Method and device for molecular sieve compound rectifying and refining ethanol product from biobutanol apparatus

A molecular sieve and ethanol technology, used in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of excessive isopropanol and water content, and achieve the goal of improving product grades, increasing market competitiveness and increasing profits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

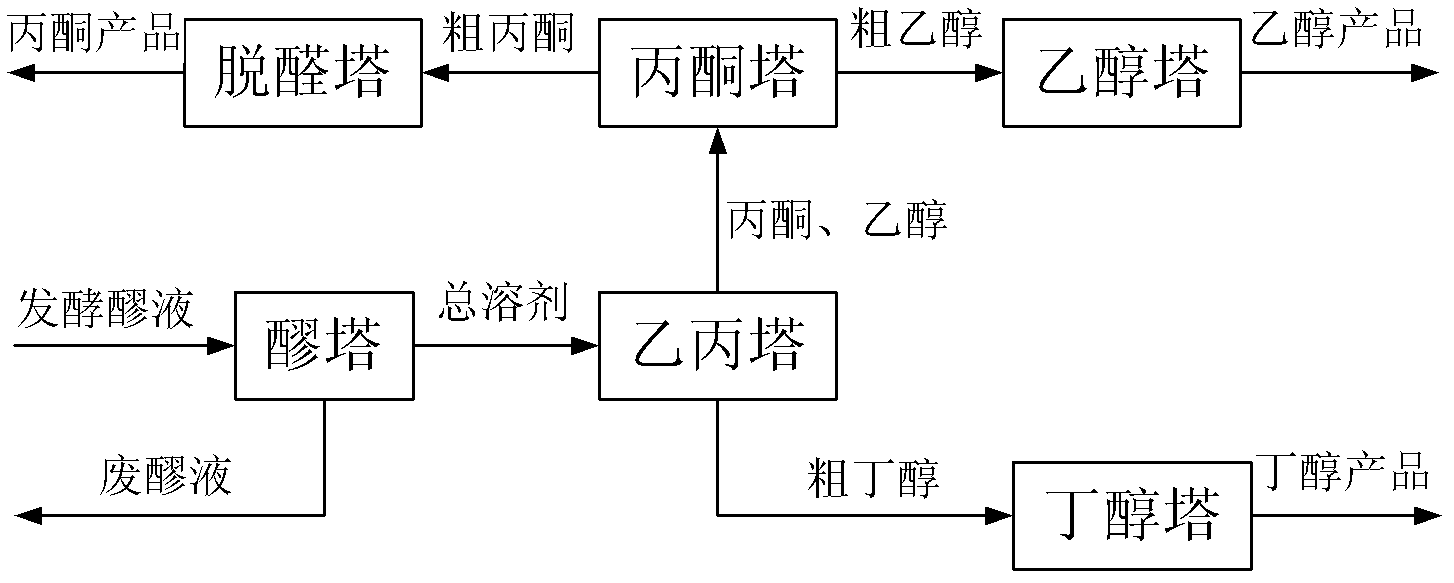

Problems solved by technology

Method used

Image

Examples

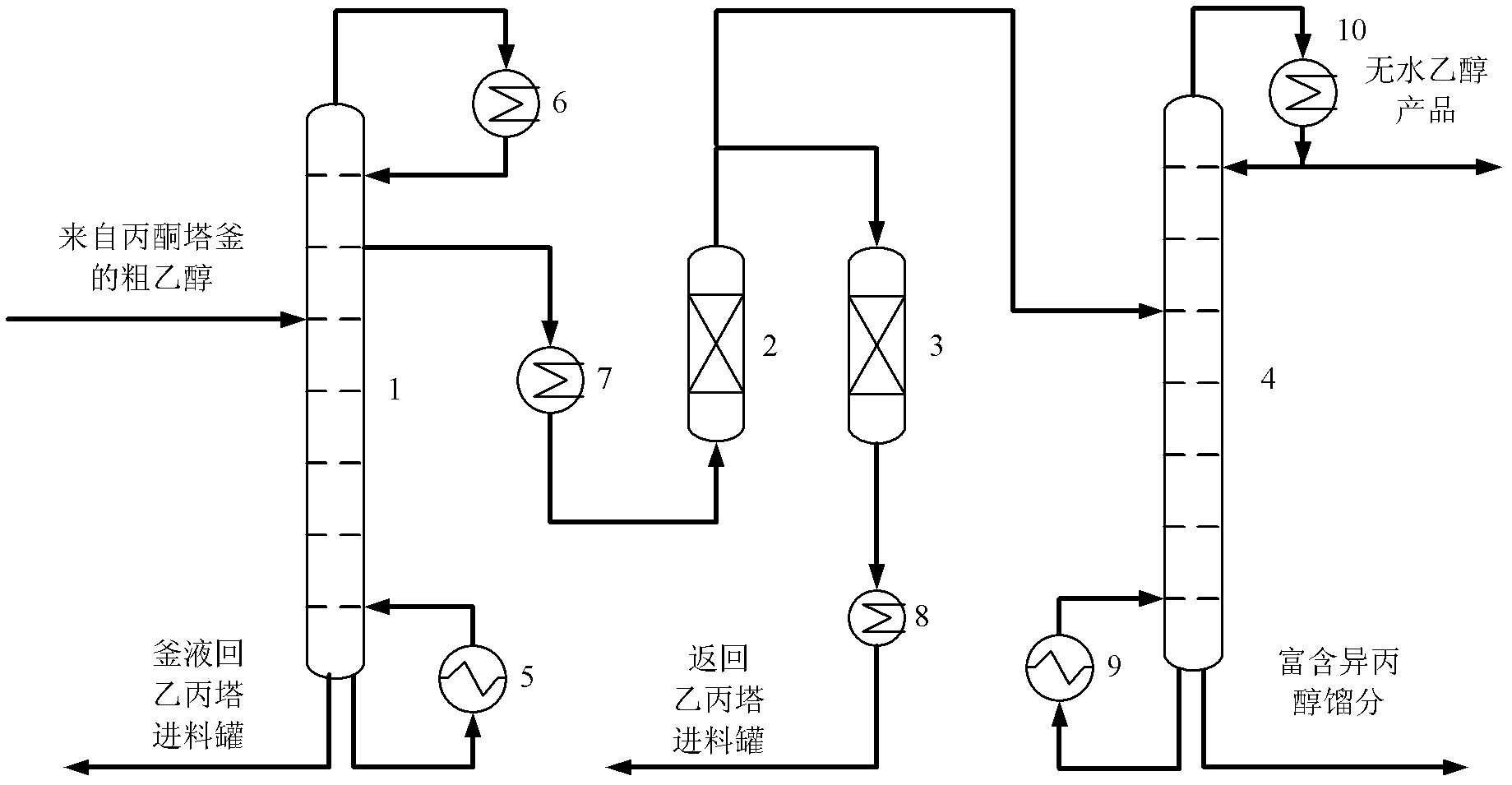

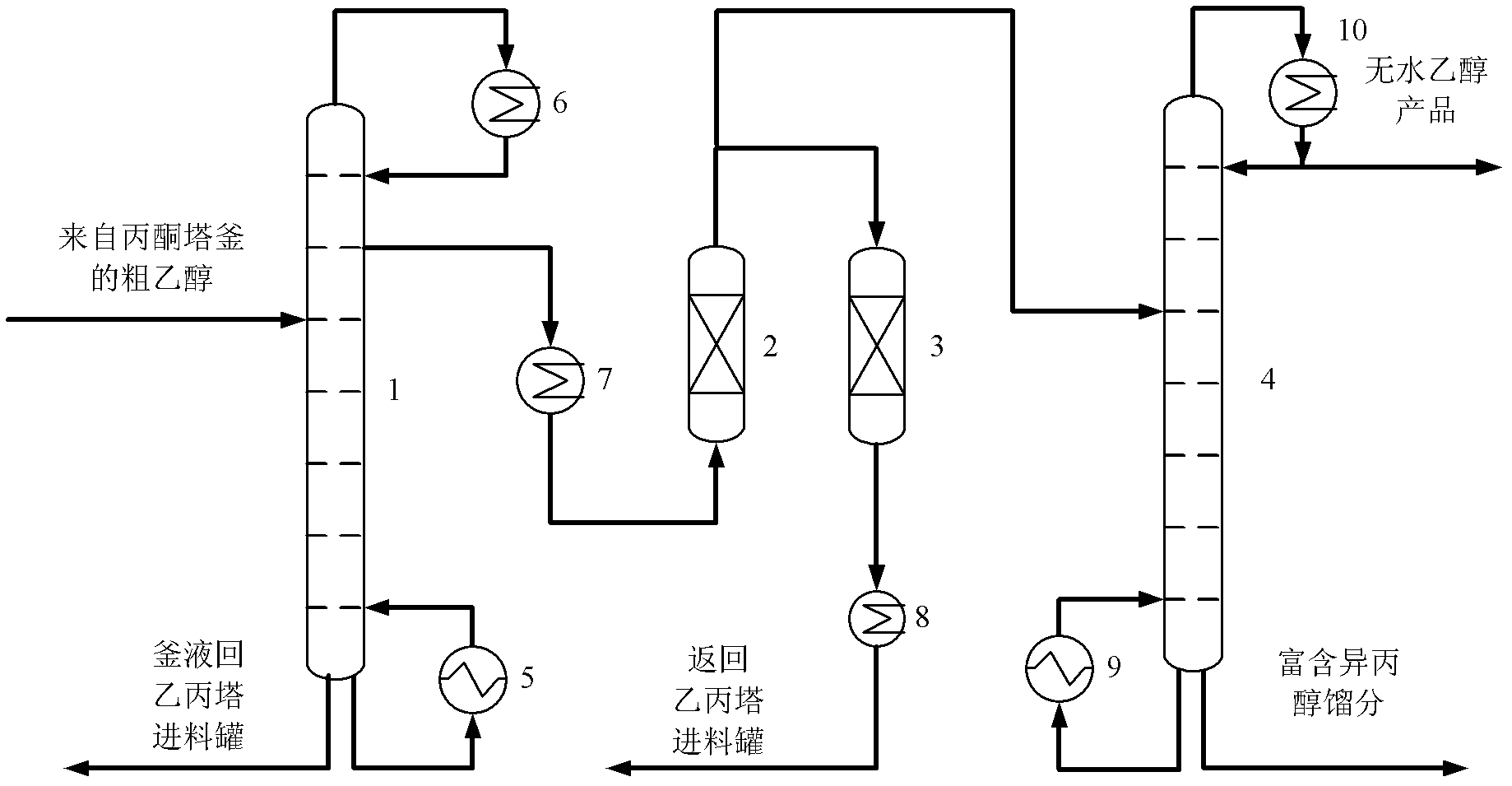

Embodiment 1

[0027] From the ethanol material extracted from the side line of the ethanol tower, wherein the ethanol content is 90%, the isopropanol content is 5%, and the water content is 5%, according to figure 2 The method and apparatus shown carry out the production of absolute ethanol. The material is a gas phase product extracted from the side line of the ethanol tower, with a flow rate of 1000kg / hr. After being overheated by the ethanol superheater to 160°C, it is continuously sent to the molecular sieve adsorption bed for adsorption and dehydration. The adsorbent used in the molecular sieve adsorption bed is A-type molecular sieve. The operating pressure of the molecular sieve adsorption bed is 0.5MPa, and the operation time of each adsorption bed is 30min, after which it is transferred to the regeneration stage. There are two molecular sieve adsorption dehydration beds, one for adsorption and dehydration, and the other for regeneration. The operating pressure in the regeneration...

Embodiment 2

[0029] From the ethanol material extracted from the side line of the ethanol tower, wherein the ethanol content is 85%, the isopropanol content is 10%, and the water content is 5%, according to figure 2 The method and apparatus shown carry out the production of absolute ethanol. Rectification, dehydration steps are basically the same as in Example 1, the difference is as follows: the product extracted from the side line of the ethanol tower is a liquid phase, and then enters the molecular sieve adsorption bed for dehydration after passing through the ethanol evaporator into steam, and the adsorbent used in the molecular sieve adsorption bed For X-type molecular sieve. After refining in the ethanol refining tower, the mass fraction of the ethanol product reaches 99.8%, reaching the national standard GB / T 678-2002 for absolute ethanol products.

Embodiment 3

[0031] From the ethanol material extracted from the side line of the ethanol tower, wherein the ethanol content is 82%, the isopropanol content is 3%, and the water content is 15%, according to figure 2 The method and apparatus shown carry out the production of absolute ethanol. Rectifying, dehydration step is substantially the same as embodiment 1, and its difference is as described below. There are 4 molecular sieve adsorption beds, the adsorbent used is Y-type molecular sieve, and the operating pressures of adsorption and desorption are 0.8MPa and 0.03MPa respectively. In one operation cycle, three adsorption beds are guaranteed to perform adsorption operation at the same time, and one is to perform desorption operation. The dehydrated ethanol material is then refined in an ethanol refining tower, and the mass fraction of the obtained ethanol product reaches 99.8%, which meets the national standard GB / T 678-2002 for absolute ethanol products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap