Visco-elastic surfactant acidizing liquid

A technology of surfactant and acidizing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult to achieve transformation goals, poor steering effect, damage to reservoirs, etc., to achieve no need for cross-linking agents and Gel breaker, good retarding and filtration control, complete flowback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Design parameters

[0023] (1) According to the requirements of the geological plan, according to the physical characteristics of the well and the practice of acidizing measures in the oilfield, in order to meet the requirements of the measures, the plugging removal radius is designed to be 3m.

[0024] (2) The designed volume of treatment liquid entering the formation is 17m 3 (V=πR 2 hφ, h=6m, φ=10.8%, R=3m).

[0025] (3) The acidizing construction process is mainly divided into four slugs

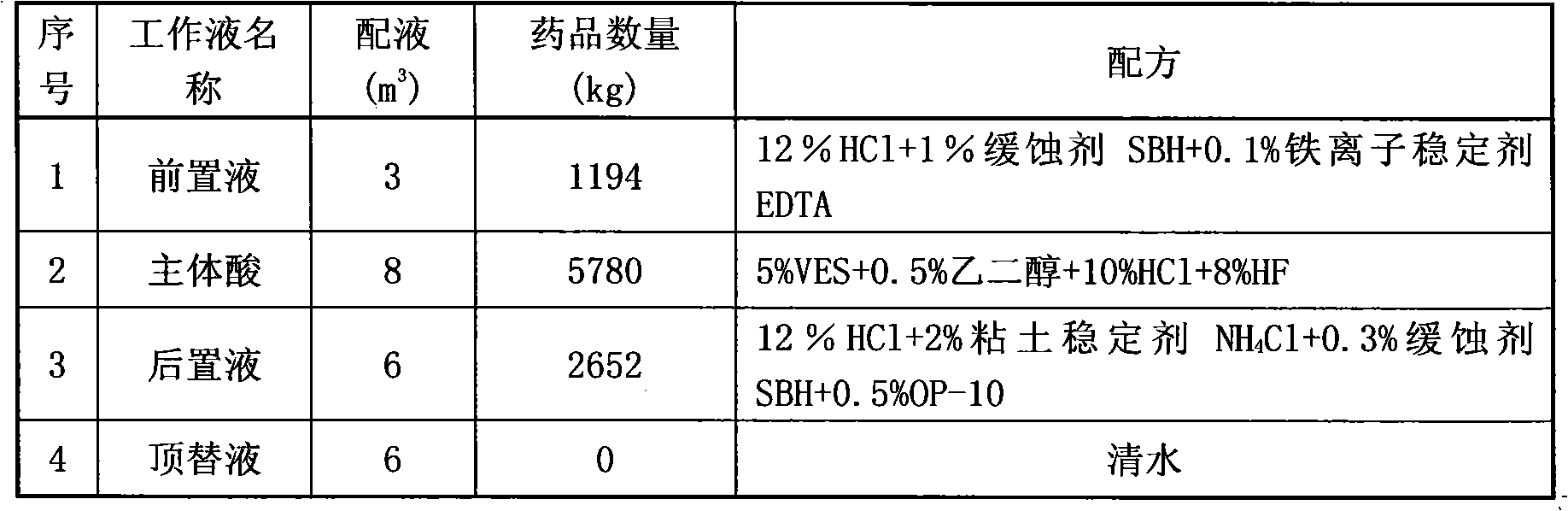

[0026] 2. Formula and quantity of working fluid

[0027]

[0028] 3. Construction steps and requirements

[0029] (1) Pull out the production tubing string from the original well for careful inspection, stab and clean it, and replace unqualified tubing and rods. It is strictly forbidden to enter the well with waxy or scaled tubing.

[0030] (2) Drill the well to the bottom of the artificial well through the lower φ118mm well gauge. If there is obstruction in the middle,...

Embodiment 2

[0038] 1. Design parameters

[0039] (1) According to the requirements of the geological plan, according to the physical properties of the well and the practice of acidizing measures in the oil field, in order to meet the requirements of the measures, the plugging removal radius is designed to be 1.5m.

[0040] (2) The designed volume of treatment liquid entering the formation is 14m 3 (V=πR 2 hφ, h=19.9m, φ=10.8%, R=1.5m).

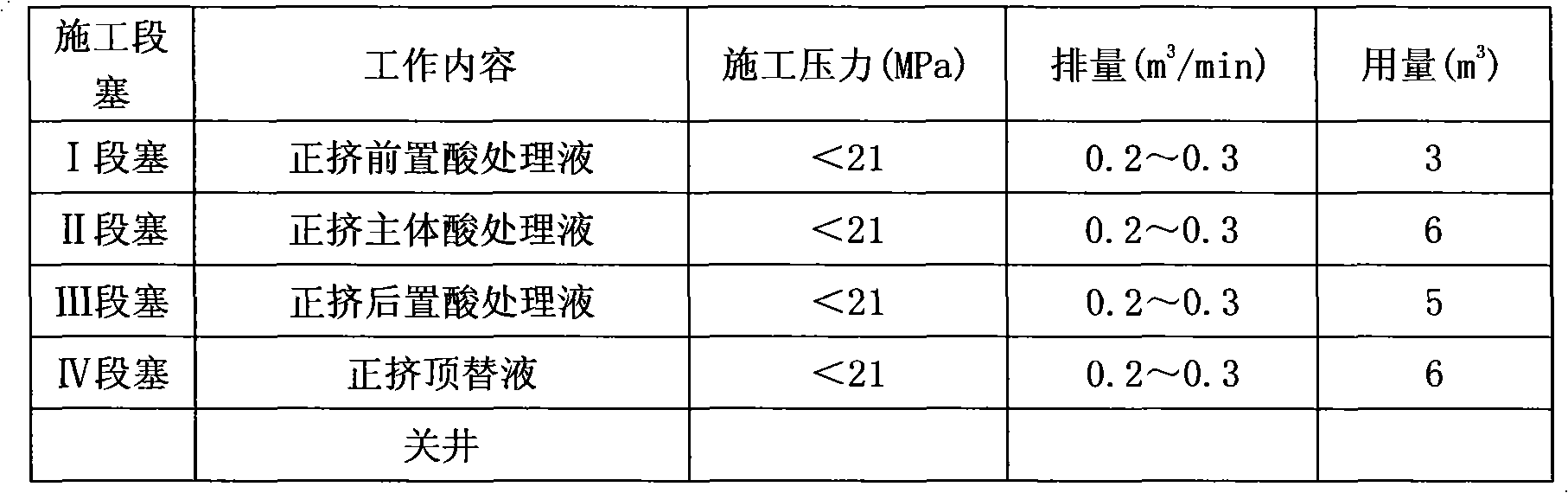

[0041] (3) The acidizing construction process is mainly divided into four slugs

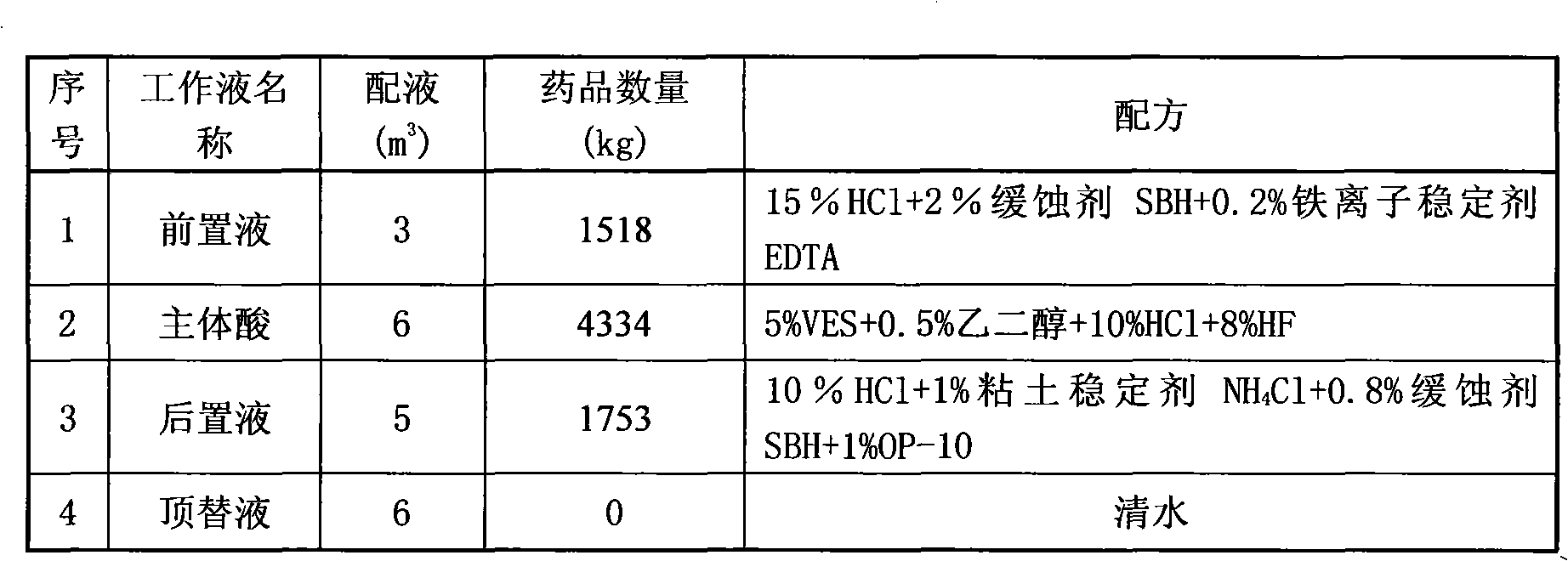

[0042] 2. Formula and quantity of working fluid

[0043]

[0044] 3. Construction steps and requirements

[0045] (1) Pull out the production tubing string from the original well for careful inspection, stab and clean it, replace unqualified tubing and rods, and strictly prohibit tubing with wax and dirt from entering the well.

[0046] (2) Drill the well to the bottom of the artificial well through the lower φ118mm well gauge. If there is obstruction in the middle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com