Propeller Fan

A technology for propellers and fans, applied in the field of propeller fans, can solve problems such as deterioration of air supply-noise characteristics, and achieve the effects of improving air supply-noise characteristics and suppressing eddy currents on the outer edge of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

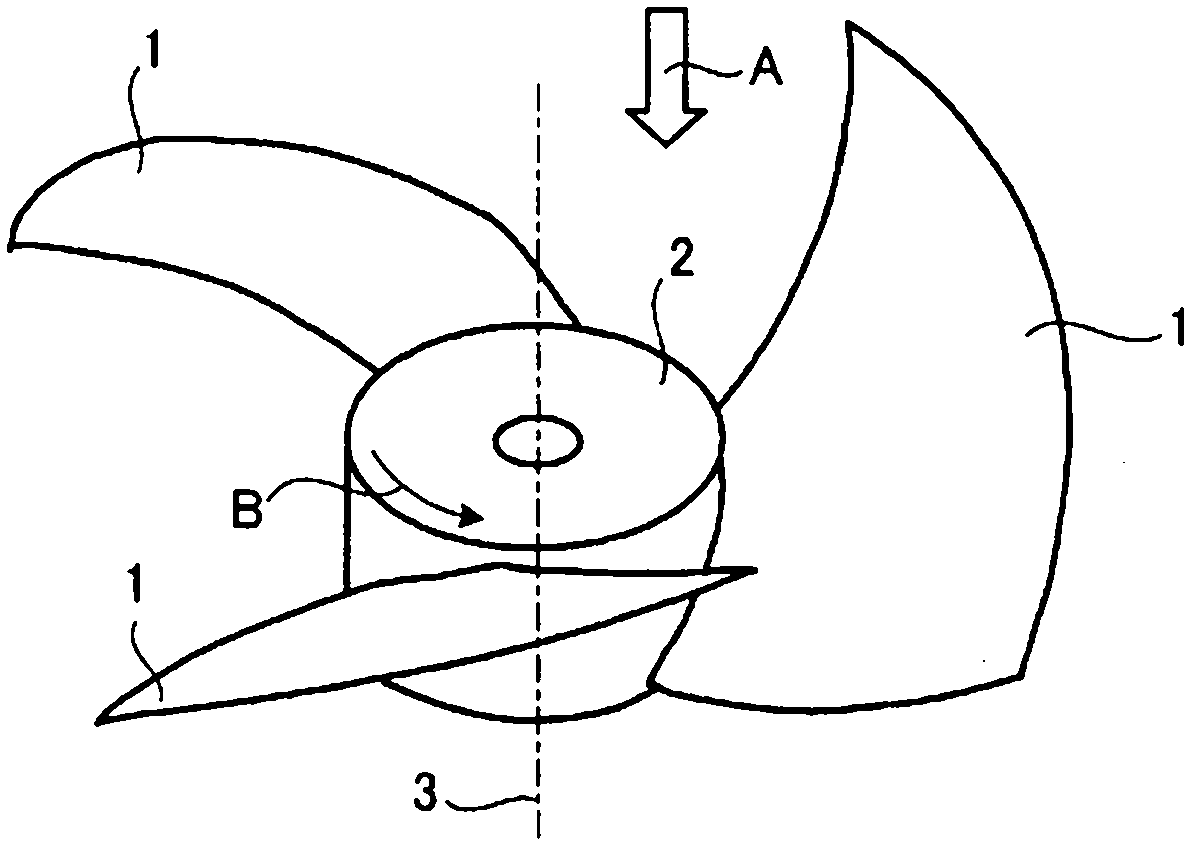

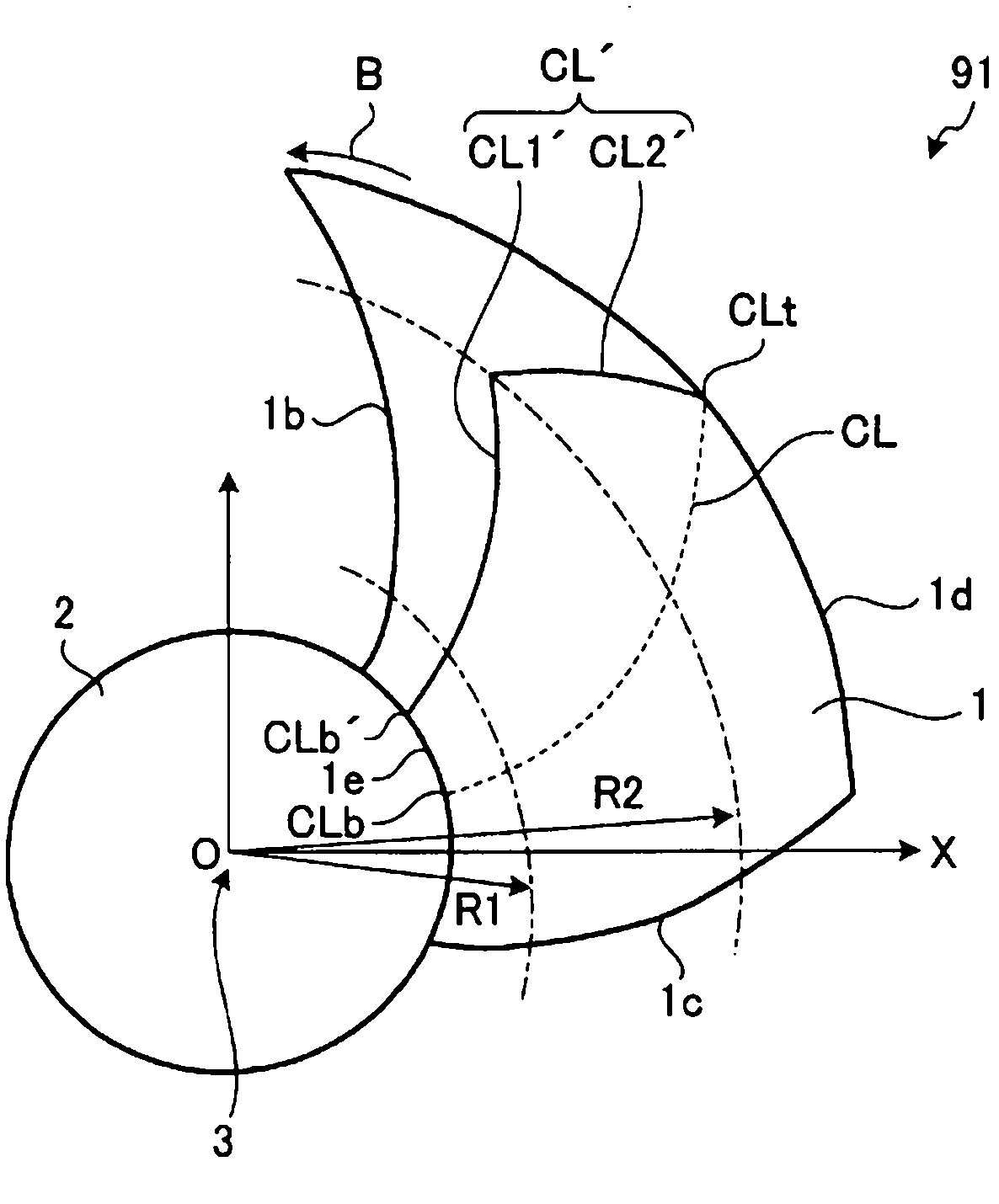

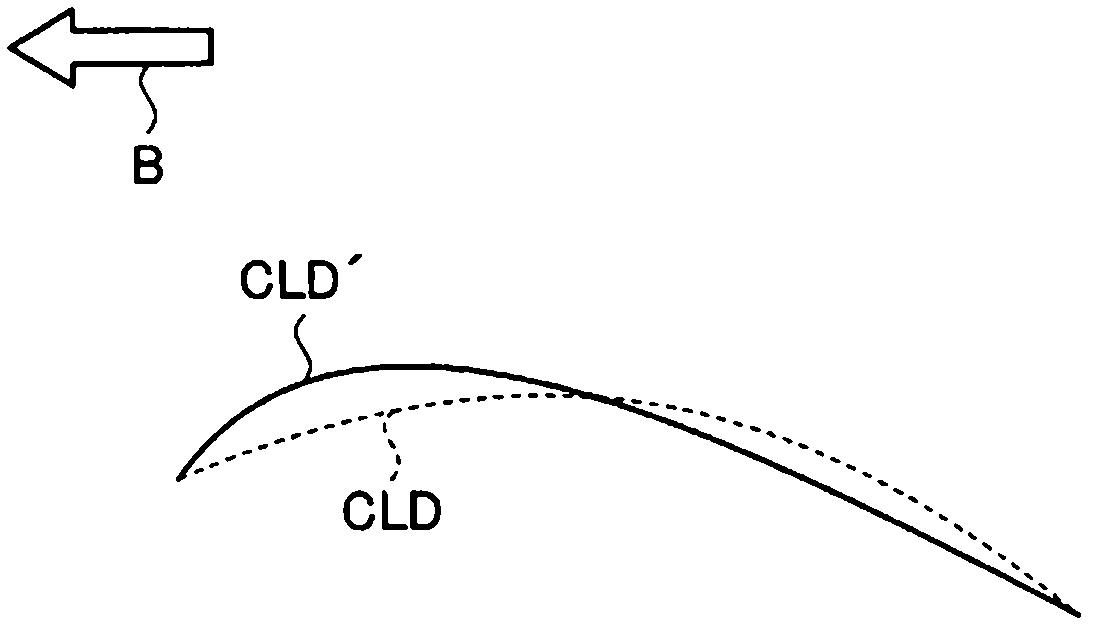

[0034] figure 1 It is a perspective view showing a general propeller fan, diagram 2-1 It is a plan view of the propeller fan according to Embodiment 1 of the present invention, Figure 2-2 It is a cylindrical cross-sectional view of the first region of the blade of Embodiment 1.

[0035] figure 1 The shown propeller fan has three blades, but the number of blades is not limited in the present invention, and other multiple numbers may be used. In the following description, the shape of one blade will be mainly described, and the shapes of other blades are also the same.

[0036] Such as figure 1 As shown, the blades 1 having a three-dimensional shape are radially mounted on the outer periphery of a cylindrical hub 2 , and the hub 2 is driven to rotate by a motor (not shown) to rotate in the direction of rotation B around the rotating shaft 3 . In addition, the hub 2 is cylindrical, but the blades 1 may be radially formed on the outer peripheral portion of the hub formed by...

Embodiment approach 2

[0053] Image 6 It is a perspective view showing a propeller fan 92 having a blade 21 according to the second embodiment. The blade 21 according to the second embodiment has the leading edge side of the blade inner peripheral portion of the blade having the maximum arc height ridge line CL' of the first embodiment formed in a wave shape 21m. . The waveform of the blade leading edge 21b becomes a maximum waveform, and gradually becomes a small waveform toward the blade center portion.

[0054] Figure 7 is indicative of Image 6 The perspective view of the airflow on the negative pressure surface side of the blade 21 according to Embodiment 2 is shown. Such as Figure 7 As shown, in the air flowing into the leading edge 21b of the blade, the wave 21m of the blade 21 generates a longitudinal vortex flow, making the airflow E2 around the inner periphery of the blade a less turbulent airflow E2, thereby reducing the noise caused by the turbulence of the airflow.

Embodiment approach 3

[0056] Figure 8 It is a perspective view showing a propeller fan 93 having a blade 31 according to the third embodiment. The blade 31 according to the third embodiment has a blade inner peripheral trailing edge side of the blade having the maximum camber ridge line CL' of the first embodiment formed in a wave form 31 m . The waveform of the blade trailing edge 31c is a maximum waveform, and gradually becomes a small waveform toward the blade center portion.

[0057] Figure 9 is indicative of Figure 8 The perspective view of the airflow on the negative pressure surface side of the vane 31 according to Embodiment 3 is shown. Such as Figure 9 As shown, the longitudinal vortex generated by the wave form 31n of the blade 31 can reduce the turbulence of the air caused by the vortex generated at the trailing edge 31c of the blade, and become the airflow E3 with less turbulence, thereby reducing the turbulence caused by the turbulence of the airflow. caused noise.

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com