Indirect lighting system

A lighting system, indirect technology, applied in lighting installations, fixed lighting installations, lighting and heating equipment, etc., can solve the problems of no beam control, low illumination level, and system efficiency is not high design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

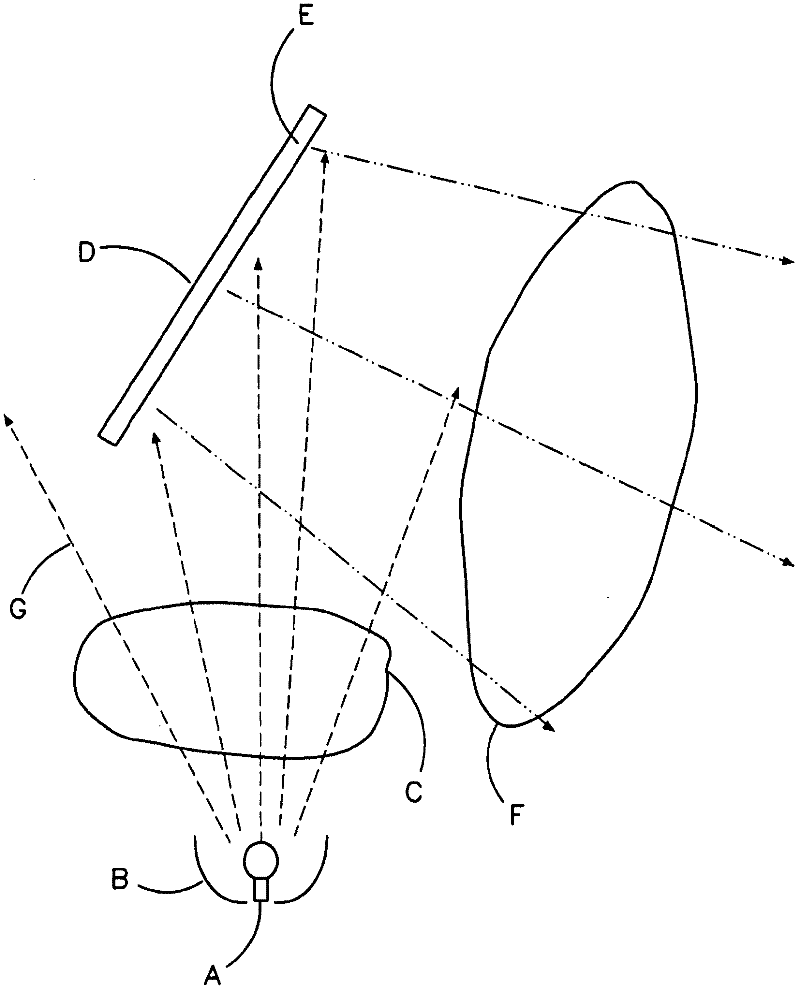

[0016] in figure 1 In the conventional indirect lighting system shown, the light source A, usually a high-intensity lamp suitable for producing a narrow beam, is hidden in a conical or parabolic reflector B. The narrower beam of light is shown by the periphery C, and this constitutes the main optical device of the indirect lighting system. It should be understood that the main optical system may also include lenses, protective screens and other devices. The secondary optical device D includes a large reflective surface E that is placed at a certain distance from the light source to cross the main beam C and redirect the light into the secondary beam F directed to an appropriate target. Such as figure 1 As shown, some of the main light G is lost without striking the reflector. It should be understood that the sub-reflector E is processed according to the appropriate degree of mirror reflection and formed into a shape suitable for the specific application. It should also be und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com