Method and apparatus for preparing semisolid slurry for automobile aluminium wheel through compound modification refinement and electromagnetic stirring

A semi-solid slurry, electromagnetic stirring technology, applied in chemical instruments and methods, mixer accessories, mixers, etc., can solve problems such as the quality and efficiency of semi-solid slurry, achieve low equipment prices, and reduce component segregation. , the effect of good filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

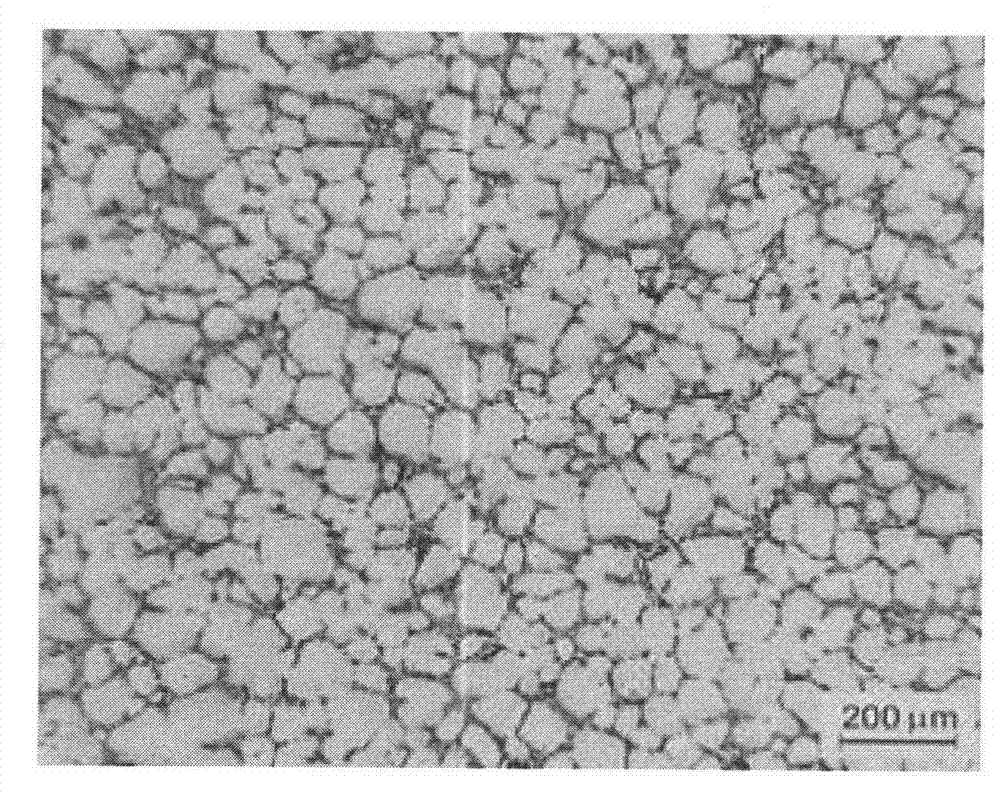

[0033] specific implementation

[0034] Firstly, alloy ingots are selected, heated and melted in a smelting furnace fueled by natural gas, and superheated alloys are prepared. The temperature of the superheated alloys is 110°C above the liquidus temperature; powder spraying and refining are carried out in the insulation room of the smelting furnace to make them clean and uniform in temperature. And the chemical composition is uniform, constant, and the segregation is small; then keep warm and stand still, waiting for use

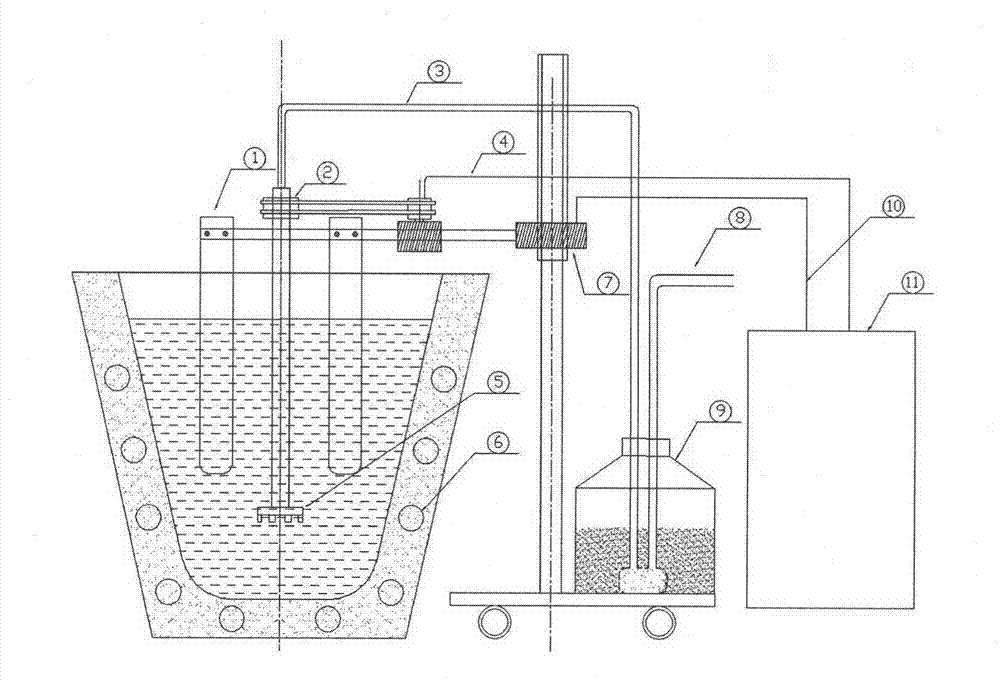

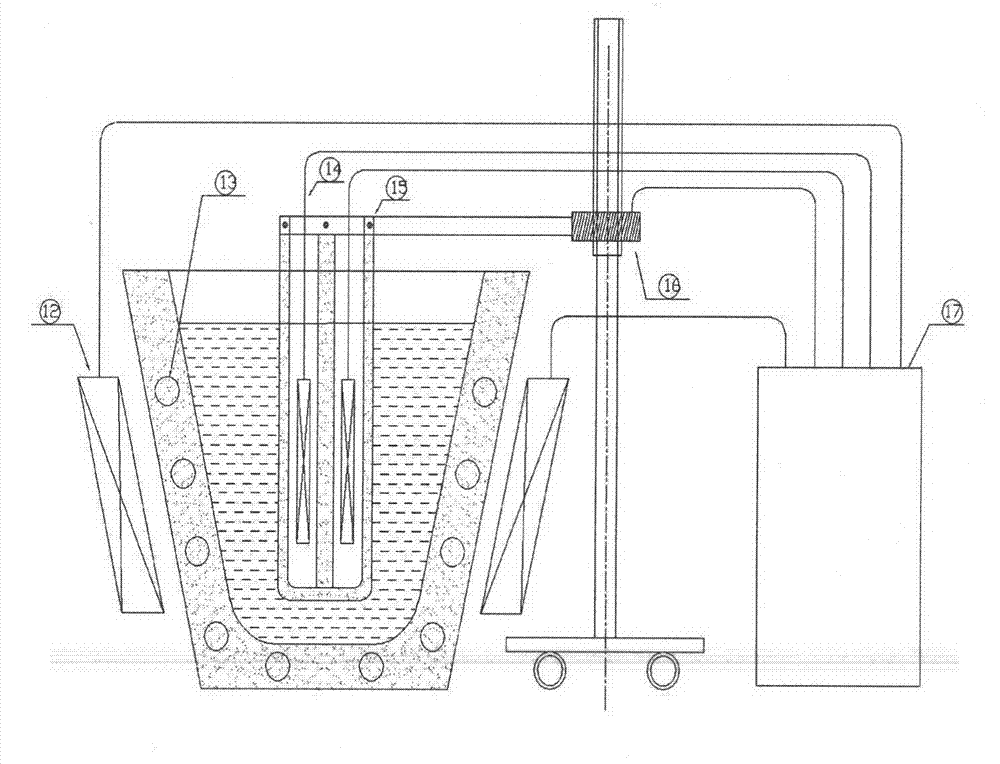

[0035] Secondly, compound refinement and compound modification are carried out on the purified alloy melt, such as figure 1 The thermal insulation transfer package for the compound refinement treatment shown includes baffles (1), graphite rotors (2), conduits (3), graphite rotor drive motors (4), graphite rotor blades (5), thermal insulation transfer Including heating resistor (6), graphite rotor lifting drive motor (7), air intake duct (8), storage tank (9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com