Gesture control device

A technology of attitude control device and motion device, which is applied to auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of simple movement, cannot meet processing requirements, and cannot realize arc surface attitude movement, and achieves the goal of improving processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

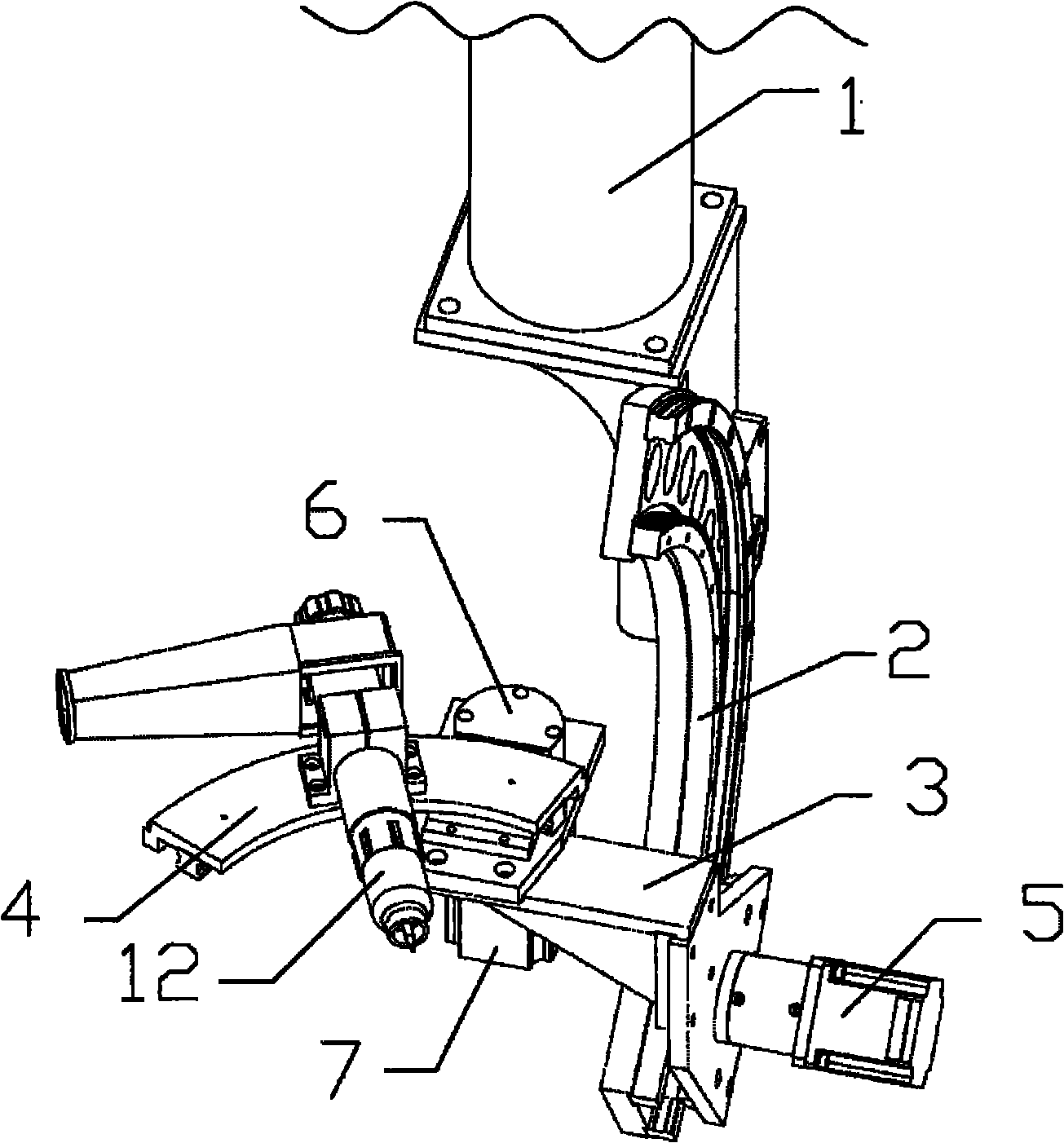

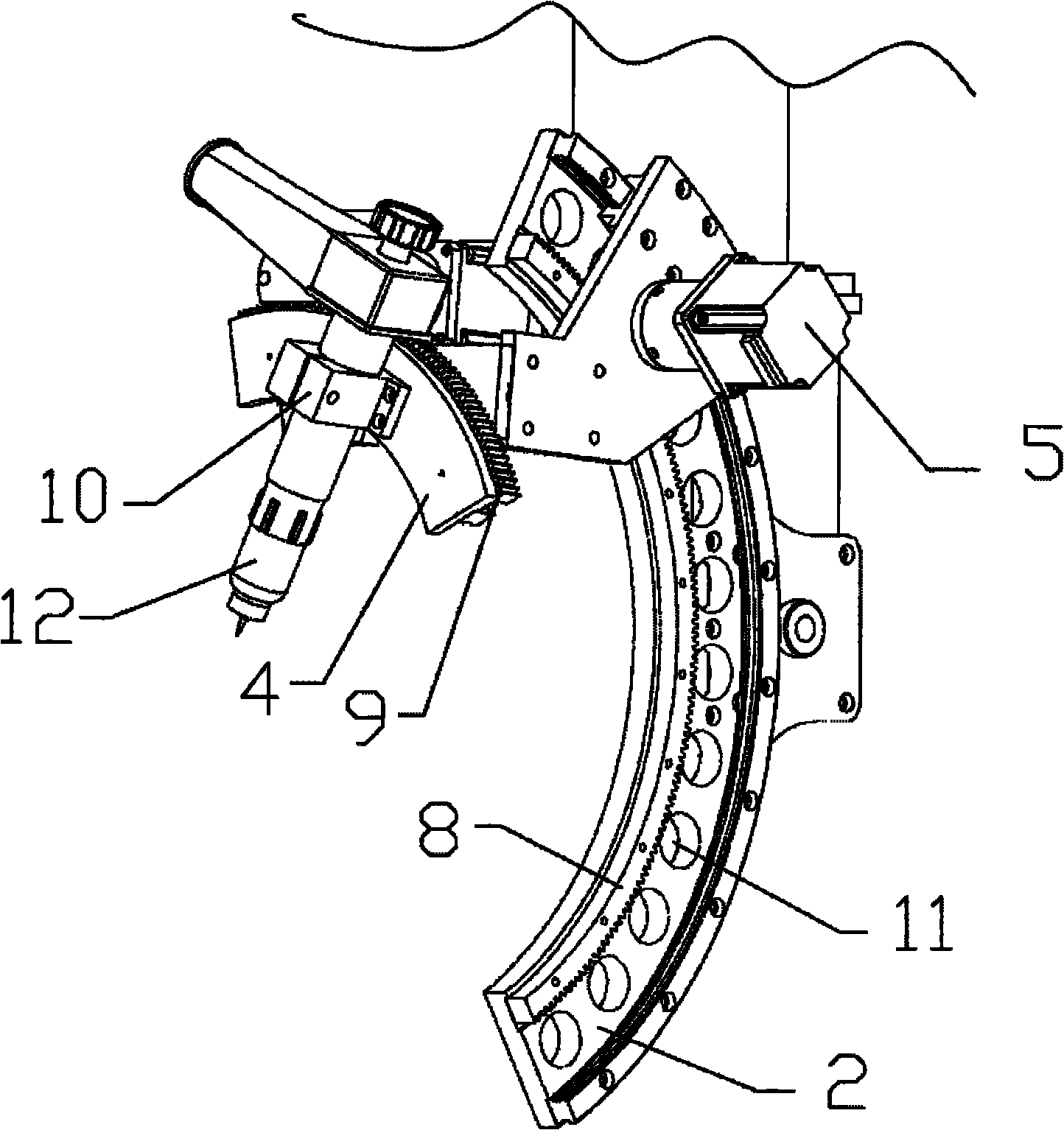

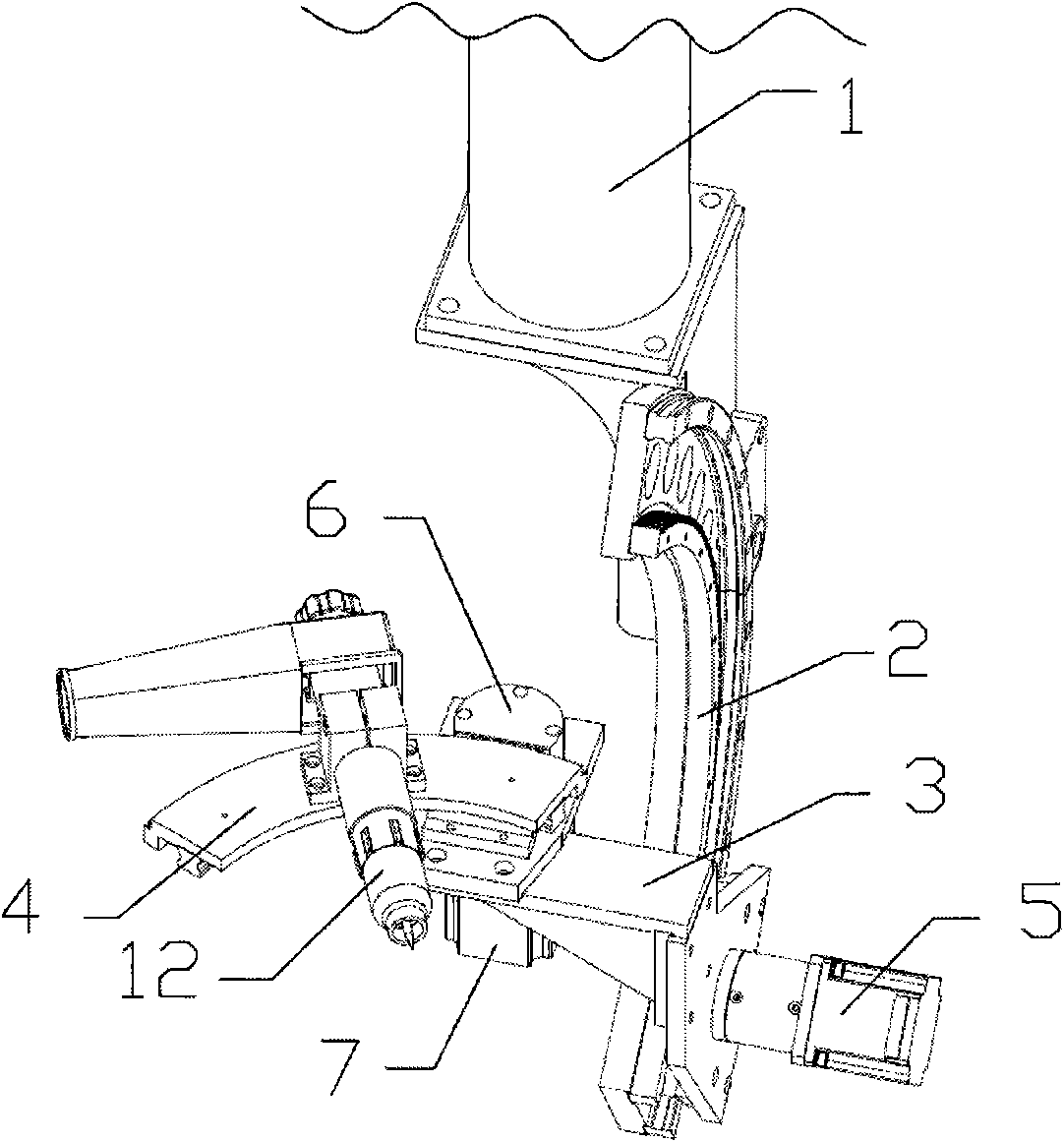

[0022] Such as figure 1 , figure 2 The attitude control device shown includes a main bracket, and its special feature is that: a longitudinal arc-shaped guide rail is provided on the main bracket, and a connecting plate is movably arranged on the longitudinal arc-shaped guide rail. At the same time, a transverse arc-shaped guide rail is movably connected to the connecting plate, and a main moving device is arranged on the connecting plate. Correspondingly, the transverse arc-shaped guide rail is driven by the auxiliary movement device on the connecting plate. Moreover, a working mechanism is arranged on the said transverse arc-shaped guide rail, and the working end of the working mechanism is always located at the center of the spherical motion track formed by the said longitudinal arc-shaped guide rail and the transverse arc-shaped guide rail. During the whole use process, the working mechanism can freely adjust the different angles of front, back, left, and right for a we...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap