Fracturing fluid jet mixer

A technology of jet mixing device and fracturing fluid, which is applied in the fields of production fluid, wellbore/well components, earth-moving drilling, etc., can solve the problem of not being able to provide fracturing fluid in real time, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

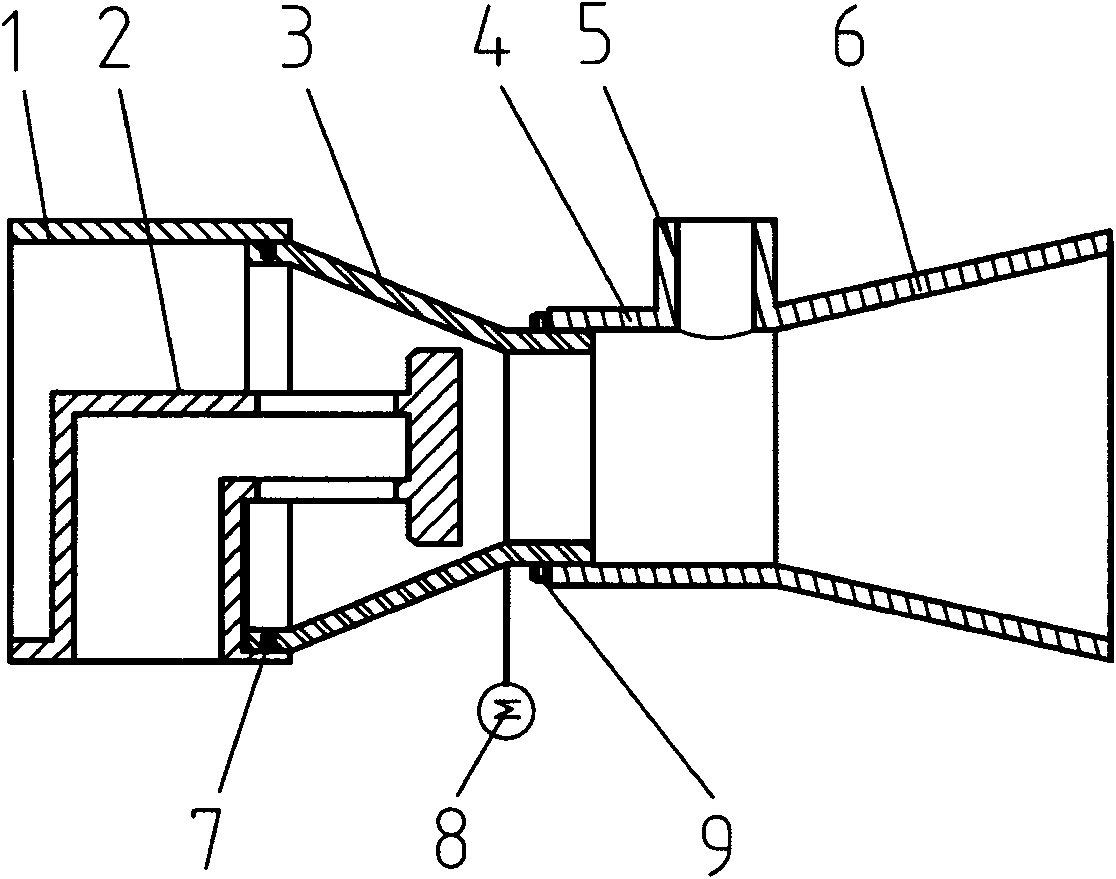

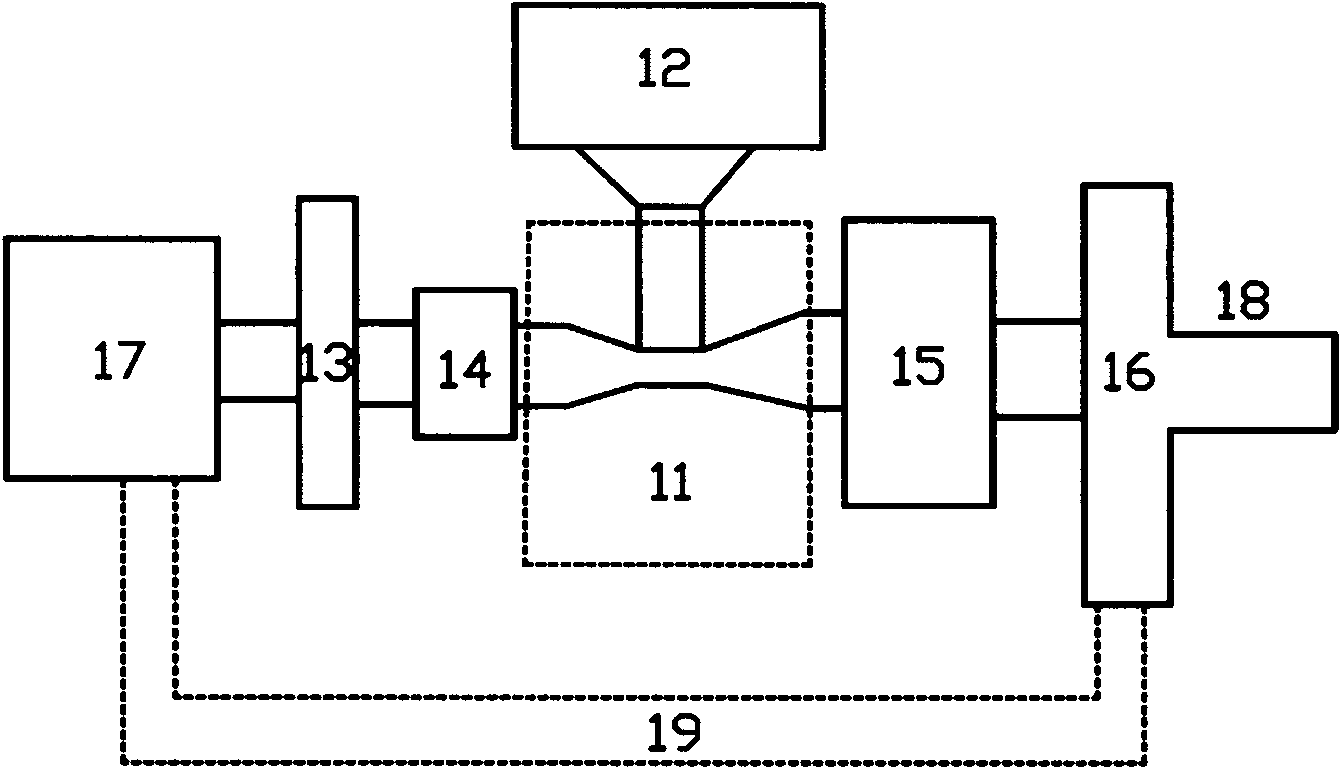

[0012] Refer to attached figure 1 . The suction pipe 1, shrinkage pipe 3, throat pipe 4, and diffuser pipe 6 of the fracturing fluid jet mixing device of the present invention are connected and installed in sequence; Large conical pipe; the additive suction pipe 5 is fixedly installed on the pipe wall of the throat pipe 4 or the suction pipe 1, and communicates with the inner hole of the suction pipe 1. The front end of the suction pipe 1 is connected to the liquid supply pump 14 of the fracturing fluid mixing system, the additive suction pipe is connected to the additive storage tank, and the diffuser pipe is connected to the mixing tank 15 of the fracturing fluid mixing system. The insertion tube 2 is a curved tube, the front end is installed on the tube body of the suction tube 1, and communicates with the outside of the suction tube 1; The axis is vertical; ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com