Automatic oil charging and discharging device of diaphragm pump

A technology of oil discharge device and diaphragm pump, which is applied in the direction of pumps, machines/engines, pumps with flexible working elements, etc., which can solve the problems of automatic discharge and achieve low cost, high reliability and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific embodiments.

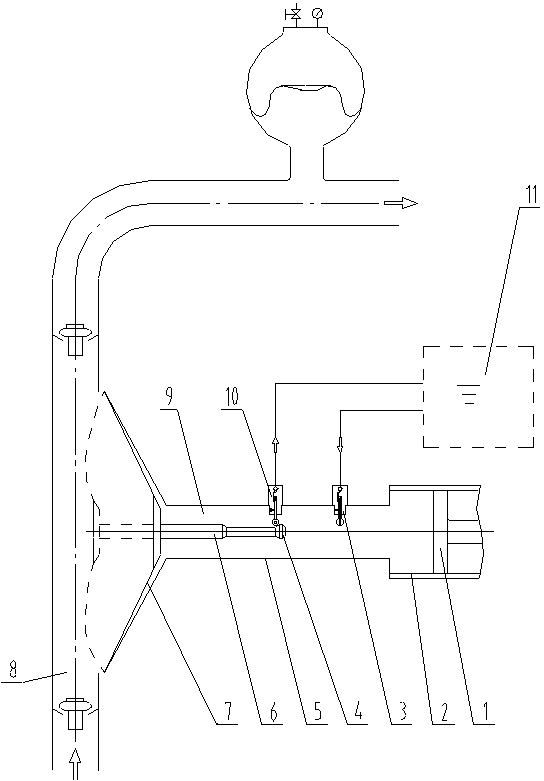

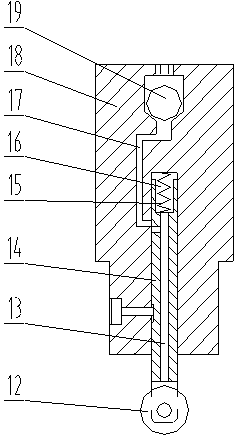

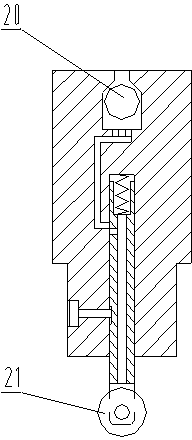

[0018] like figure 1 , figure 2 and image 3 As shown, the automatic oil replenishment and discharge device of the diaphragm pump of the present invention includes a piston cylinder 2 and a piston 1 installed in the piston cylinder 2, and the bottom of the piston cylinder 2 is connected to and communicated with one end of a hydraulic tube 5, and the hydraulic tube 5 The other end of the pipe is connected to the delivery pipe 8, and the lumen of the hydraulic pipe 5 forms an oil chamber 9. A diaphragm 7 is installed between the delivery pipe 8 and the oil chamber 9 , a guide rod 6 that goes deep into the oil chamber 9 is installed in the middle of the diaphragm 7 , and the other end of the guide rod 6 is a guide rod contact 4 . On the side wall of the hydraulic pipe 5, an oil replenishment valve 3 and an oil discharge valve 10 are installed. The connection lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com