Crank arm locking detection device and aerial work engineering machinery with same

A technology of lock detection and construction machinery, which is applied in the direction of hoisting devices, lifting equipment safety devices, etc., can solve the problems affecting the safety performance of the whole vehicle, damage, safety hazards, etc., and achieve the effect of solving the problem of crank arm reset and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

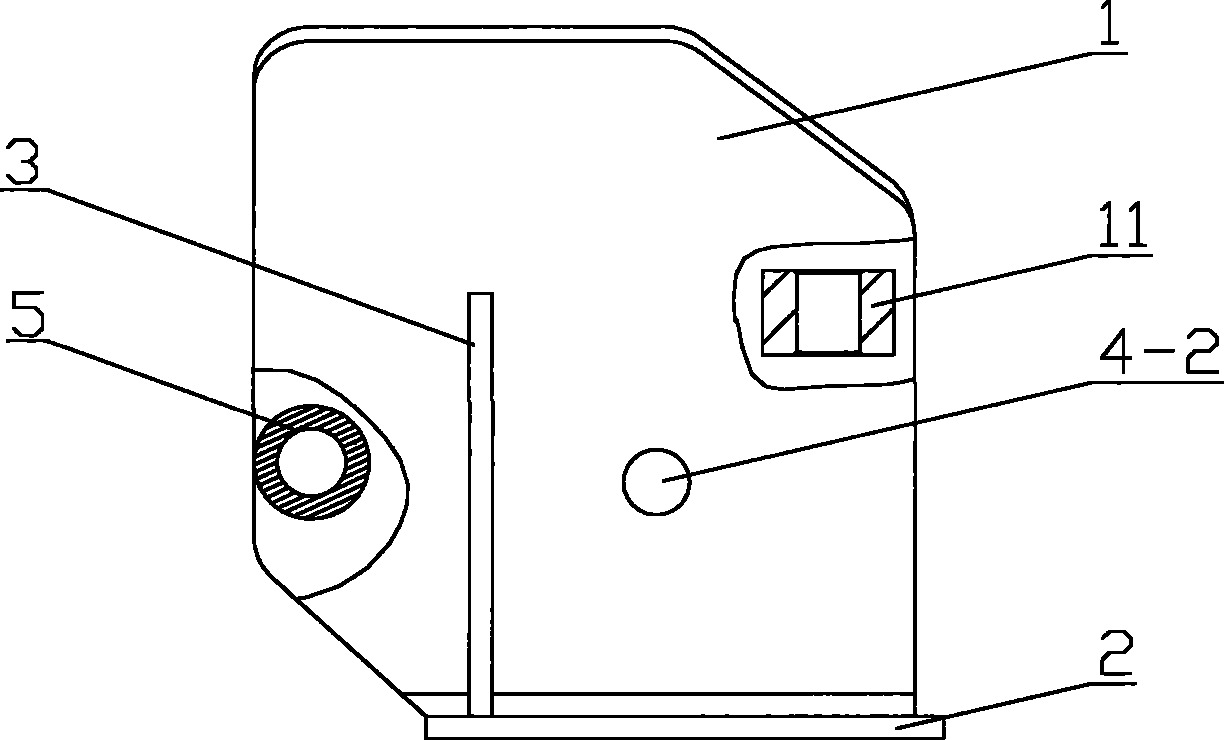

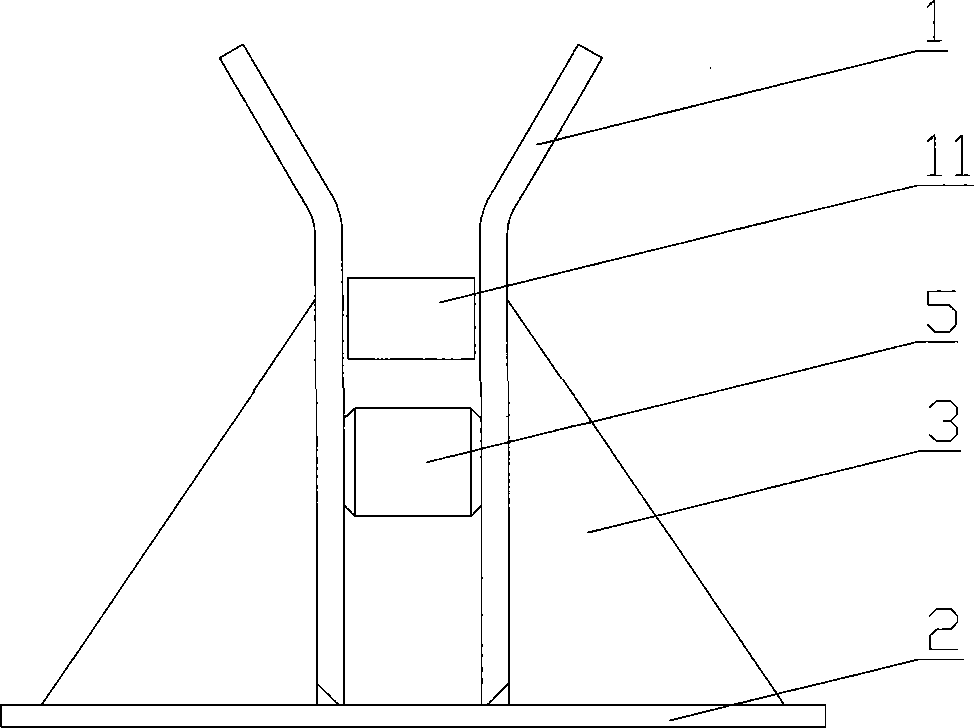

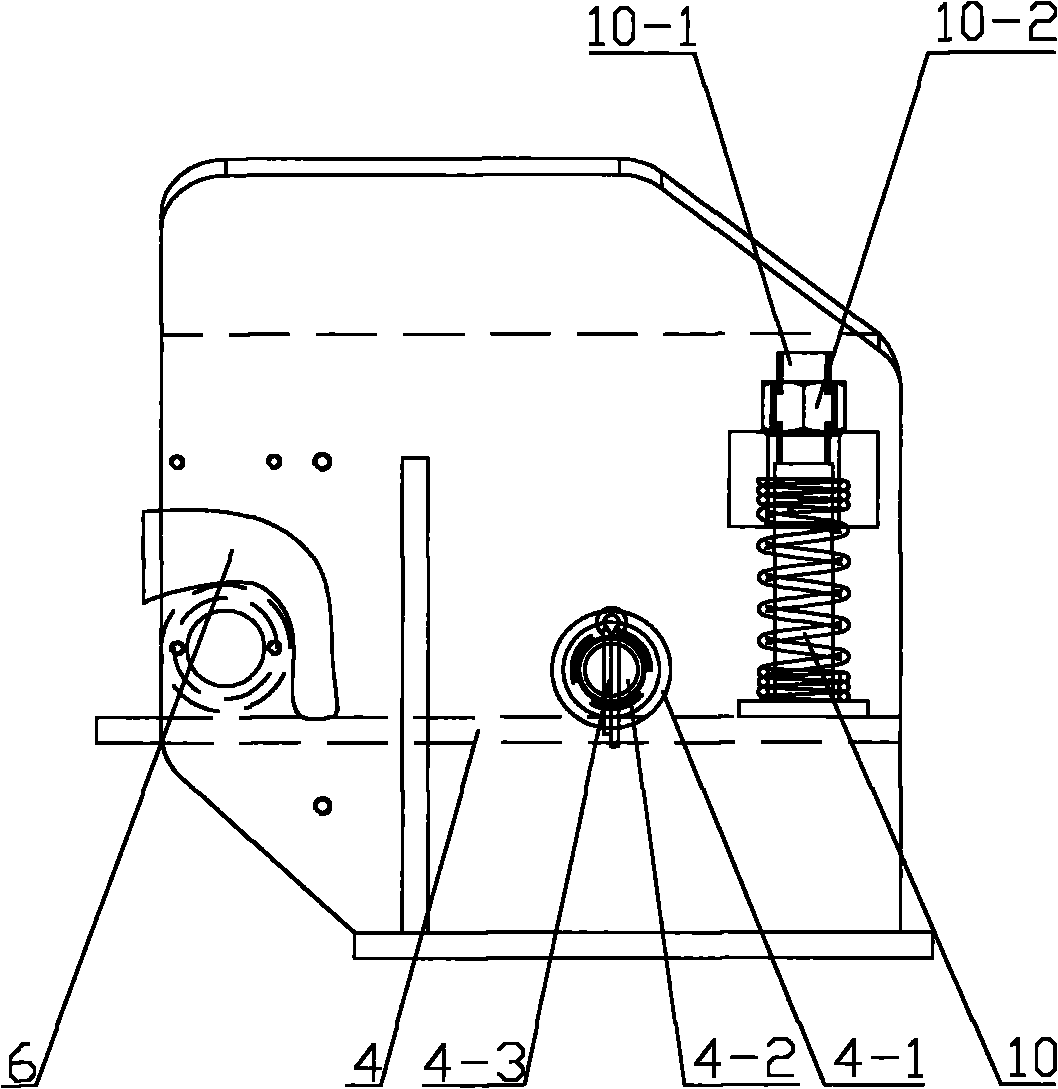

[0033] The core of the present invention is to provide a crank arm locking detection device. The device senses the crank arm recovery action transmitted by the lever mechanism through the sensor, and then controls the crank arm hydraulic cylinder to stop the action, so that the crank arm can be accurately recovered to the designated position, and at the same time, its crank arm hook can limit the swing of the crank arm along the vehicle driving direction , can comprehensively solve the problem of crank arm reset and improve the safety performance of the product. Another core of the present invention is to provide a high-altitude construction machine provided with the above-mentioned crank arm locking detection device.

[0034] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com