Seamless video display spliced wall

A video display and splicing wall technology, applied in the direction of digital output to display devices, static indicators, identification devices, etc., can solve the problems of large optical waveguide volume, high cost, increase the thickness of the display, etc., and achieve the effect of diluting the gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

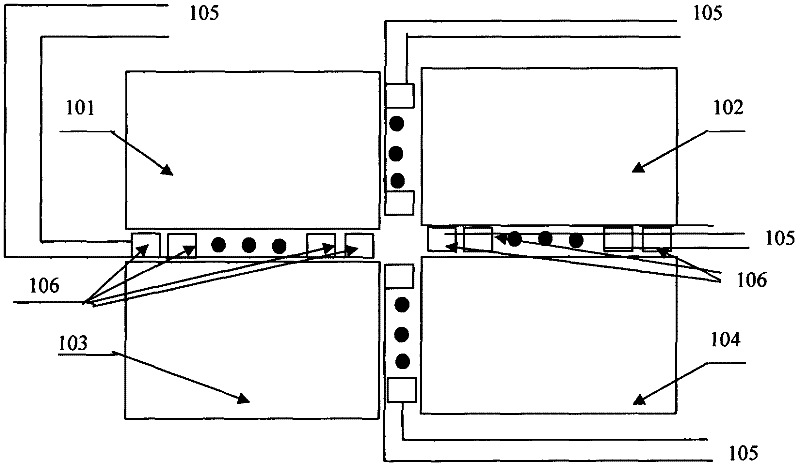

[0025] like figure 1 As shown, several LEDs 106 are placed in the gaps of the video display splicing wall, each LED 106 is connected to a power line and an independent control line 105, and the control line 105 is connected to the main control computer. The corresponding data is sent to each LED, and the color and brightness of the LED 106 are adjusted to match the displayed image outside the gap, so that the gap is no longer visible.

[0026] figure 1 It is a TV splicing wall formed by splicing four identical displays 101 , 102 , 103 , and 104 . The gap in the middle is the gap formed when the displays are spliced. In the figure, a plurality of LEDs 106 are respectively placed in the display gaps of the video display splicing wall, and are respectively connected with the main control computer by independent control lines 105 . The main control computer sends the corresponding data to each LED 106 according to the actual image displayed by the video display splicing wall, a...

Embodiment 2

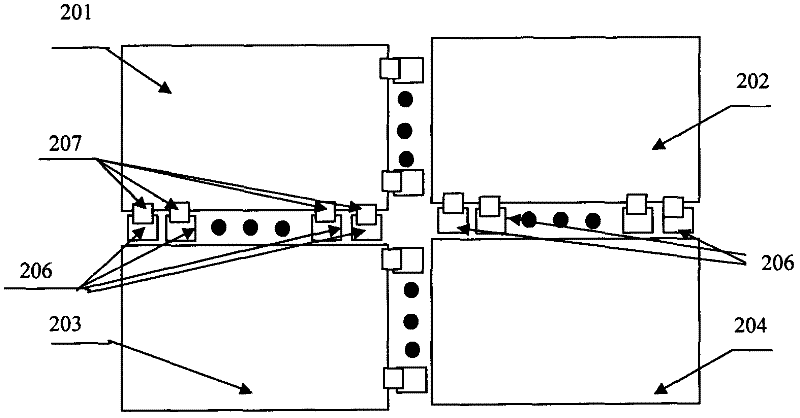

[0028] like figure 2 As shown, several LEDs are placed in the gaps of the video display splicing wall, each LED is connected to a power cord to provide the corresponding power supply, and each LED is connected to an independent light detector, which detects the adjacent display image pixels. The information is transmitted to the LEDs connected to it, and the LEDs display the same color and brightness as the video display video wall. At this time, the LED is like a "chameleon", and the light detector is like a chameleon's sensor, which changes with the change of the adjacent external environment "video display video wall".

[0029] figure 2 It is a splicing video display splicing wall formed by splicing four identical displays 201 , 202 , 203 , and 204 . Different from the first embodiment, each LED 206 placed in the splicing wall slot is not controlled by the main control computer, but by the light detector 207 . A photodetector 207 is integrated on each LED.

[0030] On...

Embodiment 3

[0033] This embodiment is an extension on the basis of the above-mentioned embodiment. It can be applied on the basis of the first embodiment, and can also be applied on the basis of the second embodiment.

[0034] like Figure 4 As shown, the LEDs further include left and right or upper and lower LEDs, each of the left (or upper) LEDs 407 displays information about adjacent pixels on the left (or upper), and each of the right (or lower) LEDs 406 displays the right (or upper) Bottom) Information about neighboring pixels. In this way, the display gap has more LEDs, and its display resolution is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com