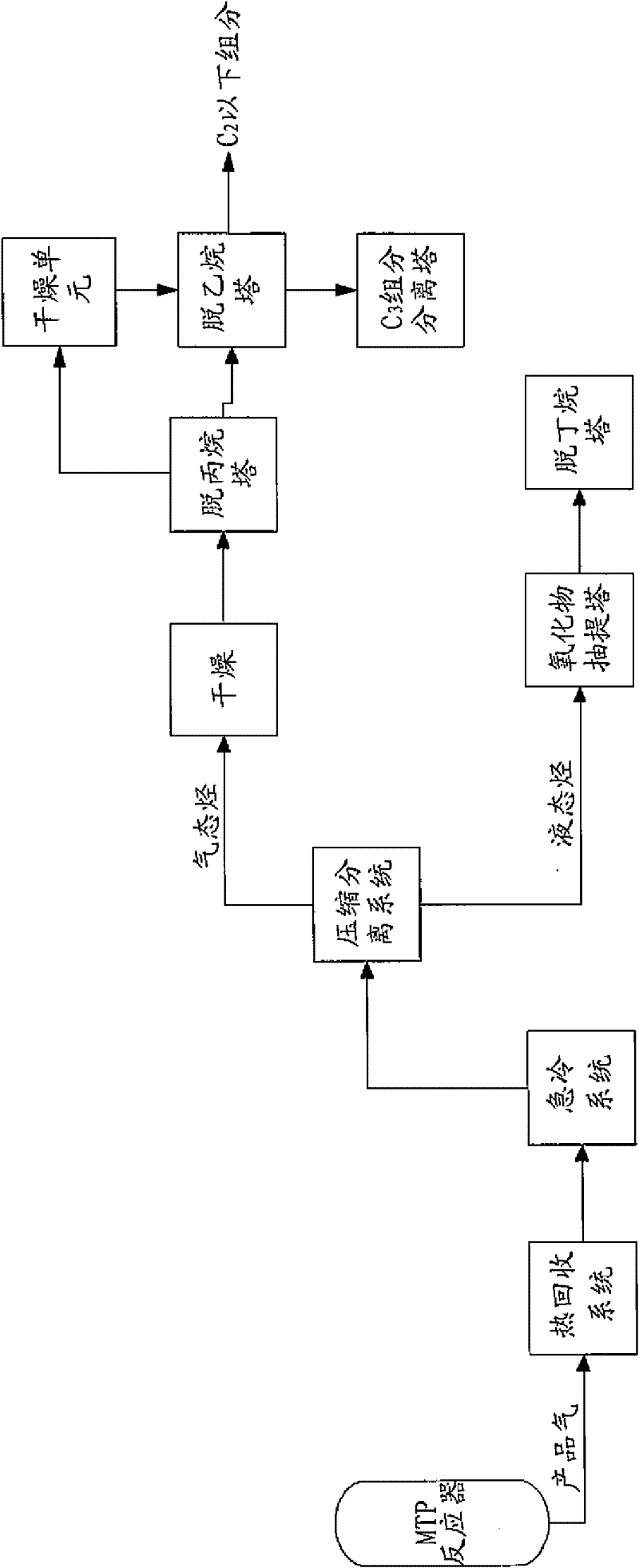

Method for controlling water content of propylene product in coal-based methanol propylene production process

A technology for methanol to propylene and product water, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve problems such as difficult regeneration, reduced water absorption capacity of molecular sieves, and influence on water absorption effect, etc., to achieve low cost of device transformation and high process efficiency. Improve the ease and solve the effect of excessive water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

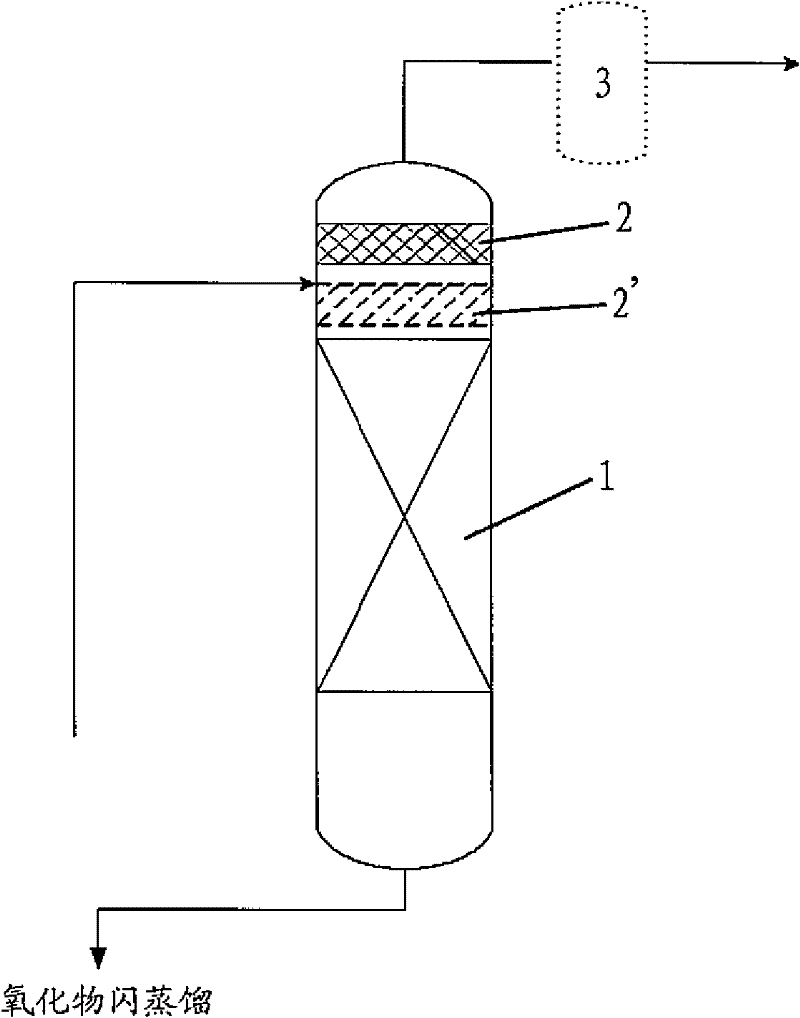

[0033] According to the oxide index at the outlet of the oxide extraction tower, adjust the feed water volume of the oxide extraction tower, and as shown in Table 1, control the liquid level of the extraction tower. The content of dimethyl ether in the liquid phase of the oxide extraction tower is 0.248wt%, and the content of methanol is 0.005wt%; the content of dimethyl ether in the gas phase is 0.312wt%, and the content of methanol is 0.009wt%. At this time, the control material feed rate is 63.80% of the column capacity. As shown in Table 1, adjust the interface gauge and liquid level gauge range of the oxide extraction tower, and adjust the liquid level control height to reduce the water content entrained at the top outlet of the tower. A Karl Fischer instrument (model DL-31, Mettler-Toledo, USA) is installed at the inlet of the oxide extraction tower and the outlet of the oxide extraction tower to measure the trace amount of water contained in the hydrocarbon products.

...

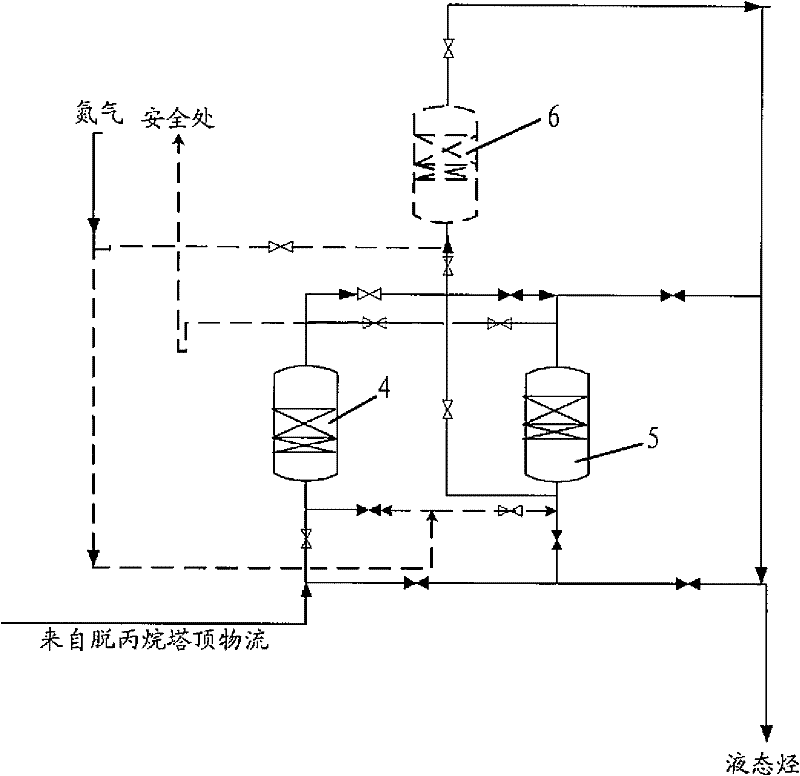

Embodiment 5-9

[0037] Modification of the oxide extraction tower, adding liquid collection devices, such as coalescers or / and dehydration tanks. See Table 2 for details of the process modification. Among them, the coalescer used is Beijing Zhaohua Xianquan Technology Development Co., Ltd., and the model is BZTC-JJX-150×1500. The manufacturer of the dehydration tank is Beijing Zhaohua Xianquan Technology Development Co., Ltd., 2400mm, capacity 34m 3 .

[0038] Table 2

[0039]

Embodiment 10

[0041] Add a dehydration tank after the outlet of the oxide extraction tower and in the front section of the dryer.

[0042] table 3

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap