Panel turnover machine for assembling lighter oil cap

A technology for oil caps and flippers, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that oil caps cannot be assembled automatically in batches, so as to facilitate recycling and reuse, reduce labor intensity of personnel, and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

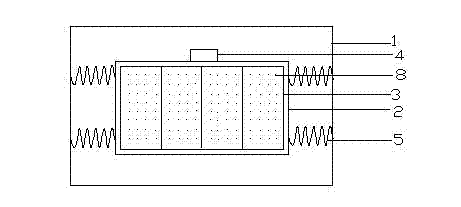

[0023] Example figure 1 and figure 2 As shown, the present embodiment provides a lighter oil cap assembly turning machine, which concentrates and pre-arranges the lighter oil cap, including a base frame 1, a working frame 2, four assembly turning plates 3, a vibration motor 4 and four springs 5, and the working The frame 2 is connected and fixed on the base frame 1 through the spring 5, and the spring 5 adopts a high-strength spring under the premise of ensuring vibration, and the vibration motor 4 is arranged on the work frame 2, or can also be connected to the work frame 2 through a connecting rod to vibrate; The frame 2 is provided with four slots with a cross bar, which facilitates the assembling of the turnover plate 3 and is fixed on the work frame 2 by flexible plugging.

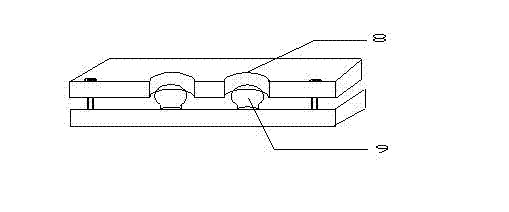

[0024] The assembly flap 3 includes an upper board and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com