Rotation angle detector

A technology of rotation angle and detector, applied in the direction of converting sensor output, instrument, measuring device, etc., can solve the problem of increasing chip size and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

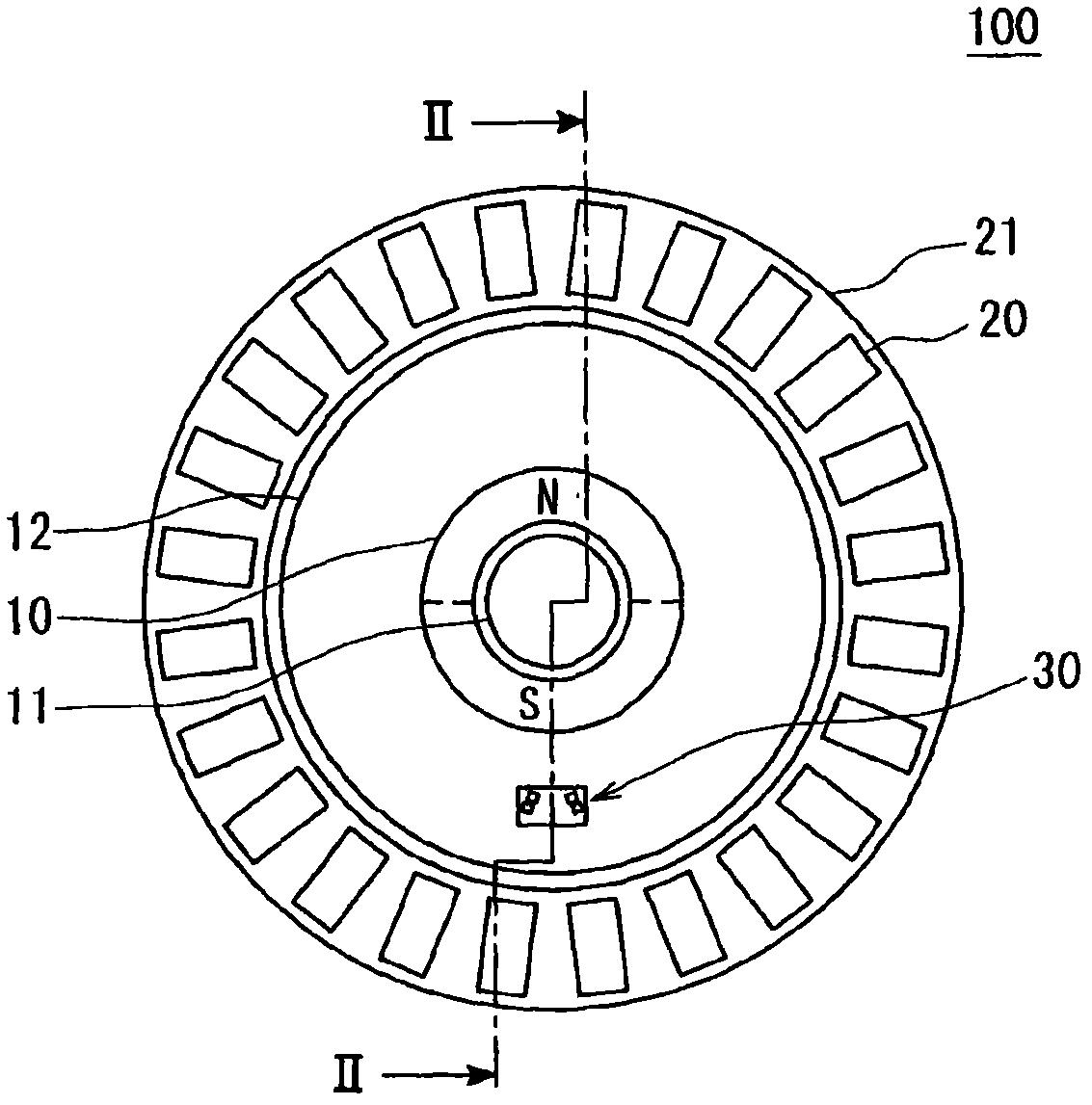

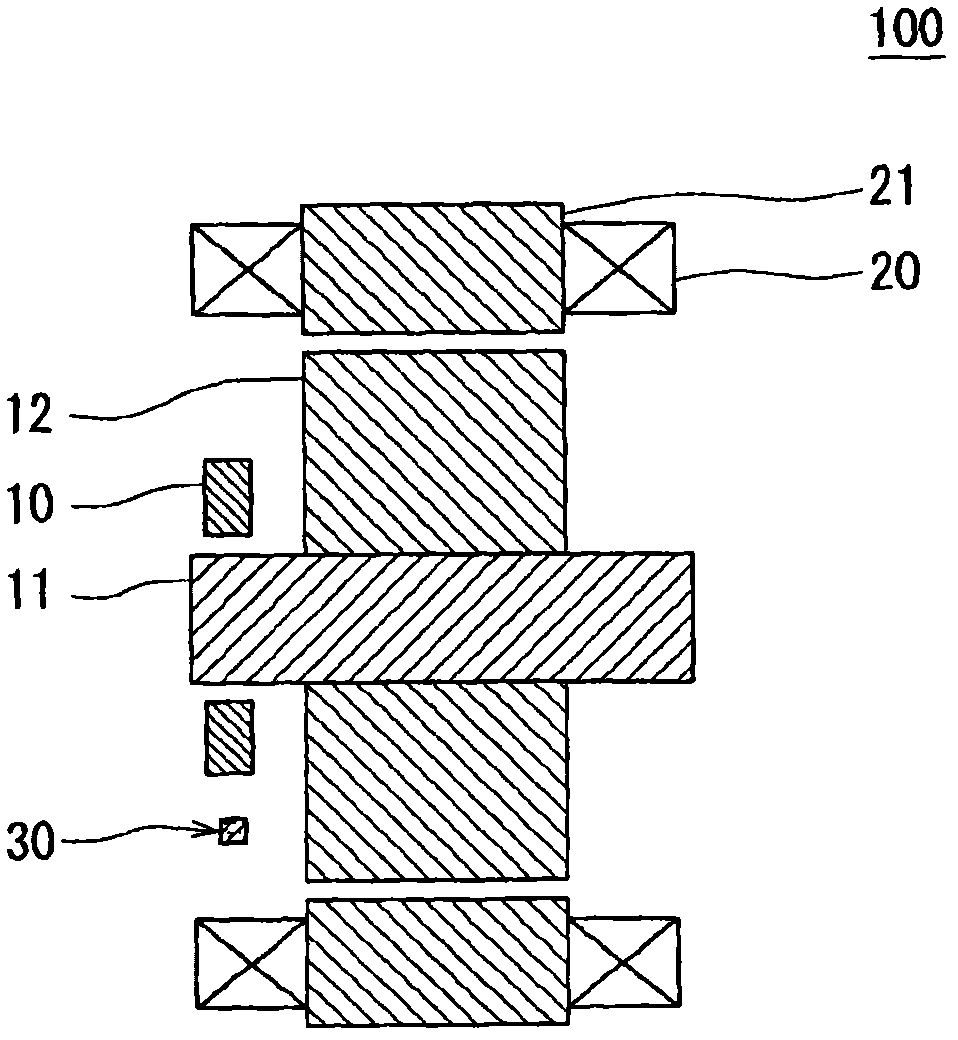

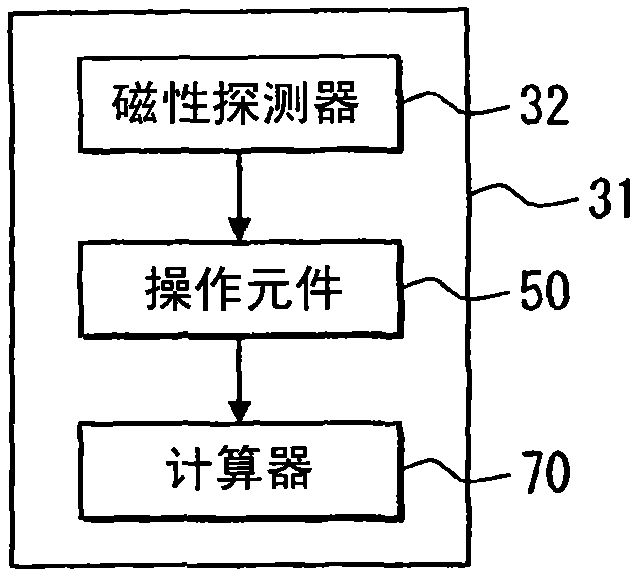

[0027] figure 1 A plan view of the rotation angle detector according to the first embodiment is shown. figure 2 shows along the figure 1 Cross-sectional view of the detector taken by line II-II. image 3 The electrical connections between the magnetic field detection element, the operating element and the calculator are shown. Figure 4 A plan view showing the relationship between the sensor chip and the magnet rotor. The rotation direction of the magnet rotor 10 is defined as the rotation direction. A direction along the thickness of the semiconductor substrate 31 is defined as a thickness direction. A direction perpendicular to the thickness direction and the rotation direction and passing through the magnet rotor center O is defined as a normal direction.

[0028] The probe 100 mainly includes a magnet rotor 10 , a sensor chip 30 , an operating element 50 and a calculator 70 . Such as figure 1 with 2 As shown, a winding 20 for generating a magnetic field surrounds th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com