Die for punching chamfers

A stamping chamfering and die technology, applied in the field of stamping chamfering die, can solve the problems of uneven chamfering, affecting the appearance quality of products, etc., and achieve high processing efficiency, easy to ensure product dimensional accuracy and shape accuracy, and simple mold debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

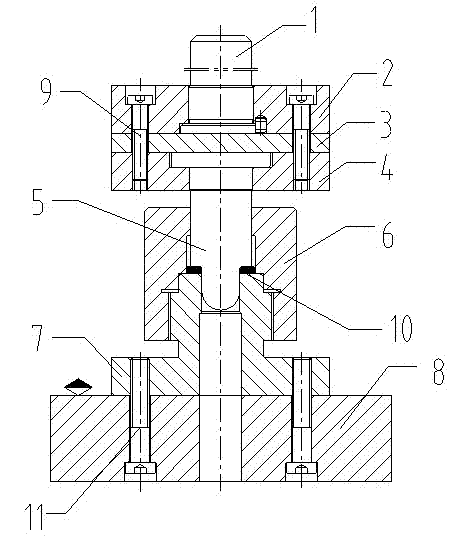

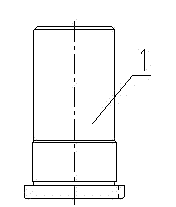

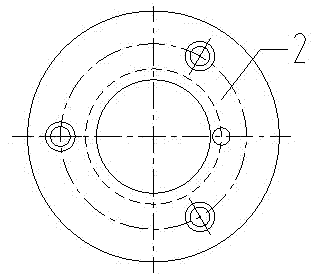

[0032] Such as figure 1 As shown, the mold for stamping chamfering of the present invention comprises a die handle 1, an upper die base 2, an upper backing plate 3, a fixed plate 4, a pressure head 5, a discharge positioning ring 6, a lower die 7 and a lower die base 8, and the Die handle 1 and the hole on the upper die base 2 are interference fit; the upper backing plate 3 is set under the upper die base 2, the fixing plate 4 is set under the upper backing plate 3, and the mold handle 1 passes through the upper die base 2 is in contact with the upper backing plate 3, one end of the upper punch 5 is set in the fixed plate 4, the other end passes through the discharge positioning ring 6 and slides with the lower die 7, and the discharge positioning ring 6 and the lower die 7 There is an annular space gap 10 between them. The lower die 7 is located below the discharge positioning ring 6, the lower die 7 is threadedly connected with the discharge positioning ring 6, the lower di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com