Anti-skidding sole and shoe comprising same

A technology of anti-slip and anti-slip sheet, applied in the field of footwear, can solve the problems of unsatisfactory anti-slip effect, increased structural cost, poor anti-slip effect, etc., and achieve the effect of firm fixation, stable support and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

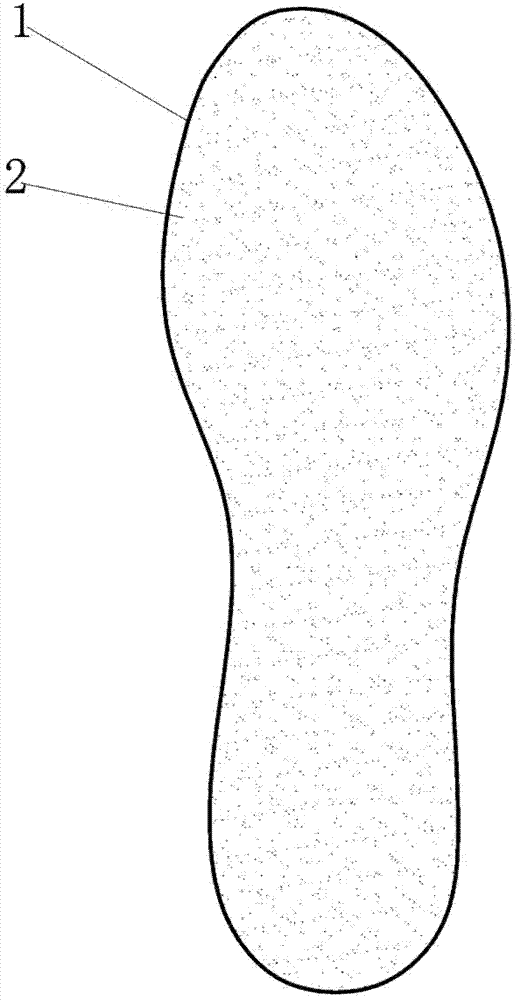

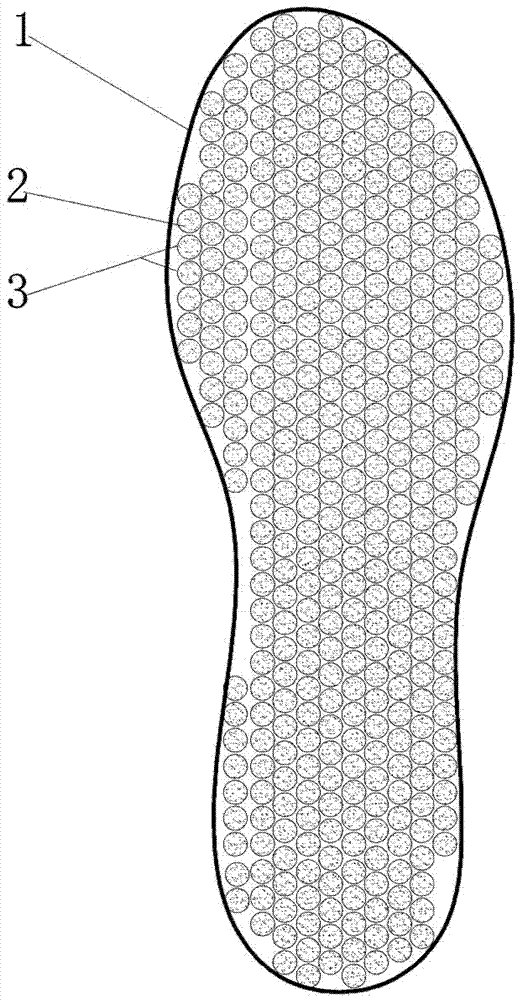

[0044] see figure 1 , a kind of non-slip sole, its outsole comprises base 1, anti-slip particle 2, and the material of described base 1 is anti-slip thermoplastic material, such as TPU, rubber material etc. The upper part of the anti-slip particles 2 is embedded in the lower surface of the base 1 and fixed, and the lower part is exposed from the base 1 to form a protrusion in contact with the horizontal ground. The anti-slip particles 2 are scattered on the lower surface of the base 1. Optimally, the area of the lower surface of the base 1 with the anti-slip particles 2 accounts for 50% of its total area, so that the bottom surface of the outsole with concave-convex fit can be better with the ground bite.

[0045] Preferably, the height of the anti-slip particles 2 embedded in the upper part of the lower surface of the substrate 1 is 1 / 3 to 1 / 2 of the height or thickness of the anti-slip particles 2 .

[0046] Preferably, the contact surfaces of each of the protrusions and...

Embodiment 2

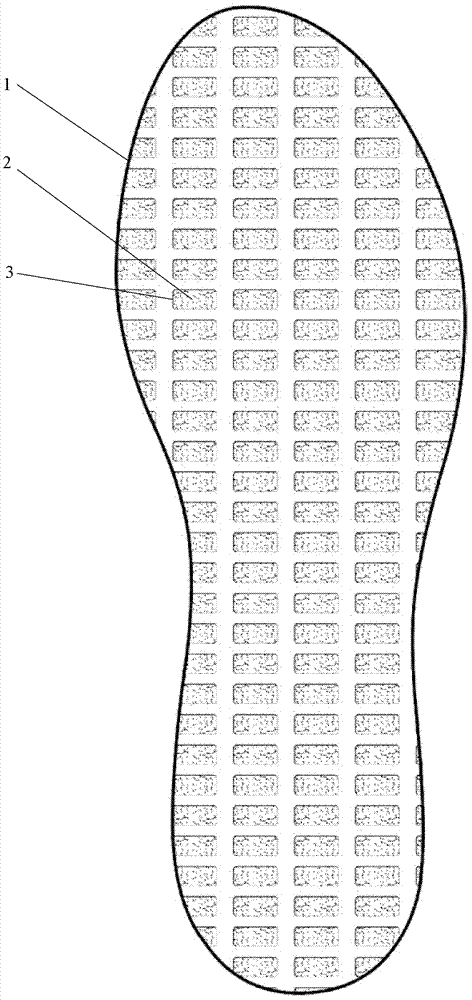

[0056] An anti-slip sole, the outer sole of which comprises a base 1 and anti-slip particles 2, the material of the base 1 is an anti-slip thermoplastic material, such as TPU, rubber material and the like. The upper part of the anti-slip particles 2 is embedded in the lower surface of the base 1 and fixed, and the lower part is exposed to the base 1 to form a protrusion in contact with the horizontal ground. The anti-slip particles 2 are neatly arranged on the lower surface of the base 1 . Preferably, the contact surfaces of each of the protrusions and the horizontal ground are on the same smooth surface. For example: the lower surface of the base 1 is a plane, and the contact surface is a plane parallel to the lower surface of the base 1; or, the smooth surface is parallel to the lower surface of the base 1 along the lateral direction of the outer bottom, and is parallel to the lower surface of the base 1 along the longitudinal direction of the outer bottom. The lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com