Automobile body control function automatic test apparatus and method thereof

A technology for automobile body and control functions, applied in the direction of electrical testing/monitoring, etc., can solve problems such as untestable control logic and timing, potential safety hazards of controllers, and long time-consuming manual testing, etc., to achieve repeatable test results, low cost, The effect of clear hardware circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

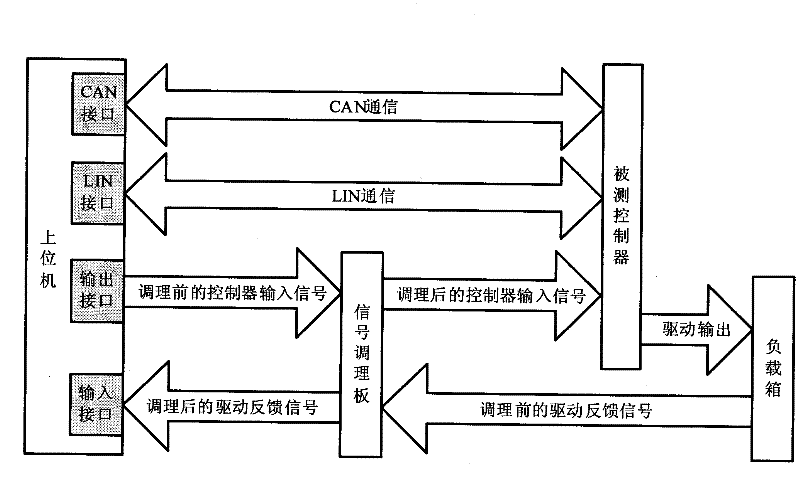

[0021] figure 1 It is the composition structure and connection schematic diagram of the automatic test device for automobile body control function of the present invention. The automatic test device is composed of a host computer, a signal conditioning board, a load box, and a tested controller; the host computer is directly connected to the tested controller through a CAN interface and a LIN interface; the output interface of the host computer is connected to the tested controller through a signal conditioning board. The input terminal of the controller is connected, and the drive output of the controller under test is connected to the load box on the one hand, and connected to the input port of the upper computer through the signal conditioning board on the other hand.

[0022] The vehicle body controller as the object under test usually has a CAN interface and (or) a LI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com