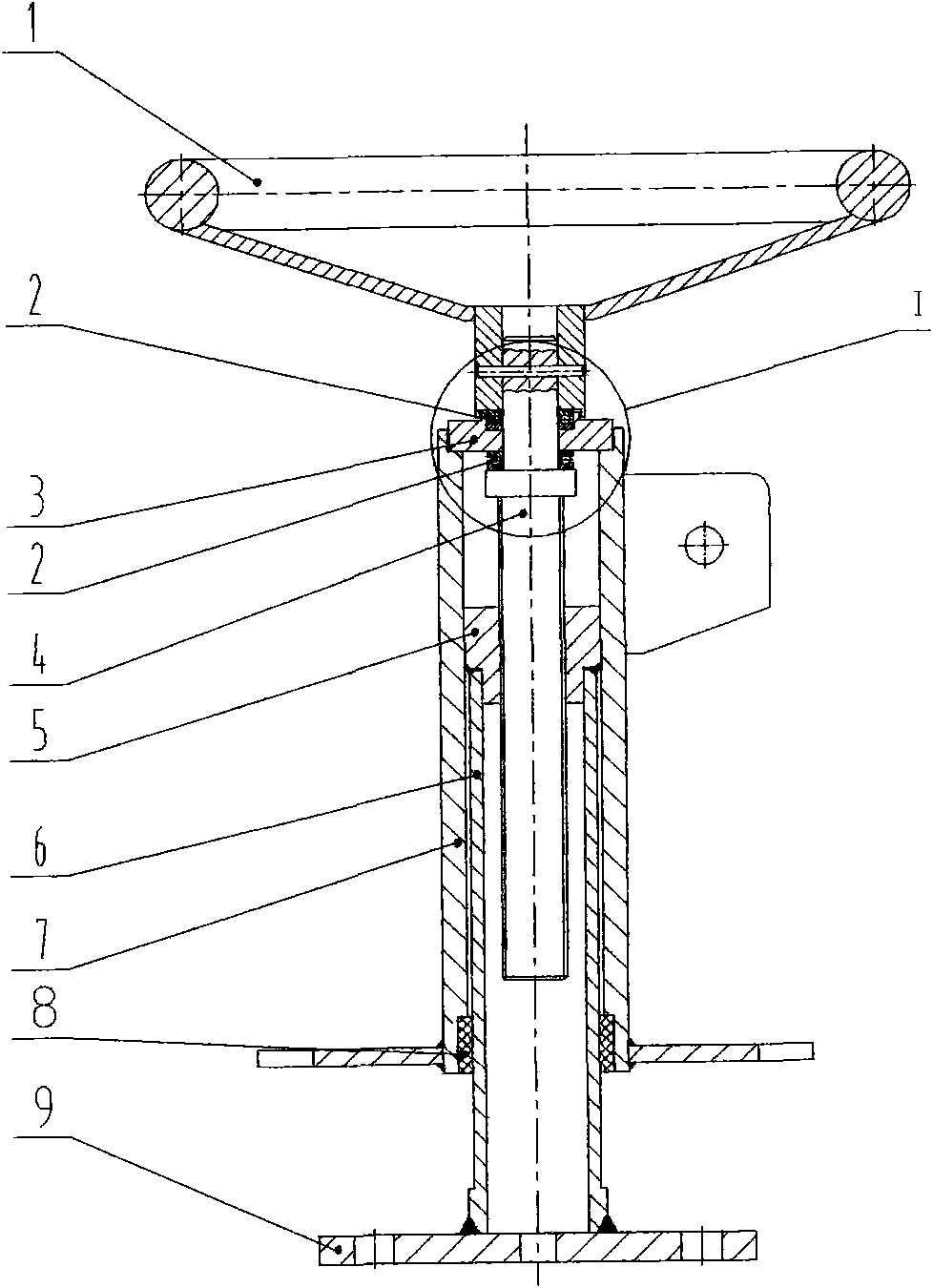

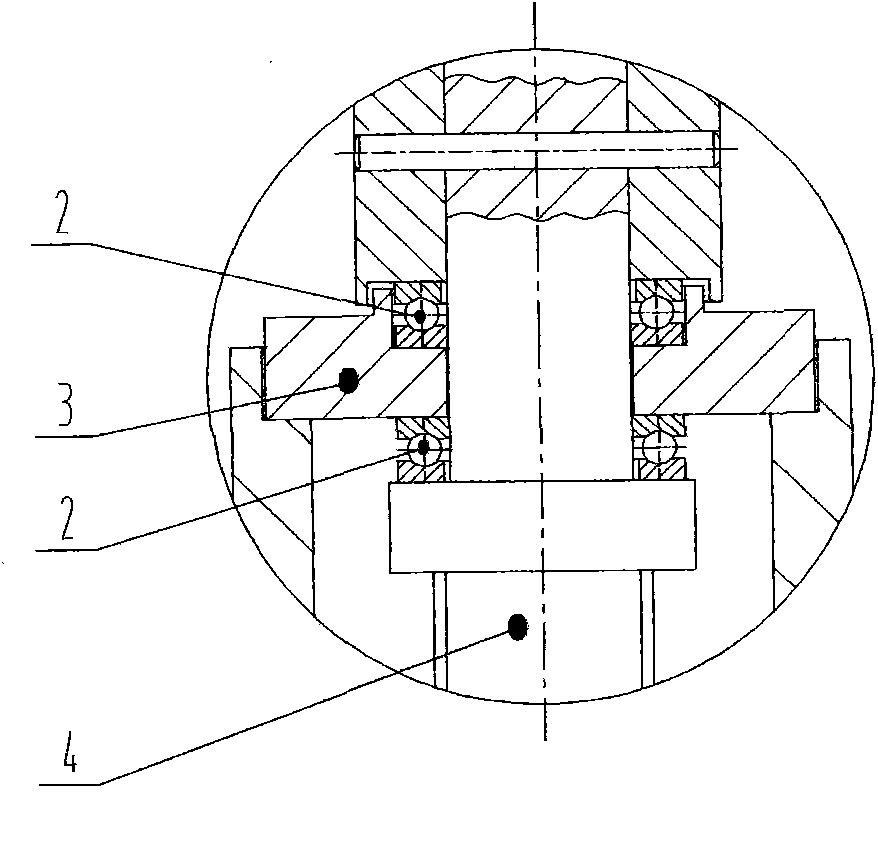

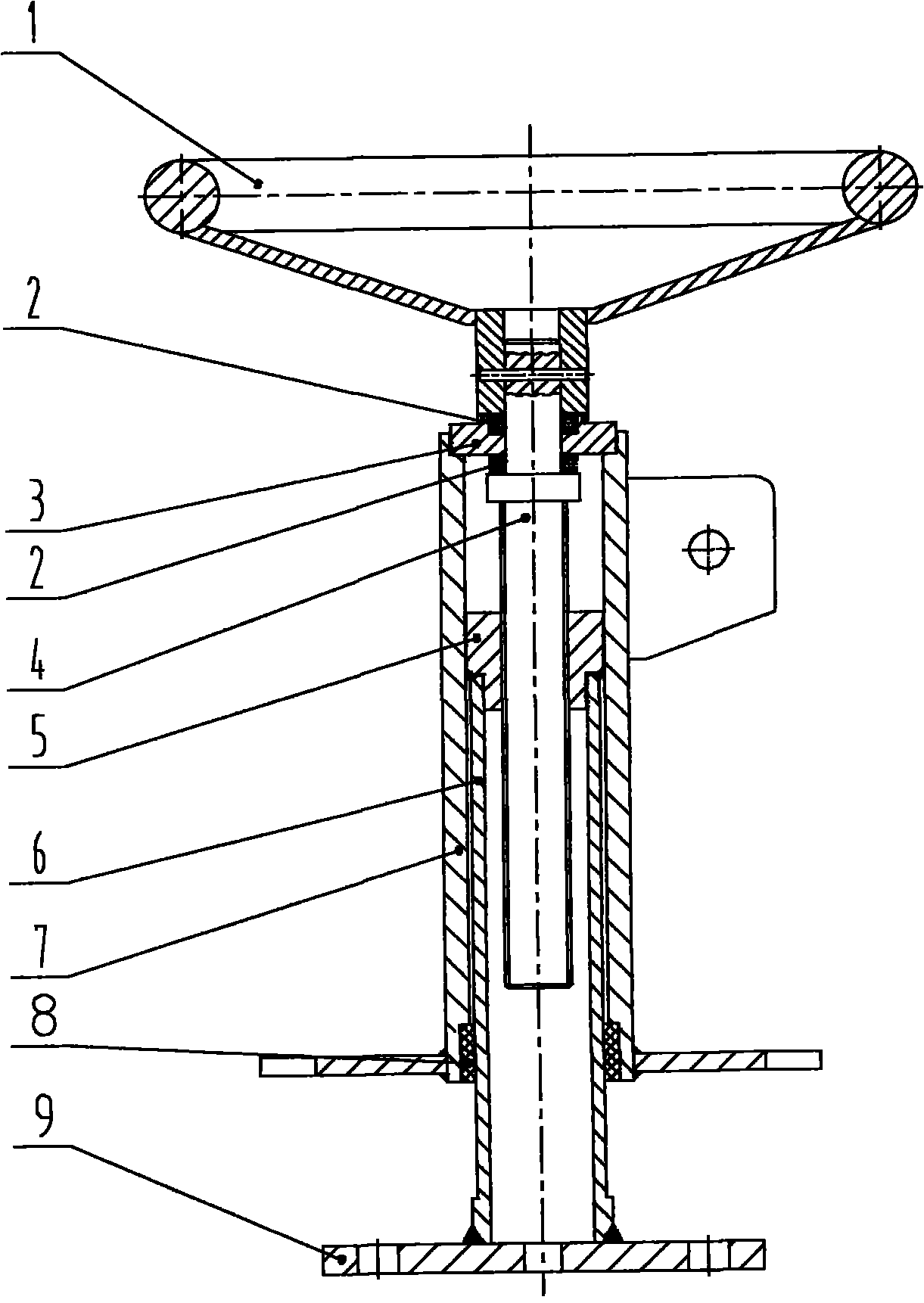

[0015] attached figure 1 The lifting device for opening and closing the oil tank cover shown includes a hand wheel 1, a thrust ball bearing 2, a bearing cover 3, a screw shaft 4, a nut 5, a supporting sleeve 6, a sleeve 7, a guide sleeve 8 and a bottom plate 9 The supporting shaft sleeve 6 is a cylindrical member, which is vertically and fixedly connected to the bottom plate 9, and a through hole is provided in the middle of the bottom plate 9; the screw shaft 4 is screwed into the nut 5 fixedly connected to the upper end of the supporting shaft sleeve 6 , constitute a lifting mechanism, the screw shaft 4 is made of stainless steel; the lower end of the sleeve 7 is embedded with a guide sleeve 8, which is coaxially fitted on the outer wall of the supporting sleeve 6; the upper end of the screw shaft 4 is set with a thrust ball bearing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com