Single-motor double-roller hydraulic sand making machine for extruding and grinding materials

A technology of extrusion grinding and single motor, which is applied in the direction of grain processing, etc., can solve the problems of poor adaptability and poor practicability, and achieve the effects of improving production quality, saving costs and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

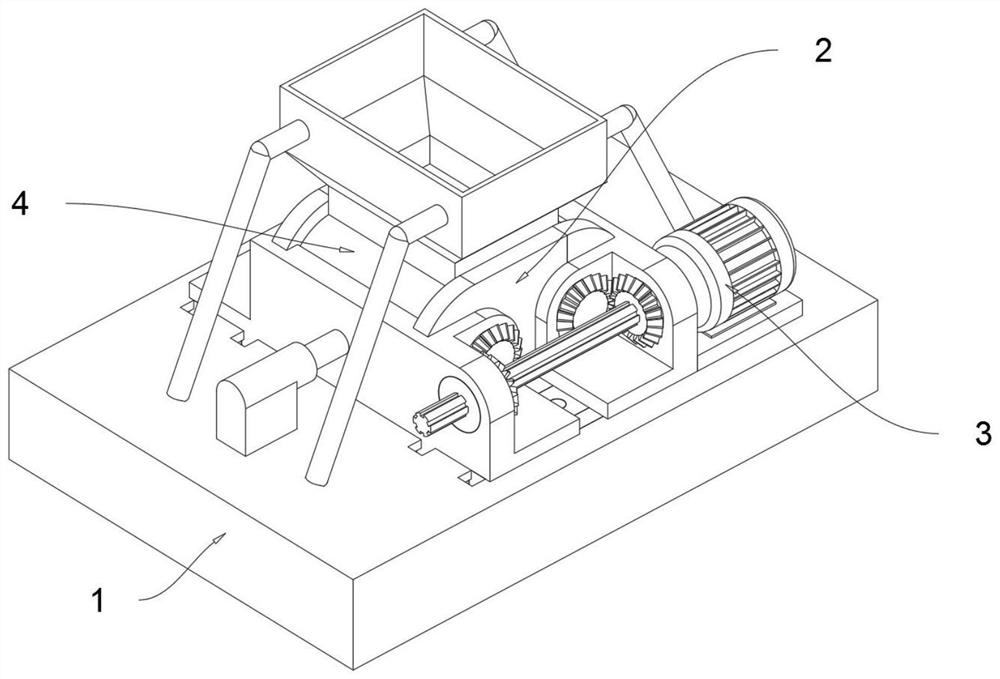

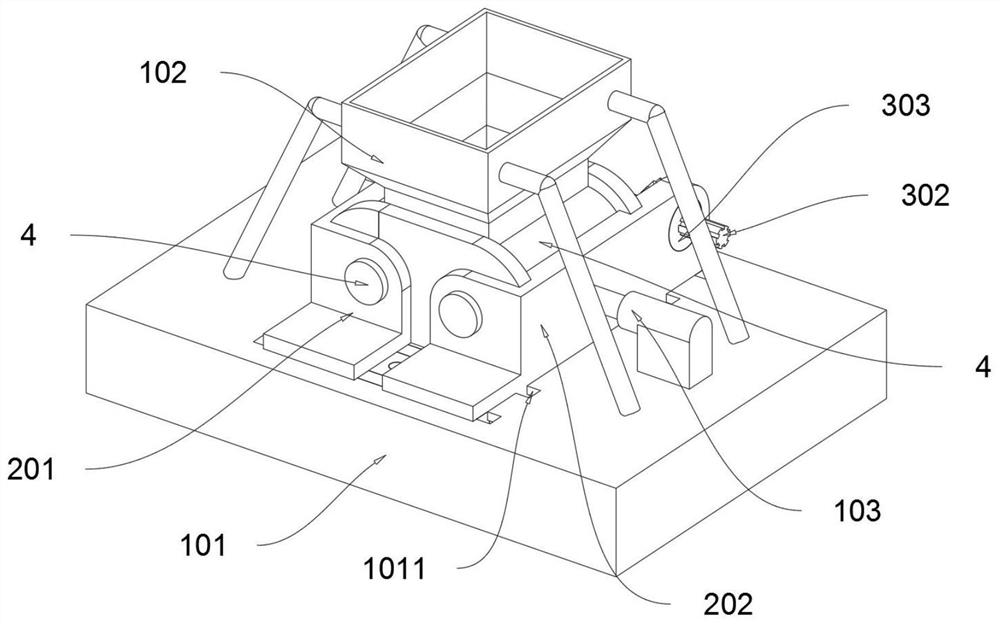

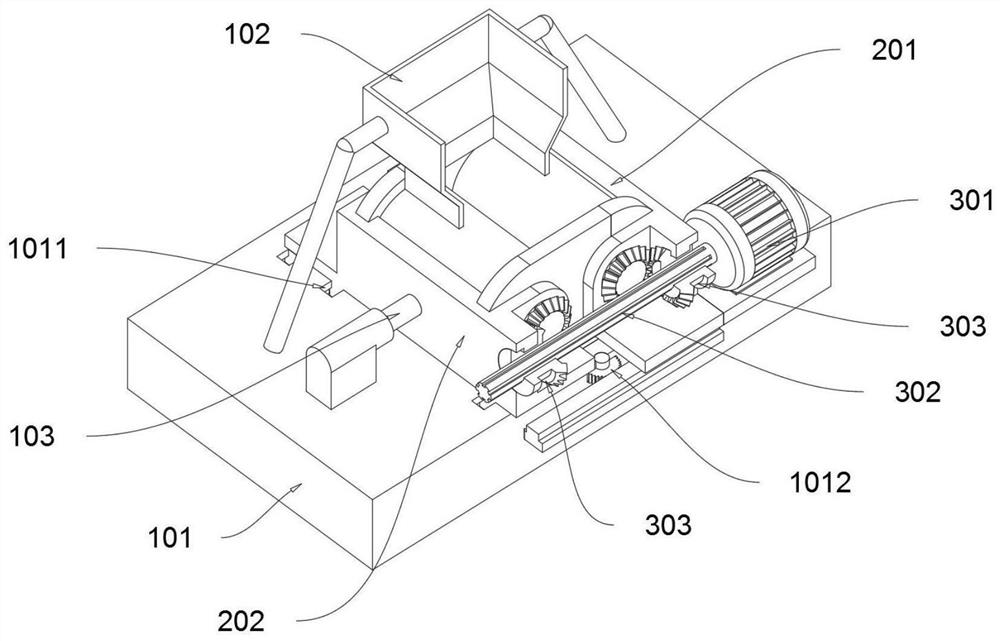

[0036] Example: Please refer to Figure 1 to Figure 8 :

[0037] The present invention proposes a single-motor double-roller hydraulic sand making machine for material extrusion and grinding, including an installation assembly 1; the installation assembly 1 includes a fixed base 101 and a feed hopper 102, and the feed hopper 102 is fixedly installed on a fixed The top of the base 101, and the top of the fixed base 101 is equipped with a roller distance adjustment assembly; the roller distance adjustment assembly includes a positioning frame plate 2 and a driving mechanism 3, and the use distance of the positioning frame plate 2 can be adjusted freely, thereby realizing two For the adjustment of the distance between the sand making rollers 4, the positioning frame plate 2 is composed of a driving frame plate 201 and an adjusting frame plate 202, and the driving frame plate 201 and the adjusting frame plate 202 are symmetrically inserted on the top of the fixed base 101; the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com