Dust recovery device based on corn starch workshop

A technology of dust recovery and corn starch, applied in transportation and packaging, separation methods, human health protection, etc., can solve the problems of low practicability, device failure, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

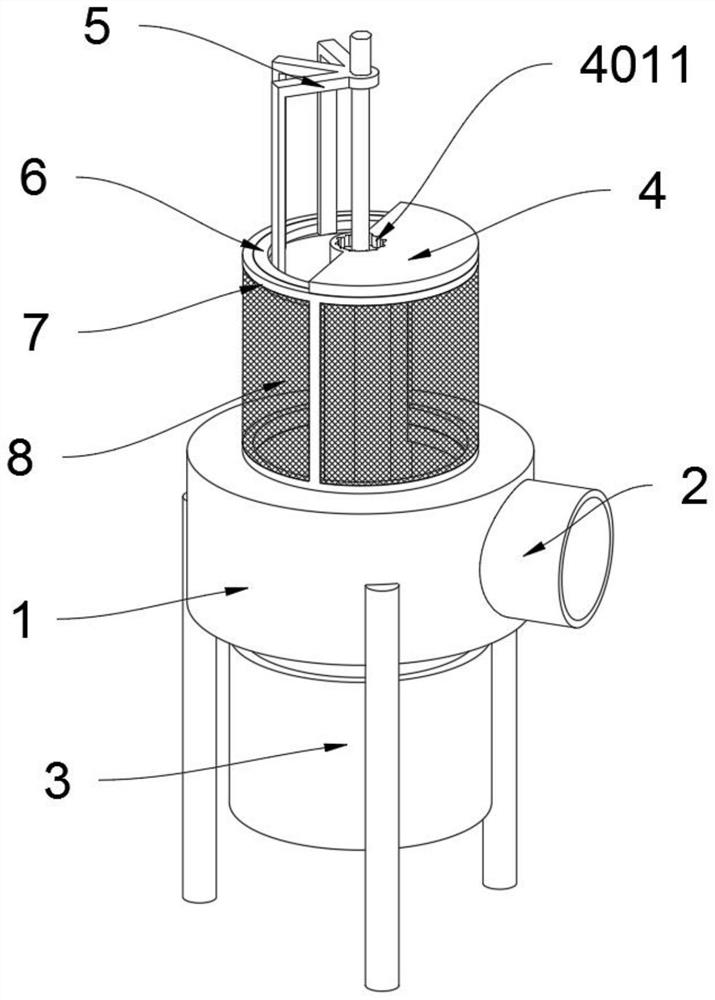

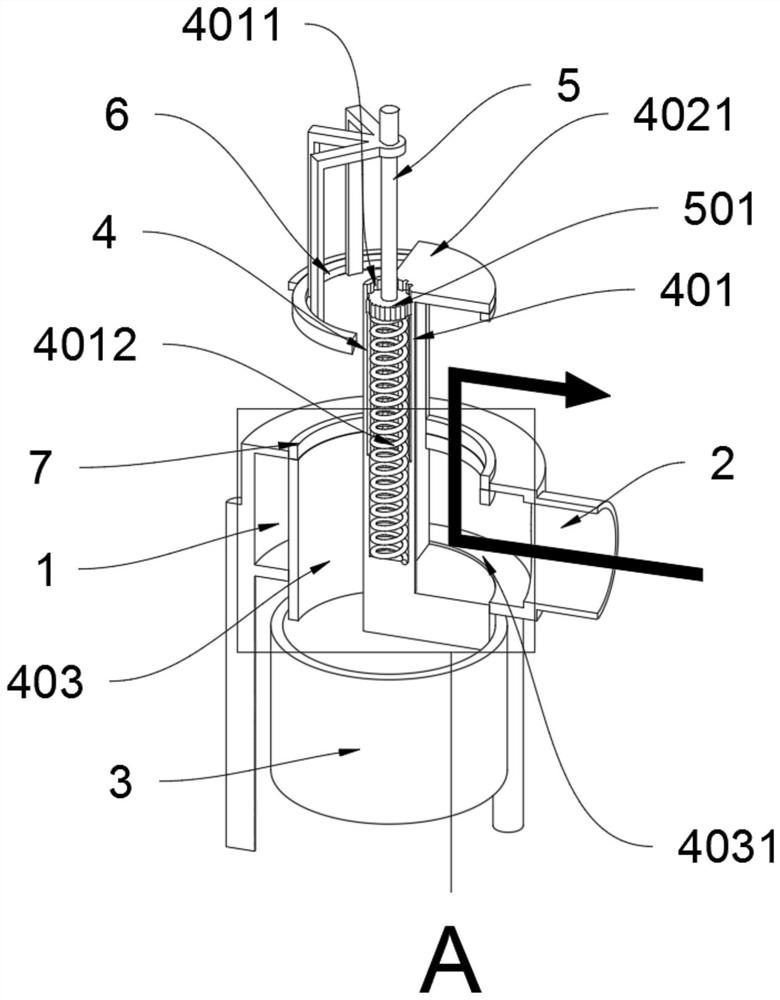

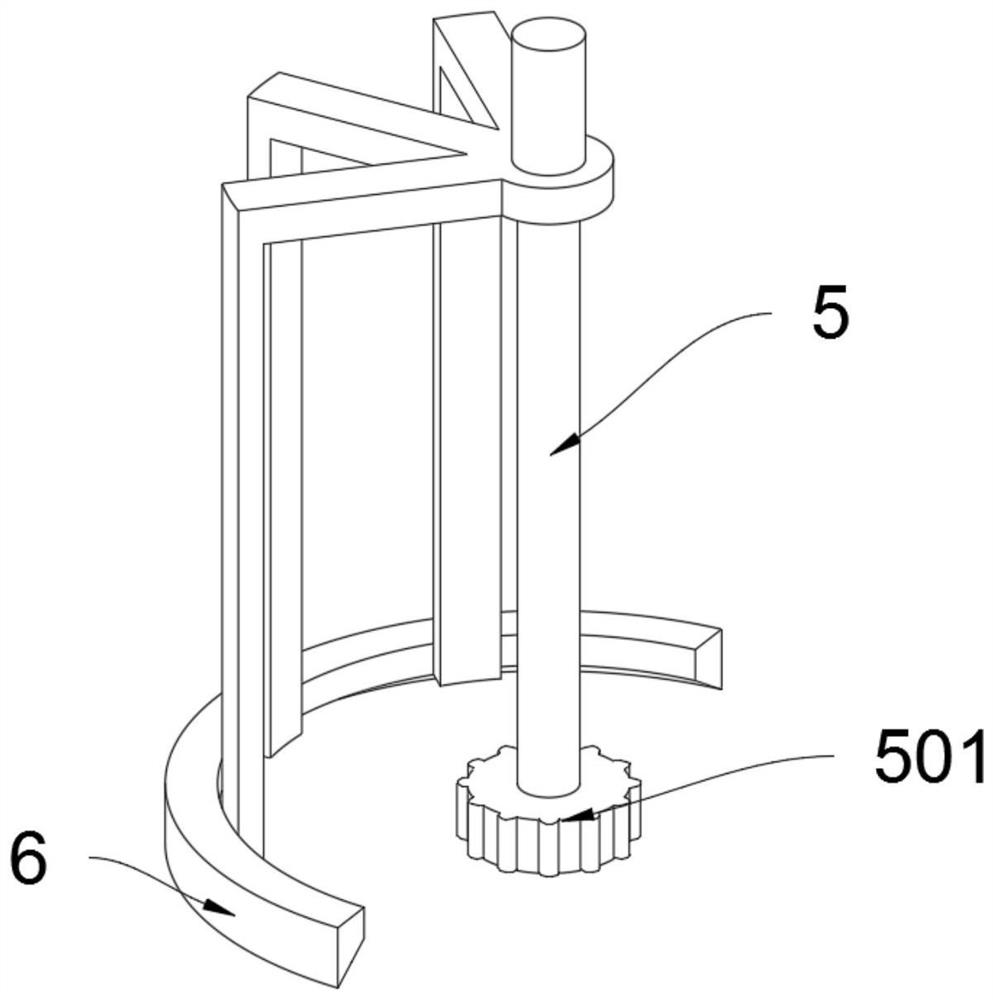

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036]The present invention provides a dust recovery device based on a corn starch workshop, comprising an exhaust fan interface 2, a dust recovery box 3, a scraping control rod 5, a dust scraper ring 6, a filter screen fixing frame 7 and a dust recovery filter cloth 8; the exhaust fan The interface 2 is fixedly connected to the middle part of the side of the air inlet hood 1, and the exhaust fan interface 2 is connected to the air supply pipe of the exhaust fan; the dust recovery box 3 is screwed to the bottom of the control hood 4; the control hood The bottom of 4 is rotatably connected to the bottom of the cover body of air intake hood 1; the scraping control rod 5 is plugged into the inside of the control shroud 4; the dust scraper ring 6 is fixedly connected to the bottom of the rod body of the scraping control rod 5; the filter screen is fixed The bottom of the frame 7 is fixedly connected to the top of the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com