Load-variable loading test device and method for detecting load by using same

A technology of loading test device and variable load, which is applied in the directions of ground installation, transportation and packaging, aircraft component testing, etc., which can solve the problems of the nose landing gear system protrusion performance not being involved in the nose landing gear system protrusion test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

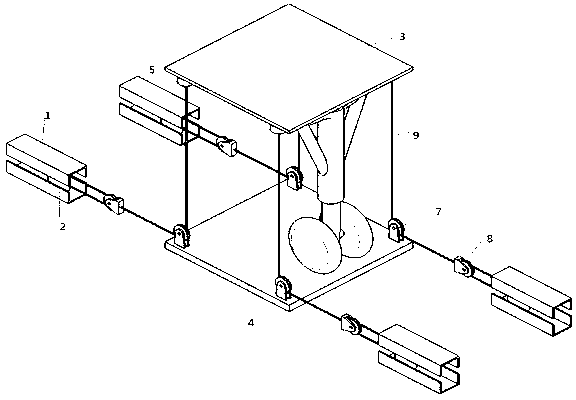

[0025] like figure 1 As shown, the variable load loading test device of the present invention includes a top plate 3, a bottom plate 4, a hydraulic actuator 2 and a friction slide rail 1, and the friction slide rail 1 includes an upper slide rail and a lower slide rail, and the hydraulic actuator cylinder 2 Located between the upper slide rail and the lower slide rail, it also includes four pulley devices that make the top plate 3 move vertically relative to the bottom plate 4, and each pulley device includes bottom plate pulleys fixed on the four corners of the bottom plate 4 7. The top plate 3 and the bottom plate 4 are the same square, the four top corners of the top plate 3 are respectively provided with load sensors 5, the hydraulic actuator 2 is provided with a steel wire rope, and the steel wire rope goes around the bottom plate pulley 7 is connected with load sensor 5.

Embodiment 2

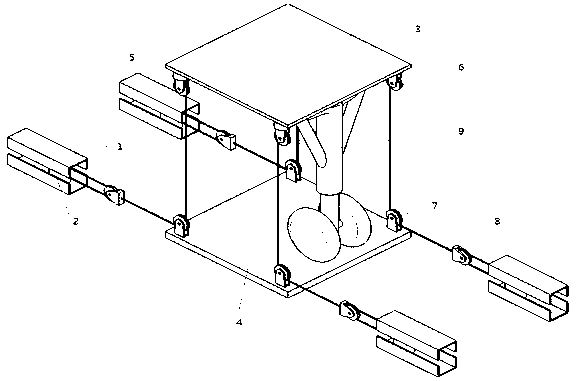

[0027] like figure 2 As shown, the variable load loading test device of the present invention includes a top plate 3, a bottom plate 4, a hydraulic actuator 2 and a friction slide rail 1, and the friction slide rail 1 includes an upper slide rail and a lower slide rail, and the hydraulic actuator cylinder 2 Located between the upper slide rail and the lower slide rail, it also includes four pulley devices that make the top plate 3 move vertically relative to the bottom plate 4. The top plate 3 and the bottom plate 4 are the same square, and the four pulleys of the top plate 3 Load sensors 5 are respectively arranged on each of the top corners, and each pulley device includes a bottom plate pulley 7 fixed on the four top corners of the bottom plate 4 and a movable pulley 8 between the friction slide rail 1 and the bottom plate 4. The moving cylinder 2 is provided with a steel wire rope, and the steel wire rope is connected to the load sensor 5 around the floor pulley 7 and the...

Embodiment 3

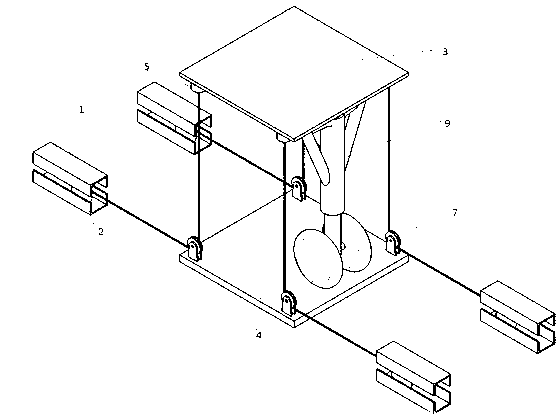

[0029] like image 3 As shown, the variable load loading test device of the present invention includes a top plate 3, a bottom plate 4, a hydraulic actuator 2 and a friction slide rail 1, and the friction slide rail 1 includes an upper slide rail and a lower slide rail, and the hydraulic actuator cylinder 2 Located between the upper slide rail and the lower slide rail, the top plate 3 and the bottom plate 4 are the same square, and the four top corners of the top plate 3 are respectively provided with load sensors 5, and the top plate 3 is opposite to the bottom plate 4. Four pulley devices that move vertically, each pulley device includes bottom plate pulleys 7 fixed on the four corners of the bottom plate 4, top plate pulleys 6 arranged below the load sensor 5 and friction slide rails 1 and the bottom plate The movable pulley between 4, the hydraulic cylinder 2 is provided with a steel wire rope, and the steel wire rope goes around the movable pulley 8, the bottom plate pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com