Steel crown and aluminum skirt combined type piston for diesel engine

A combination of piston and diesel engine technology, applied in the direction of pistons, mechanical equipment, engine components, etc., can solve the problems of piston oil passage, poor cooling, diesel engine damage, etc., to reduce the risk of instability, simplify design, and avoid slipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

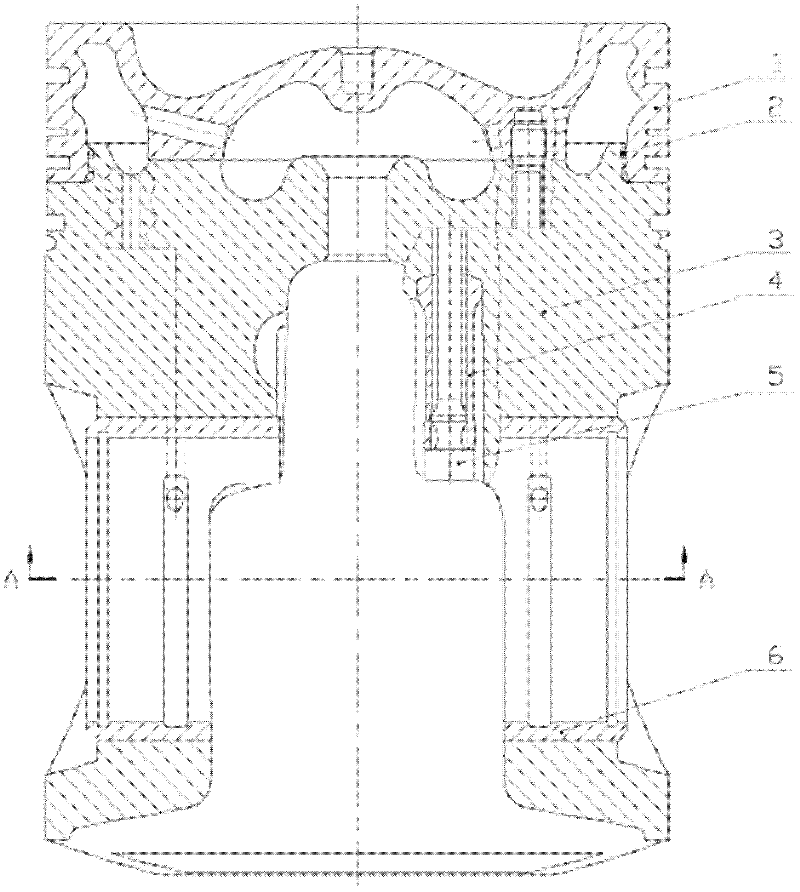

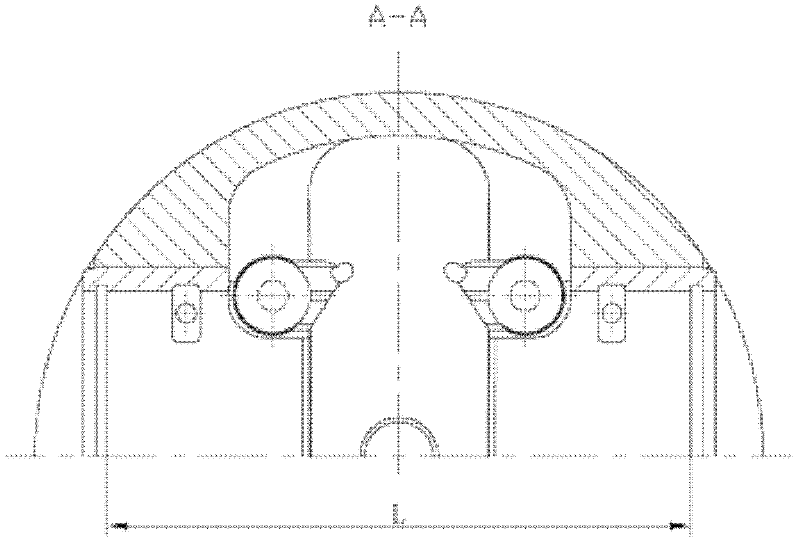

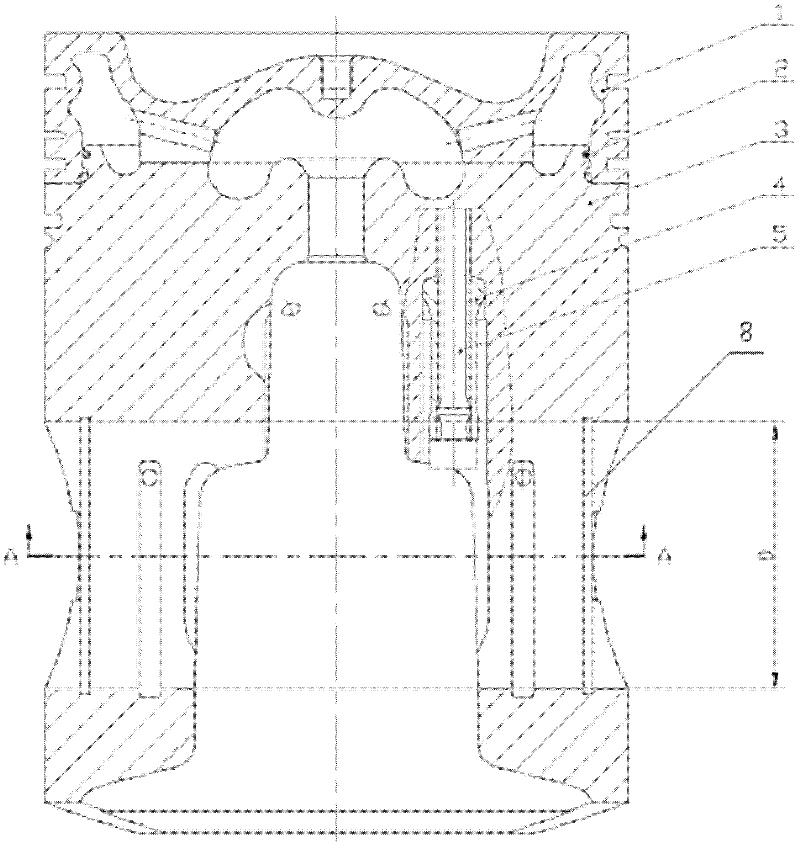

[0014] The steel head aluminum skirt combined piston for diesel engine of the present invention is composed of piston head 1, piston skirt 3, connecting screw 5, piston skirt 4 and other parts. It is a φ120mm pin hole. Compared with the existing structure of the piston, the design of the piston skirt pin hole structure and shape line and the support ring surface 7 shape line in the top of the piston skirt 3 have been improved. The specific plan is as follows:

[0015] (1) The copper bushing 6 is canceled for the pin hole of the piston skirt.

[0016] Such as image 3 As shown, in order to meet the deformation coordination between the piston pin and the piston skirt pin hole during the working process of the piston, the piston skirt pin hole is designed as a special-shaped pin hole, that is, the shape of the piston skirt pin hole is a combination of a cylindrical section and a flared section. Such as image 3 As shown, the maximum radius difference between the two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com