Packaging shell structure for semiconductor power module

A technology for power modules and encapsulation shells, which is applied to semiconductor devices, semiconductor/solid-state device components, and electric solid-state devices, etc., can solve problems such as excessive contact resistance, low installation efficiency, shaking, etc. It is convenient to install connectors and strengthen the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

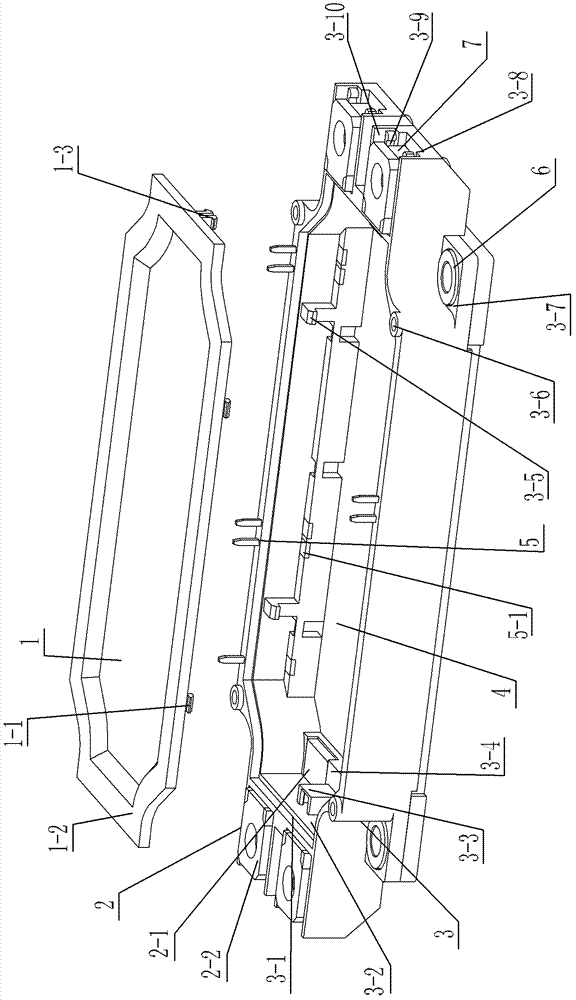

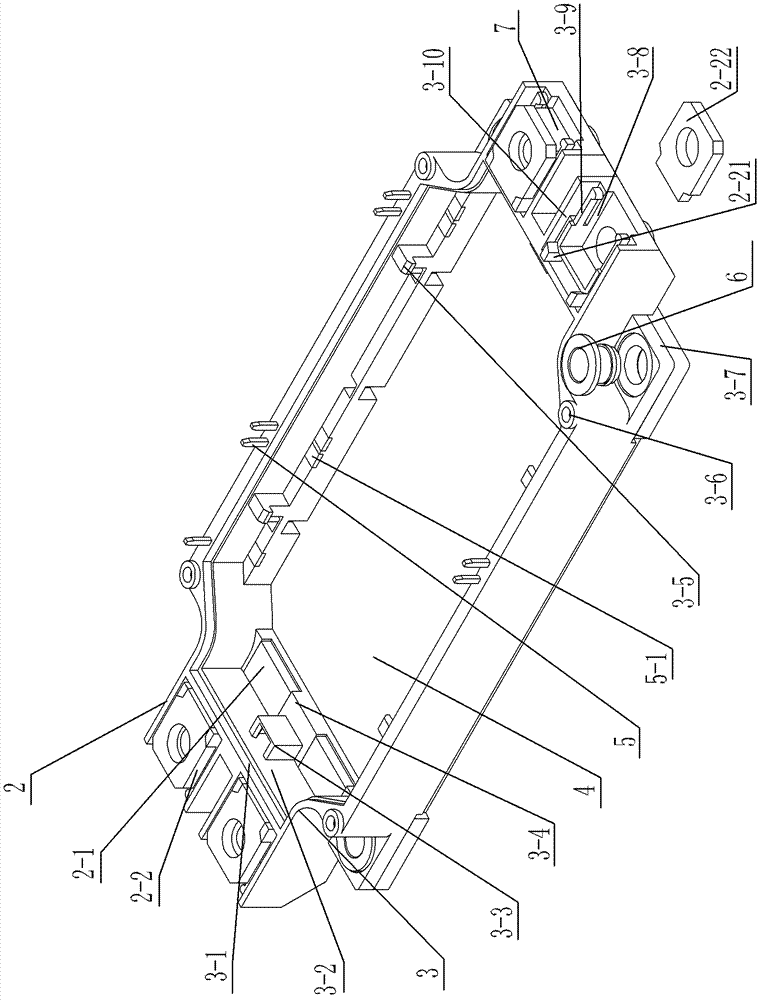

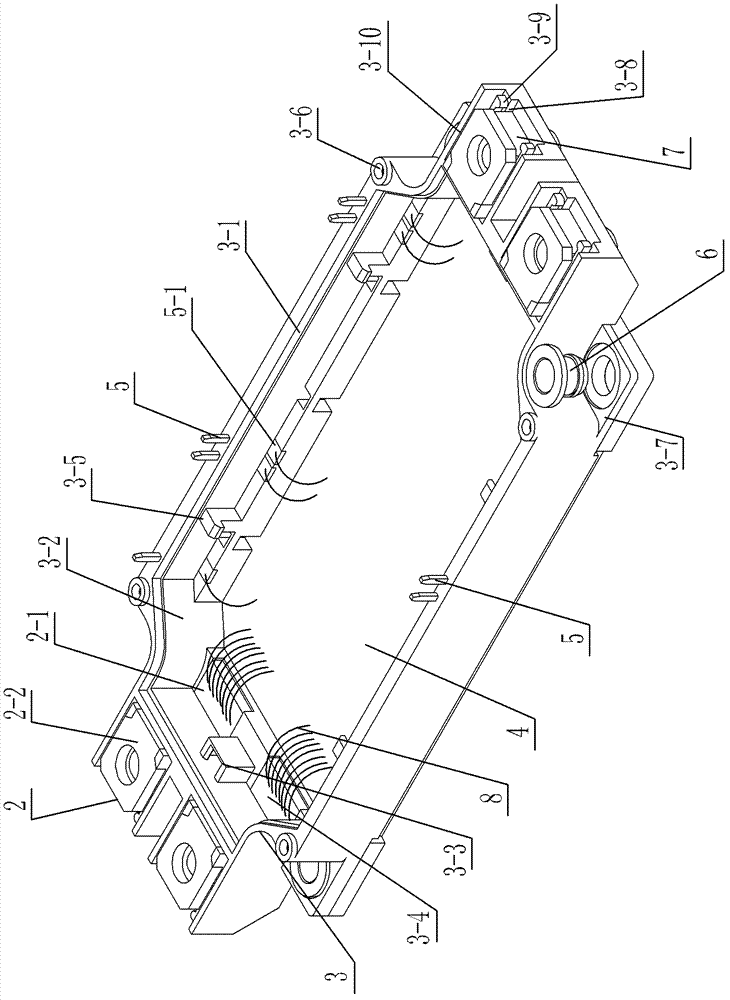

[0011] See Figure 1~3 As shown, the semiconductor power module packaging shell structure of the present invention includes a housing 3 with surrounding wall panels 3-2, a cover plate 1 and a bottom plate 4 installed on the housing 3, and a metal-ceramic substrate is welded on the bottom plate 4, at least The four electrodes 2 are respectively embedded in the wallboards 3-2 on both sides of the housing 3, and the aluminum wire bonding seat 2-1 of each electrode 2 is arranged on the base 3-4 inside the wallboard 3-2, and the connecting seat 2-2 is arranged on each electrode seat 3-10 on the outside of the wallboard 3-2, and the connection seat 2-2 of each electrode 2 has a plane and a mounting hole connected to the copper bar, and the mounting hole of the connection seat 2-2 Corresponding to the mounting holes on the respective electrode holders 3-10, when four electrodes 2 are used, four electrode holders 3-10 are provided on the housing 3, and the data of the electrode holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com