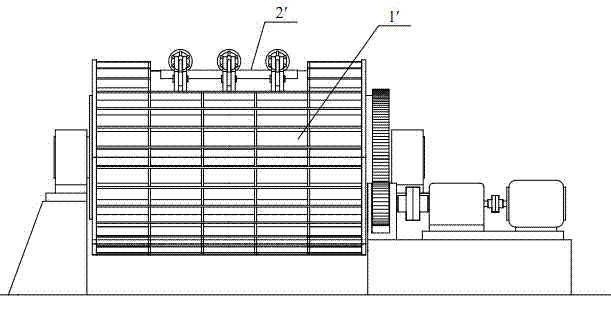

Novel anchor chain polishing barrel

A technology of drums and anchor chains, which is applied to grinding machines, machine tools for surface polishing, metal processing equipment, etc., and can solve problems such as difficult removal, easy knotting, and difficult knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

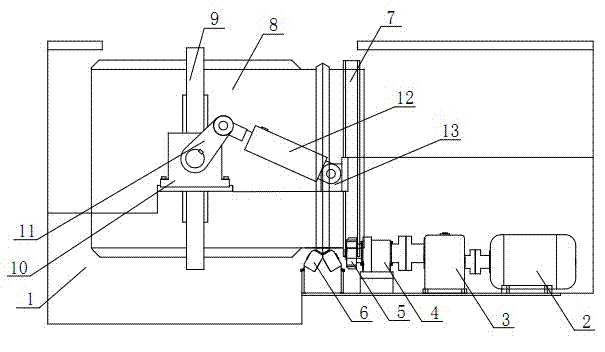

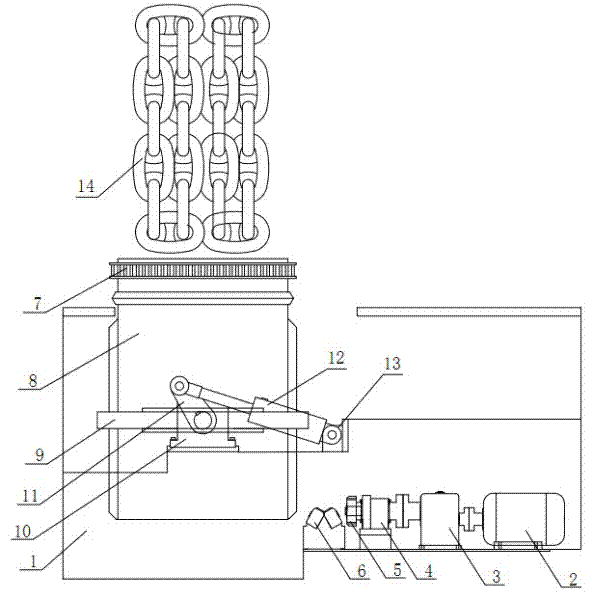

[0019] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

[0020] refer to figure 2 , image 3 , a new type of anchor chain drum, including a built-in part 1, a drum 8, the drum 8 is located in the embedded part 1, a rolling motor is fixed on the embedded part 1, and the rolling motor includes sequentially connected The motor 2, the speed reducer 3, the gear shaft 4, the driving wheel 5 is installed on the gear shaft 4, the large gear 7 is meshed on the driving wheel 5, and the drum 8 is a drum with one end open, The drum 8 is provided with a bung; the large gear 7 is fixed on the open end of the drum 8; the drum 8 is equipped with an outer hoop 9, which is rotatably connected to the On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com