Automatic discharging device for koji making disc machine

The technology of automatic unloading device and disc koji making machine is applied in the directions of biochemical cleaning device, enzymology/microbiology device, biological material sampling method, etc., which can solve the problems of easy injury, material leakage, waste of raw materials, etc. Achieve the effect of avoiding equipment damage, reducing labor intensity, and ensuring reliability and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

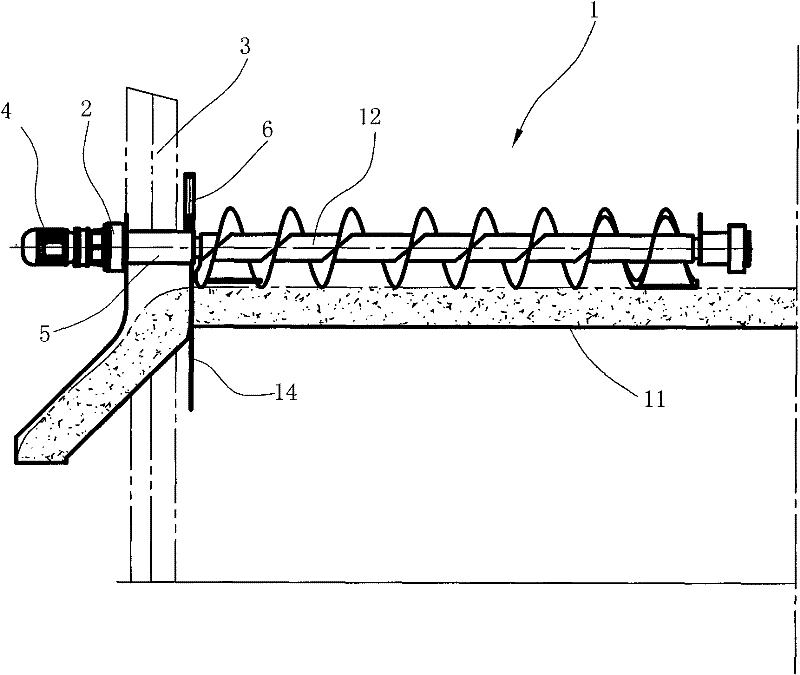

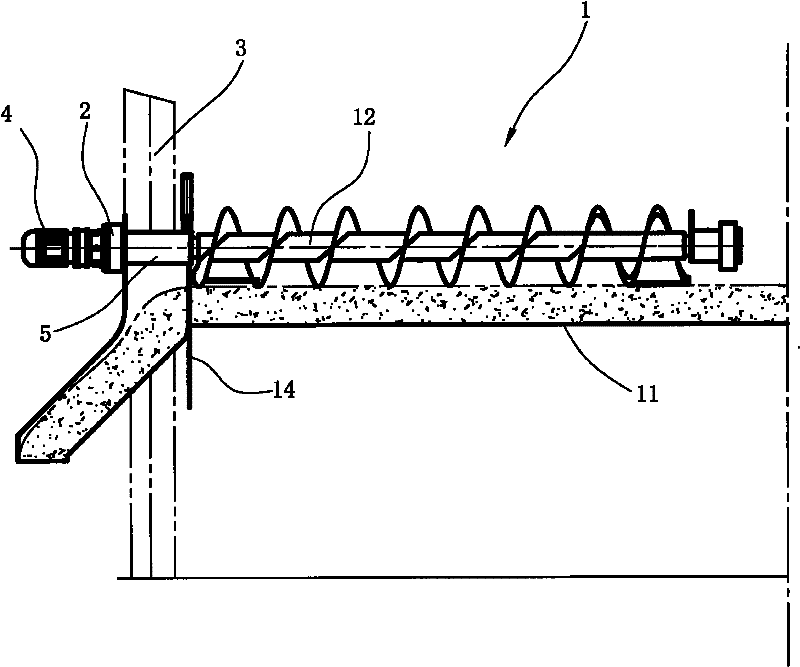

[0016] Such as figure 1 with figure 2 As shown, the disc koji making machine includes:

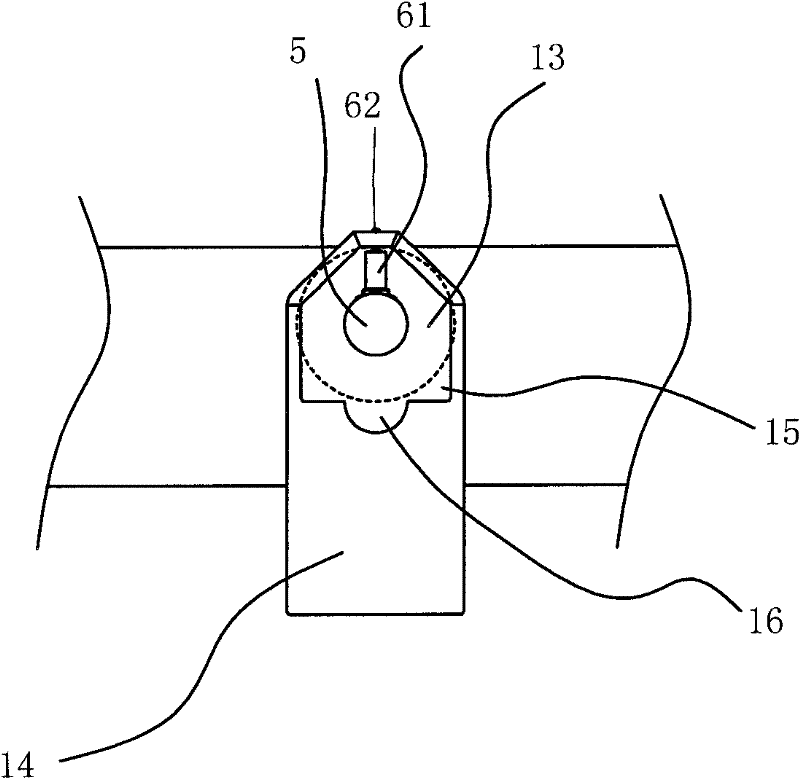

[0017] In the chamber body 1, the chamber body 1 is a place for making koji, and a rotating disk 11, a manipulator (not shown), a screw conveyor 12 and a temperature and humidity control mechanism (not shown in the figure) are provided in it, and the chamber body A discharge port 13 is provided on the side wall, and a valve plate 14 is provided on the discharge port 13 .

[0018] Wherein, the screw conveyor 12 is arranged above the turntable 11, the screw rod of the screw conveyor 12 is connected with the output shaft of the first motor 4, and the screw rod of the screw conveyor is driven to rotate by the first motor 4. A sleeve 5 is sheathed at the position where the screw rod is connected to the output shaft of the first motor 4 , the screw rod rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com