Stepping motor control circuit and analog electronic timepiece

A stepping motor, control circuit technology, applied in the direction of motor generator control, electromechanical clocks, clocks and watches, etc., can solve the problems of wrong rotation or non-rotation, unstable driving, low power supply voltage, etc., and achieve the avoidance and avoidance of rotation The effect of static in the middle and reliable needle drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, a stepping motor control circuit according to an embodiment of the present invention and an analog electronic timepiece using the stepping motor control circuit will be described. In addition, in each drawing, the same code|symbol is attached|subjected to the same part.

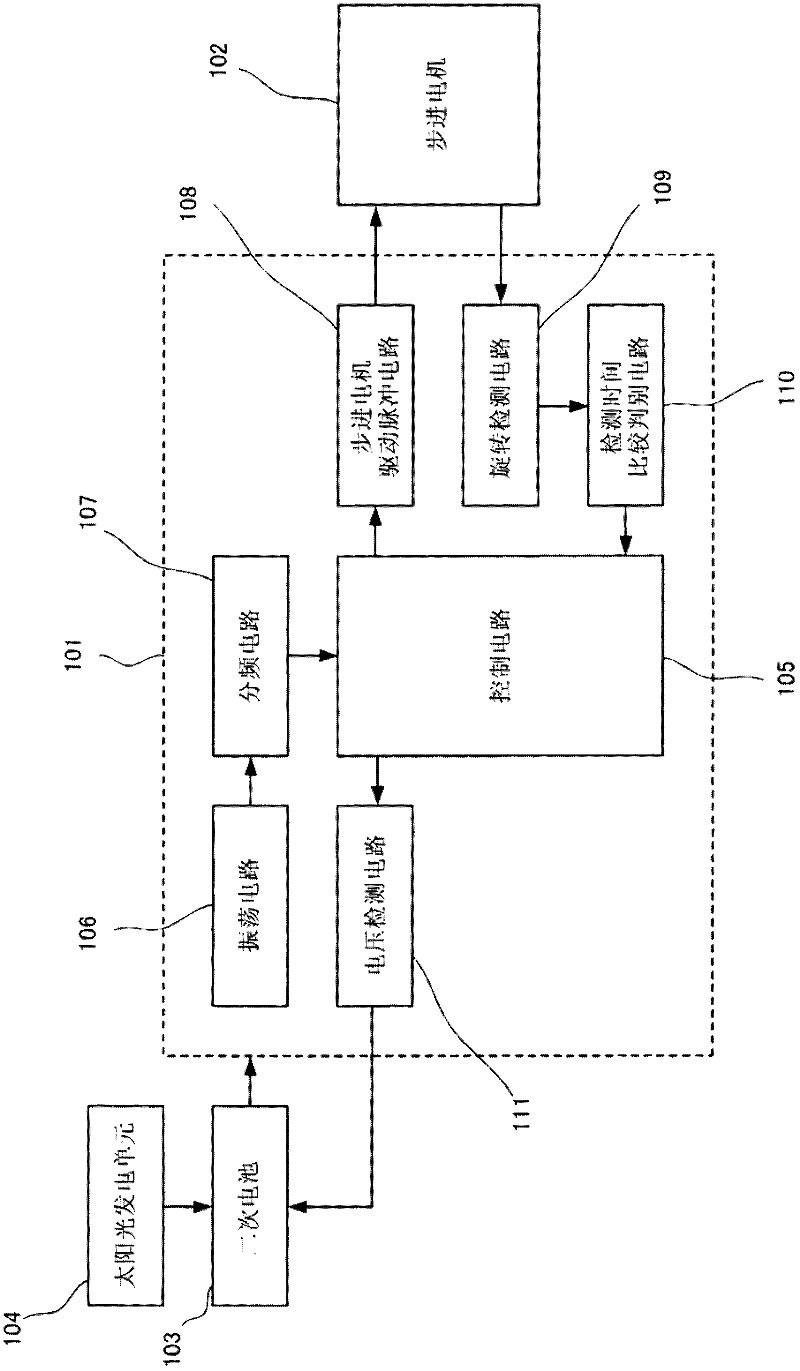

[0025] figure 1 It is a block diagram of an analog electronic timepiece using a stepping motor control circuit according to an embodiment of the present invention, showing an example of an analog electronic wristwatch.

[0026] exist figure 1 Among them, the analog electronic clock has: a stepping motor control circuit 101; a stepping motor 102, which is controlled by the stepping motor control circuit 101 to rotate, and drives the time pointer and the calendar mechanism (not shown) to rotate; as a secondary power supply The battery 103 supplies driving power to circuit elements such as the stepping motor control circuit 101 and the stepping motor 102 ; the solar power generation unit 104 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com