Load sensitive turning hydraulic system of loading machine

A load-sensitive steering system technology, applied in fluid steering mechanisms, mechanical equipment, fluid pressure actuating devices, etc., can solve problems affecting loader performance and return on investment, high labor intensity for drivers, and poor steering performance, etc., to achieve Achieve mass production, improve operating efficiency, and improve steering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

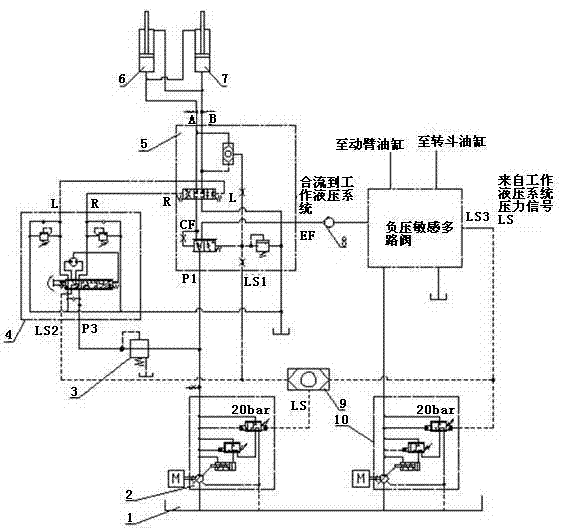

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The present invention includes:

[0015] Steering system: The steering system is mainly composed of a hydraulic oil tank 1, a first load-sensitive constant pressure variable plunger pump 2, a pressure reducing valve 3, a small displacement steering gear 4, a flow control valve with a priority valve function and a load signal feedback function Amplifying valve 5, left steering oil cylinder 6, right steering oil cylinder 7, one-way valve 8 and shuttle valve 9, the load-sensitive constant pressure variable plunger pump 2 provides working oil pressure to flow amplifying valve 5 and steering gear 4, The load feedback pressure signal of the flow amplifying valve 5 controls the LS control valve of the load-sensitive constant pressure variable plunger pump 2; the L port of the steering gear 4 is connected to the right end of the main spool valve L of the flow amplifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com