Acoustical generator front cover and manufacturing method thereof

A production method and technology for sound generators, which are applied in the direction of voice amplifiers in branch offices, can solve the problems of external temperature or vibration detachment, general sealing effect, and gasket detachment from the front cover, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The front cover of the sounder of the present invention is connected with an external installation carrier such as a mobile phone case to fix the sounder and transmit the sounding hole to the outside through the mobile phone case.

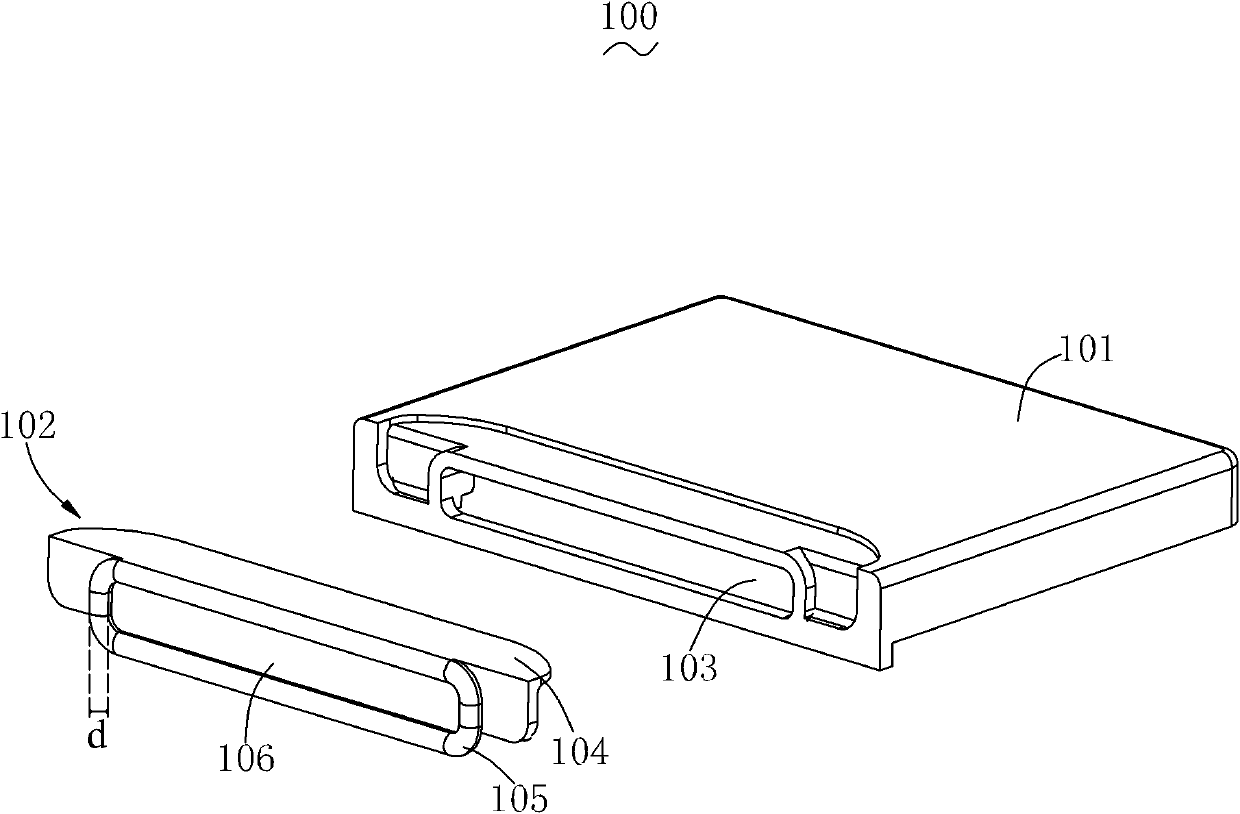

[0022] Such as figure 1 Shown is the front cover 100 of the sound generator of the present invention. The front cover 100 includes a cover body 101 and a gasket 102 disposed on the cover body 101. The gasket 102 is connected to an external mounting carrier (such as a mobile phone case). The cover 101 is provided with a sound outlet 103 communicating with the outside world, the gasket 102 is provided with a main body 104 connected to the cover 101, and a connecting part 105 protruding from the main body 104 and connected to the mobile phone casing. In the present invention , the contact surface between the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com