Air brick protective valve

A protection valve and ventilation brick technology, applied in the field of metallurgy, can solve the problems of blocking ventilation bricks and unable to blow open, blocking ventilation holes of ventilation bricks, affecting the rhythm of steelmaking, etc., to extend service life and reliability, ensure ventilation, Avoid the effect of the clearing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The problem to be solved in this embodiment is that the ventilation holes on the ventilation bricks are blocked by molten steel during the current smelting process, causing the ventilation bricks to be blocked and unable to be blown open to form a dead bag, which seriously affects the rhythm of steelmaking.

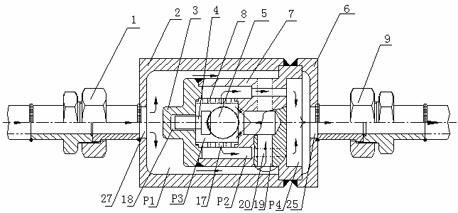

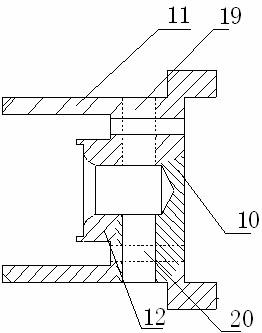

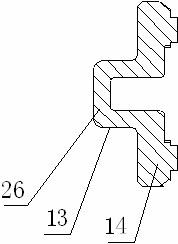

[0024] To this end, this embodiment provides figure 1 The air-permeable brick protection valve shown is composed of a valve body 2 with a cavity, a guide seat 3, a guide rod 4, a steel ball 5, a sleeve 8, a valve body seat 7, an end cover 6, a left spherical straight-through joint 1, and a right spherical straight-through joint. The valve body seat 7 is composed of a valve body seat base 10, an annular wall 11 arranged on the edge of the valve body seat base 10 and extending to the left, and a hollow column 12 arranged in the center of the valve body seat base 10 , the length of the hollow column 12 in the axial direction is less than the length of the annular wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com