Fracturing construction device for oil and gas development

A construction device and fracturing technology, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problem of the reduction of the area of the throat, the inability to provide fracturing fluid in real time according to the needs, and the increase of the flow rate, etc. problem, to achieve the best mixing ratio, flexible design and balanced mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

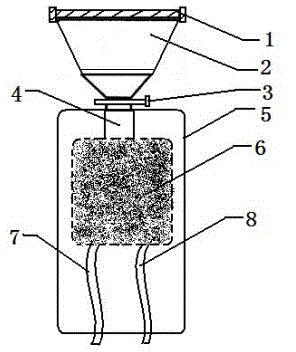

[0012] This embodiment provides a fracturing construction device for oil and gas development, which is characterized in that: the fracturing construction device for oil and gas development includes a flange (1), a hopper (2), and a control valve ( 3) Discharging pipe (4), outer protective shell (5), mixing tank (6), suction pipe (7), discharge pipe (8);

[0013] Among them: the filling hopper (2), the discharging pipe (4), and the mixing tank (6) are connected and installed in turn. The filling hopper (2) is provided with a flange (1), and the lower end of the filling hopper (2) is connected to the discharging pipe ( 4) There is a control valve (3) at the connection, the mixing tank (6) is set in the outer protective shell (5), two hoses are set under the mixing tank (6), one is the suction pipe (7), the other is the discharge Tube (8).

[0014] The feeding hopper (2) is a conical hopper with a large upper part and a smaller lower part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com