Self-excitation device for 5KW power-generation welding machine

An electric welding machine, 5KW technology, applied in the direction of synchronous generators, etc., can solve the problems of high cost, low cost and high failure rate of auxiliary excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

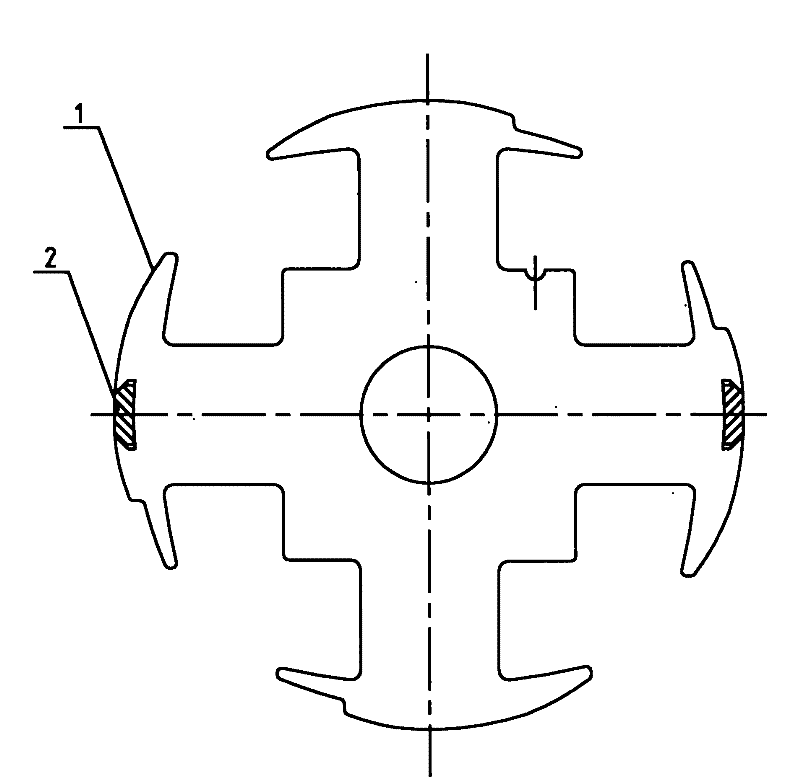

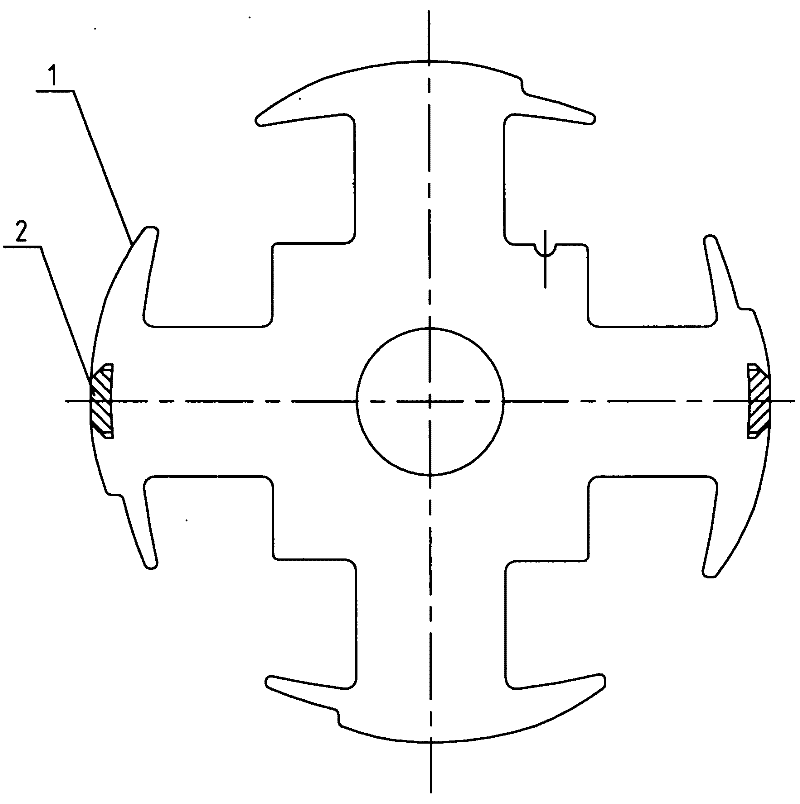

[0012] Such as figure 1 In the shown embodiment, the self-exciting device of the 5KW power generation welding machine includes a permanent magnet 2 installed on the rotor 1 and an auxiliary winding arranged on the stator, and the permanent magnets are symmetrically arranged on the rotor 1 left and right.

[0013] The permanent magnet 2 installed on the rotor 1 generates a magnetic field. During the rotation of the rotor 1, the auxiliary winding installed on the stator cuts the magnetic field lines to generate current, thereby realizing the purpose of power generation. The self-excitation of this 5KW power generation welding machine The device has the advantages of low cost and low failure rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com