Patents

Literature

65results about How to "Efficient use of power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

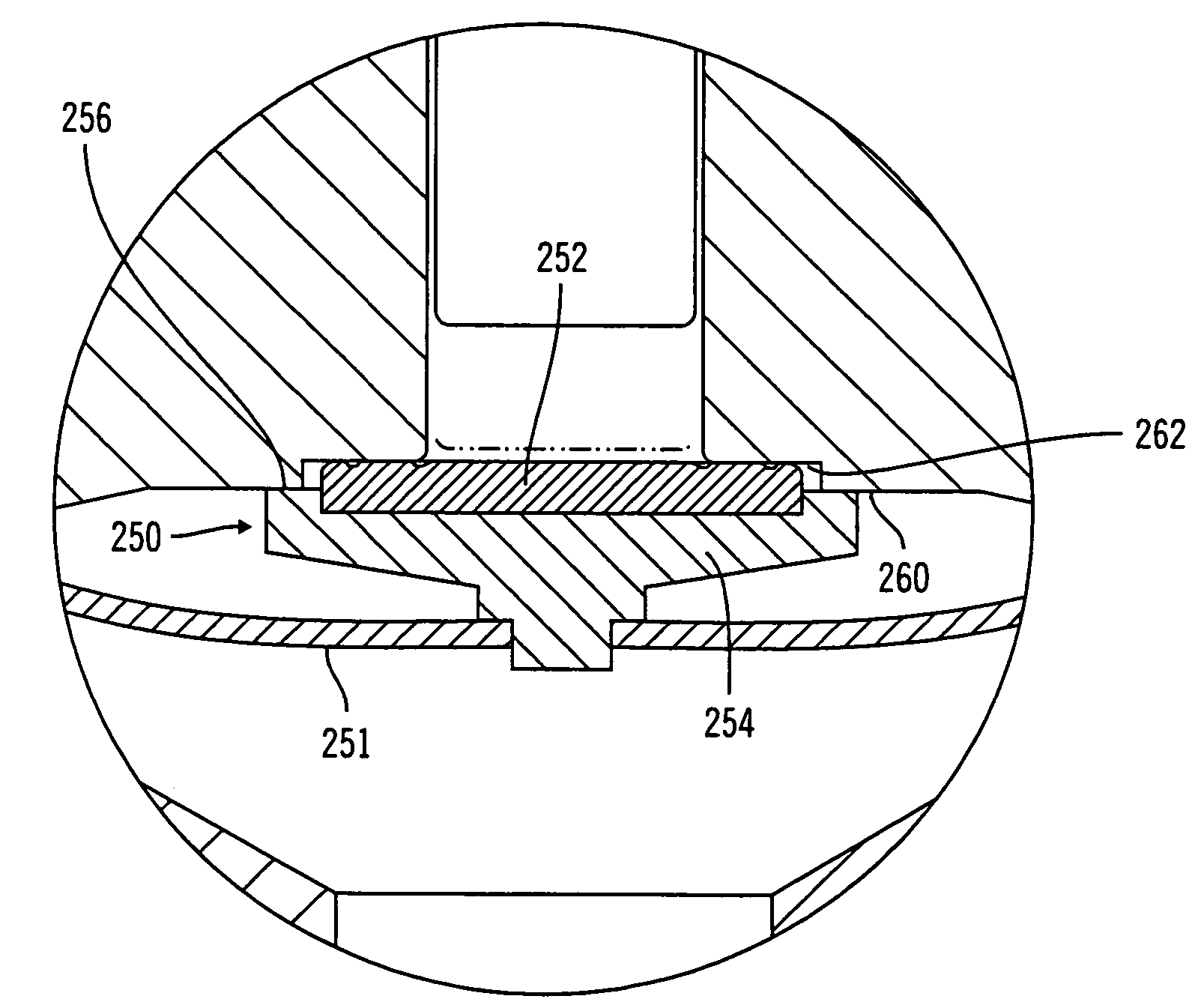

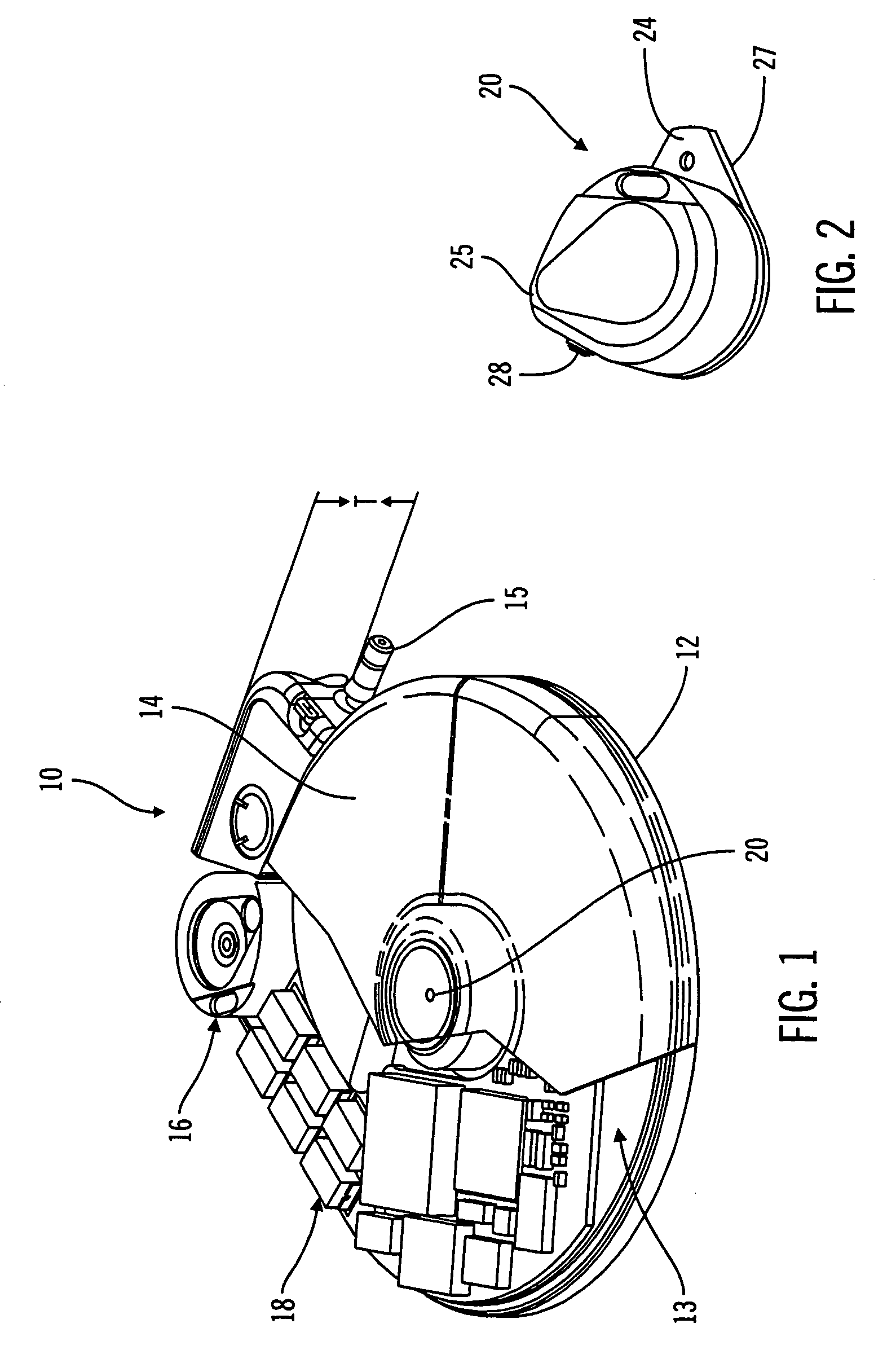

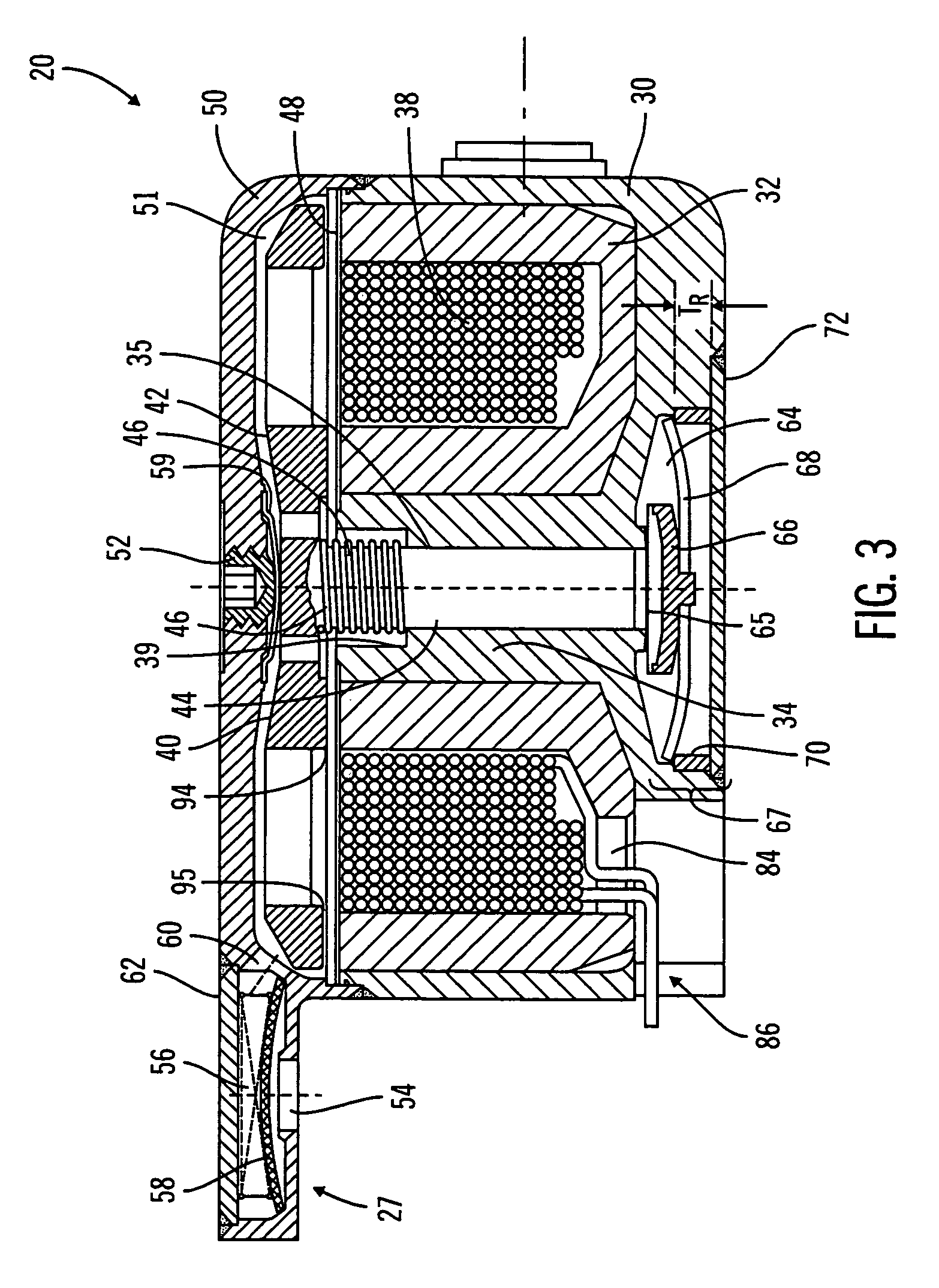

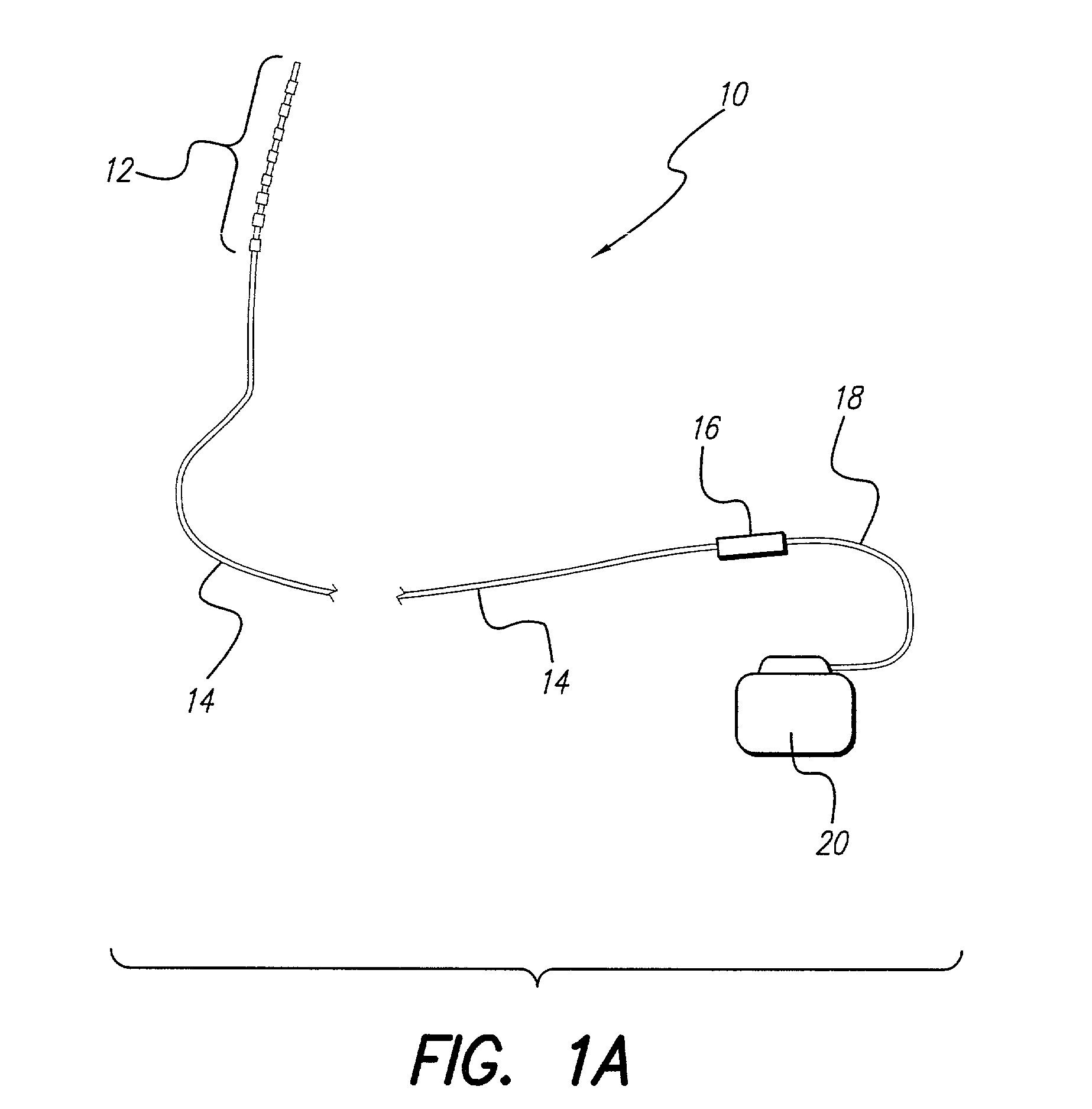

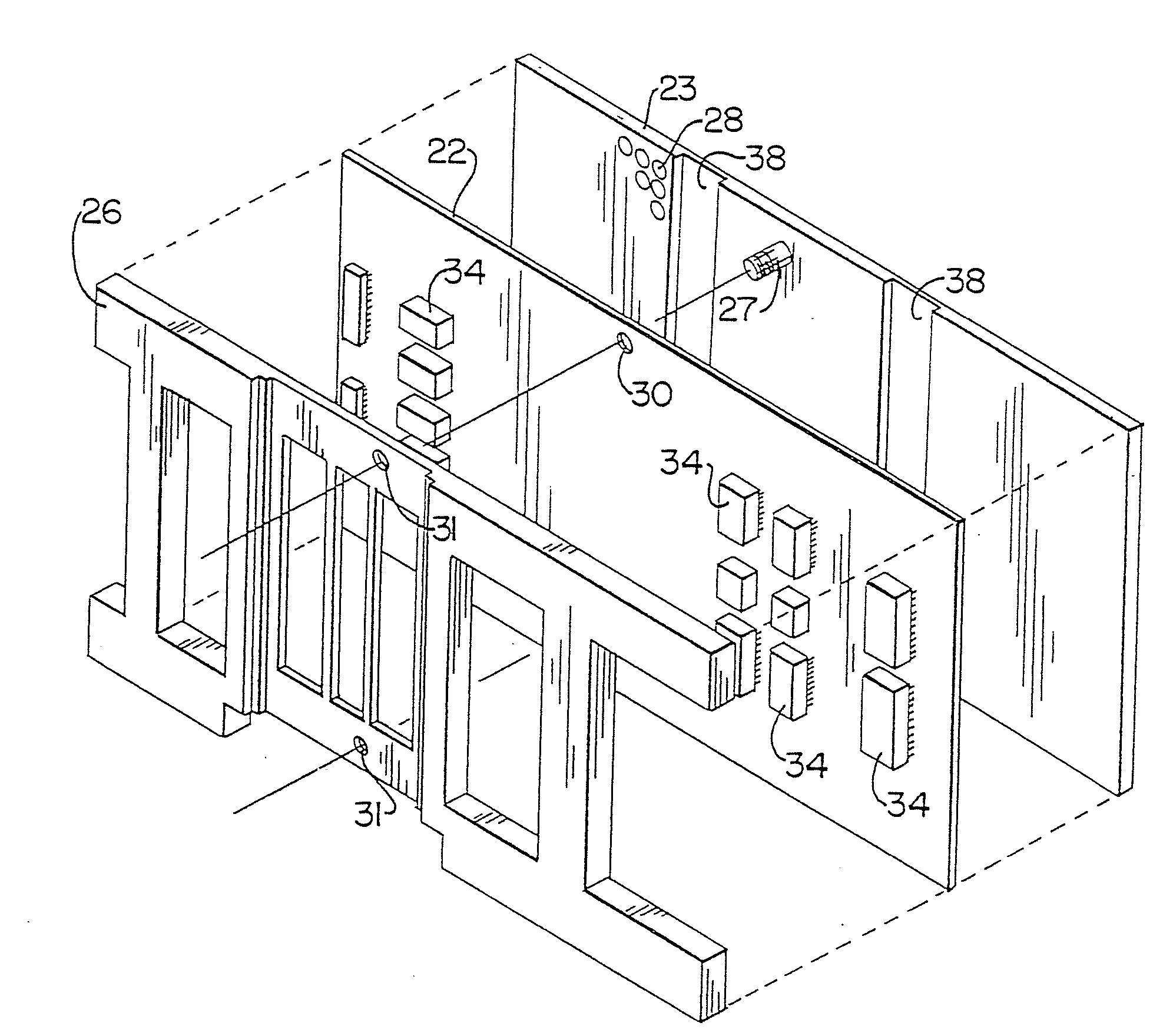

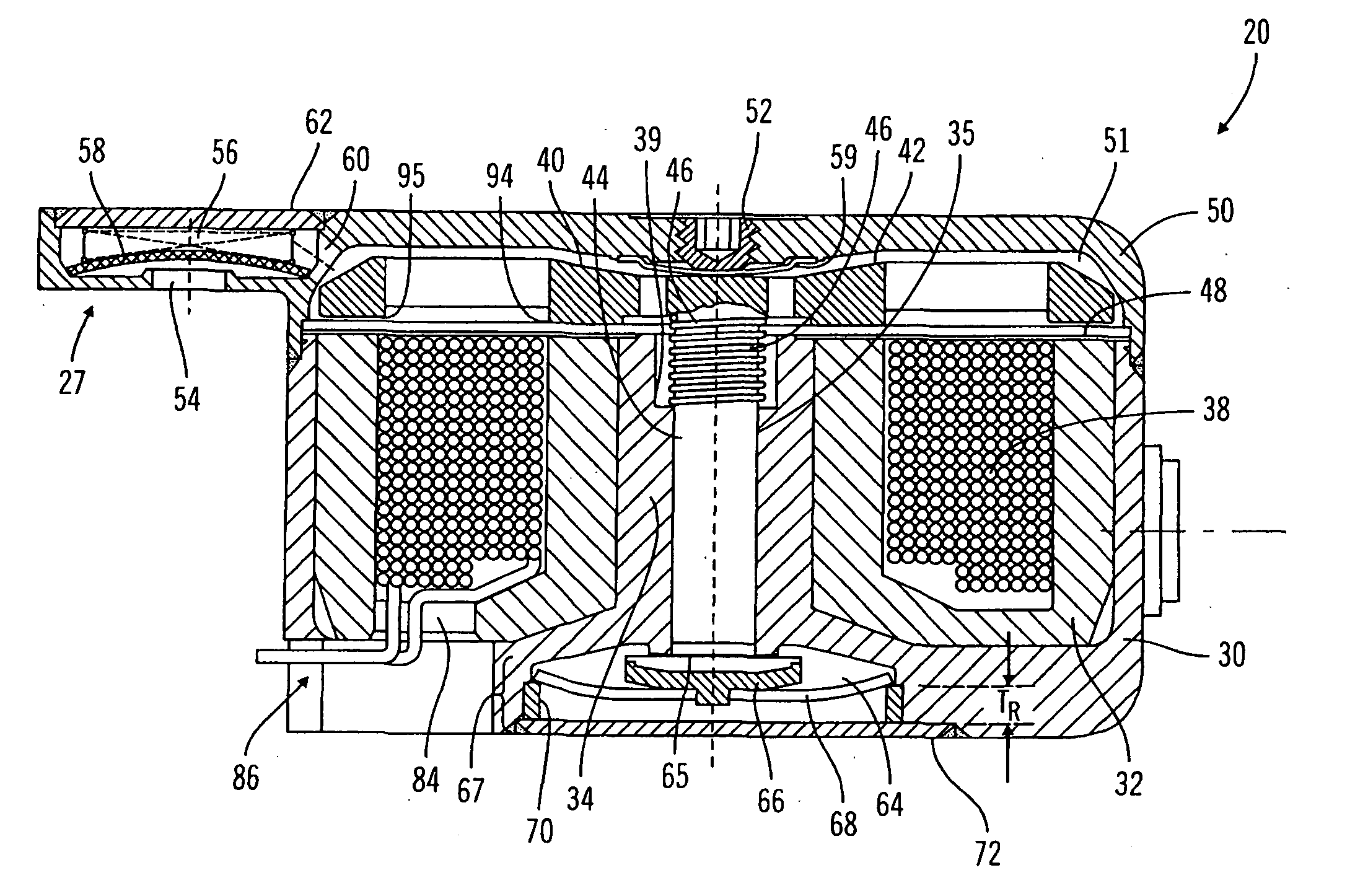

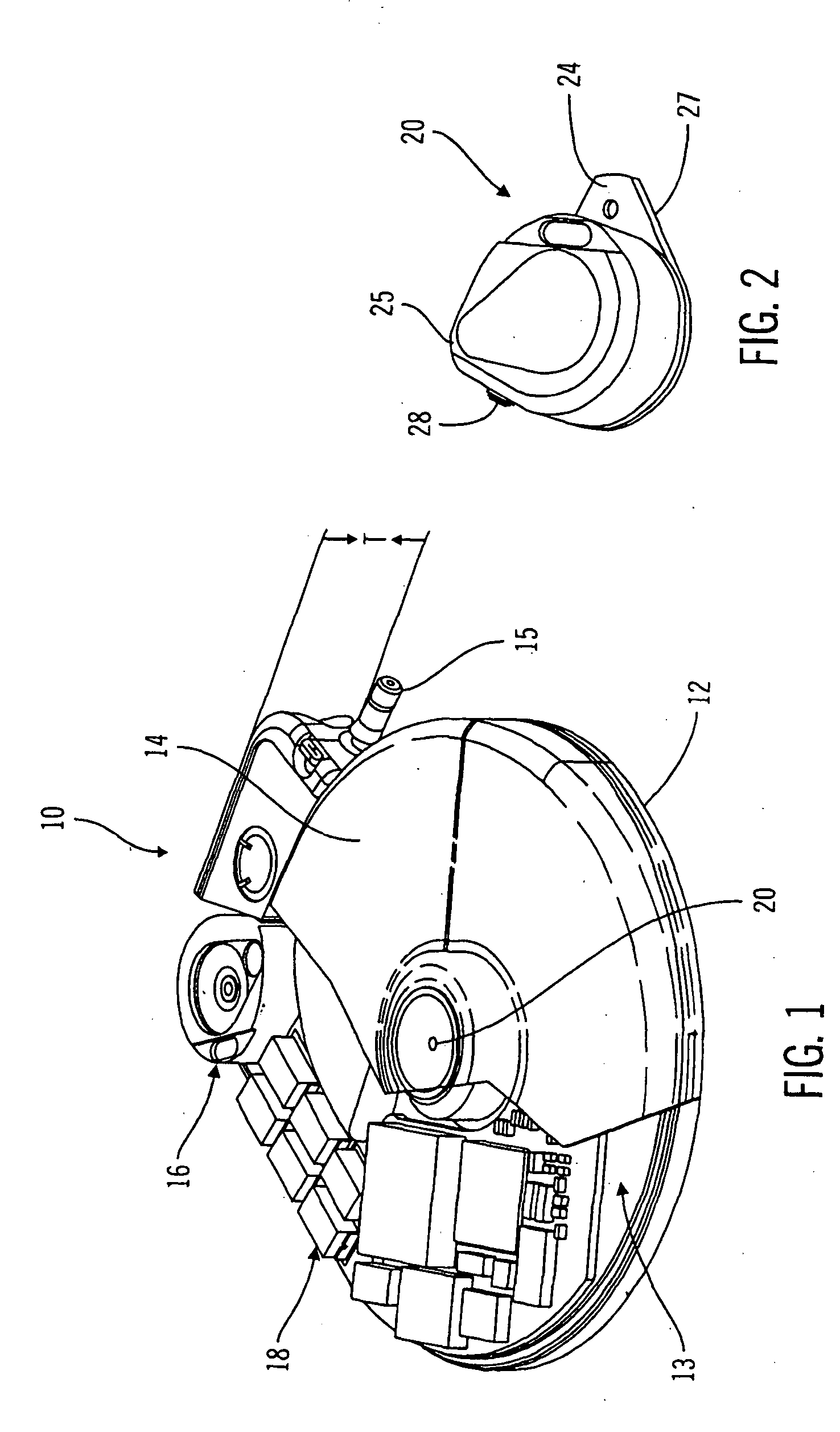

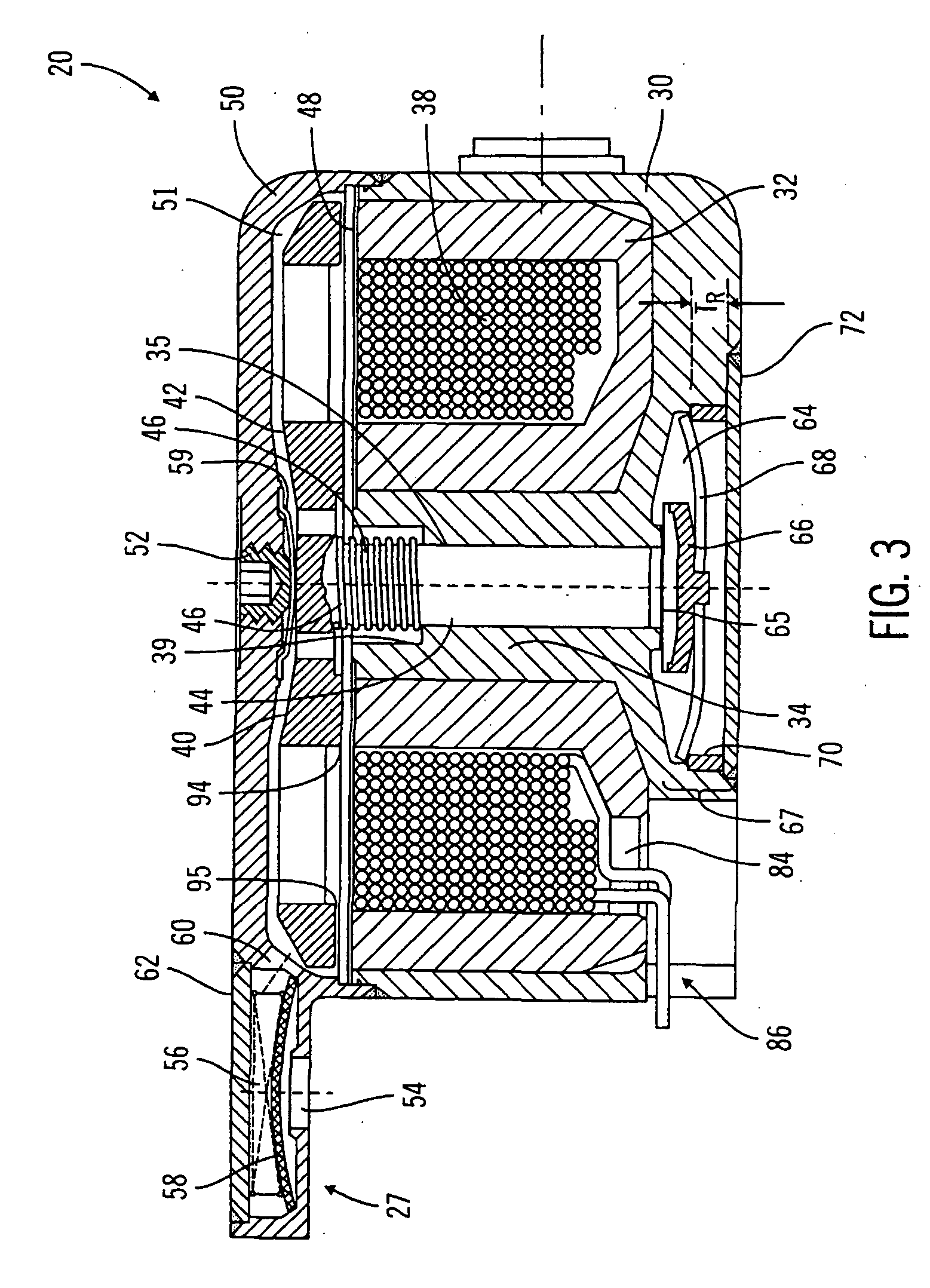

Infusion device and driving mechanism for same

InactiveUS7396353B2Small thickness dimensionMinimize traumaPharmaceutical delivery mechanismMedical devicesEngineeringElectromagnetic field

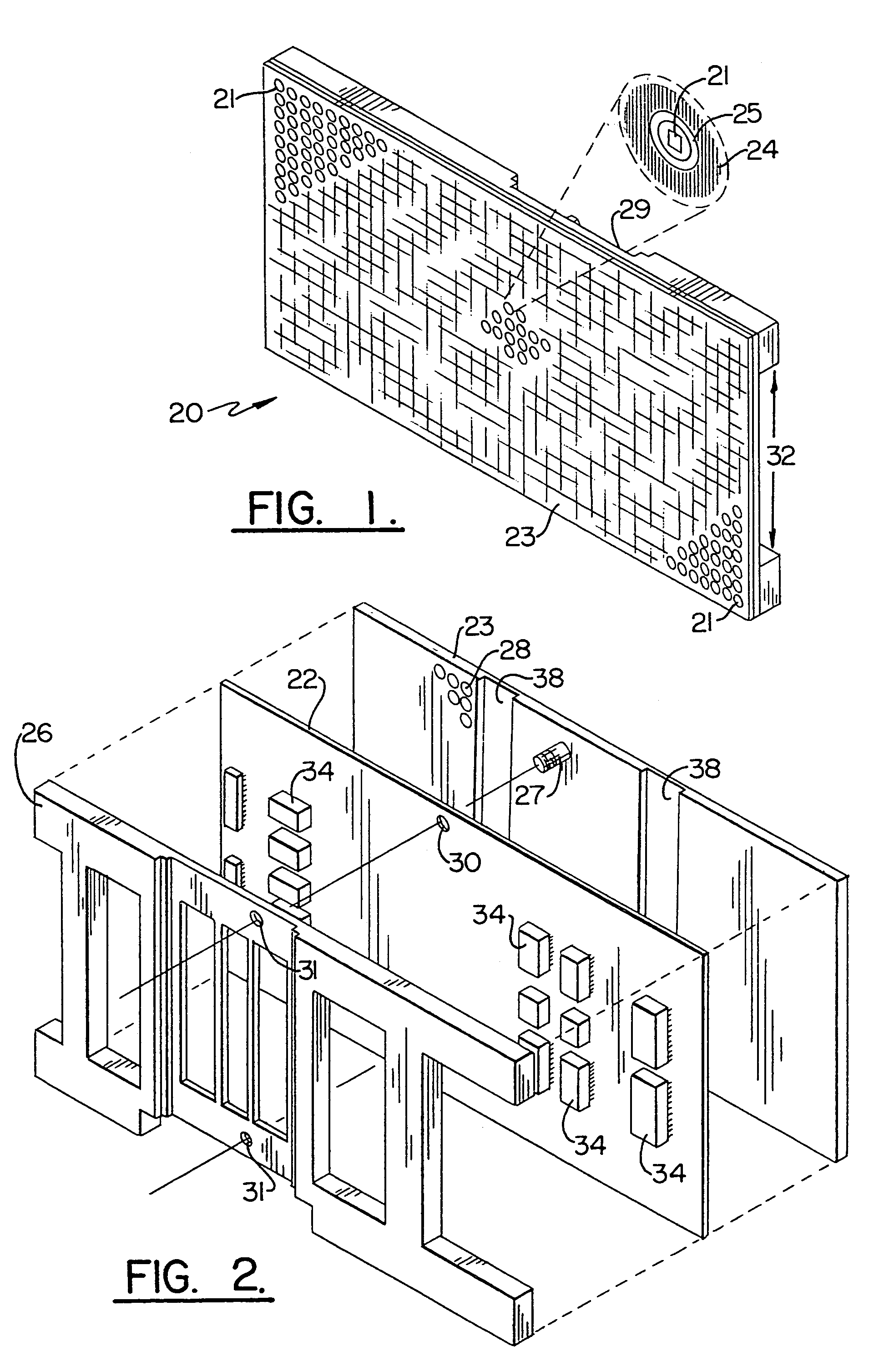

A drive mechanism for delivery of infusion medium a coil capable of being electrically activated to provide an electromagnetic field. The coil surrounds a piston channel extending in an axial direction. The piston channel provides a passage for communication of infusion medium to an outlet chamber located at one end of the piston channel. An armature is located adjacent the coil, on one side of the axial channel. The armature is moveable toward a forward position, in response to the electromagnetic field produced by activation of the coil. A piston is located within the piston channel and is moveable axially within the channel to a forward position, in response to movement of the armature to its forward position. The armature and piston are moved toward a retracted position, when the coil is not energized. In the retracted position of the piston, a piston chamber is formed between the piston and a valve member and is filled with infusion medium. As the piston is moved to its forward position, the piston chamber volume is reduced and pressure within the piston chamber increases to a point where the pressure moves the valve member into an open position. When the valve member is in the open position, medium from the piston chamber is discharged into an outlet chamber located on the opposite side of the coil relative to the armature. An outlet is provided in flow communication with the outlet chamber, for discharging infusion medium from the outlet chamber.

Owner:MEDTRONIC MIMIMED INC

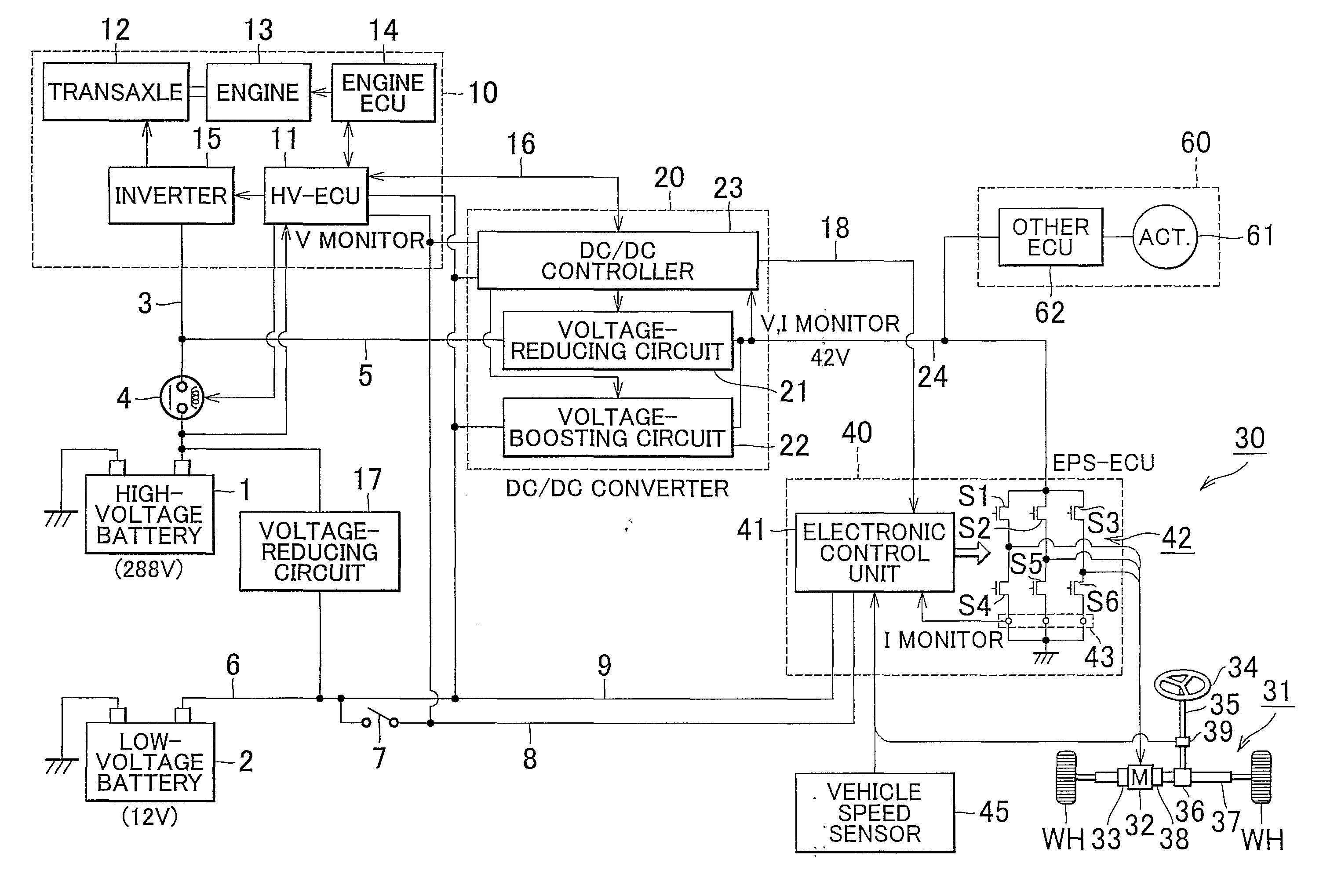

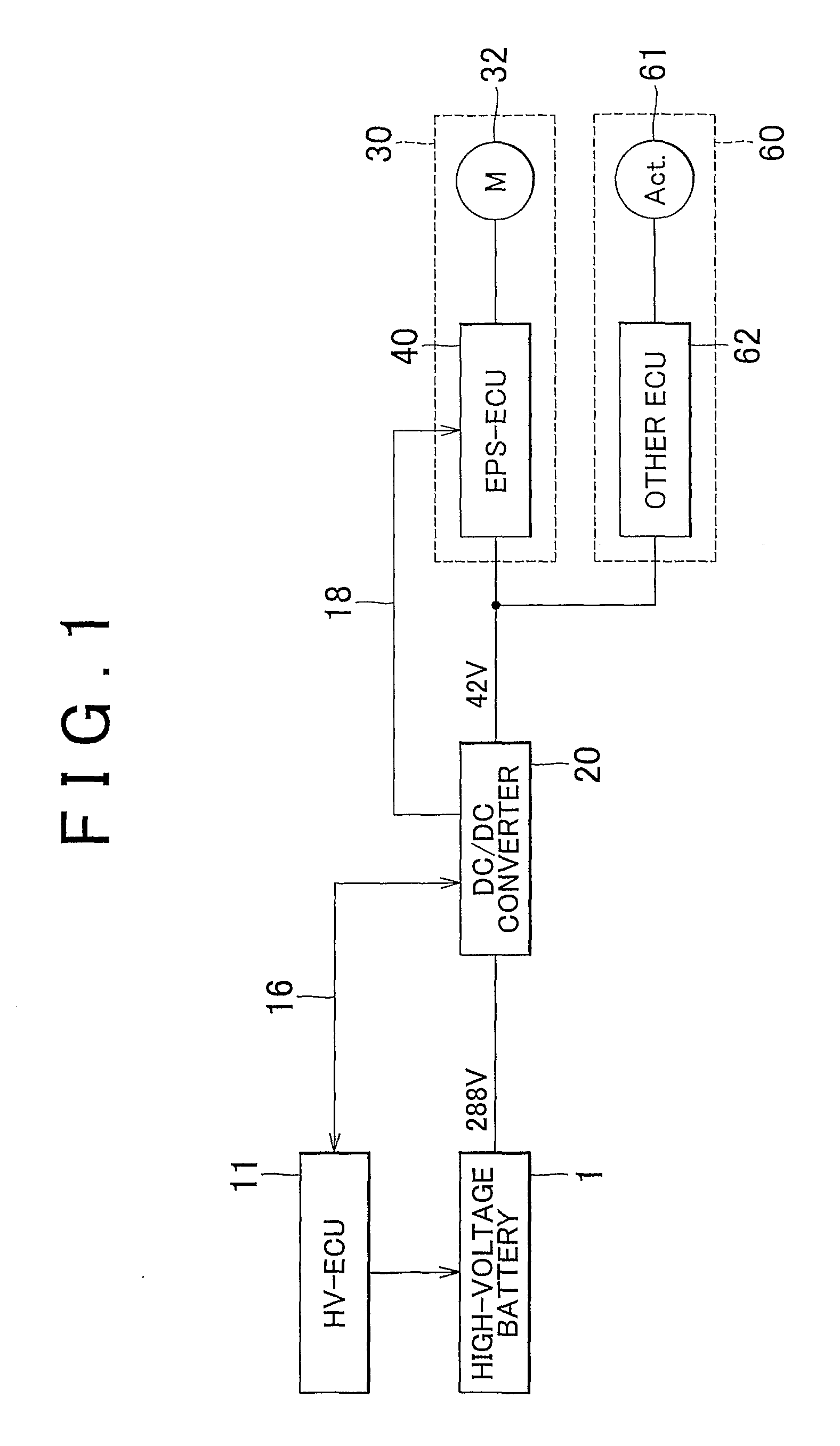

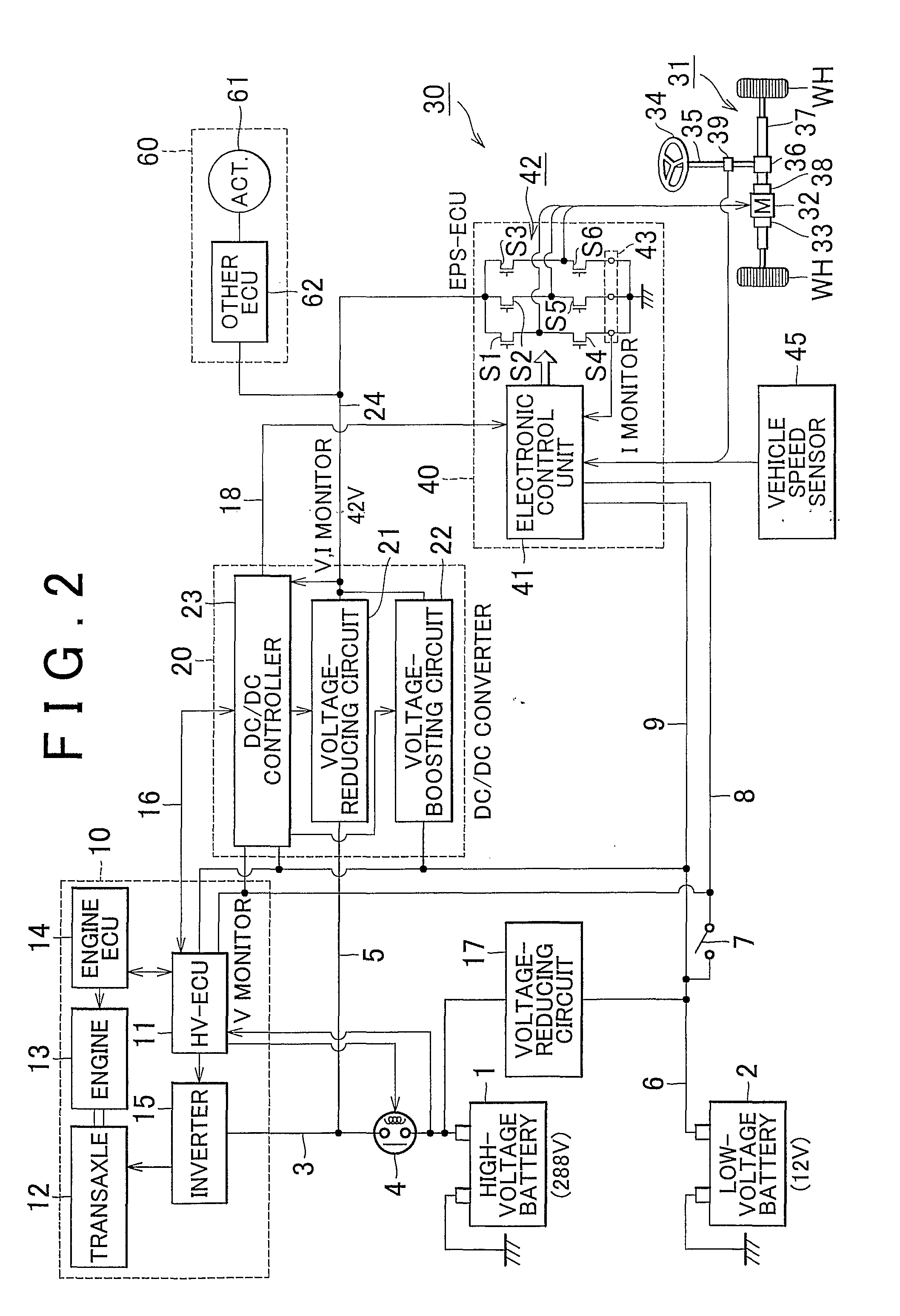

Power Supply Controller

InactiveUS20080234897A1Improve securityImprove reliabilityDigital data processing detailsPlural diverse prime-mover propulsion mountingElectric power steeringPower controller

A power supply controller controls the output of a DC / DC converter, so that the power output can be used not only by an electrical power steering apparatus, but by other operating / driving controllers as well. The controller may command the DC / DC converter to reduce the voltage of the high-voltage battery to a prescribed voltage or to boost the voltage of the low-voltage battery to a prescribed voltage when appropriate. In addition, the controller may also command the gradual reduction of the power supplied by the DC / DC converter to the power steering apparatus. The gradual reduction in power prevents a sudden change in the steering feel, which improves drivability of the vehicle.

Owner:TOYOTA JIDOSHA KK

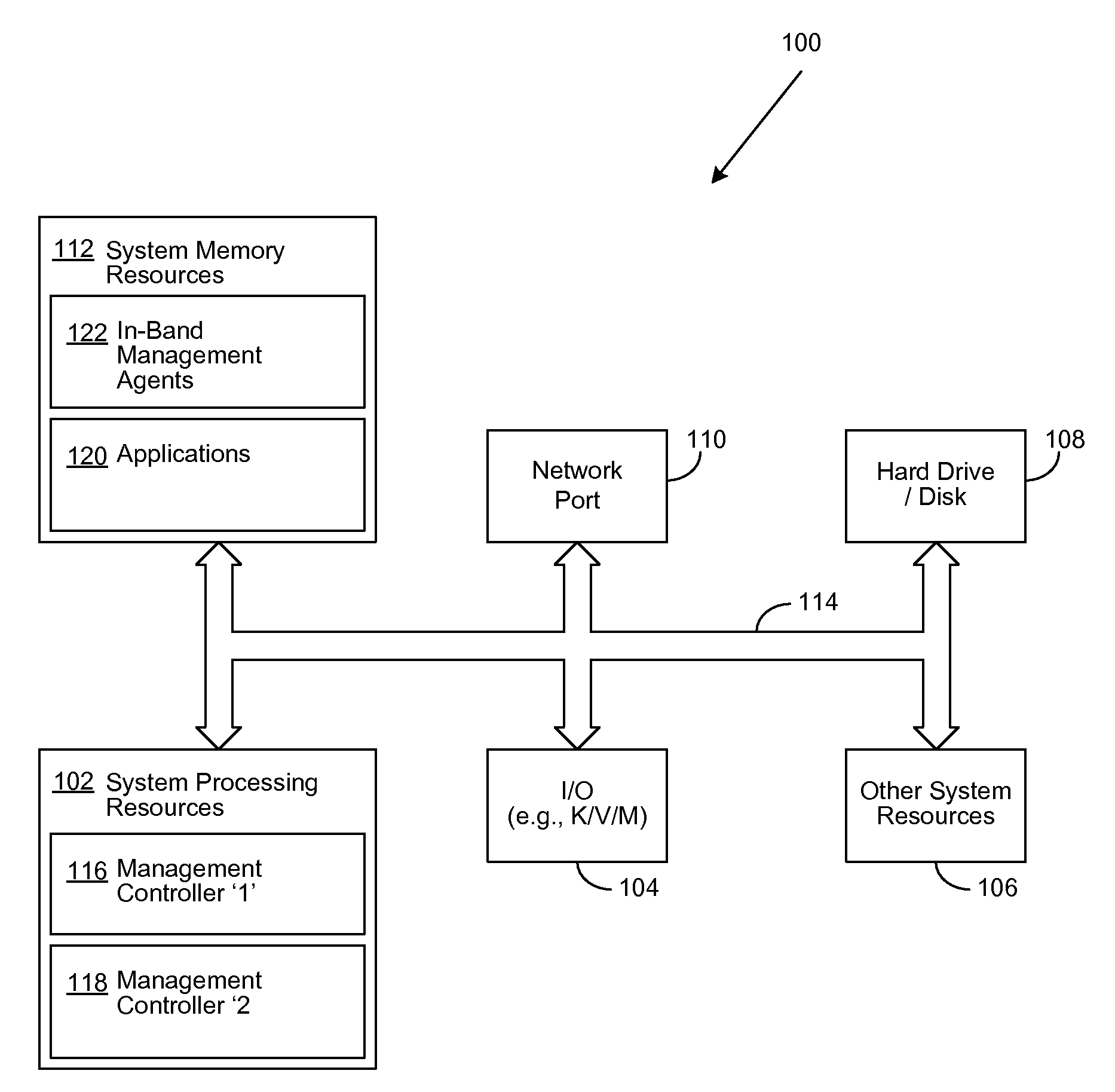

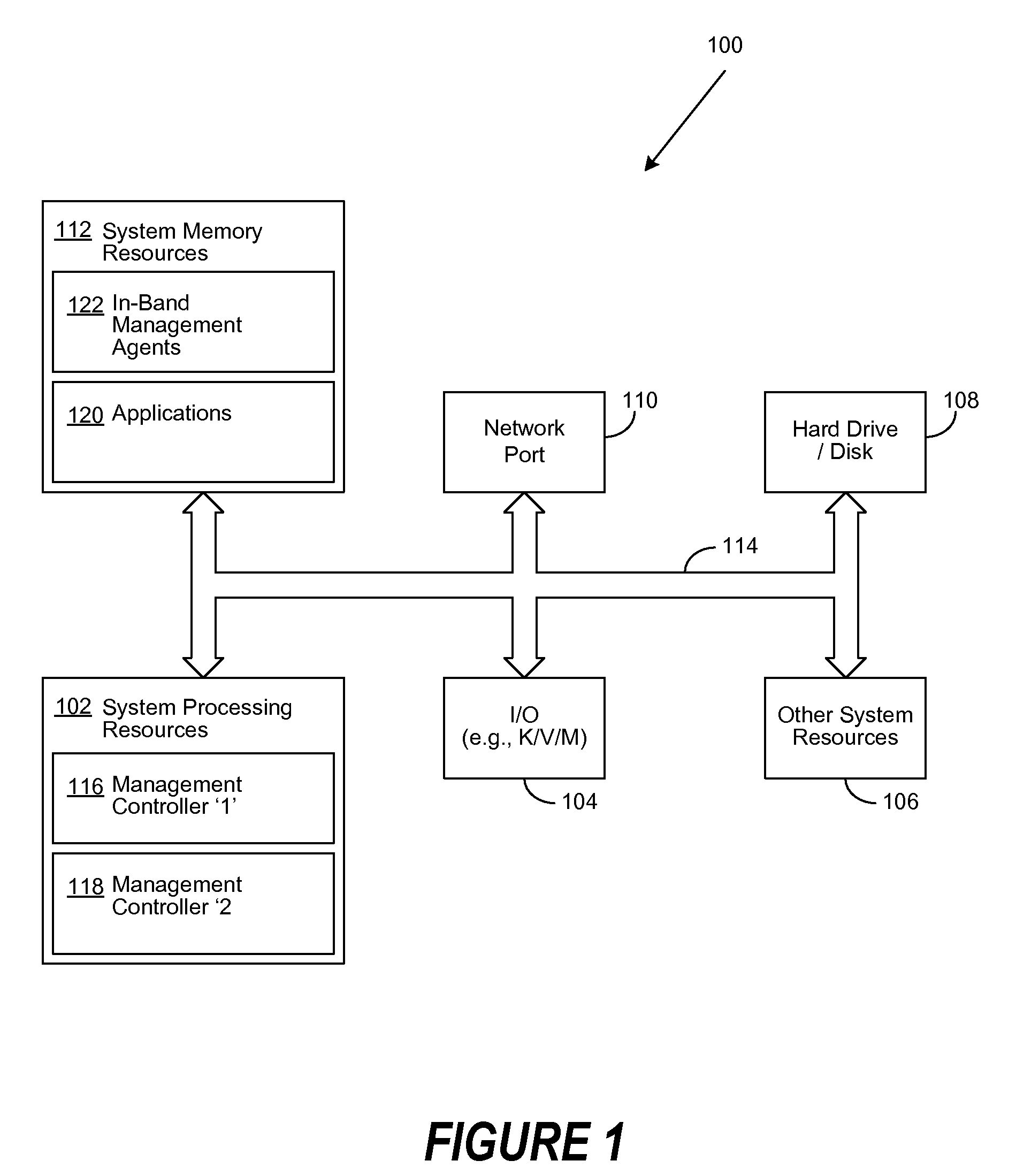

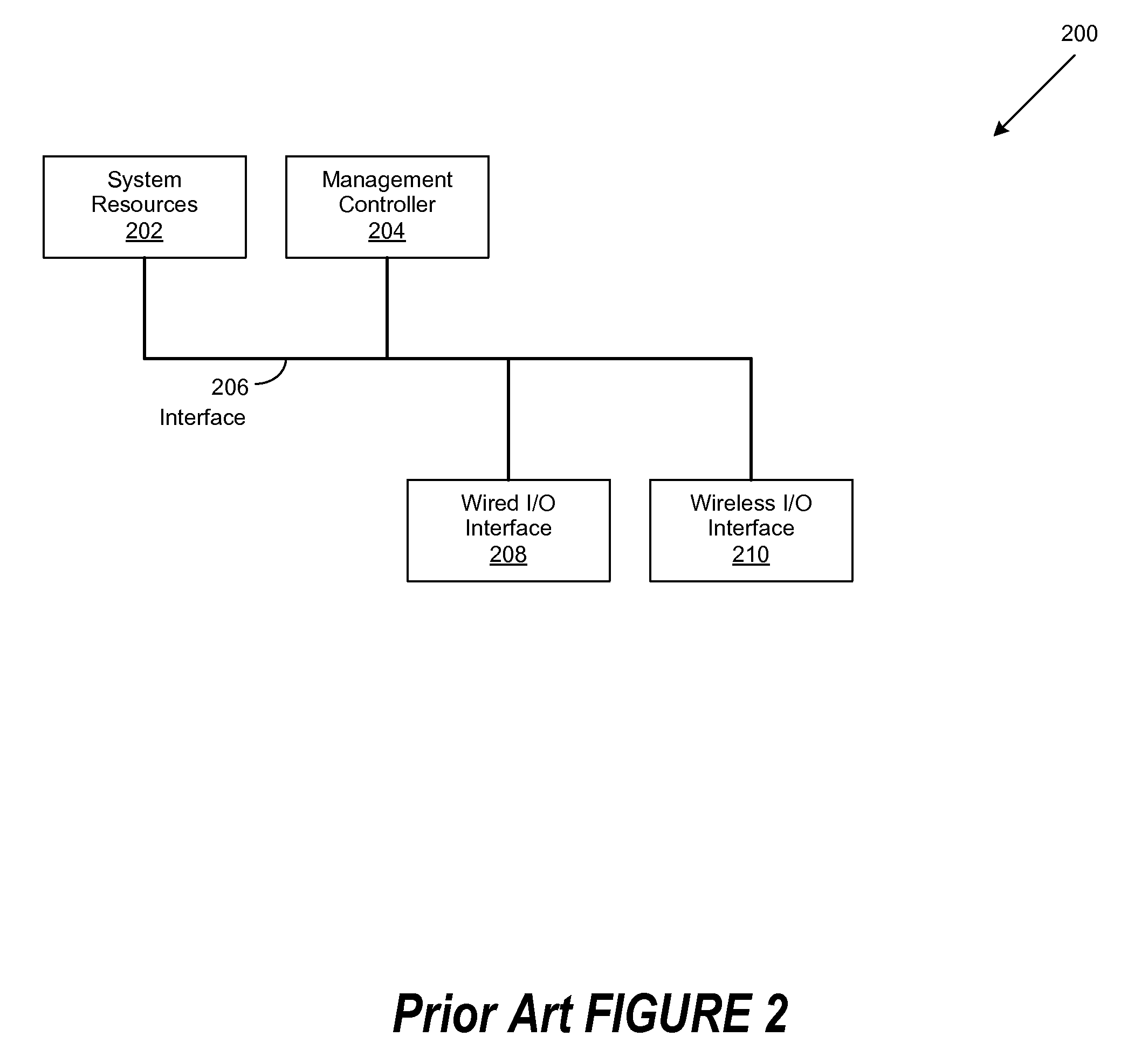

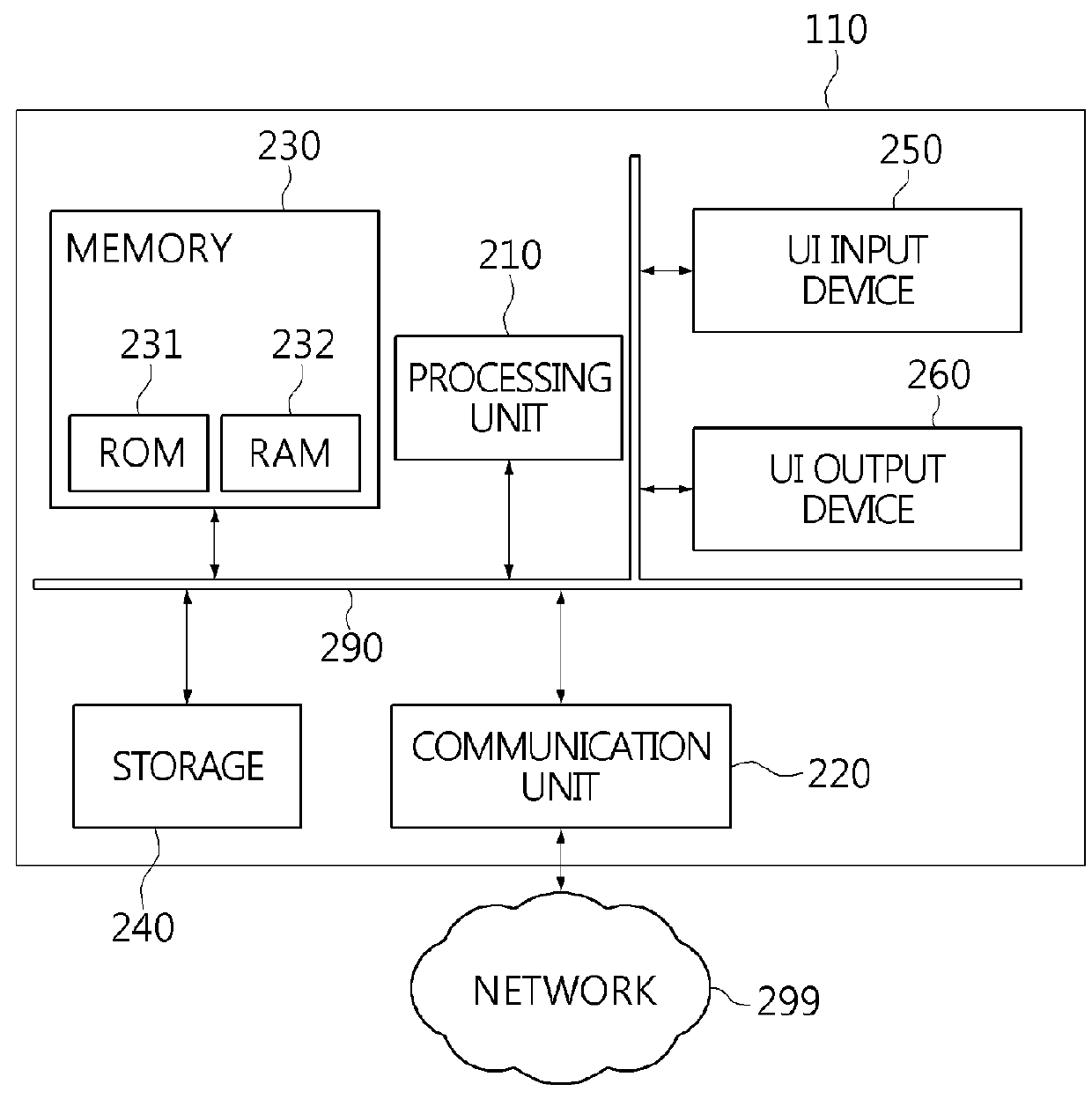

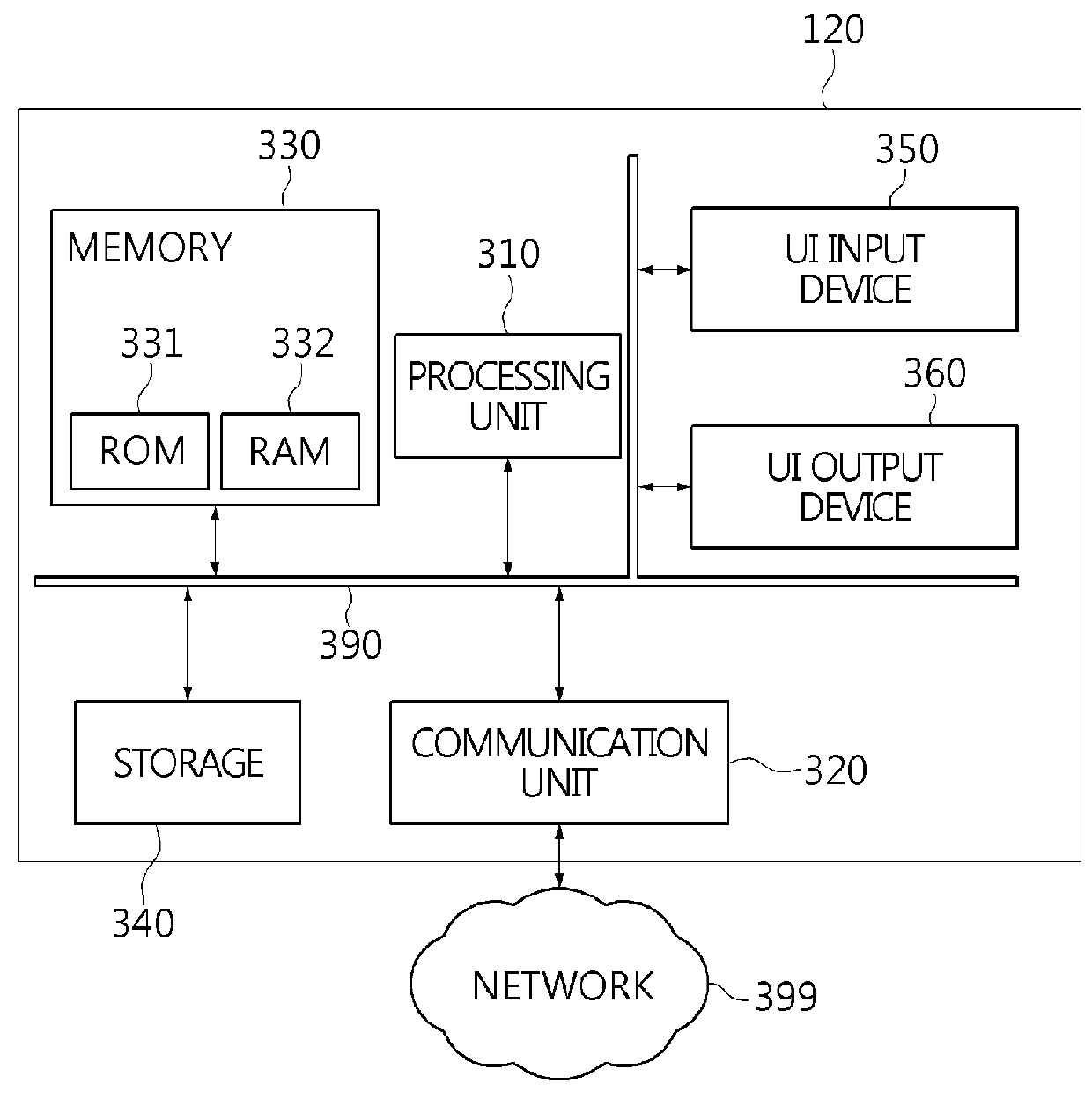

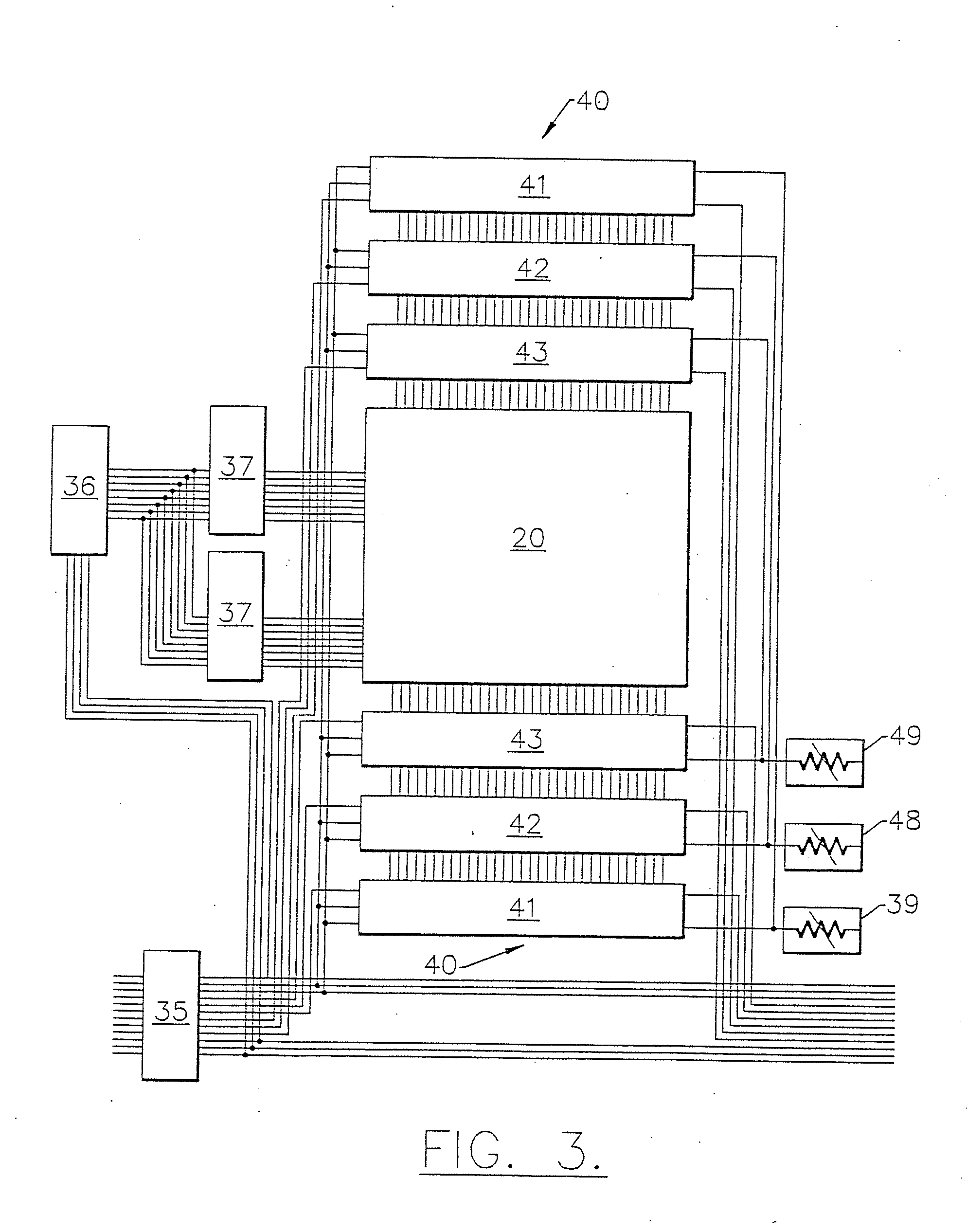

Distributed Out-of-Band (OOB) OS-Independent Platform Management

InactiveUS20080147858A1Efficient use of powerMaintain consistencyMultiple digital computer combinationsData switching networksPhysical interfaceMulti method

A system and method is disclosed for a distributed out-of-band (OOB) management controller system enabling efficient usage of power while providing multiple methods and levels of communication between intelligent devices. Two or more management controllers collaboratively operate in a predetermined manner including, but not limited to, peer-to-peer, master / slave, or independently. Management information consistency is maintained across a system's power states by implementing distributed intelligent devices that directly interact as communication devices to local or remote management consoles. A management protocol is implemented such that management information is communicated between managed elements and management controllers over physical interfaces or via a network connection. A first management controller is implemented to communicate with managed elements via a bus that is available only when the system is under full power and a second controller is implemented to communicate with the same managed elements for most power states, including low power. The second management controller remains operable to generate simple management information packets or use packets stored in communications devices to generate primitive or higher-level alert functions.

Owner:DELL PROD LP

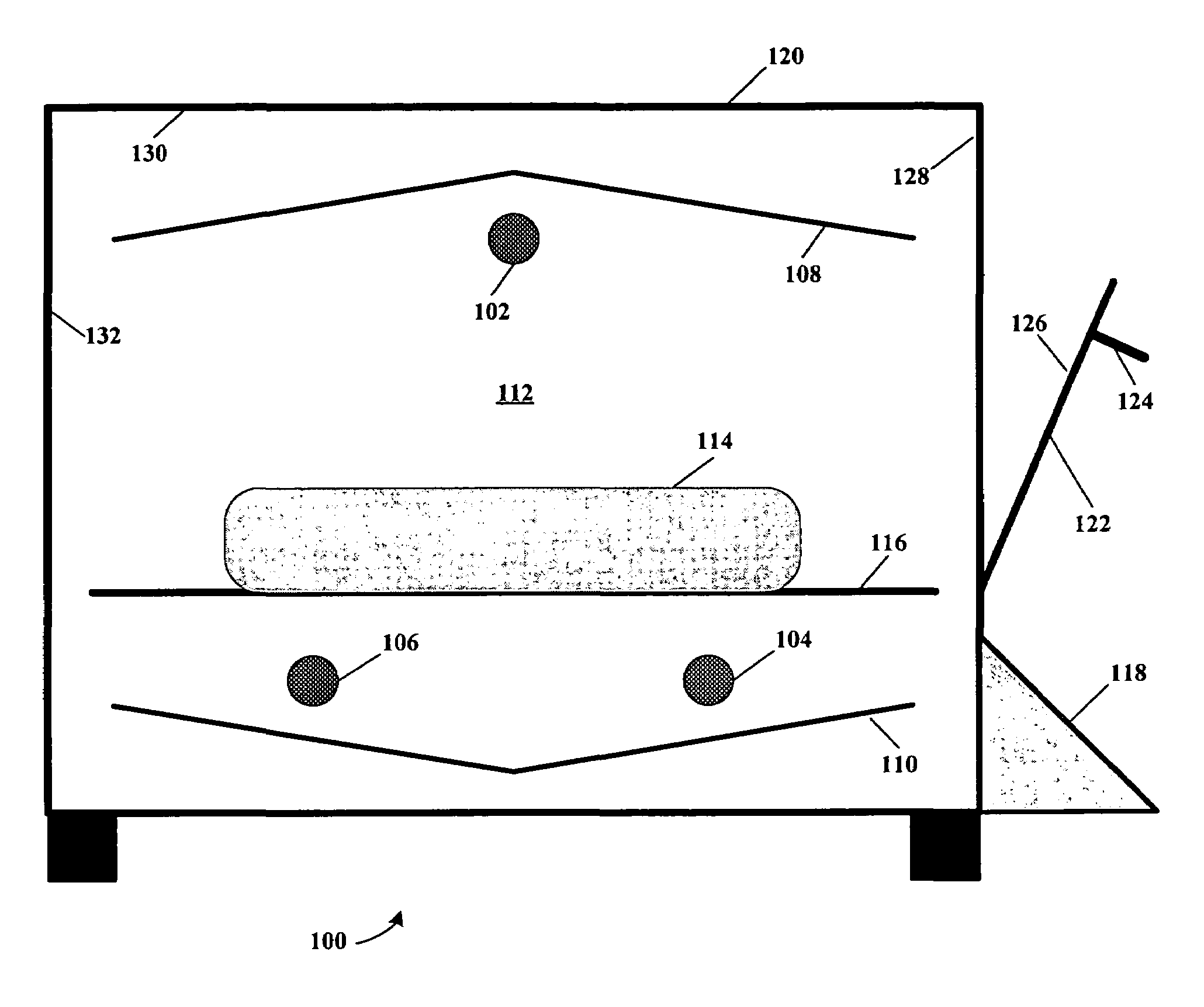

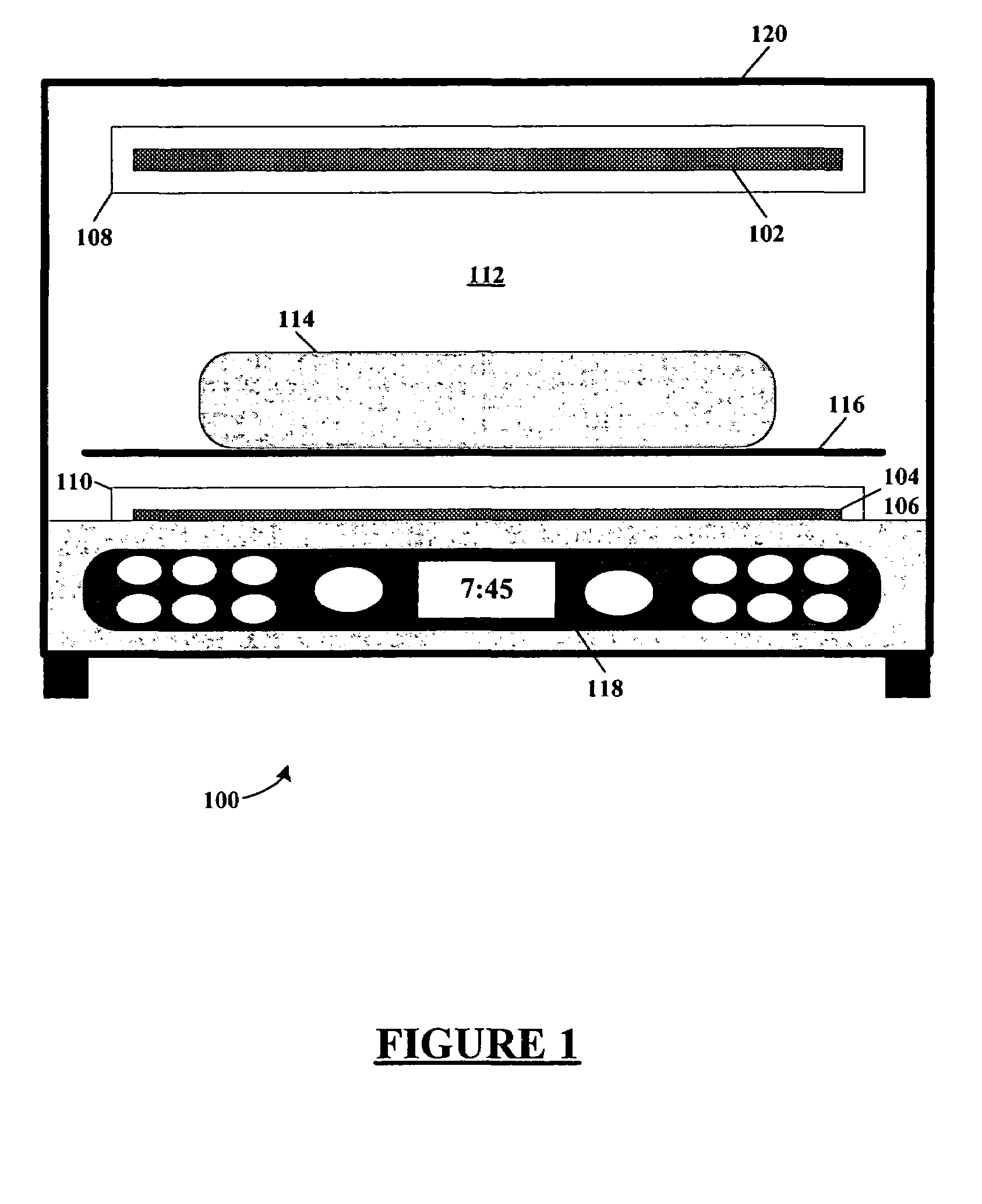

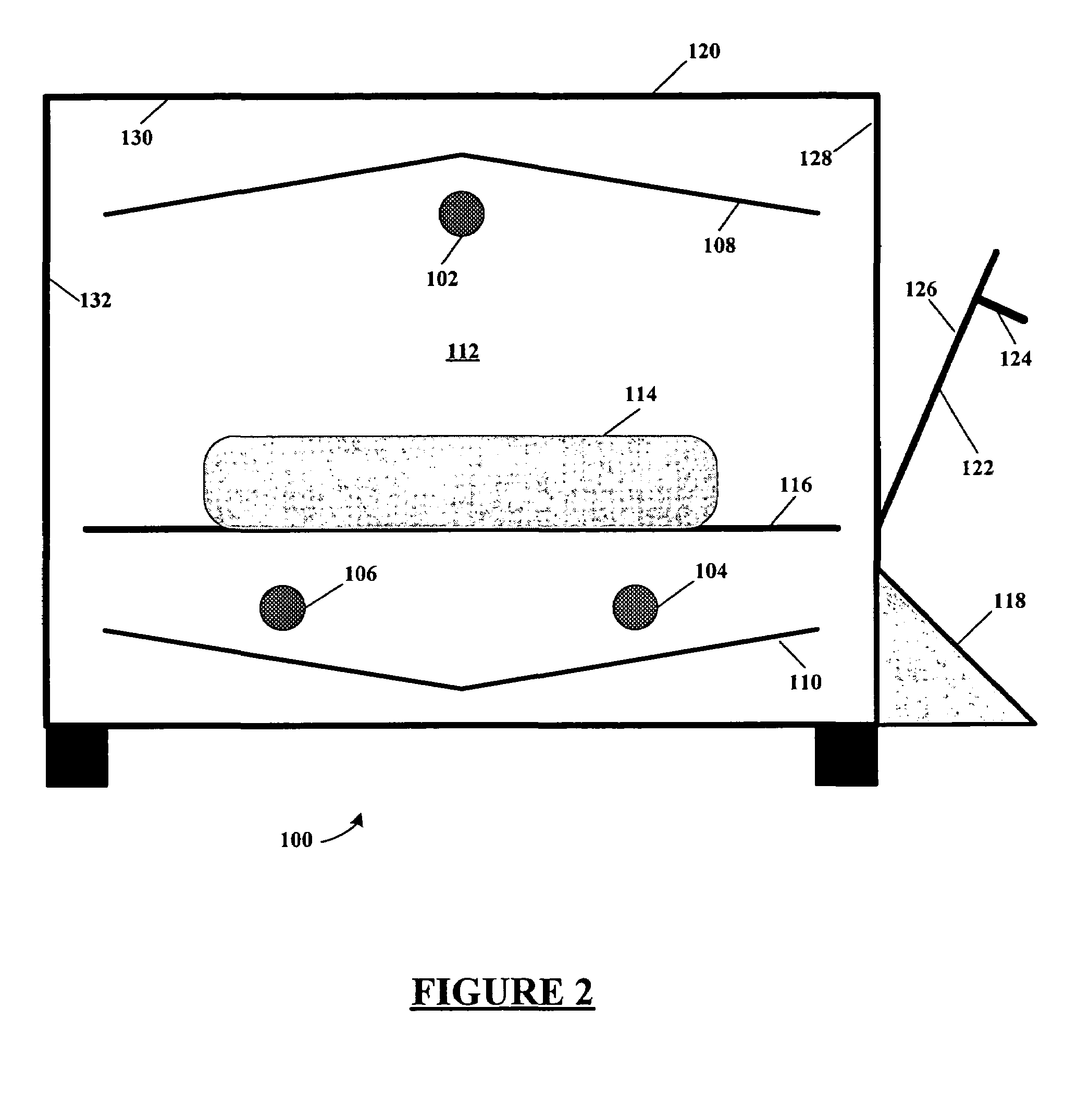

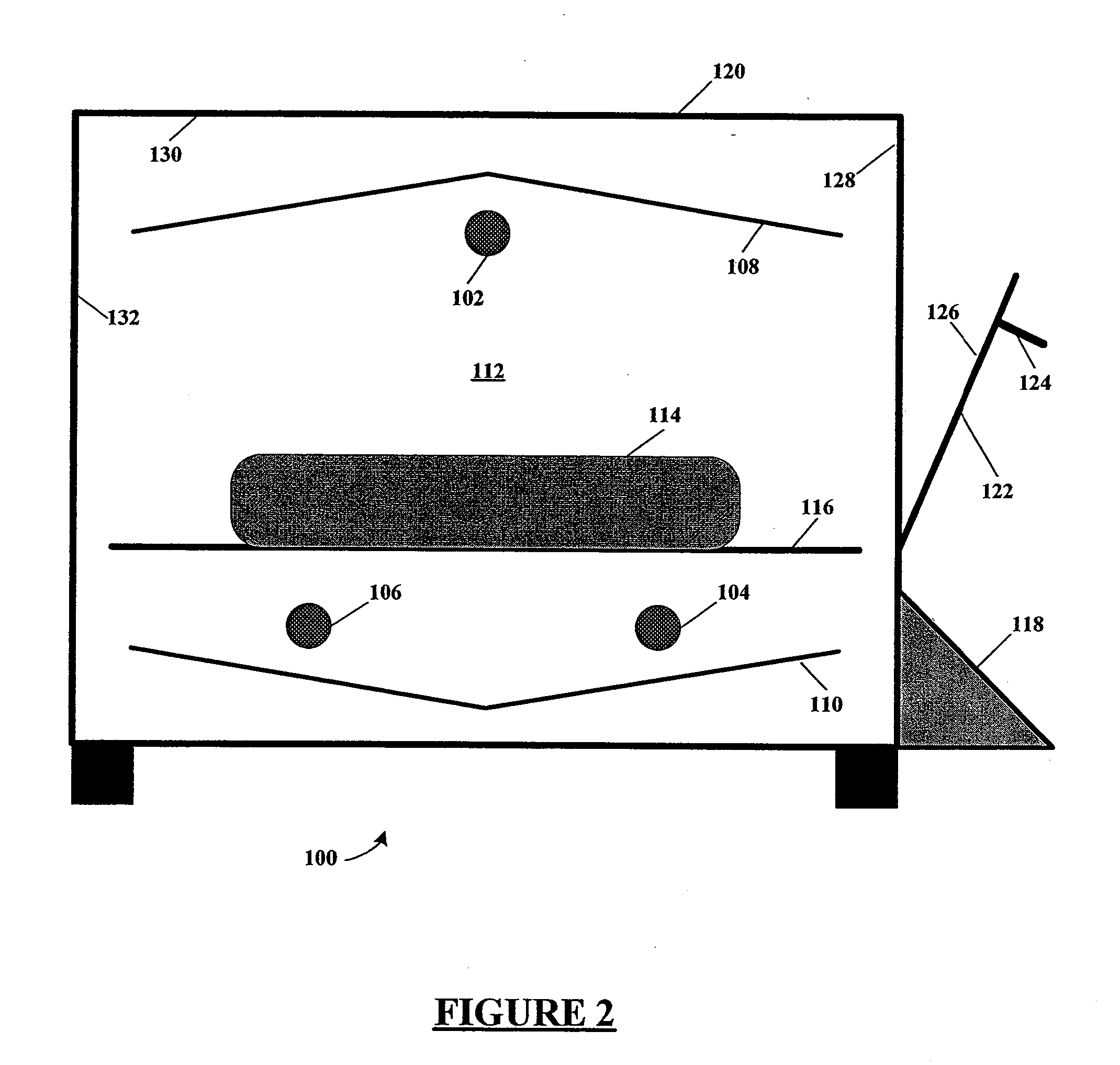

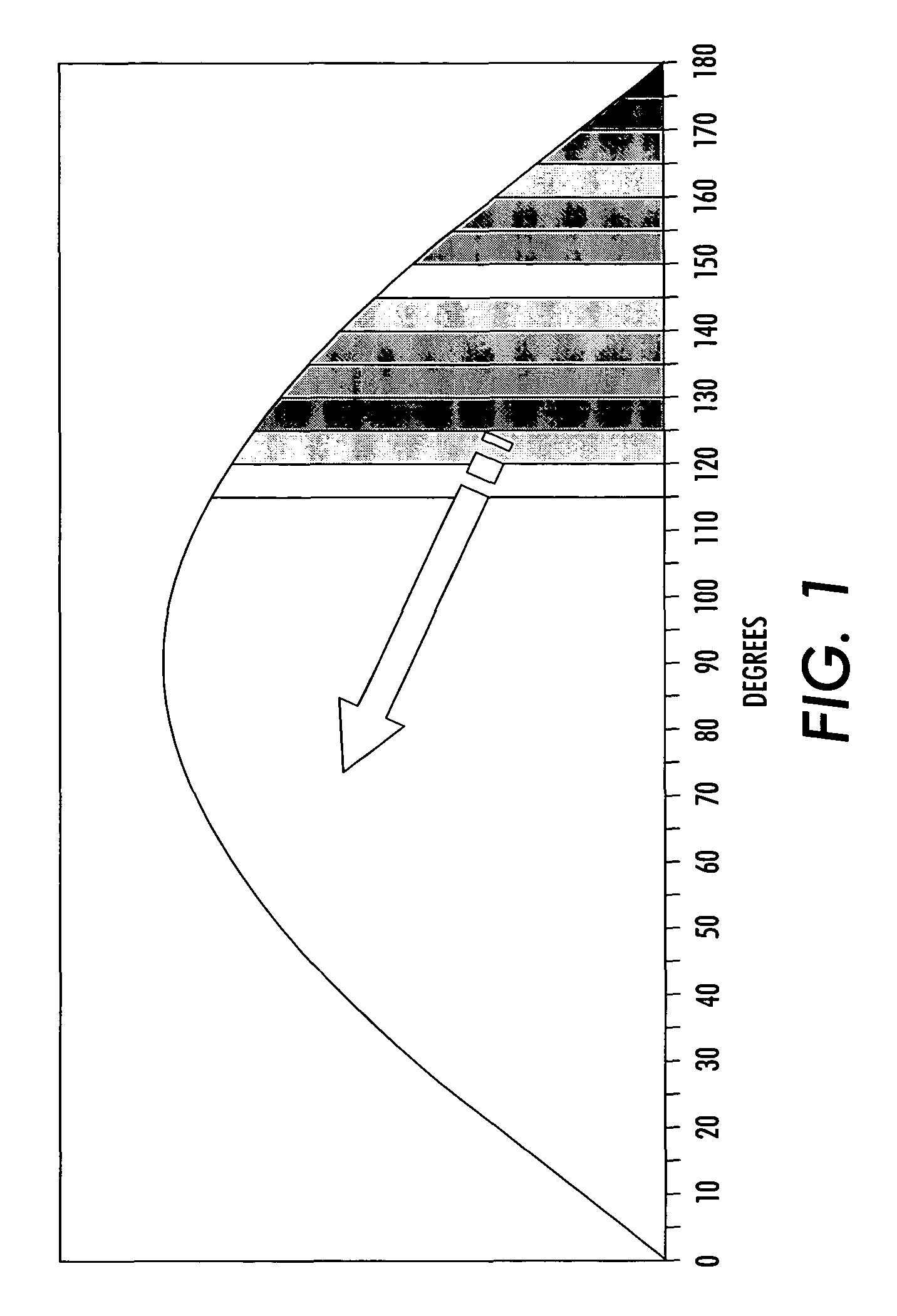

Multi-purpose oven using infrared heating for reduced cooking time

ActiveUS7323663B2High speedEfficient use of powerRadiation pyrometryDomestic stoves or rangesThermal energyRadiant heat

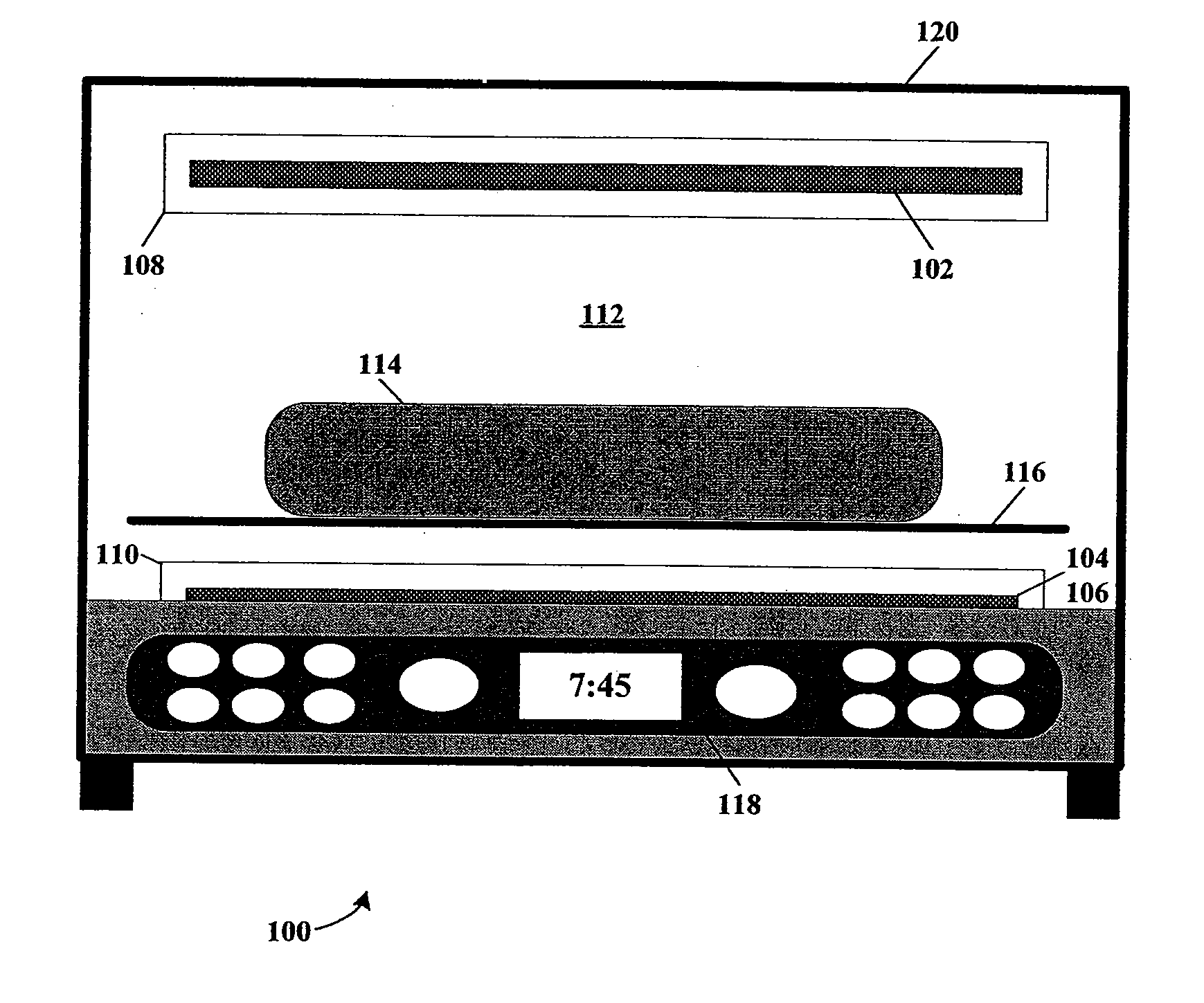

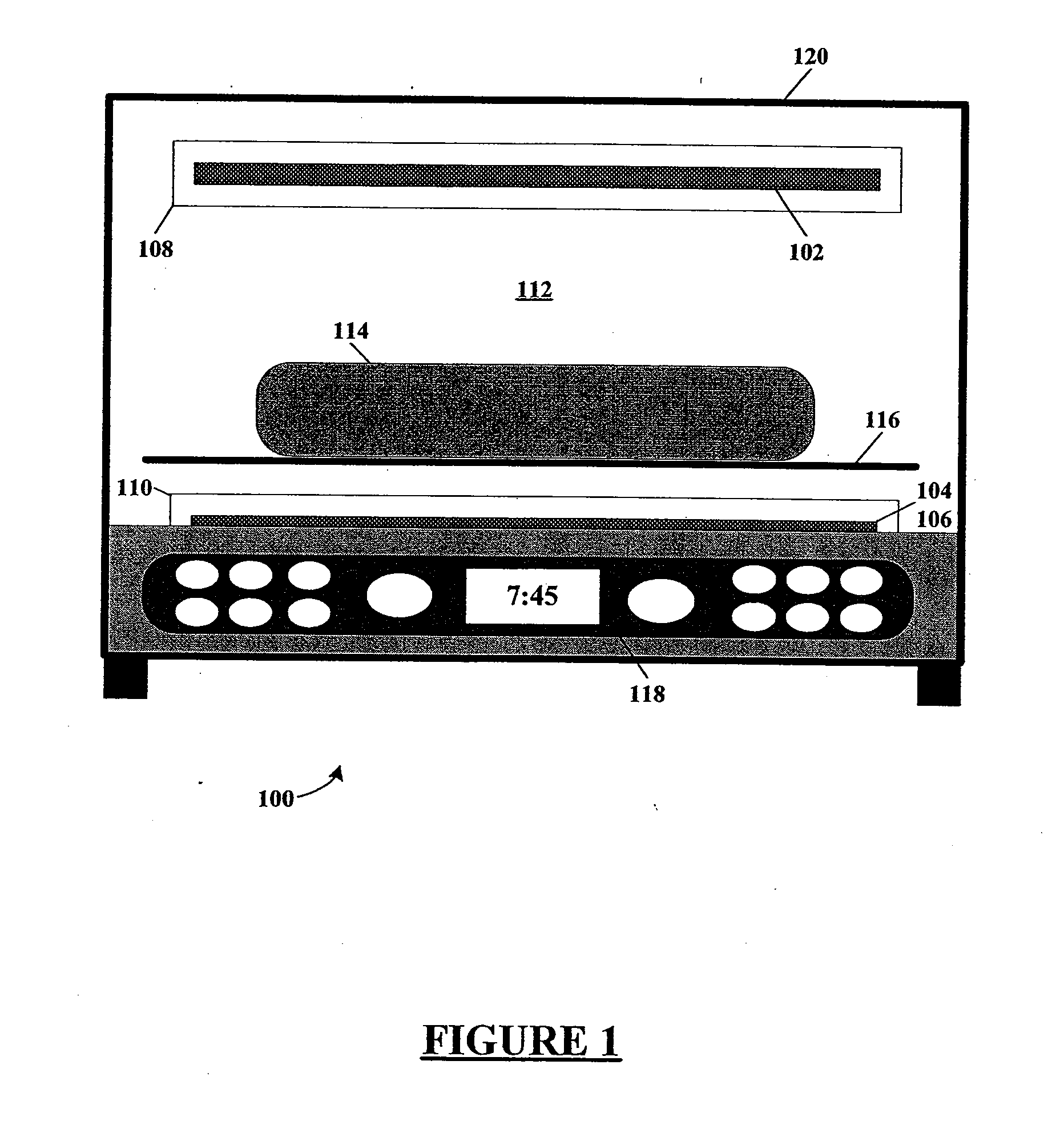

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and re-heats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

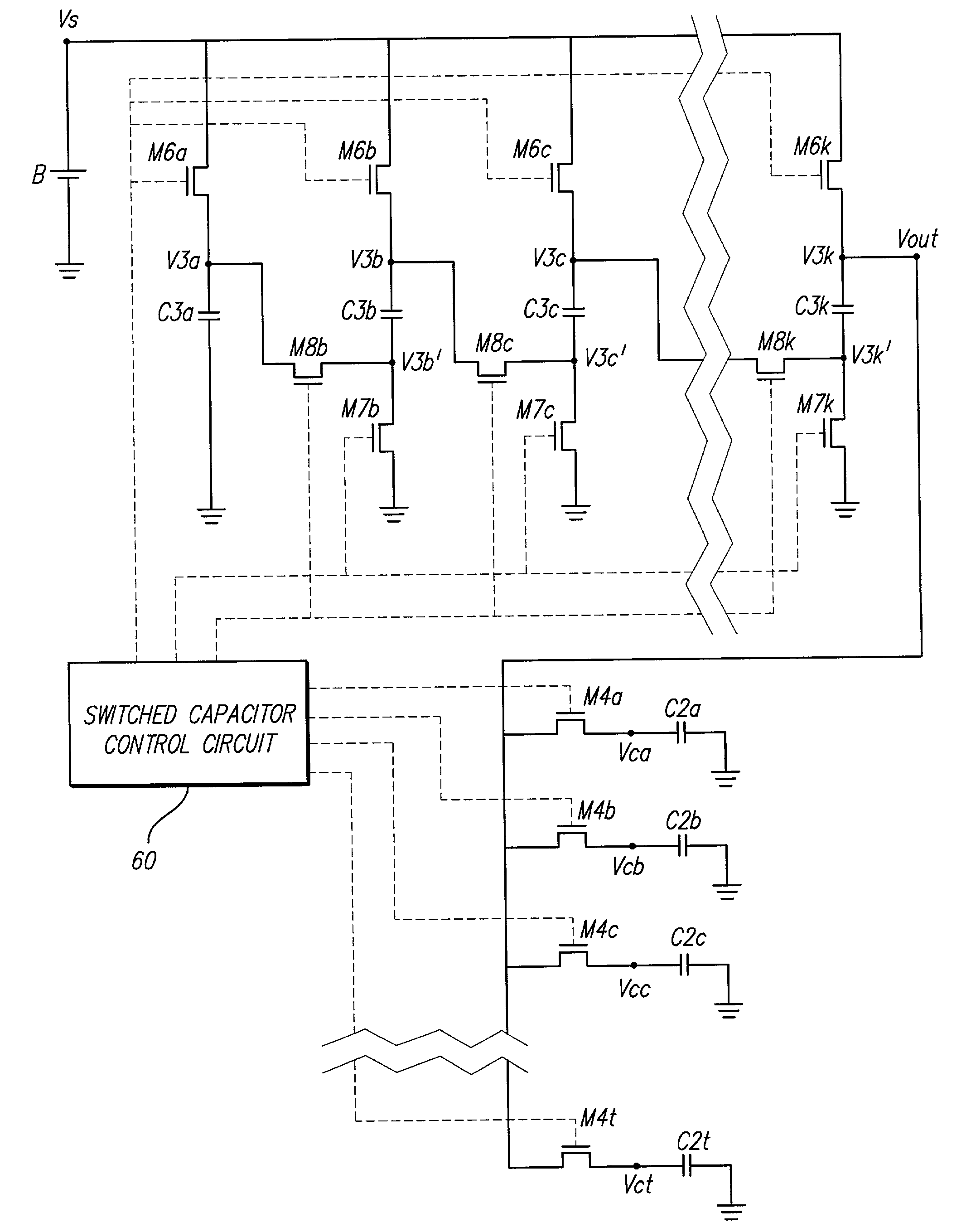

Multi-compliance voltage generator in a multichannel current stimulator

InactiveUS7009313B1Efficient use of powerMinimize power consumptionDc network circuit arrangementsApparatus without intermediate ac conversionVoltage generatorEngineering

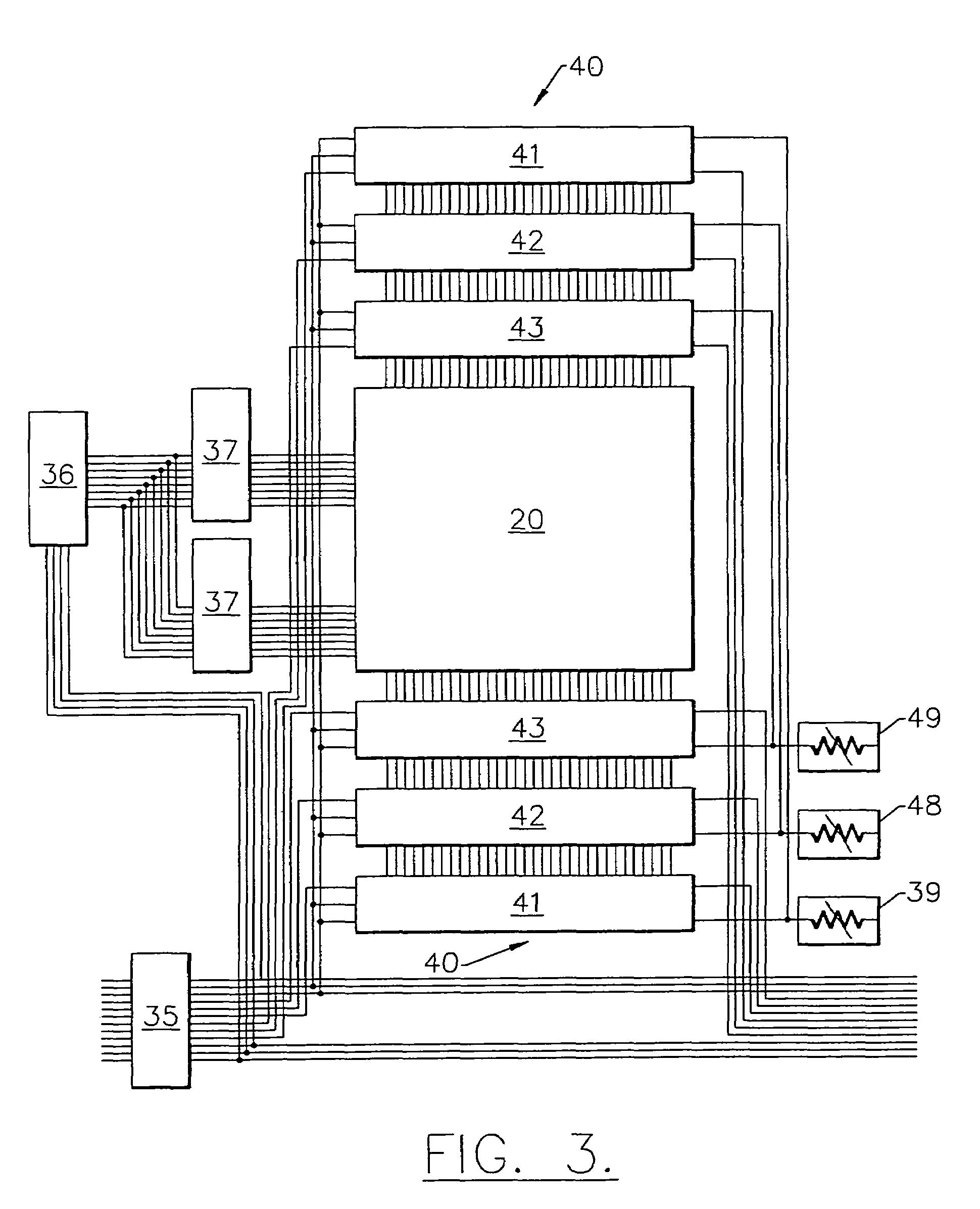

An improved multi-voltage power supply charges individual small capacitors to different voltages. Each small capacitor is assigned to a circuit, and is charged to a voltage level sufficient for the circuit. In one embodiment, an improved switching regulator includes a multiplicity of small capacitors. The small capacitors are assigned to stimulation channels of a stimulation system. Each channel has a unique compliance voltage which the assigned small capacitors are charged to. By charging the small capacitors to the corresponding compliance voltages, versus charging a single large capacitor to the maximum compliance voltage, unnecessary power dissipation is avoided. In another embodiment, a switched capacitor power supply benefits from the present invention in the same manner as the switching regulator power supply. Further, any system requiring a plurality of different voltages may benefit from the present invention.

Owner:BOSTON SCI NEUROMODULATION CORP

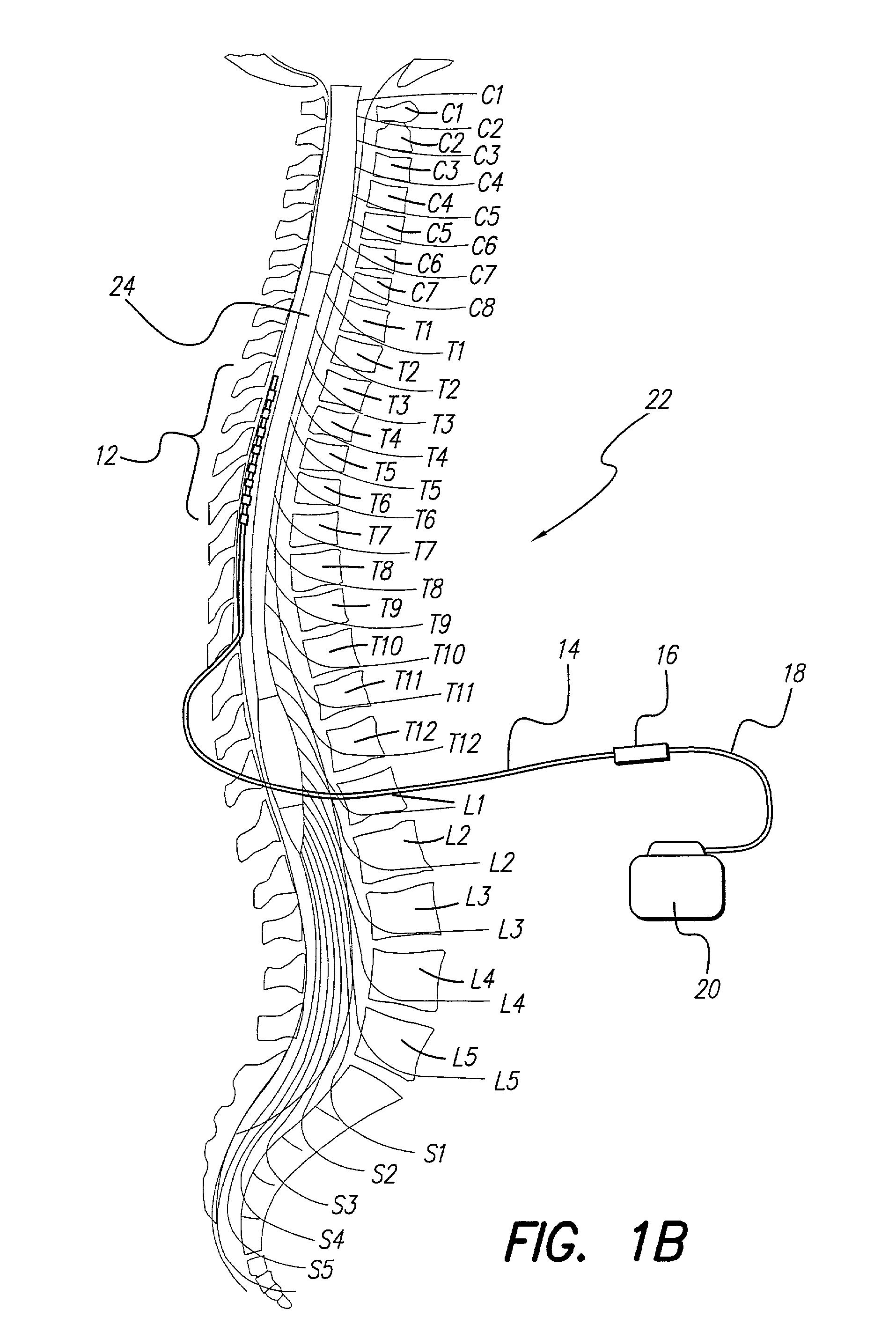

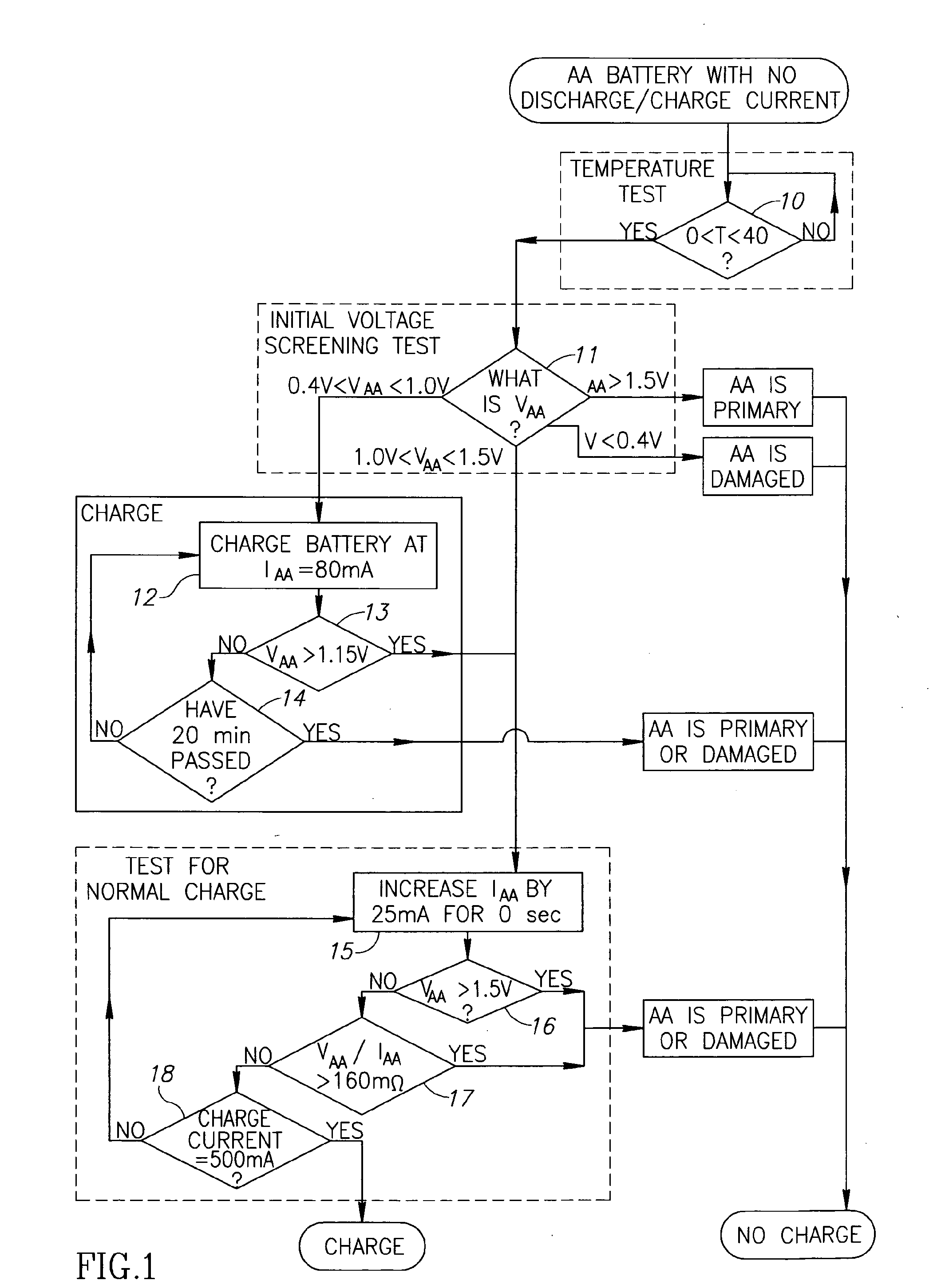

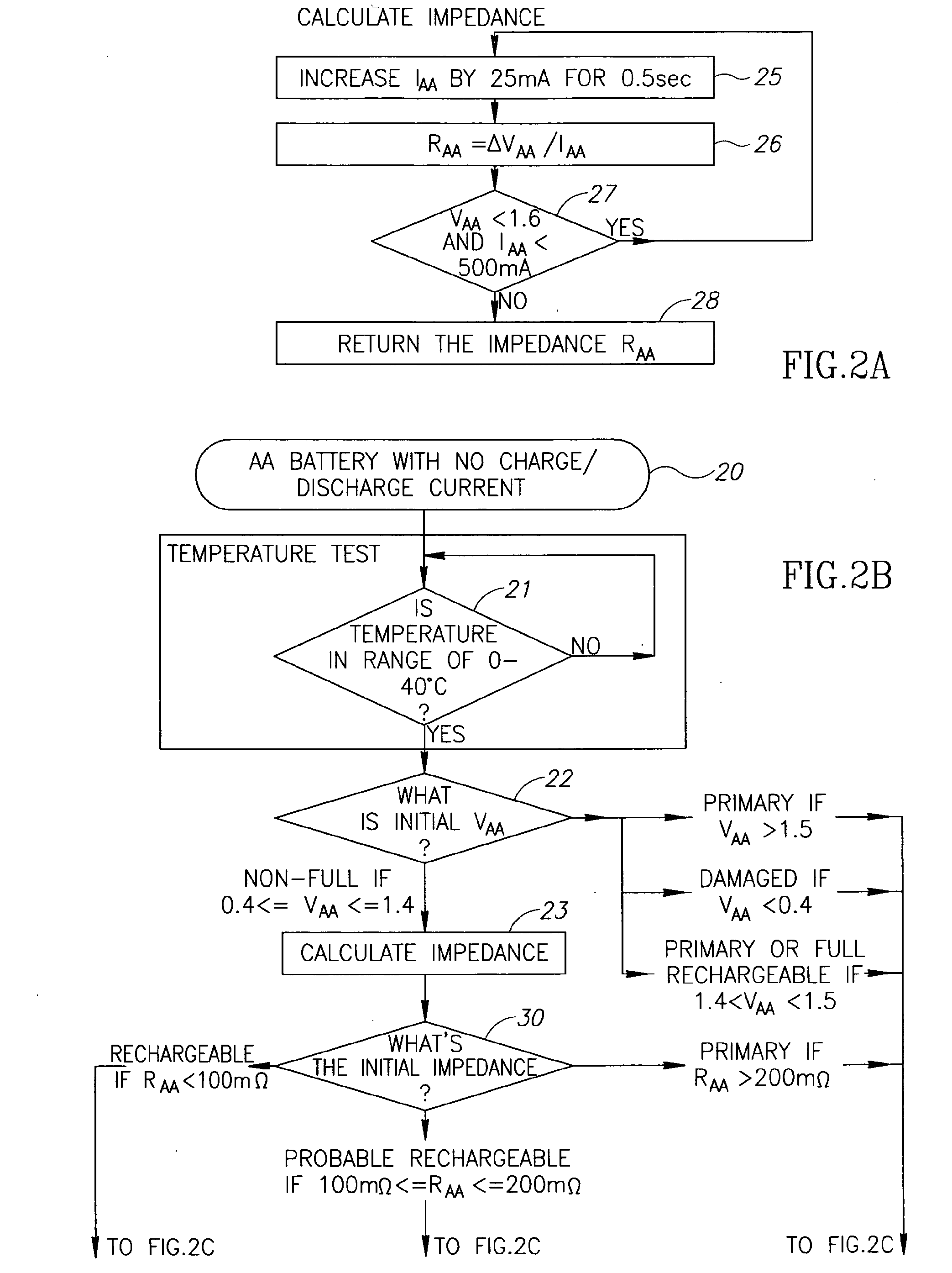

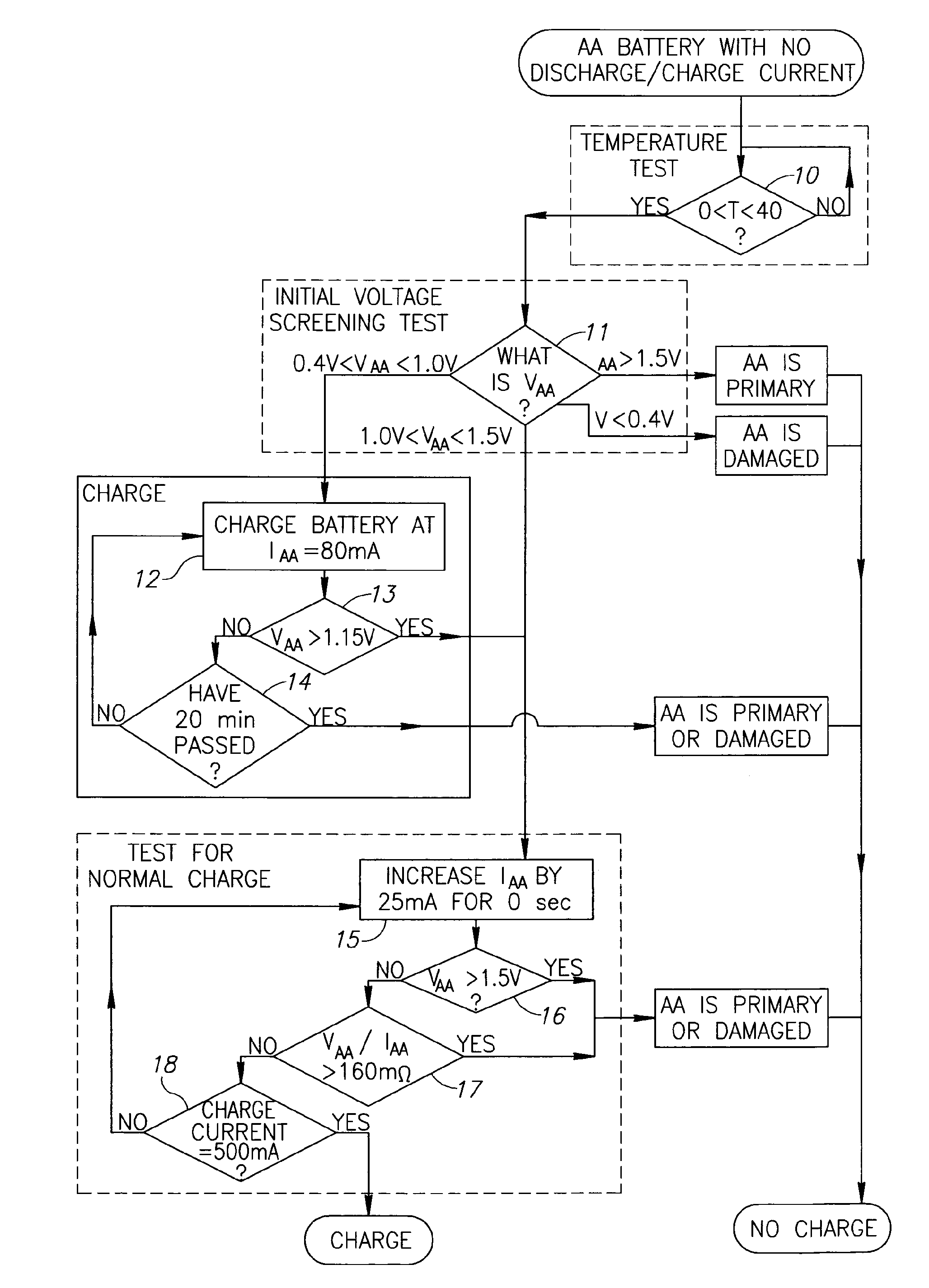

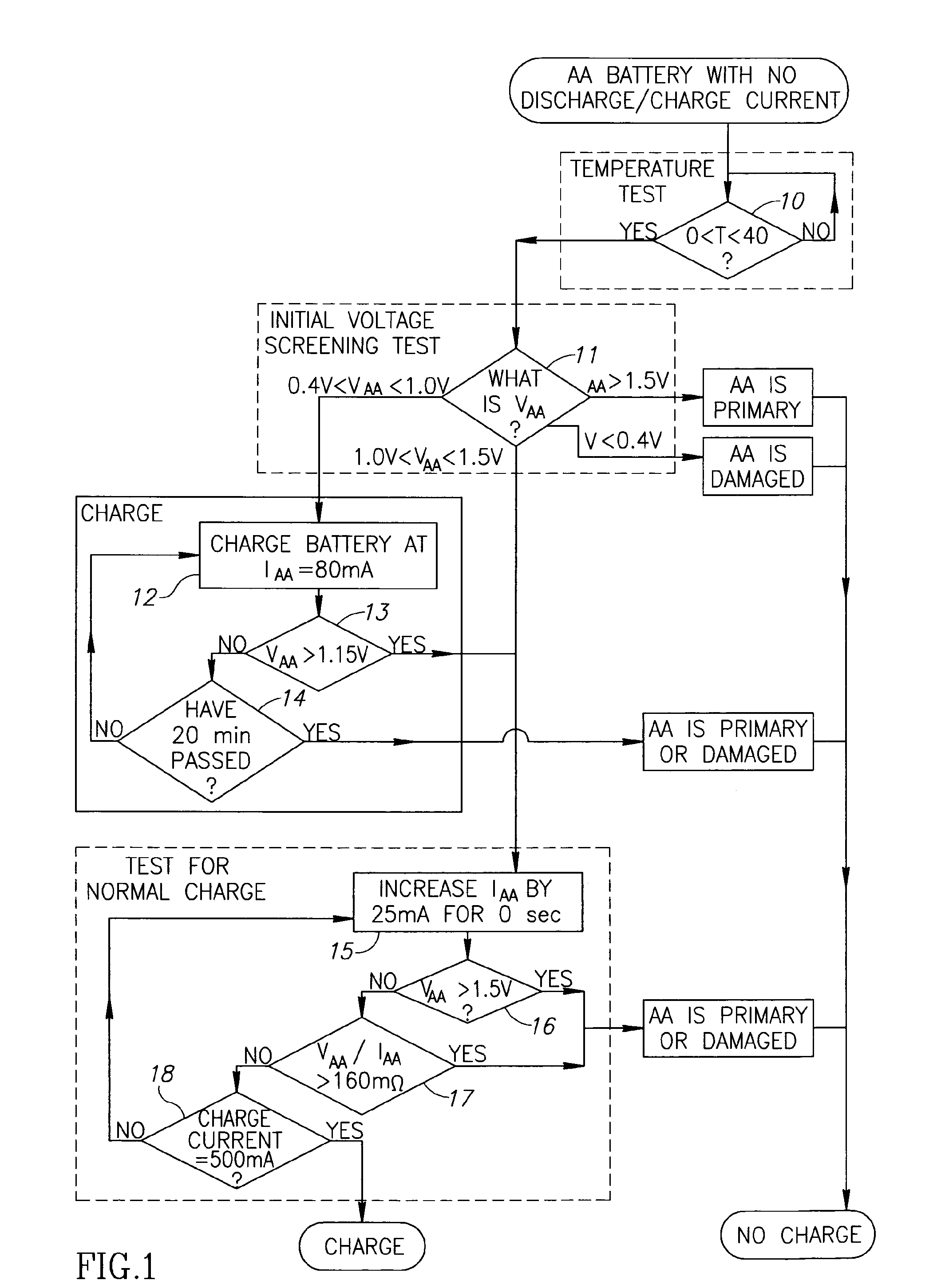

Charging methods for battery powered devices

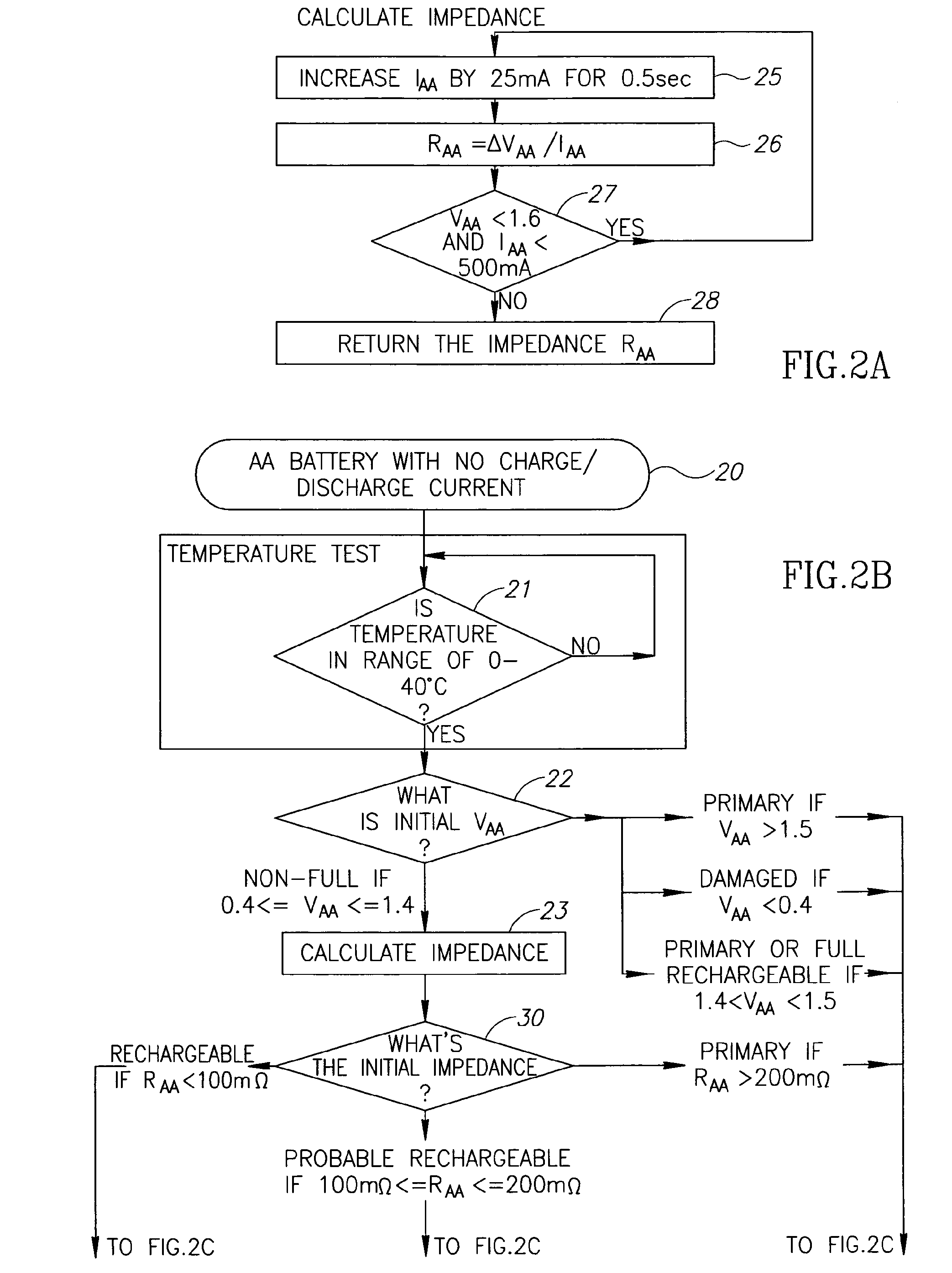

ActiveUS20100013430A1Avoid chargingAccurate balanceCharge equalisation circuitElectric powerBattery chargeTerminal voltage

A battery charge control system including an algorithm for determining whether the battery chemistry of a battery pack for use in a portable electronic device is primary, in which case charging is prevented, or secondary, in which case charging is enabled. The routine operates by measuring the terminal voltage and temperature of the battery under certain predetermined tests, which generally include a combination of voltage and internal impedance tests performed during charge or discharge. Additionally, a method is described to detect and to correct for lack of cell balance within the rechargeable battery pack of a portable electronic device. A cell or cells of the battery pack which are close to depletion, or are completely depleted, are detected, and a discharge / charge routine is executed to provide for optimum recharging of all of the cells of the battery, thus ensuring proper cell balance, and most efficient power usage.

Owner:TOWER SEMICONDUCTOR

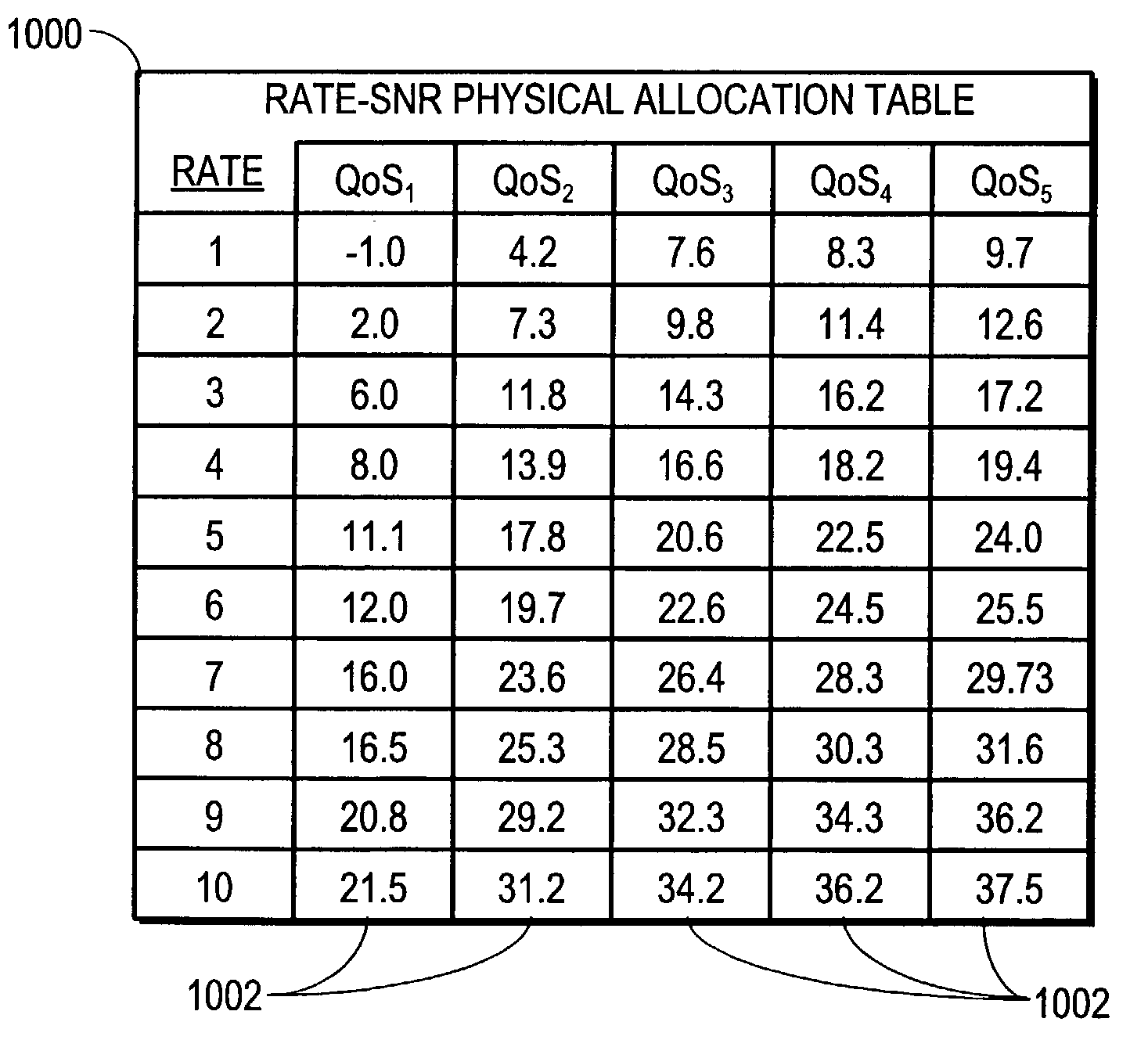

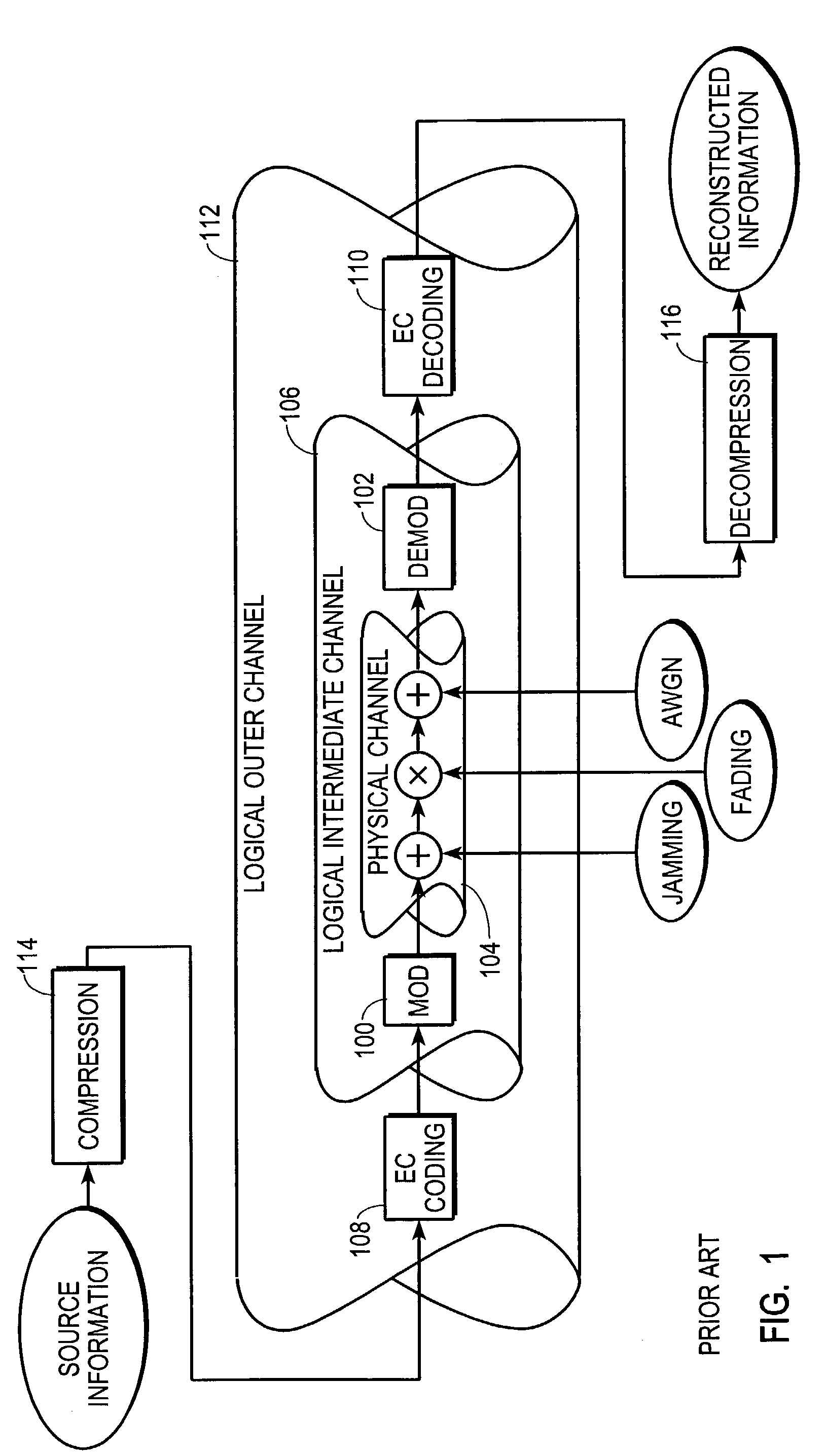

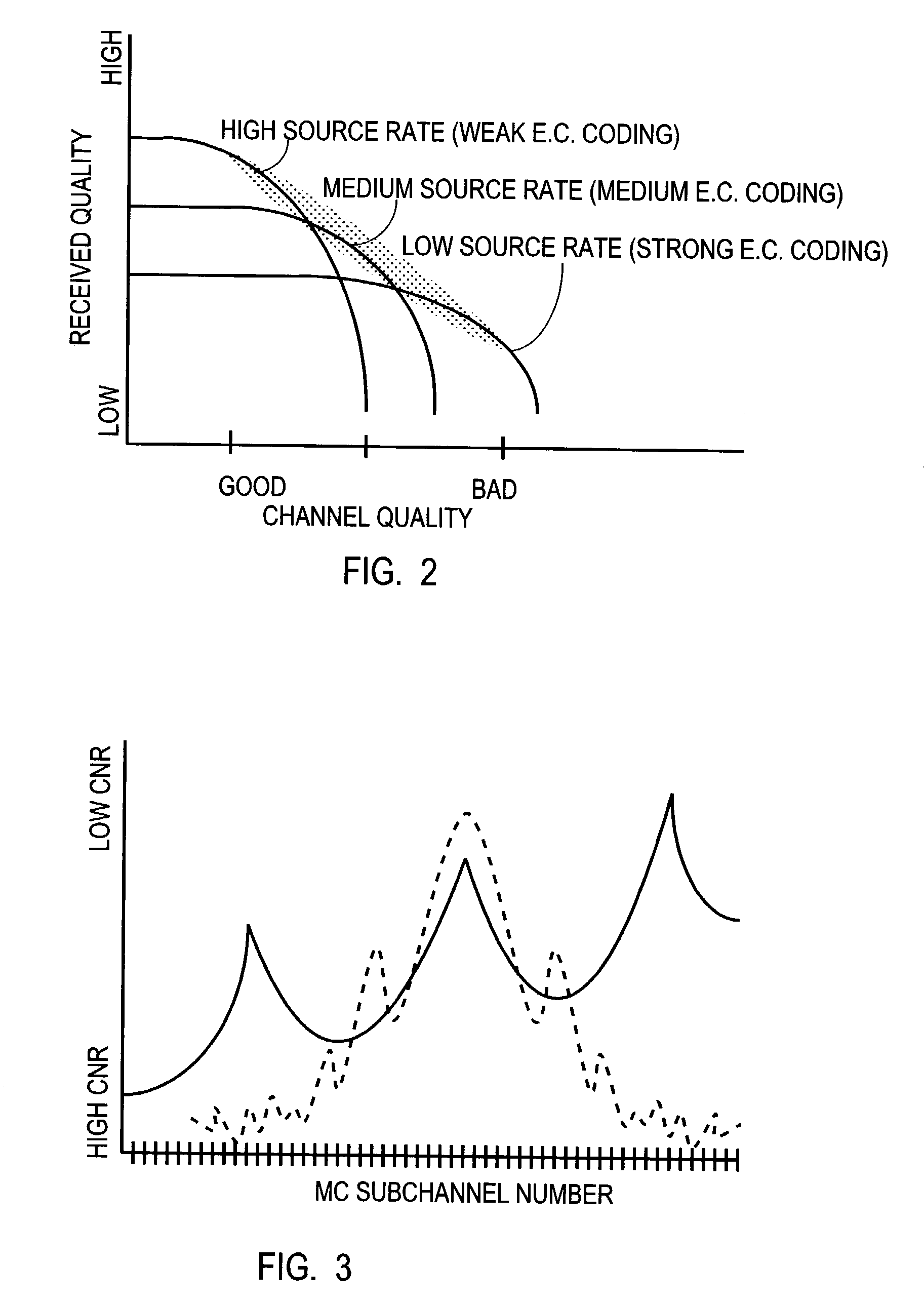

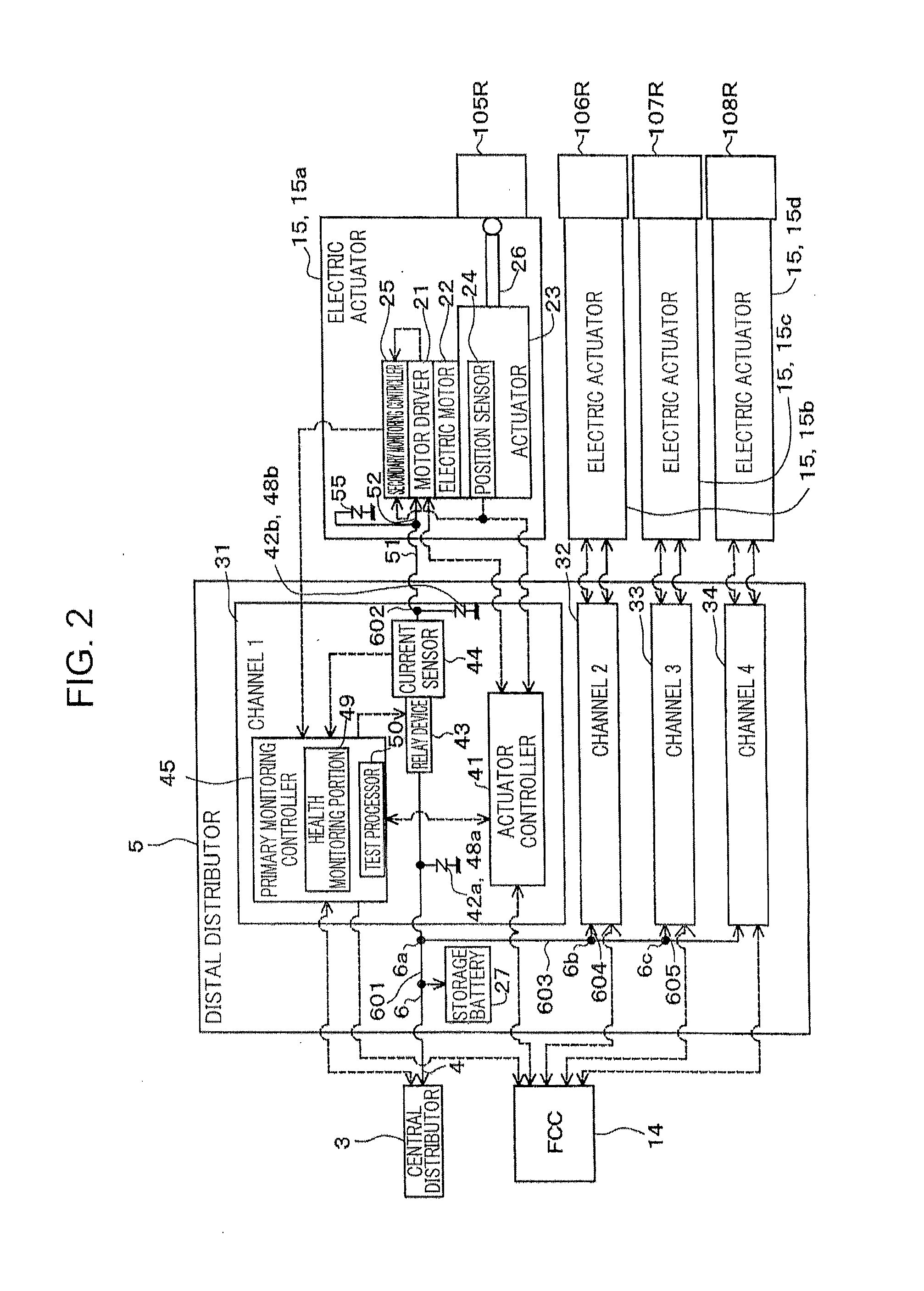

Multi-carrier modulation with source information allocated over variable quality communication channel

ActiveUS7310301B1Suitable for useImprove efficiencyPower managementModulated-carrier systemsCommunications systemSignal quality

A multi-carrier communication system (400) groups subchannels (802) into different quality-of-signal (QoS) regions (804). An unconstrained optimization process (1200) is performed independently for the subchannels (802) of the different QoS regions (804) to allocate bit rates and power to the individual subchannels (802) so that the indicated QoS will result. Coders (504, 508, 512, 516) partition and error-correction encode source information using encoding schemes matched to the different QoS regions (804). A set (1100) of only a few directed QoS partition vectors (1102) direct the unconstrained optimization process (1200) to attempt bit-rate and power allocations on only a few promising groupings of subchannels (802) and QoS regions (804). An iterative process may take place between bit-rate and power allocation on one side and source information coding on the other for different directed QoS partition vectors (1102) to identify the best solution.

Owner:GENERAL DYNAMICS MISSION SYST INC

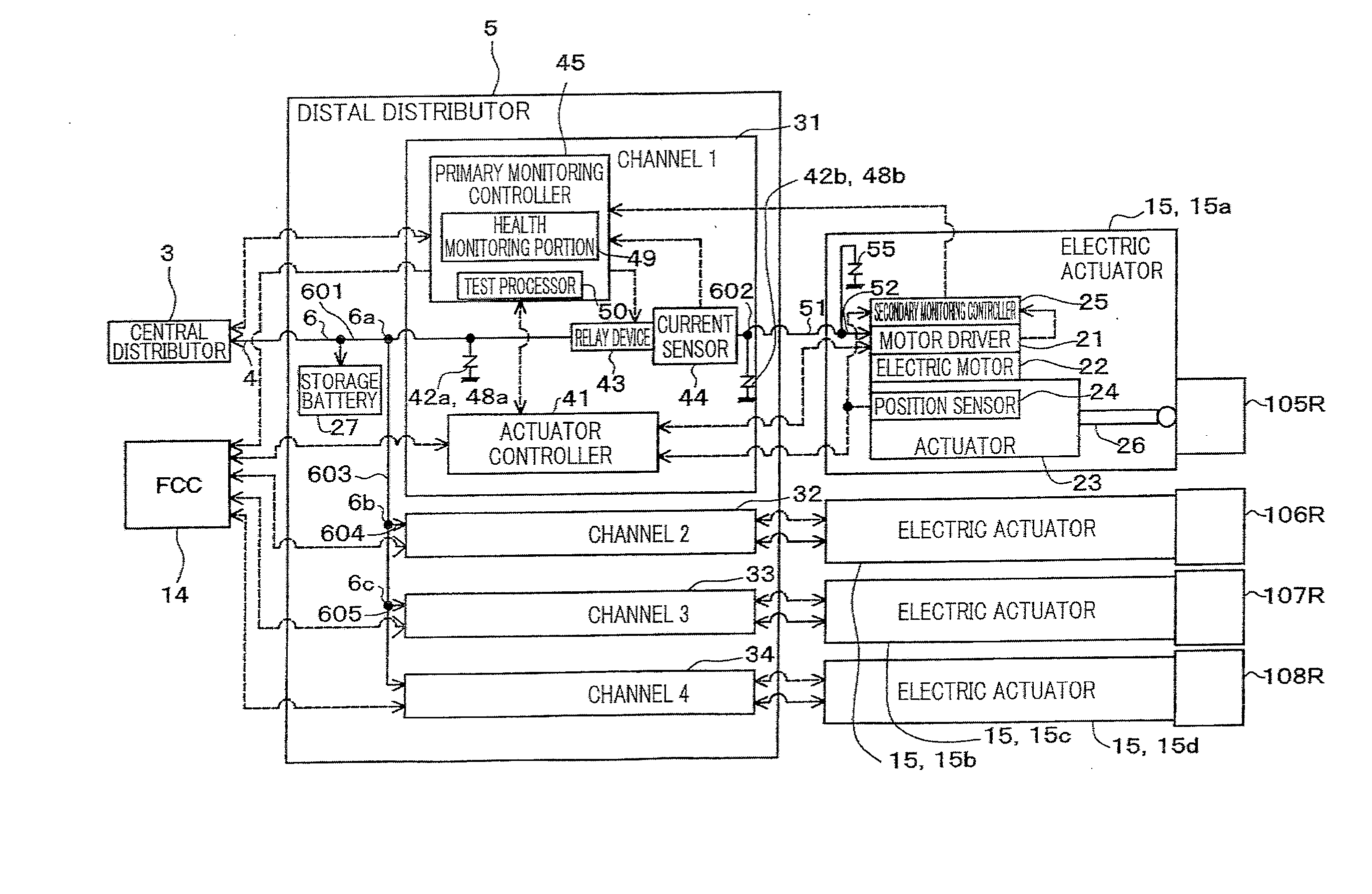

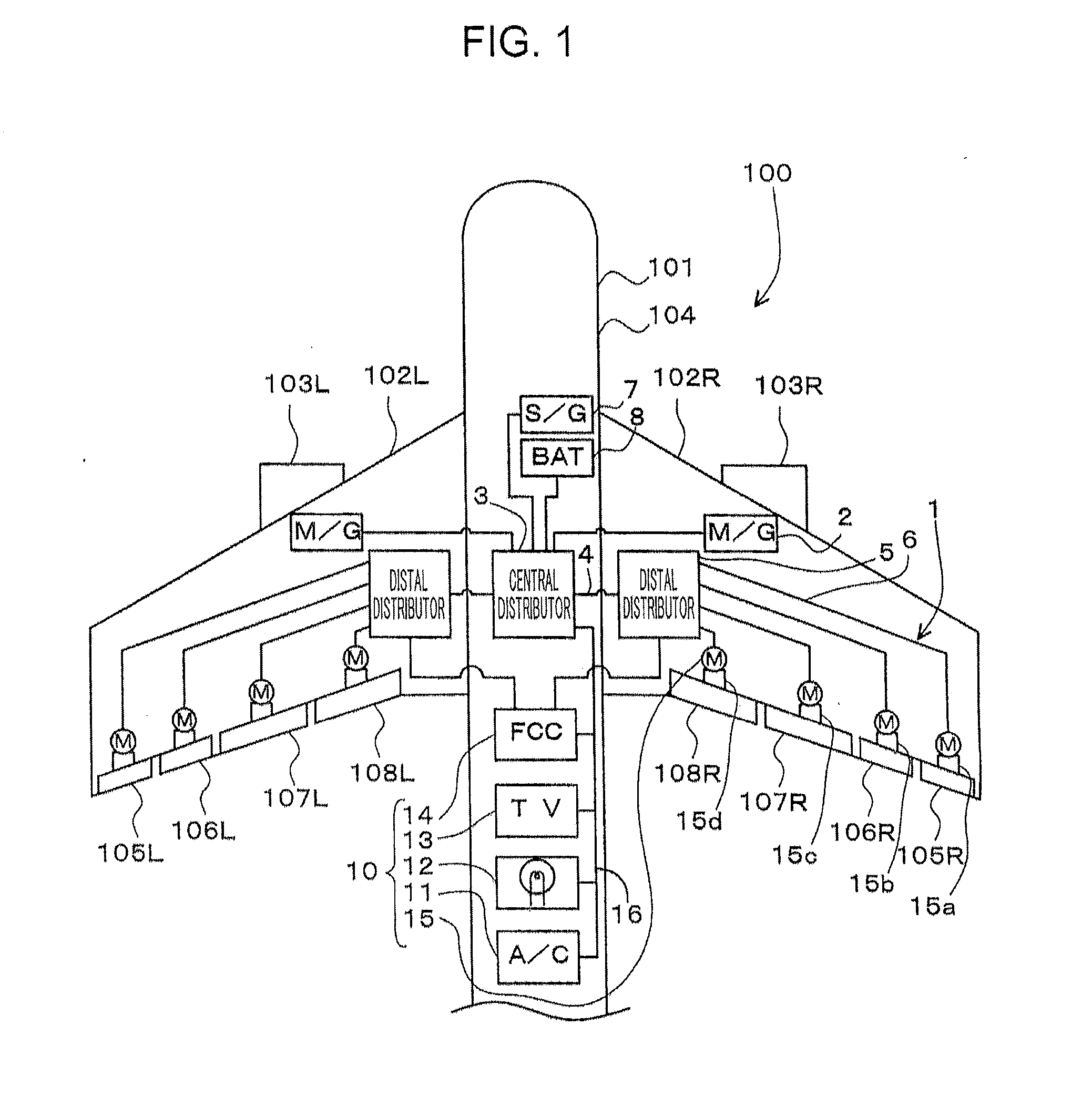

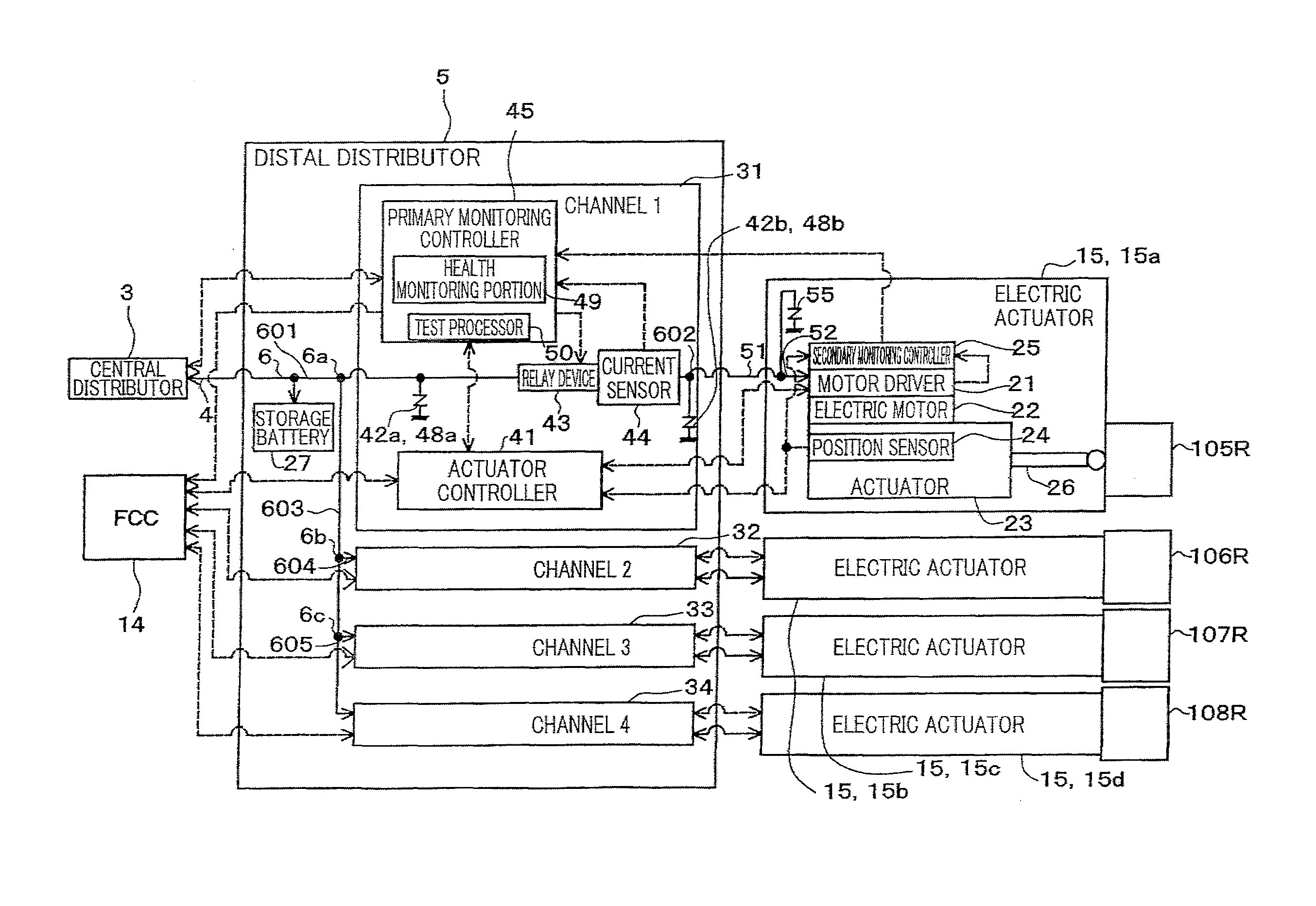

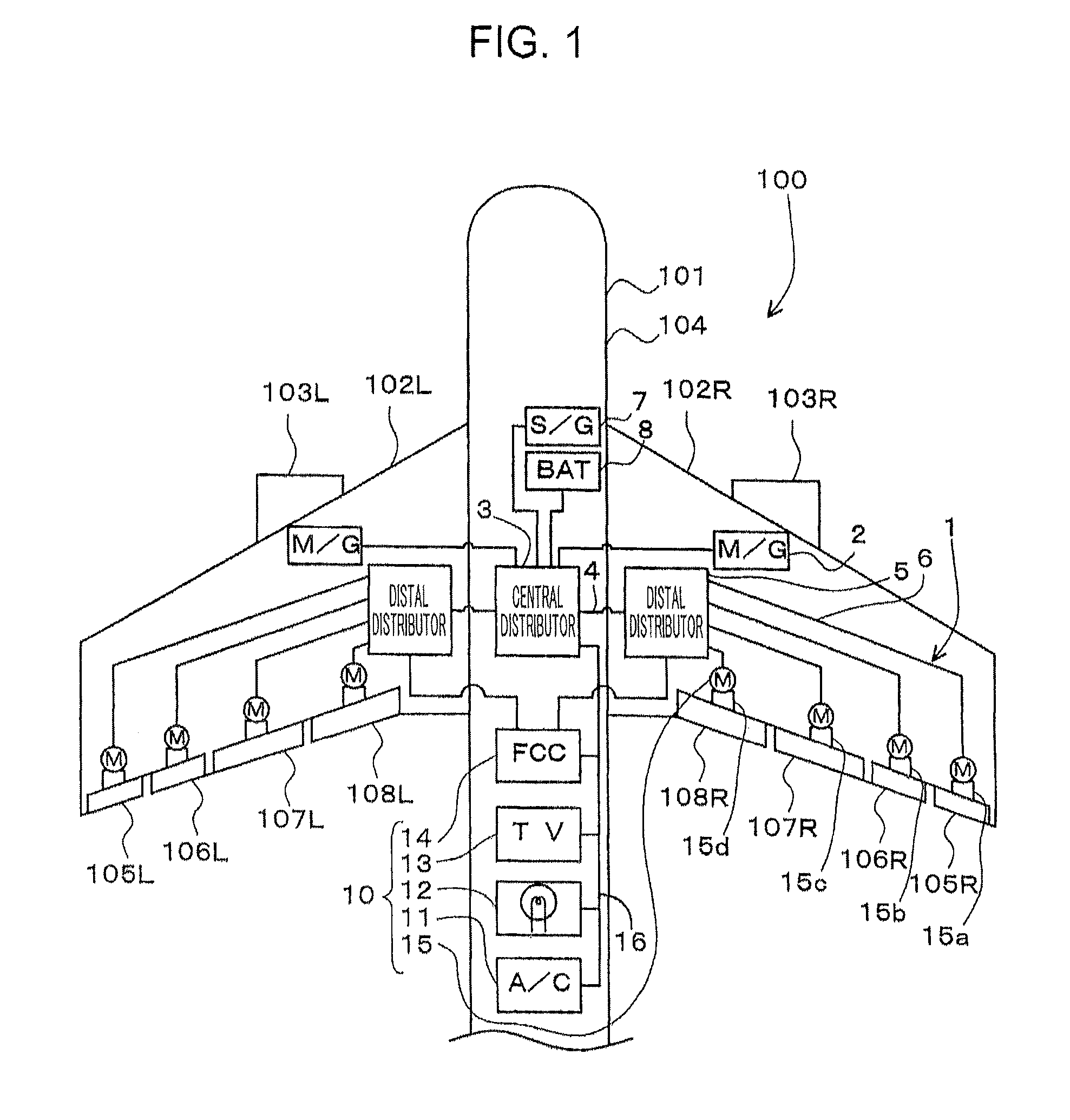

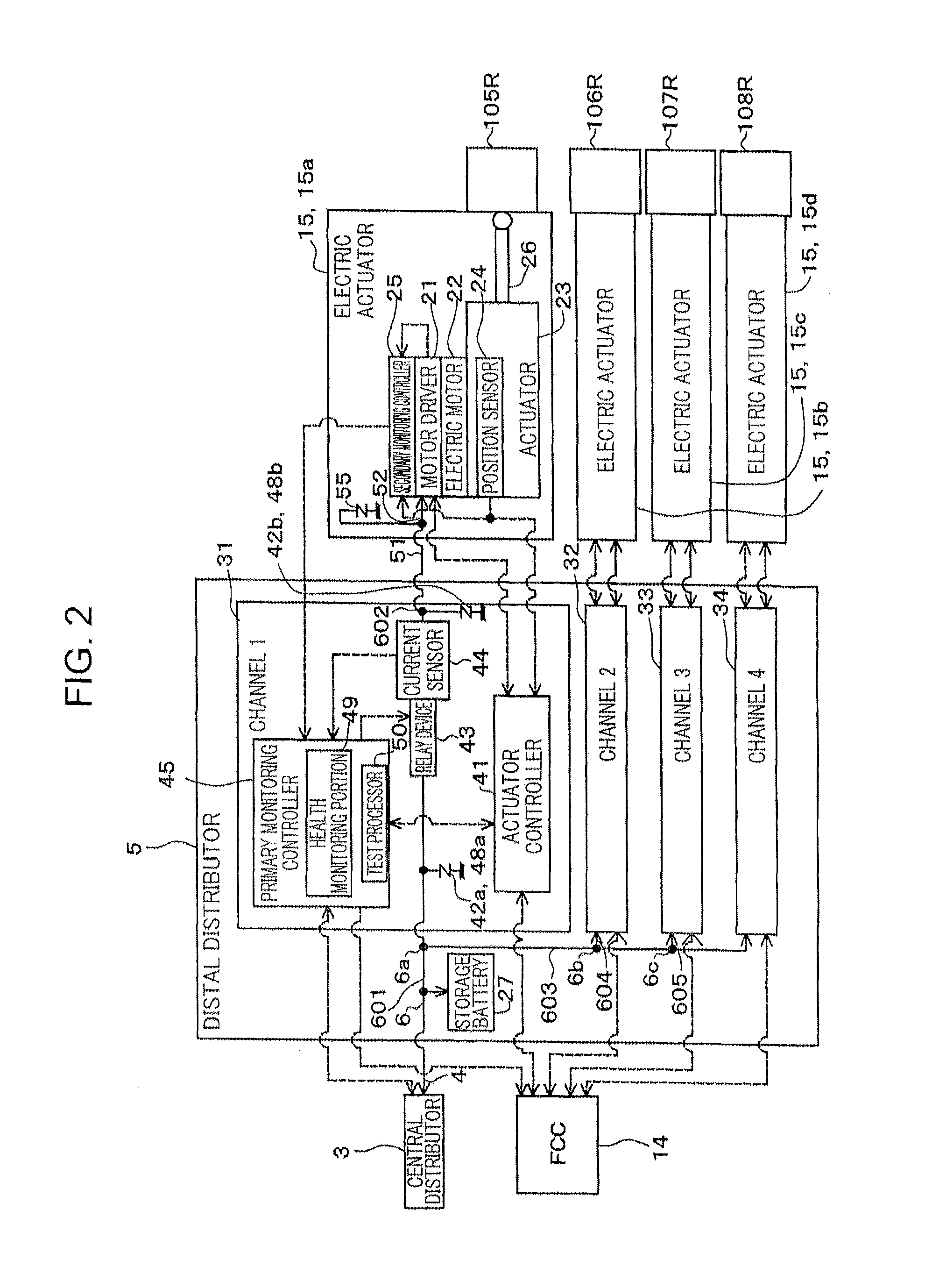

Distribution apparatus

ActiveUS20150123622A1Efficient use of powerEfficient powerElectric power distributionPower installationsElectric power systemEngineering

Provided is a power system 1 including a distal distributor 5, an electric actuator 15a which receives a supply of power from the distal distributor 5, and a relay device 43. Regenerative power generated by the electric actuator 15a is output to a storage battery 27.

Owner:NABLESCO CORP

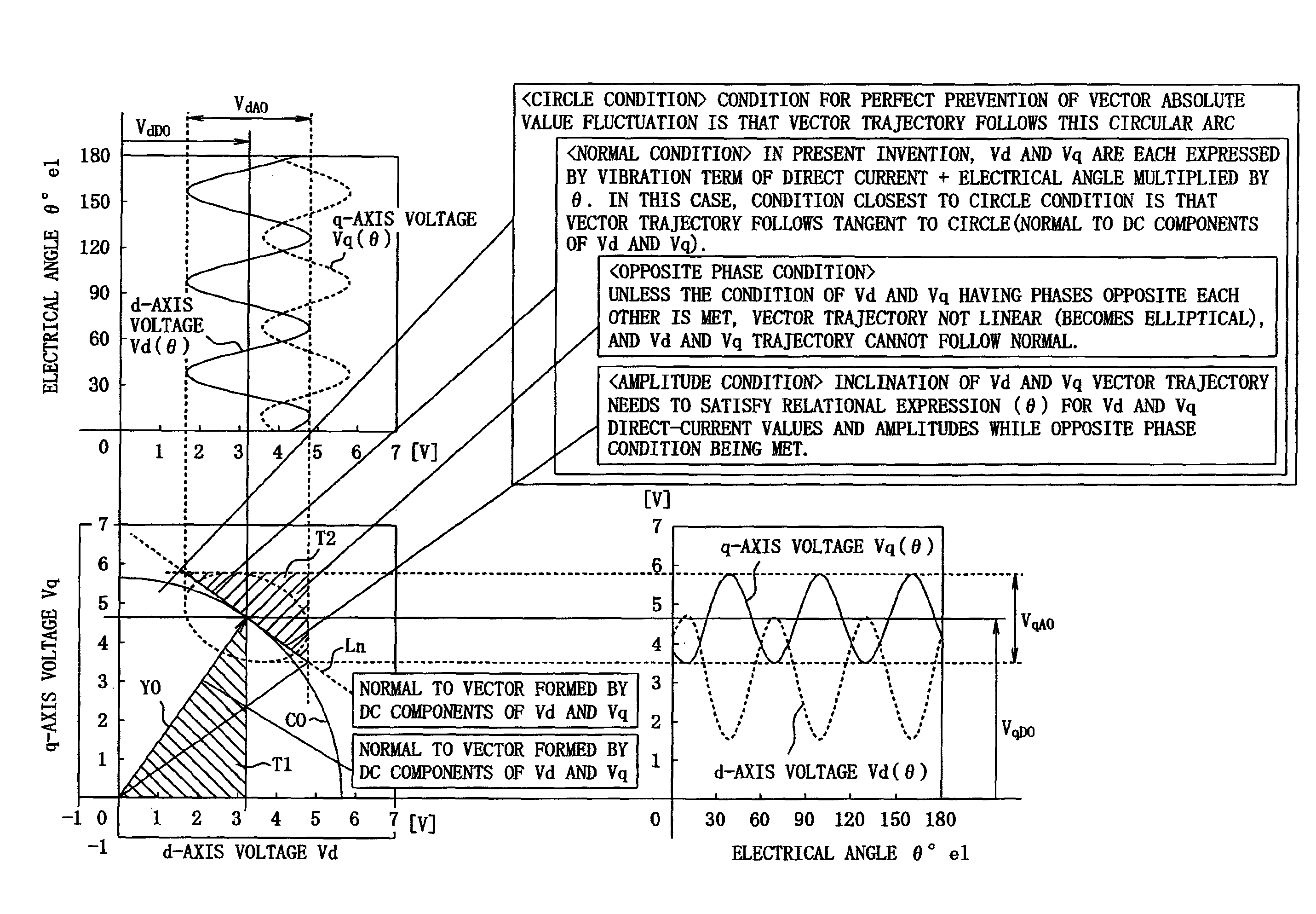

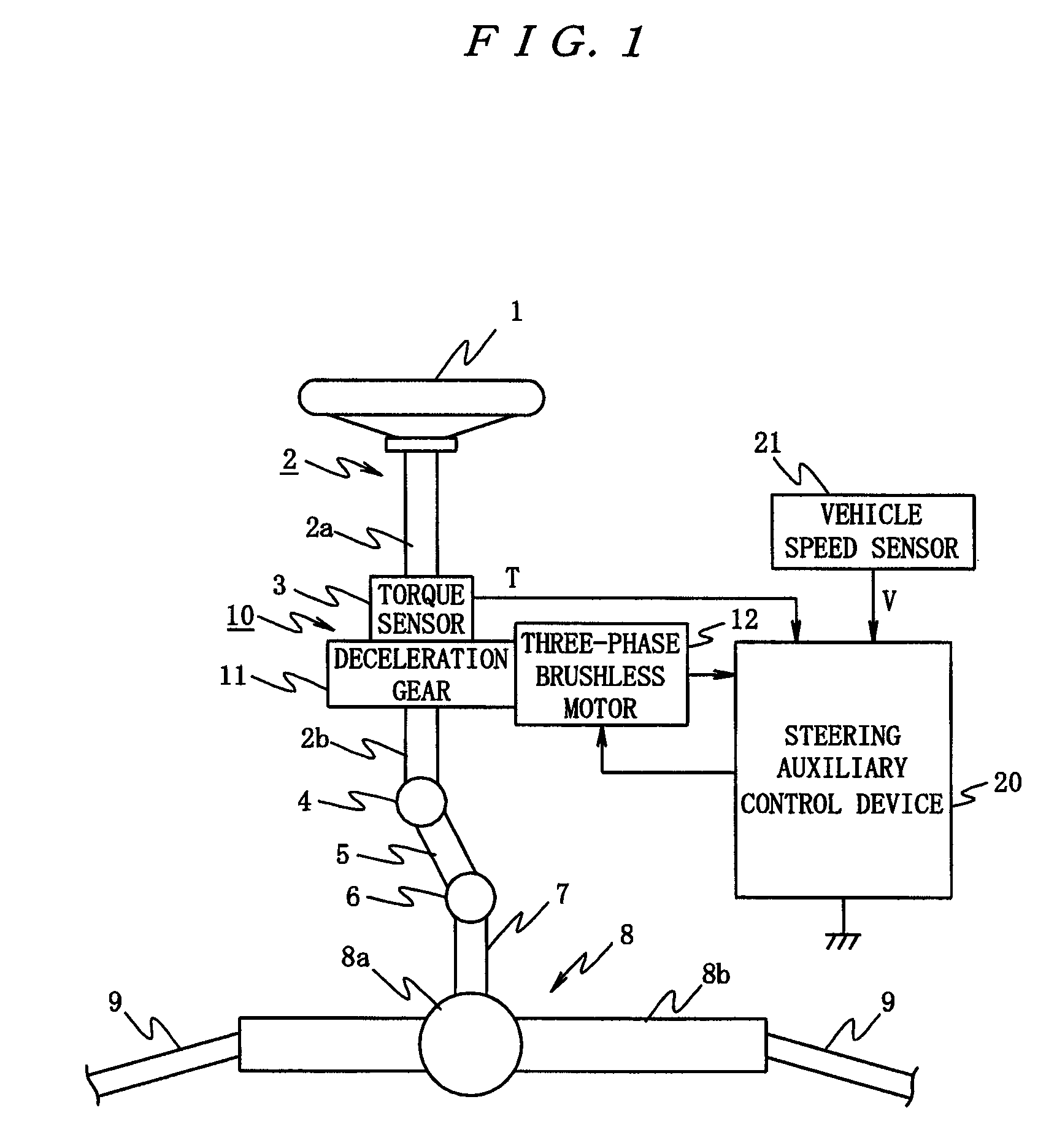

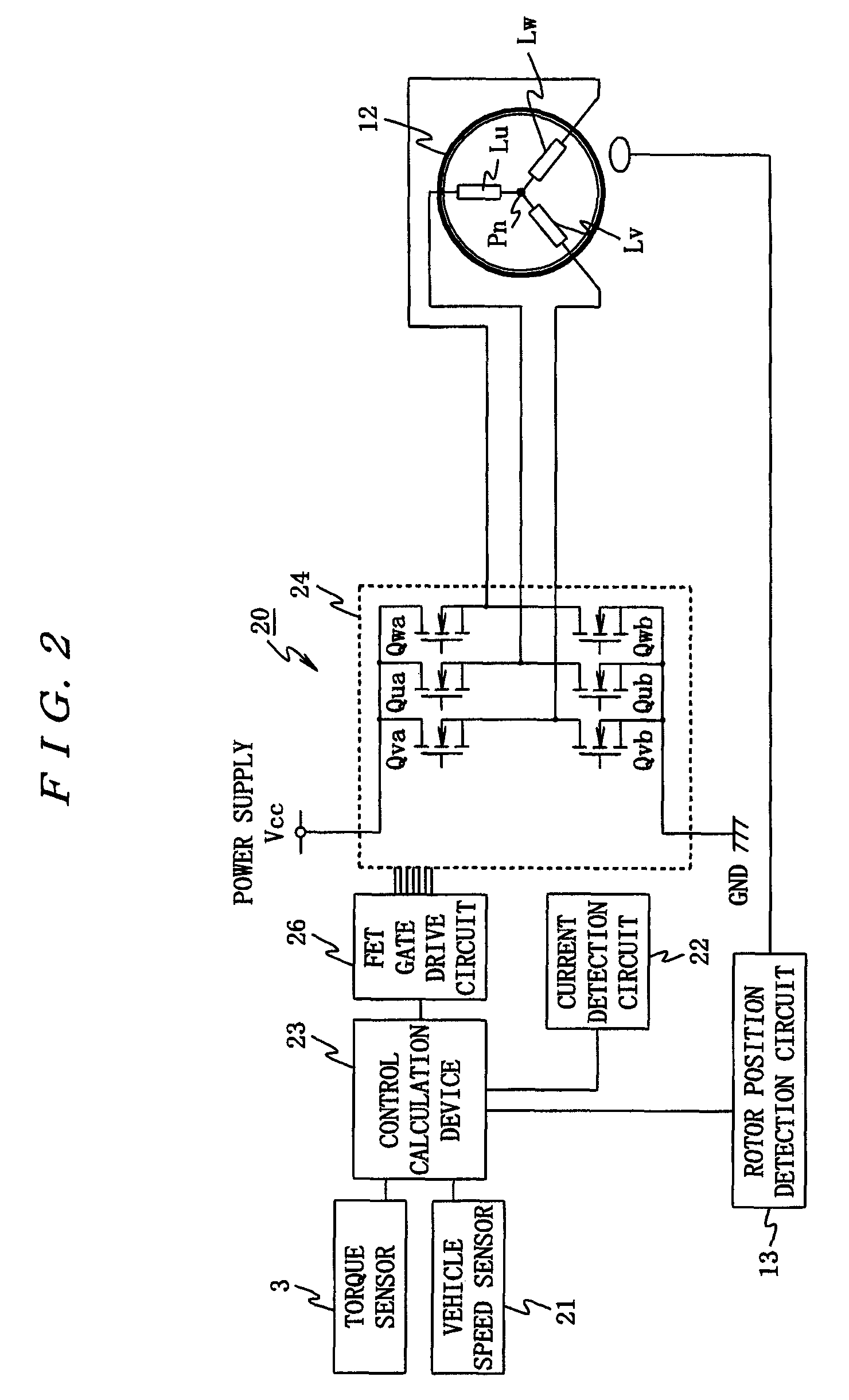

Motor control device and motor-driven power steering system using the same

ActiveUS8080957B2Efficient use of powerImprove steering performanceSingle-phase induction motor startersTorque ripple controlBrushless motorsPhase currents

Owner:NSK LTD

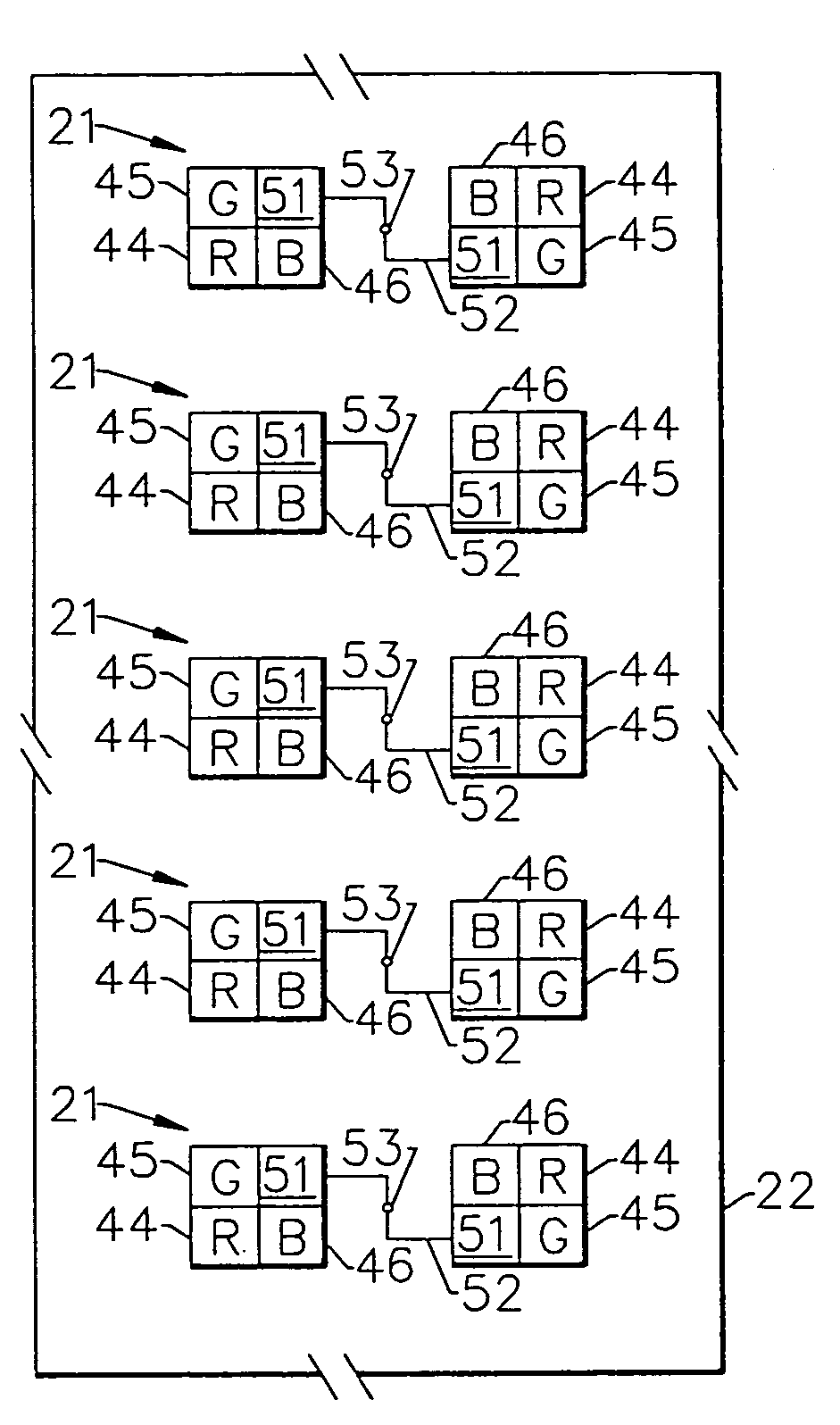

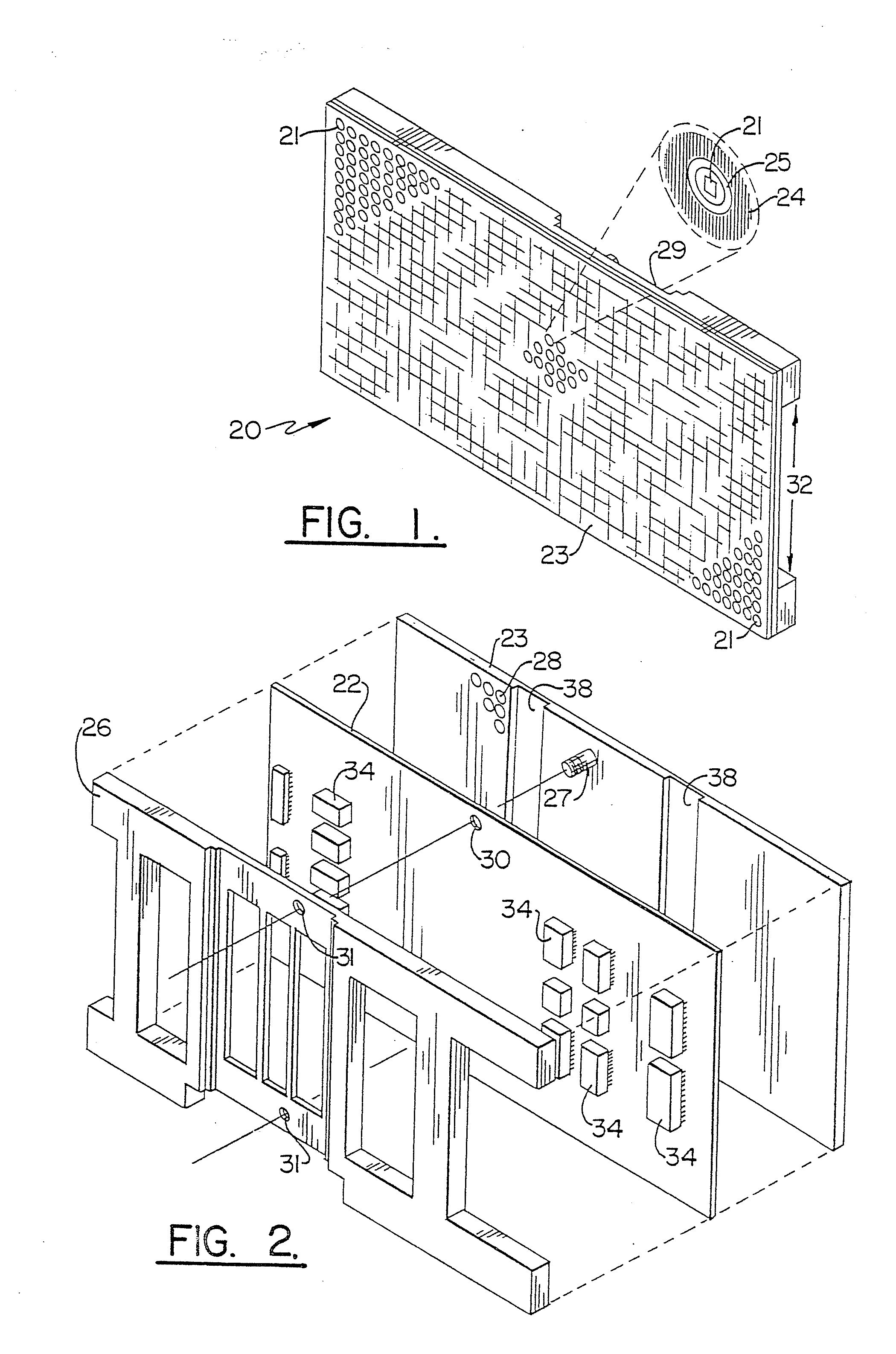

True color flat panel display module

InactiveUS7385574B1Increasing the thicknessMore brightnessStatic indicating devicesSemiconductor devicesFlat panel displayLight-emitting diode

A full color flat panel display module is formed of a matrix of pixels in rows and columns. Each pixel is formed of respective red, green and blue solid state light emitting diodes that can form any color on that portion of a CIE curve that falls within a triangle whose sides are formed by a line on the CIE curve between 430 nm and 660 nm, a line between 660 nm and a point between 500 and 530 nm, and a line between the 500-530 nm point and 430 nm.

Owner:CREE INC

Method for cooking a food with infrared radiant heat

ActiveUS20080029503A1High speedEfficient use of powerDomestic stoves or rangesElectrical heating fuelThermal energyProcess engineering

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and reheats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

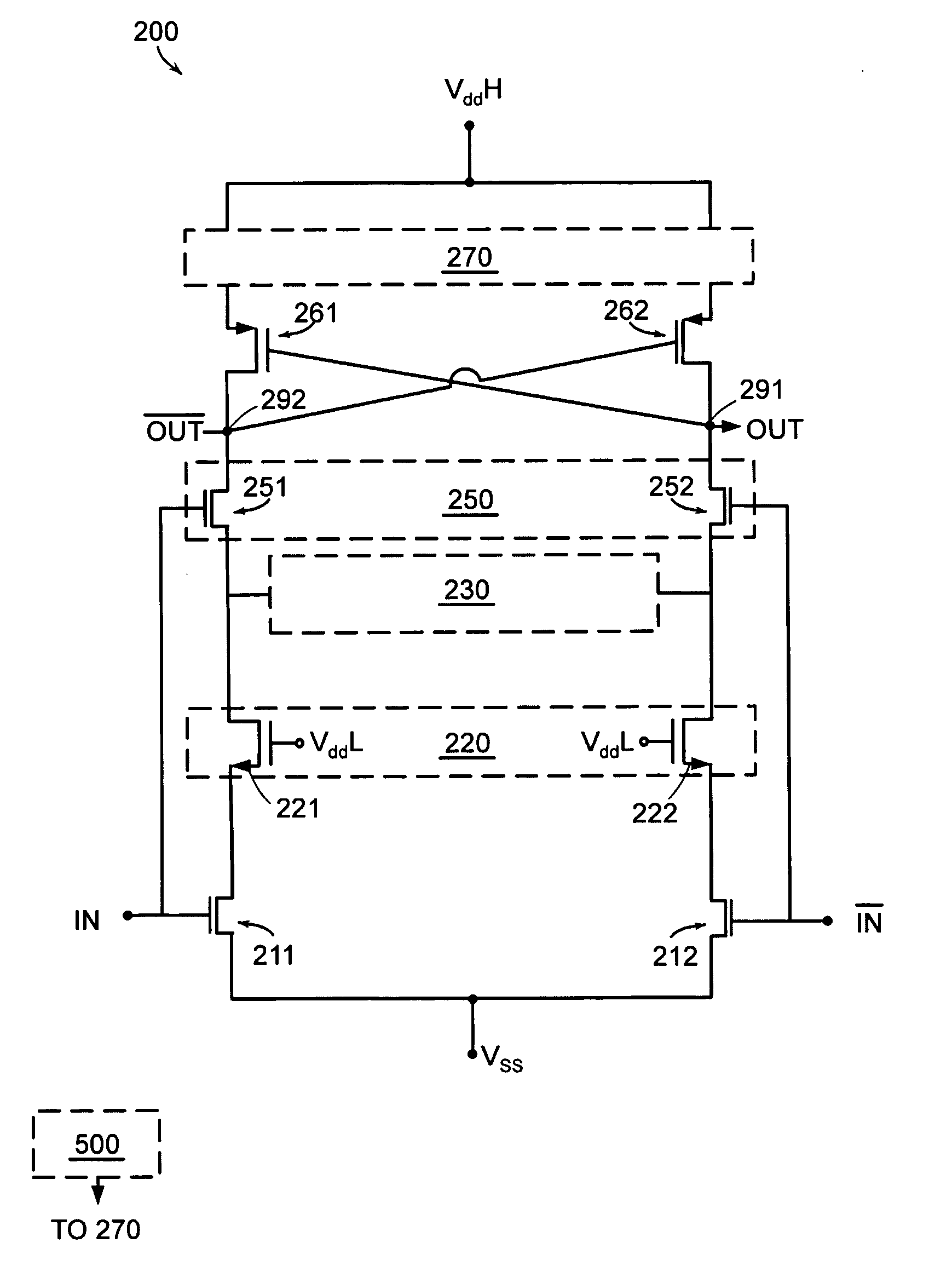

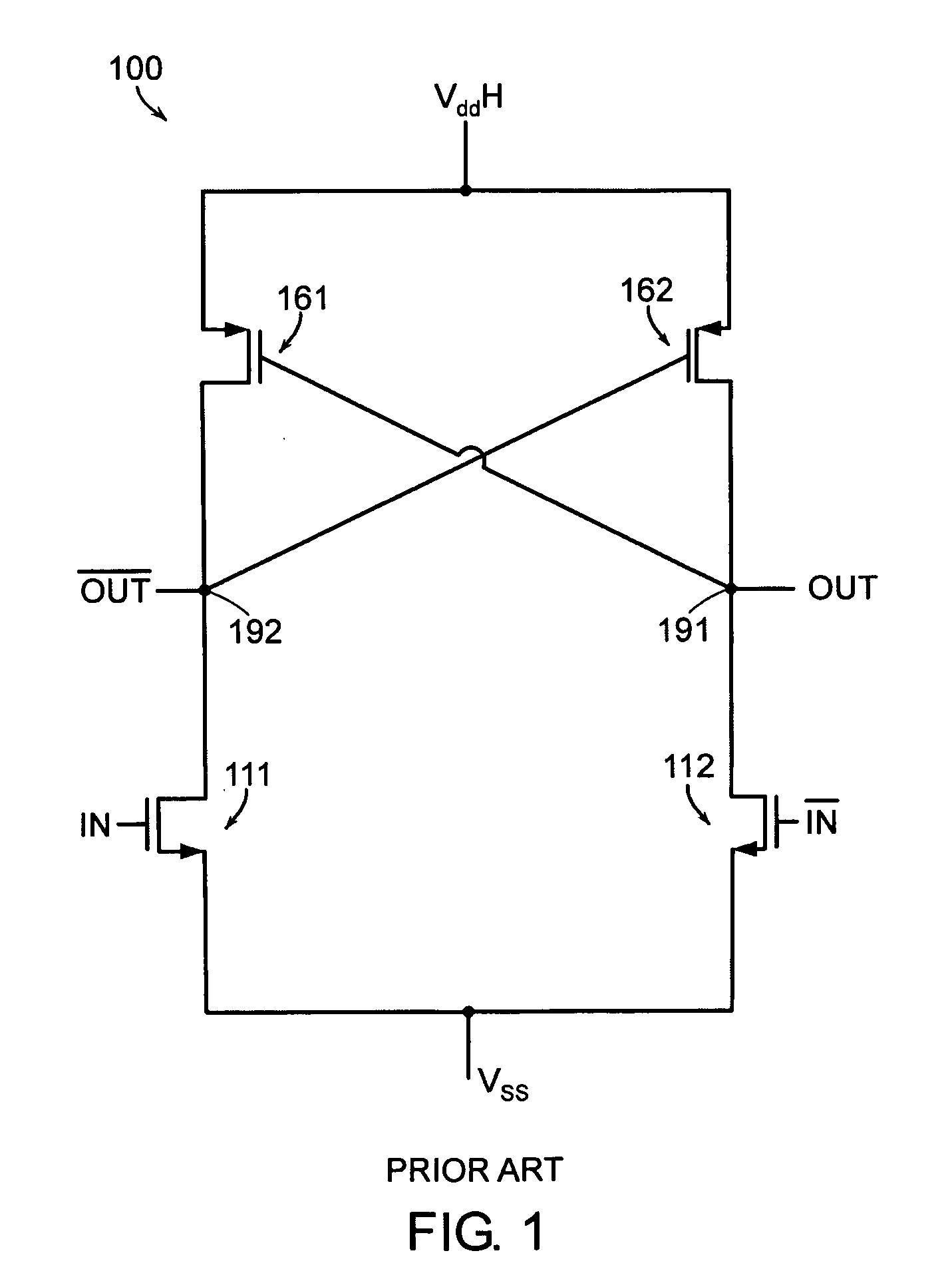

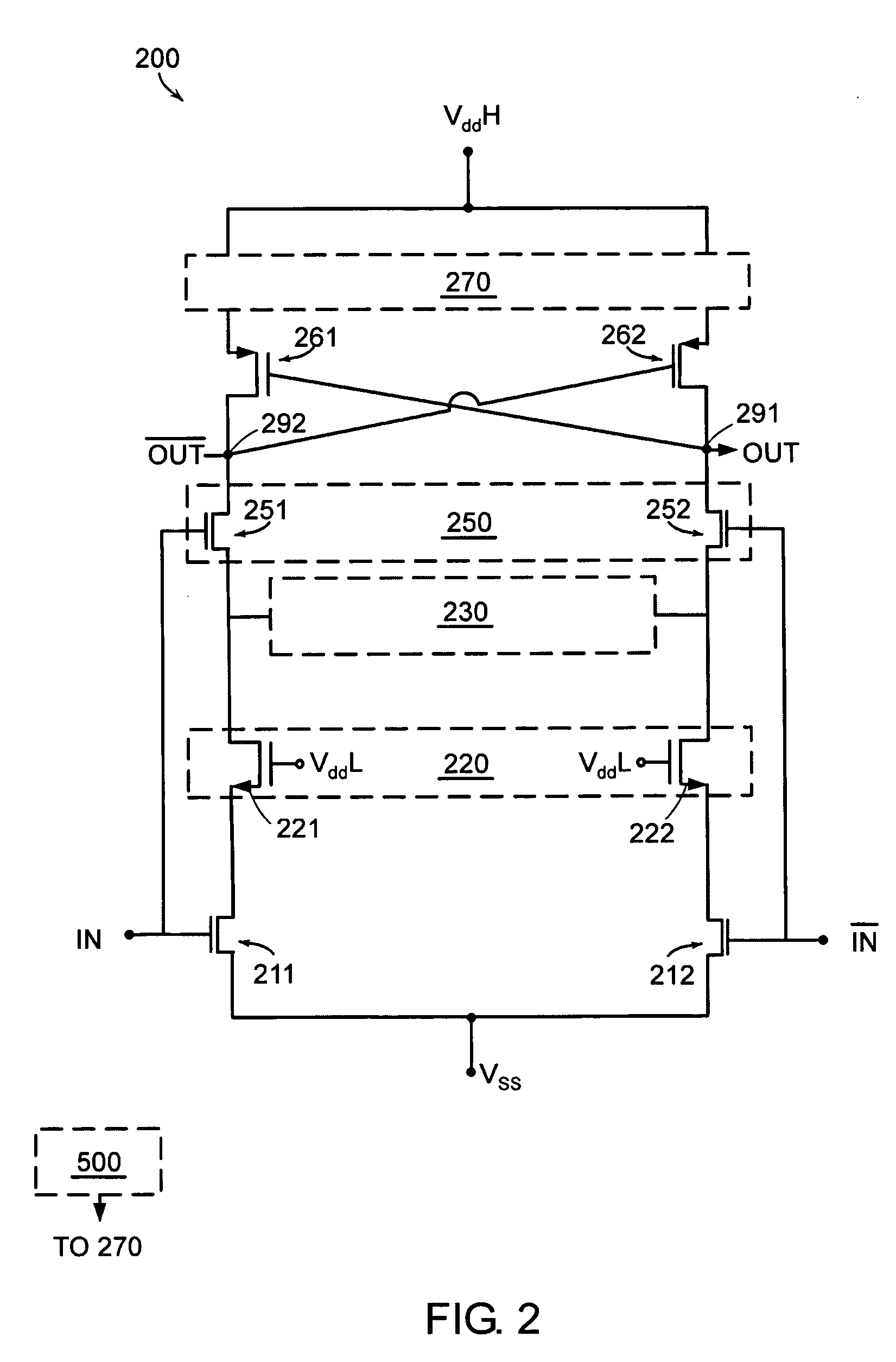

Logic level voltage translator

InactiveUS20050184788A1Accurate operationEfficient use of powerPulse automatic controlInstant pulse delivery arrangementsVoltage converterEngineering

A voltage level translator provides an output signal having an external voltage in response to an input signal having an internal voltage. The voltage level translator includes first and second input signal transistors, first and second output signal transistors, and includes a signal stabilization circuit and / or an enable circuit. A ready-signal generation circuit provides a ready signal indicating that a voltage supply is at an operating voltage. The ready-signal generation circuit can include unbalanced transistors.

Owner:ANALOG DEVICES INC

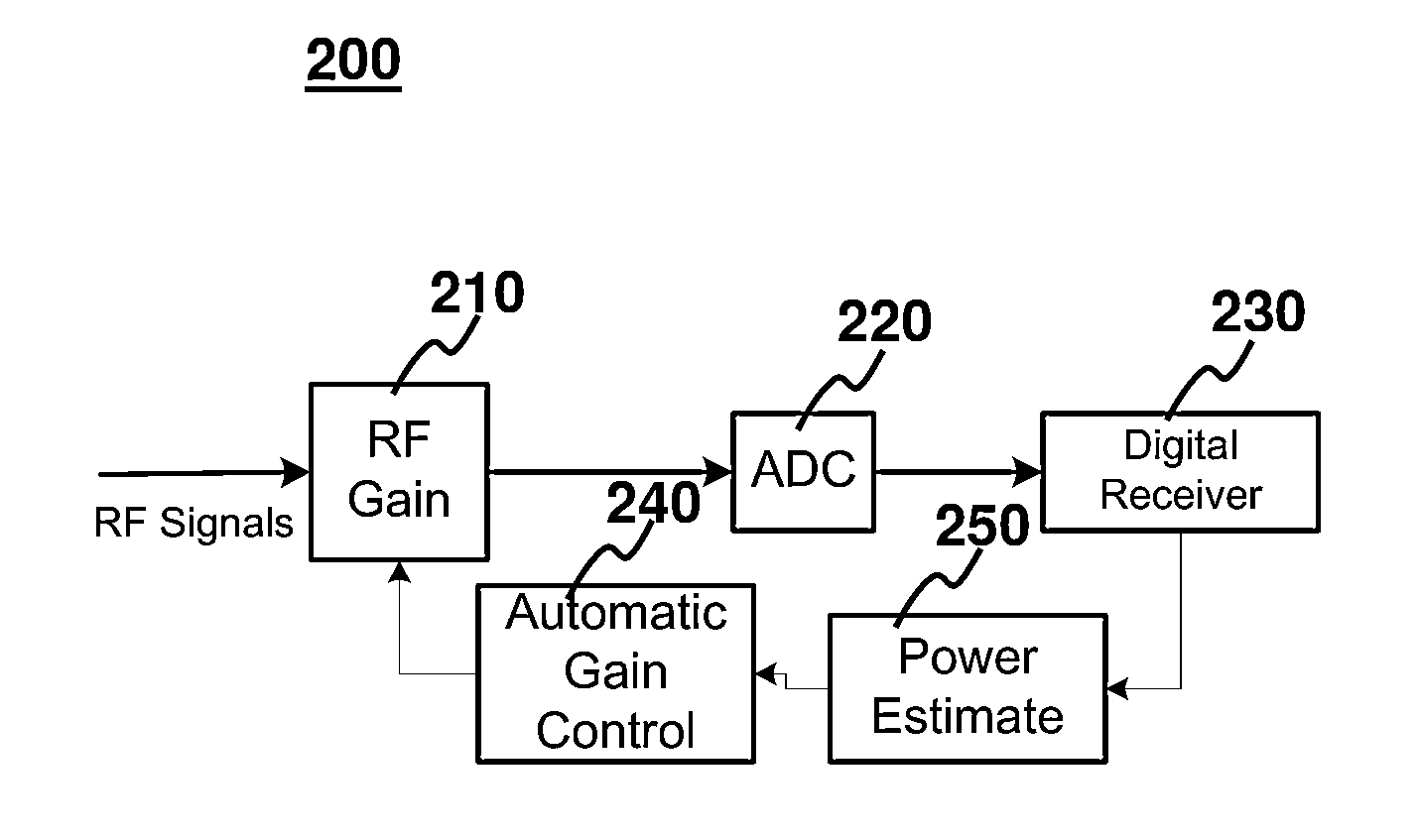

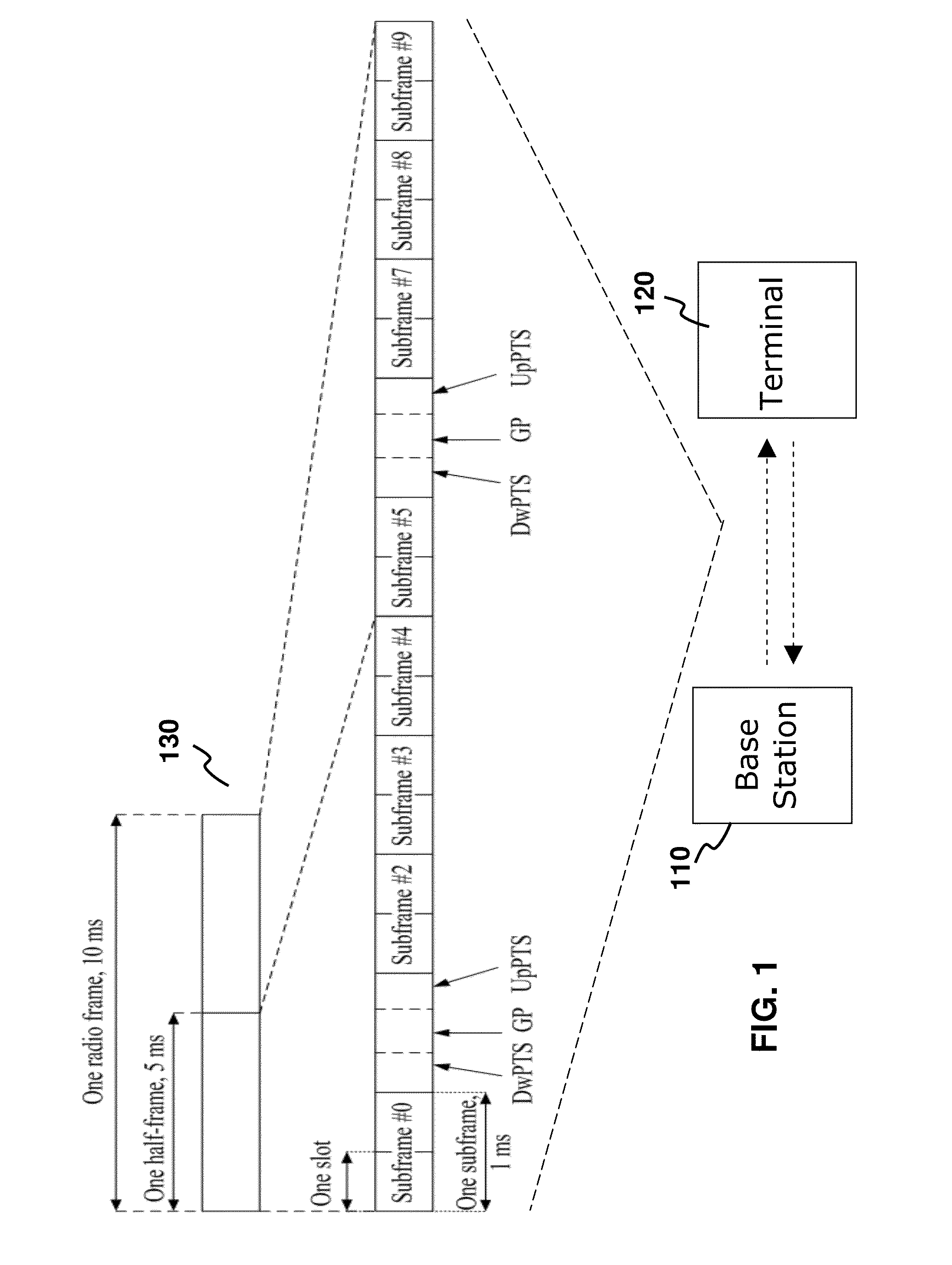

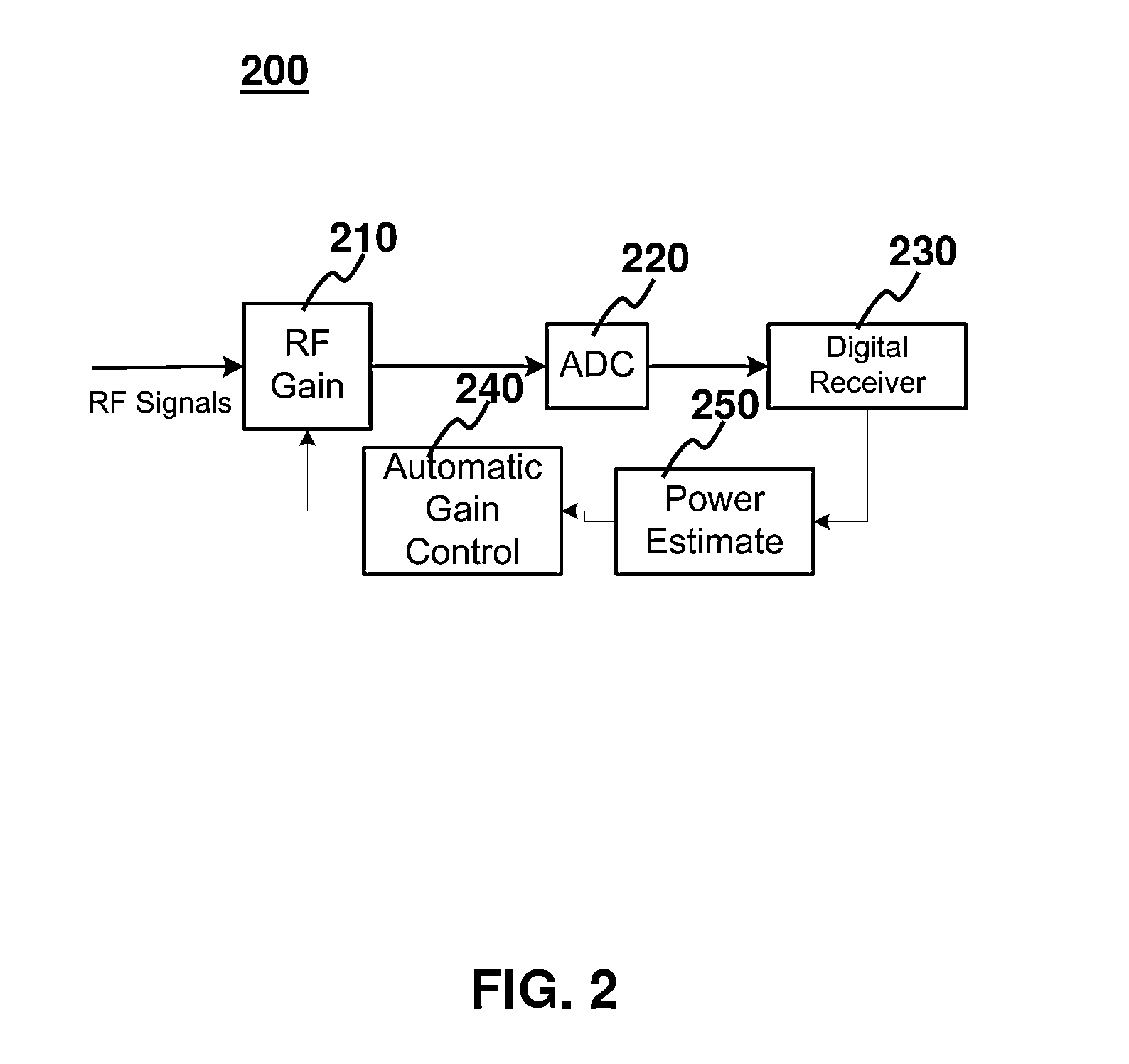

Method and apparatus for automatic gain control in a td-lte system

ActiveUS20130322269A1Efficient use of powerPower will not be drained out too quicklyPower managementError preventionPeak valueAutomatic gain control

This invention describes method and apparatus for automatic gain control (AGC) for a TD-LTE system, taking into consideration the TD-LTE frame structure. In one embodiment, an AGC method comprises: adjusting RF gain for subframe j (where 0<=j<=9) in a radio frame according to an average peak signal power of subframe j in previous radio frames when a terminal is lack of information in downlink timing and in uplink / downlink configuration; computing a first average signal power in one or more downlink subframes as received from at least one base station when the terminal has information in downlink timing but is lack of information in uplink / downlink configuration; and computing a second average signal power in one or more downlink subframes as received from at least one base station when the terminal has information in downlink timing and in uplink / downlink configuration.

Owner:HONG KONG APPLIED SCI & TECH RES INST

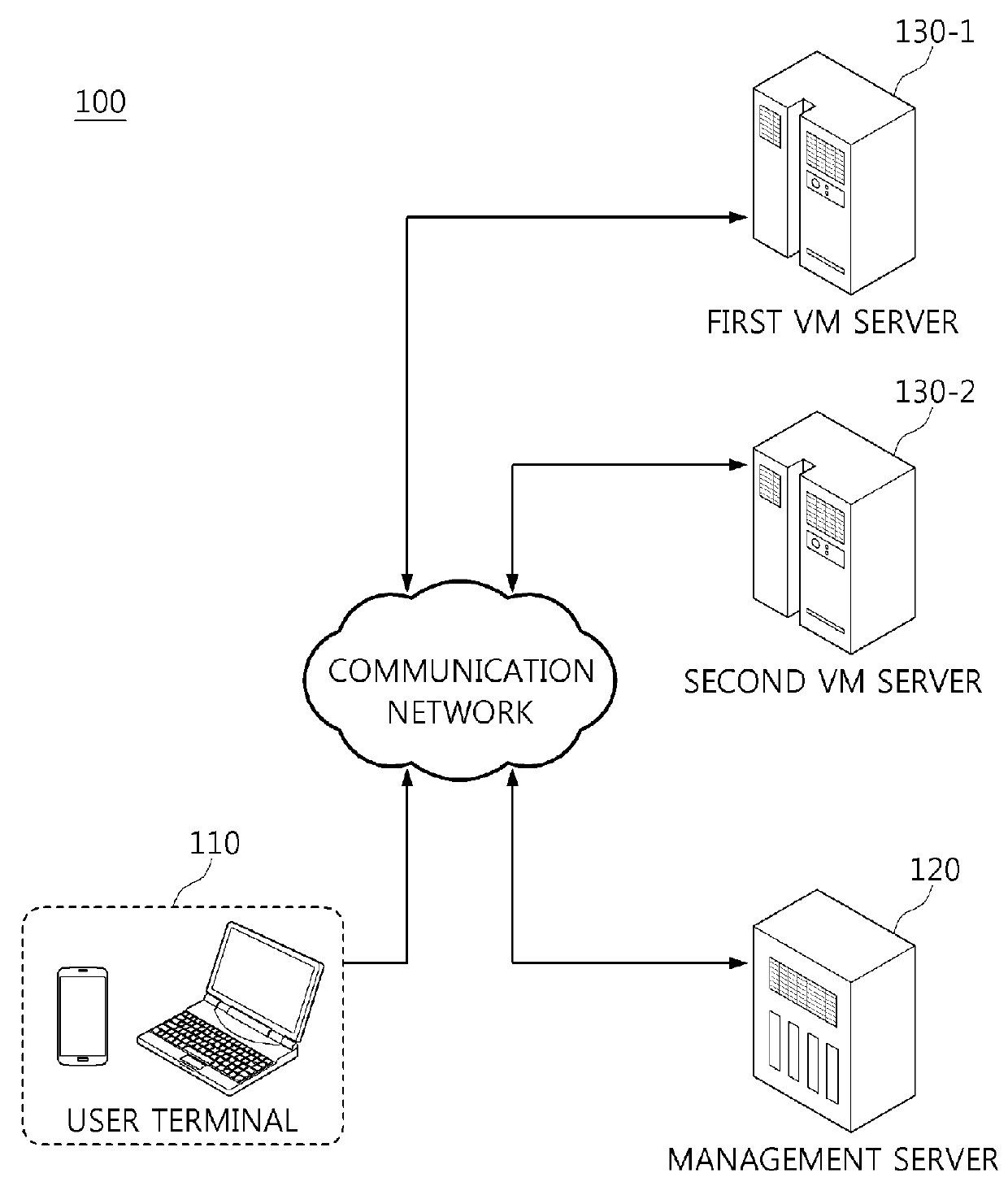

Method, apparatus and system for selectively providing virtual machine through actual measurement of efficiency of power usage

ActiveUS20180267820A1Enable energy savingSave energyResource allocationVolume/mass flow measurementPower usageNetwork virtualization

Disclosed are a method, apparatus, and system for selectively providing a virtual machine through actual measurement of efficiency of power usage. When a user terminal requests to provide a virtual machine, candidate virtual machines are activated on multiple virtual machine servers. Input data provided by the user terminal are provided to each of the multiple candidate virtual machines through replication and network virtualization, and identical candidate virtual machines are run on the multiple virtual machine servers through replication and network virtualization. When the candidate virtual machines are run, one of the candidate virtual machines is finally selected as the virtual machine to be provided to the user terminal based on efficiency of power usage.

Owner:ELECTRONICS & TELECOMM RES INST

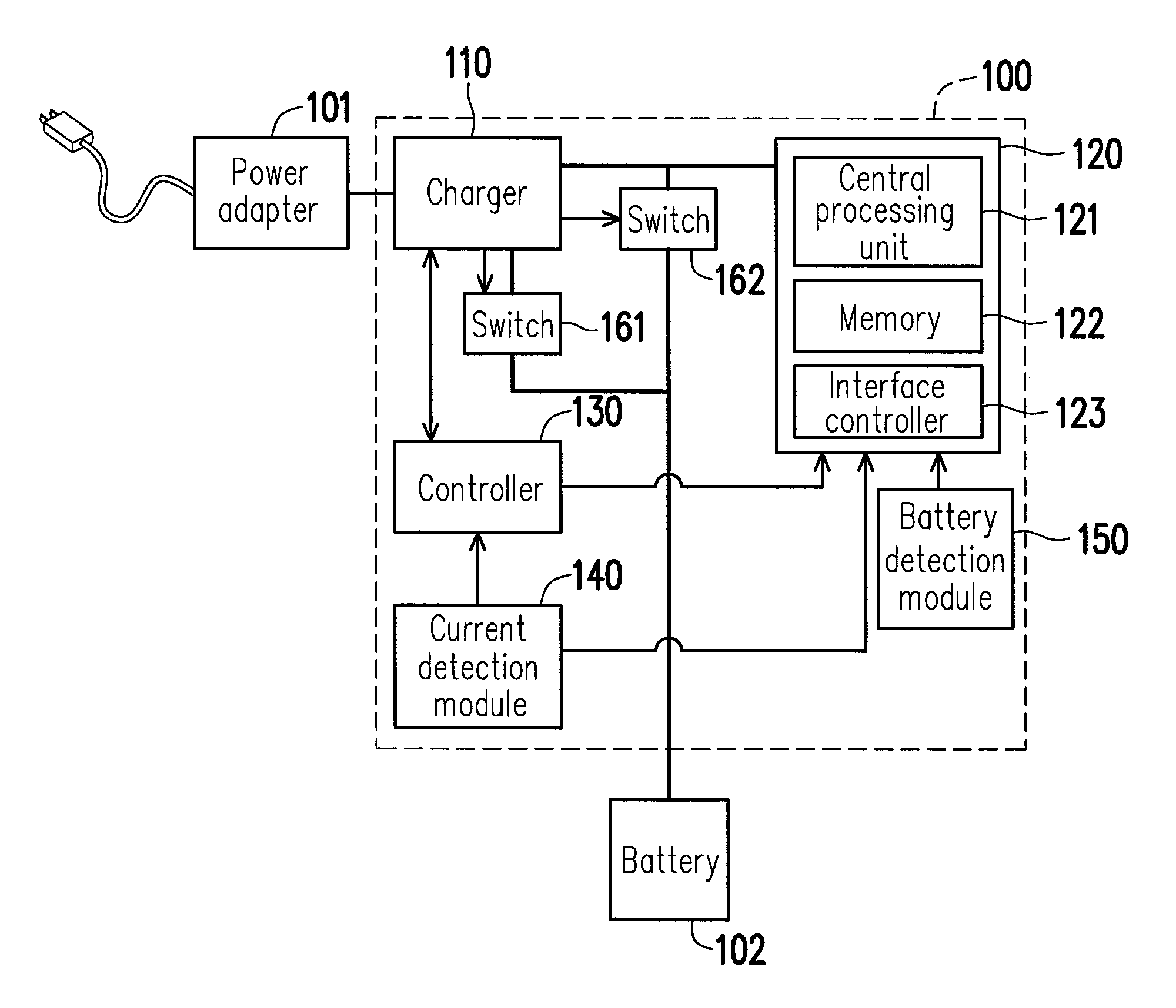

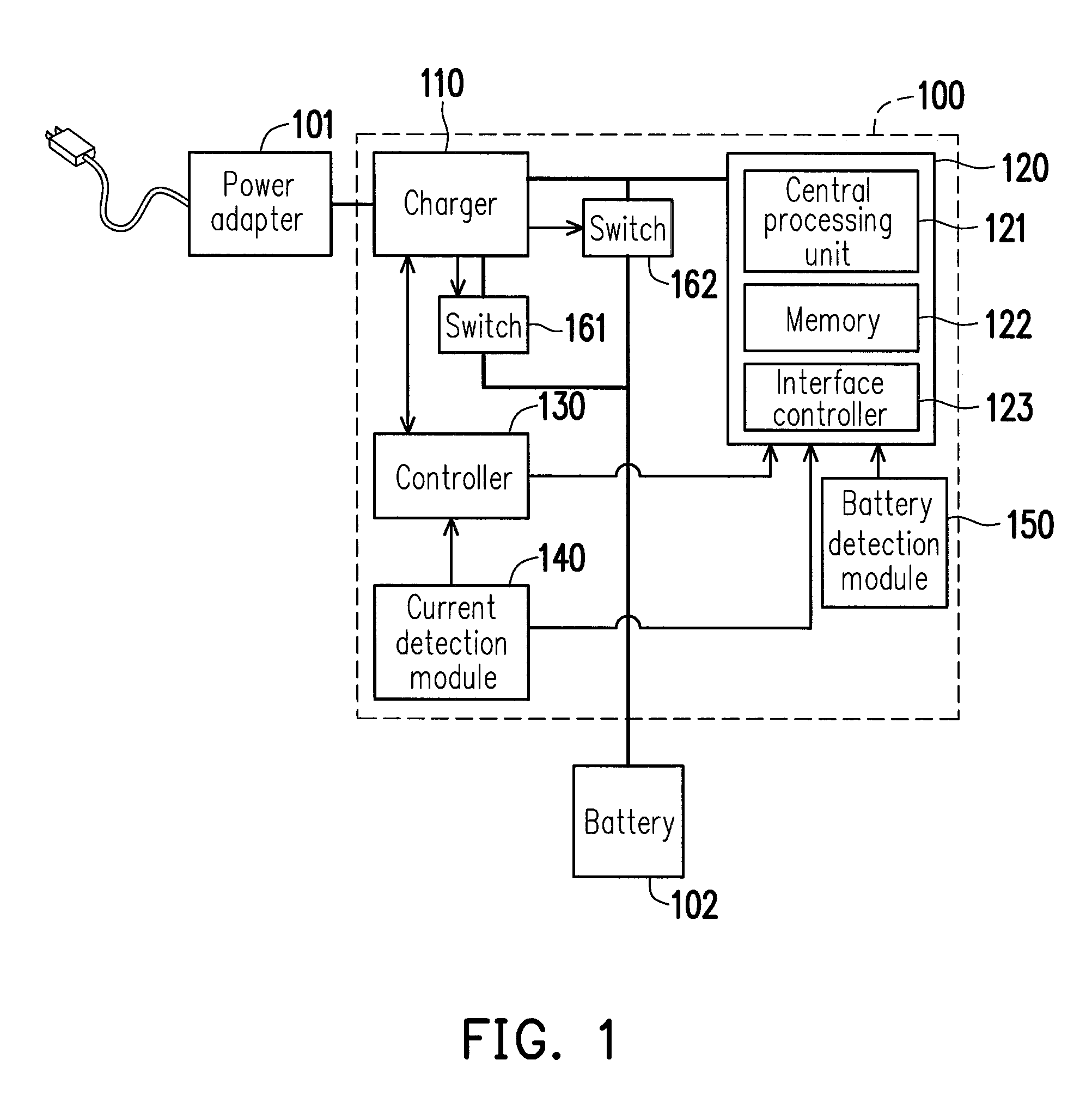

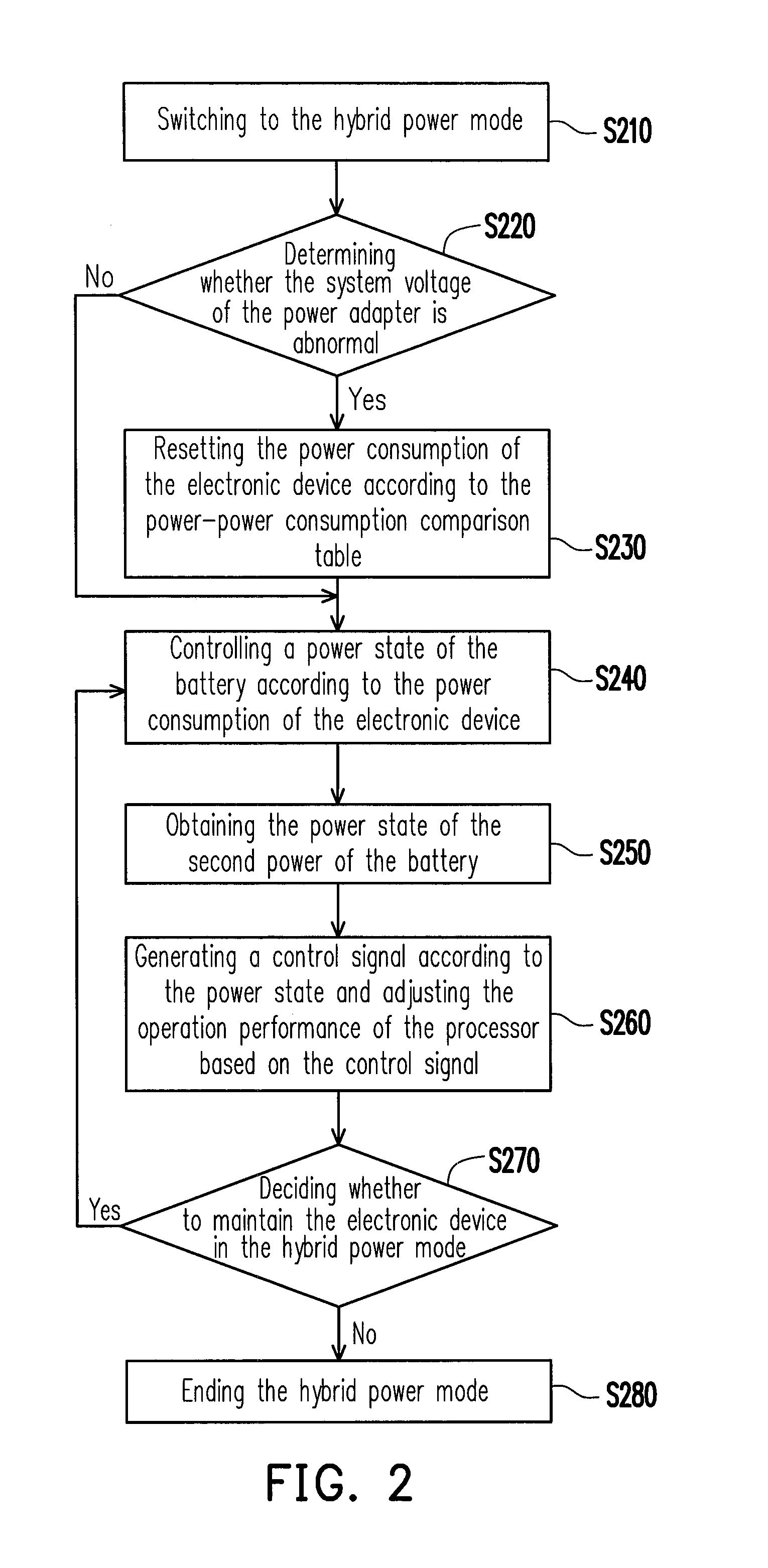

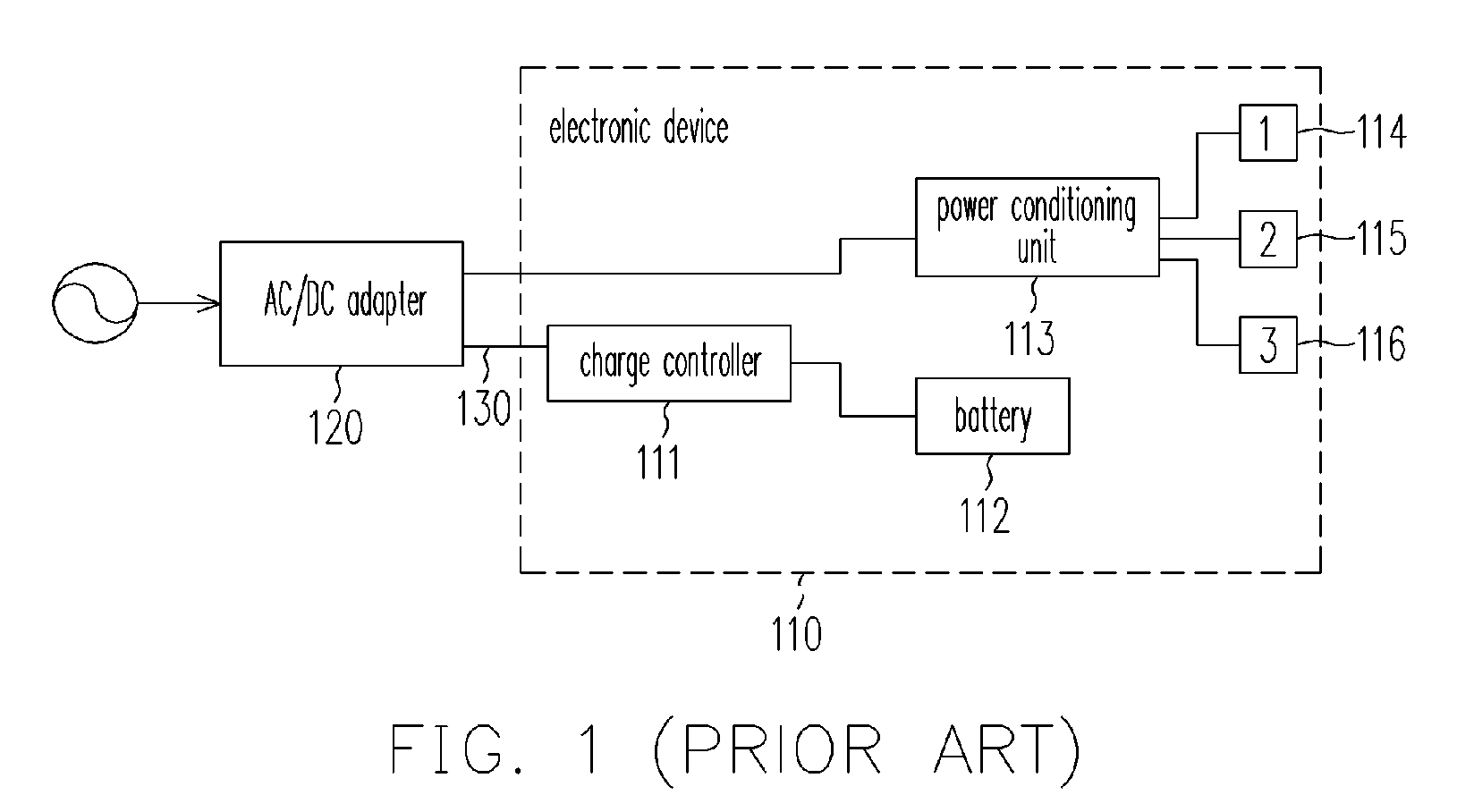

Electronic device and power management method thereof

ActiveUS20130124892A1Improved power consumption efficiencyRun timeEnergy efficient ICTVolume/mass flow measurementElectrical batteryPower management

A power management method is suitable for an electronic device including a controller, a processor and a battery, and includes following steps. A first power is provided to the electronic device by a power adapter, and a maximum value of the first power is smaller than a maximum value of a rated consumed power of the electronic device. A power state of a second power of the battery is obtained by the controller. A control signal is generated according to the power state, and the processor adjusts an operation performance of the processor based on the control signal. The operation performance of the processor is continuously adjusted according to the power state.

Owner:COMPAL ELECTRONICS INC

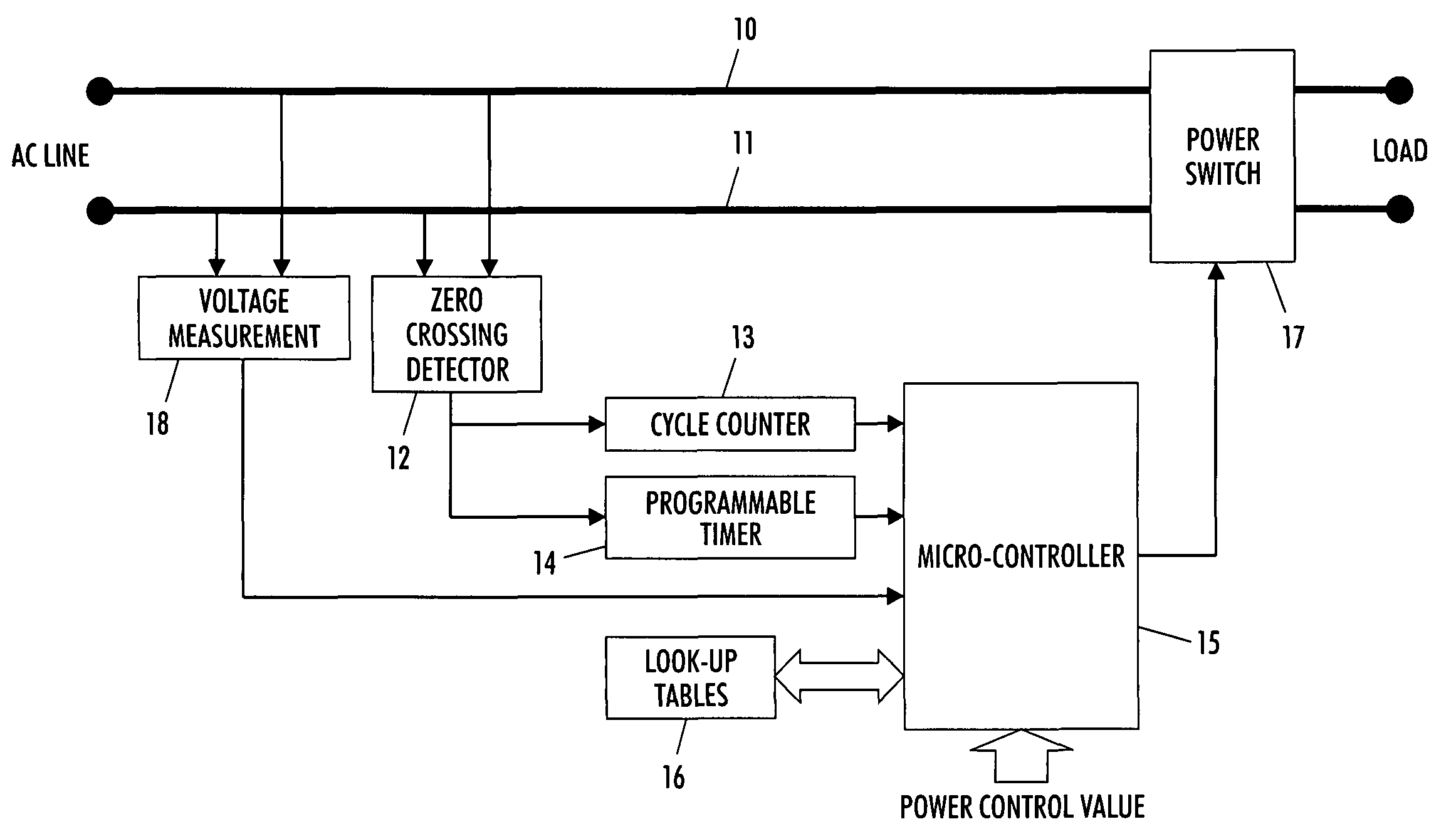

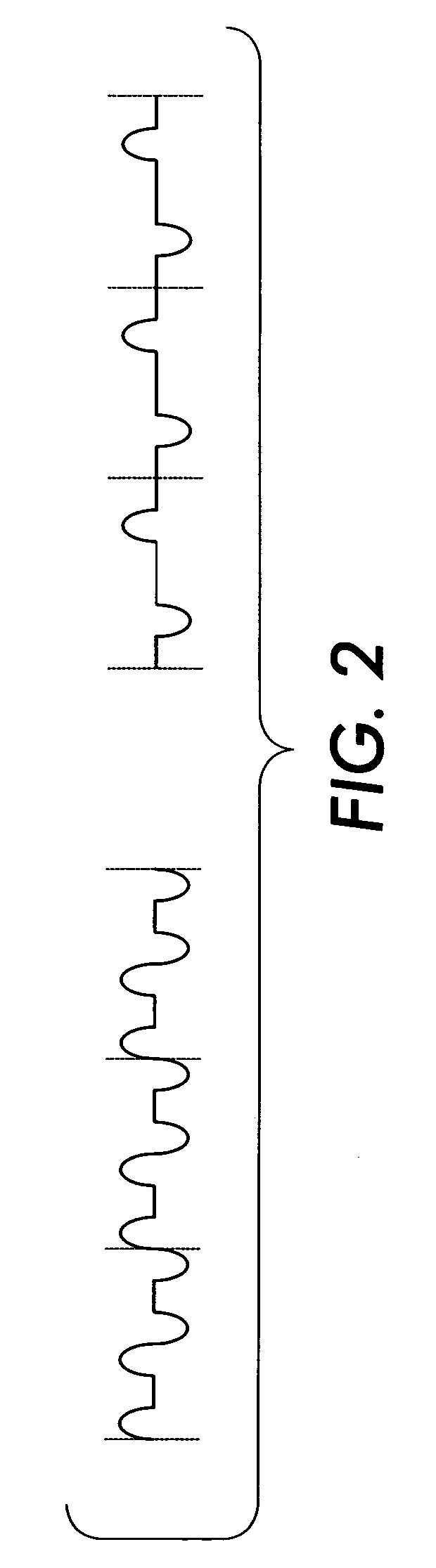

Power control using at least 540 degrees of phase

InactiveUS7893680B2Fine tuning of amountIncrease heightMultiple input and output pulse circuitsDc network circuit arrangementsHarmonicEngineering

A circuit and method for generating an electrical alternating current power signal in which the alternating current signal is dropped once at a non-zero crossing point in every 540 plus N degrees, where N is a non-negative number. This manner of controlling power to a device enables wide ranges of power control while generating acceptable levels of power line harmonics and while conforming to existing international regulations governing voltage variations.

Owner:XEROX CORP

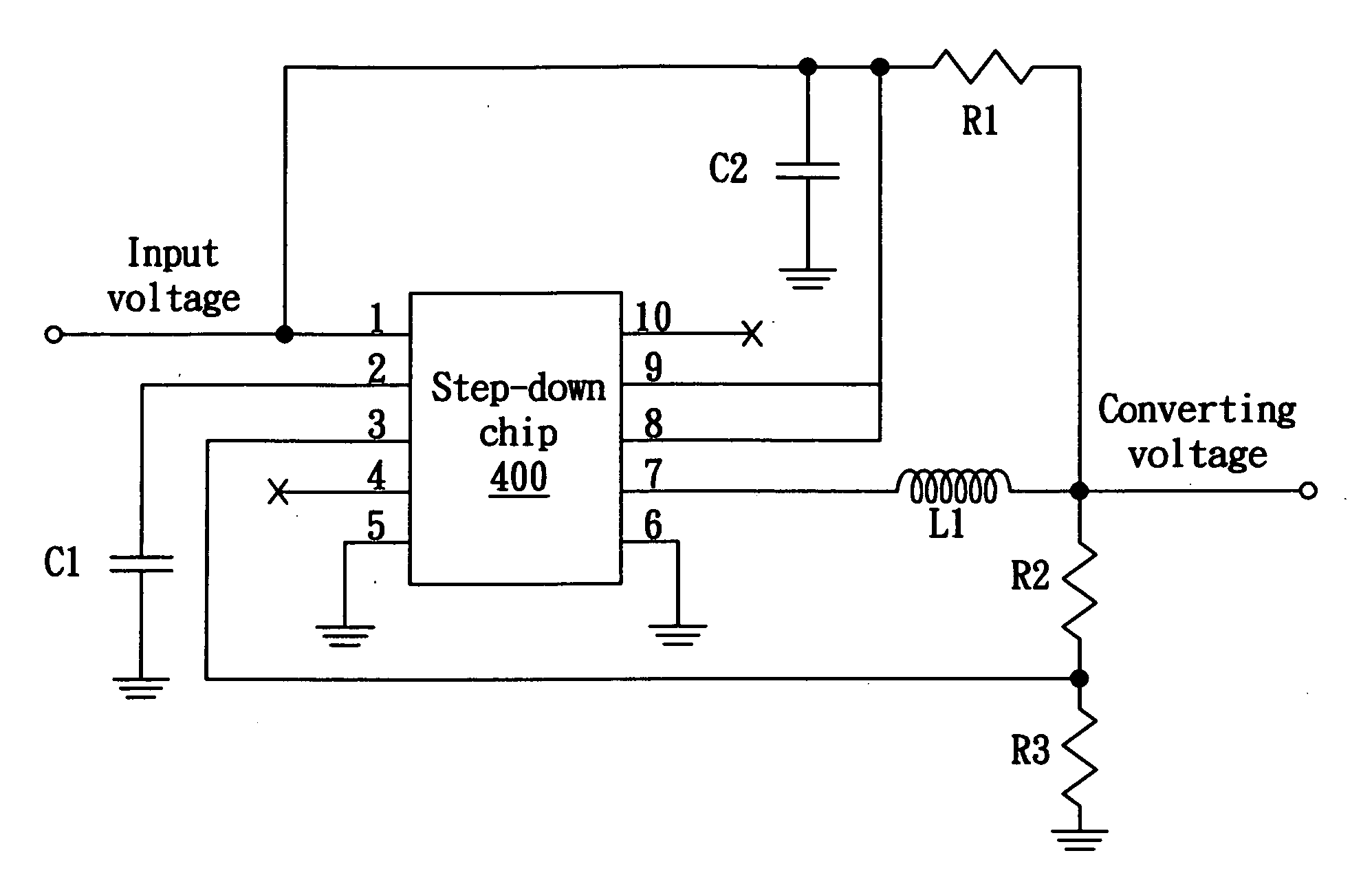

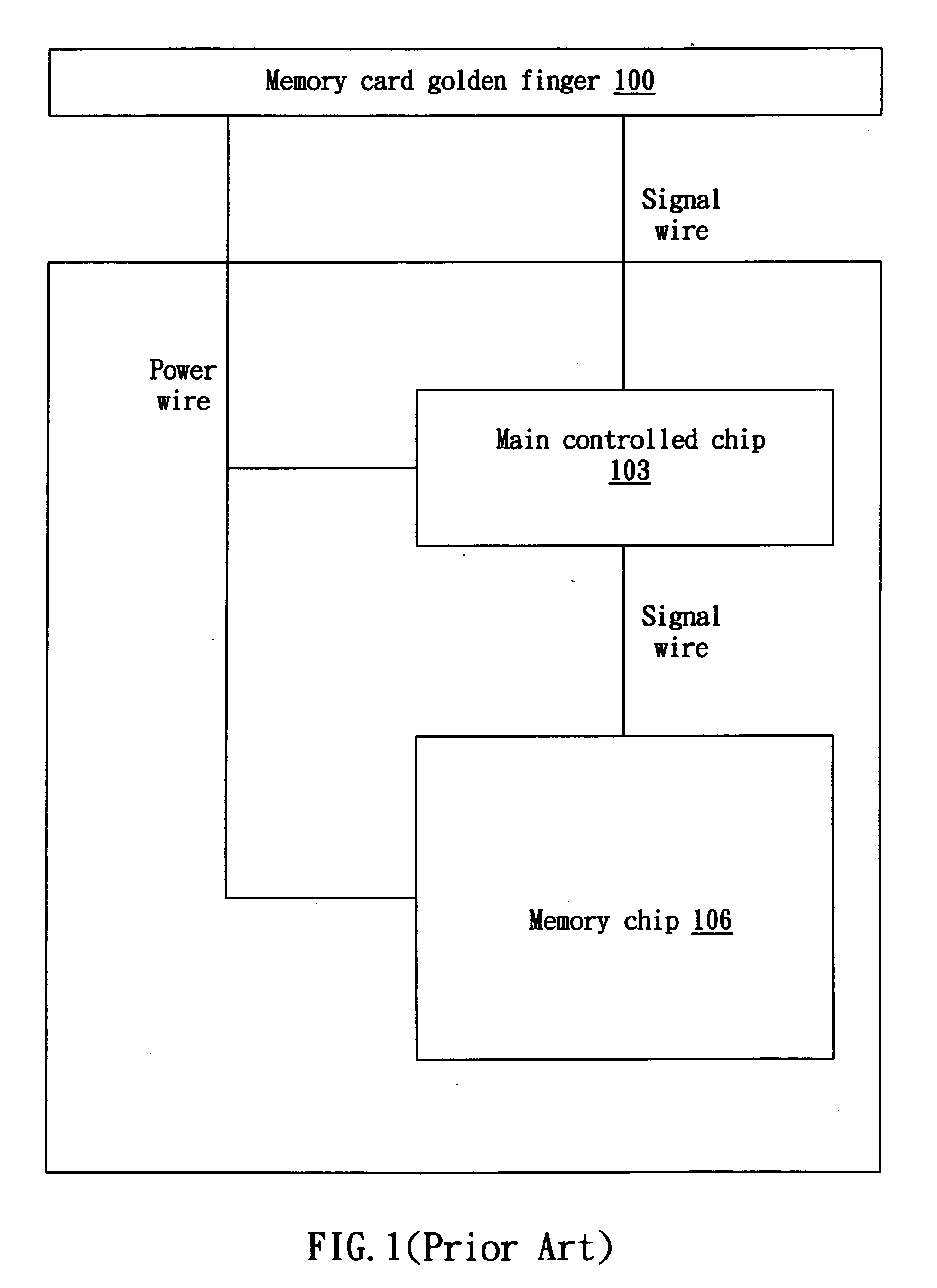

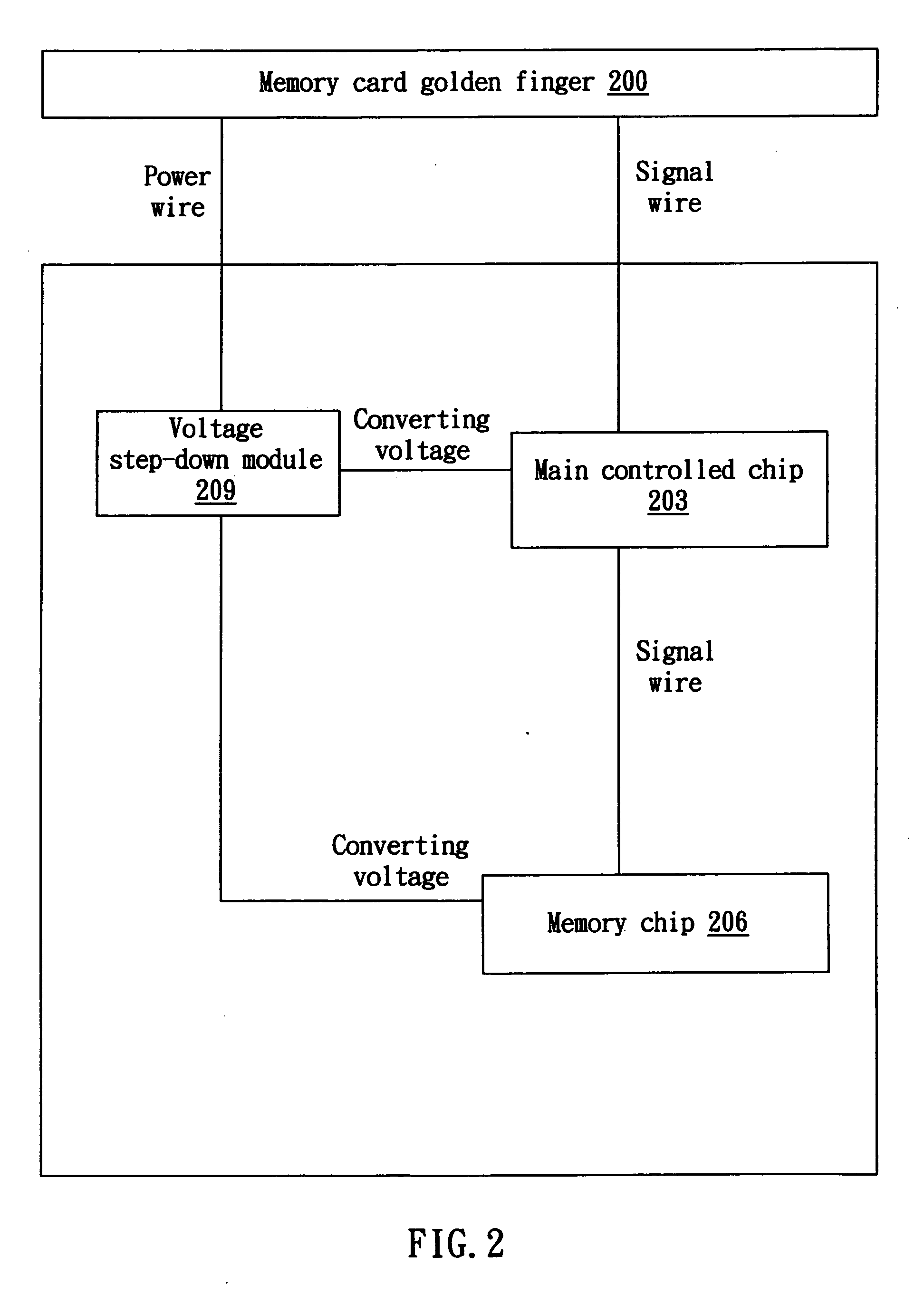

System for converting input voltage in memory card

InactiveUS20060250832A1Improve convenienceImprove efficiencyDigital storageRecord carriers used with machinesWork periodEngineering

A system in the memory card for converting the input voltage is used to provide the most suitable voltage for the internal devices. The input voltage from external device is limited by association and specification, so is not truly suitable to the voltage demand of the internal devices. This problem could cause the power loss and reduce aging of the internal devices. The present system convert the input voltage for the voltage demand of the internal devices by switching boost-up or step-down, so as to increase the power efficiency, the operation time and having more different choices in internal devices.

Owner:SILICON POWER

True Color Flat Panel Display Module

InactiveUS20080231567A1Increasing the thicknessTrue colorStatic indicating devicesFlat panel displayLight-emitting diode

A full color flat panel display module is formed of a matrix of pixels in rows and columns. Each pixel is formed of respective red, green and blue solid state light emitting diodes that can form any color on that portion of a CIE curve that falls within a triangle whose sides are formed by a line on the CIE curve between 430 nm and 660 nm, a line between 660 nm and a point between 500 and 530 nm, and a line between the 500-530 nm point and 430 nm.

Owner:CREE INC

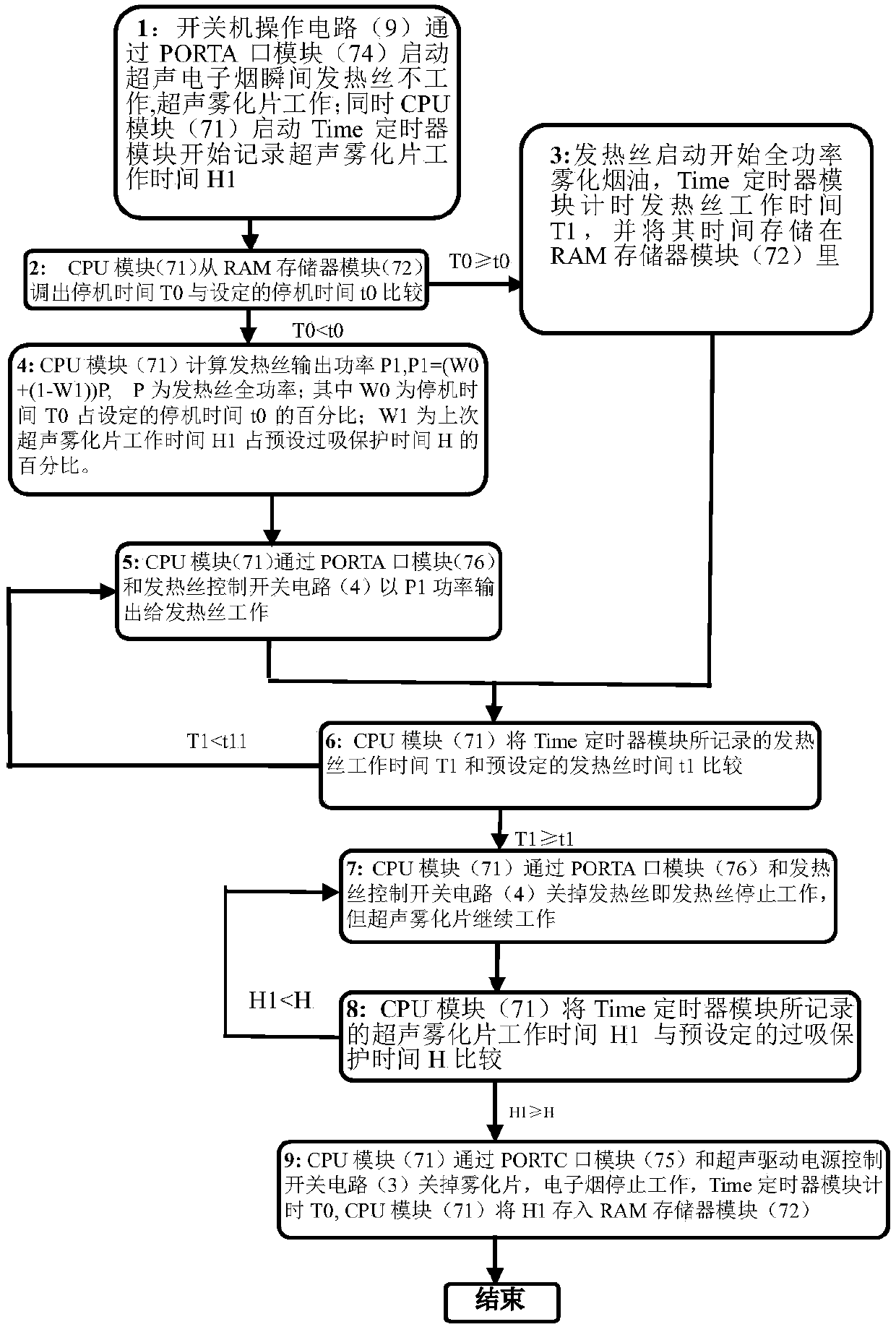

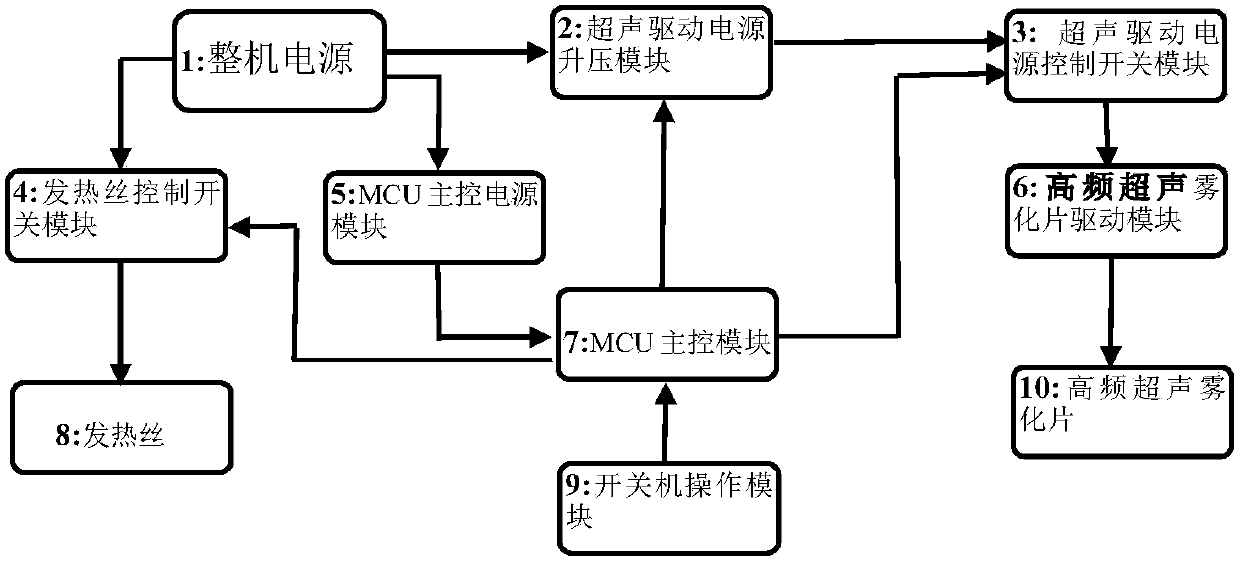

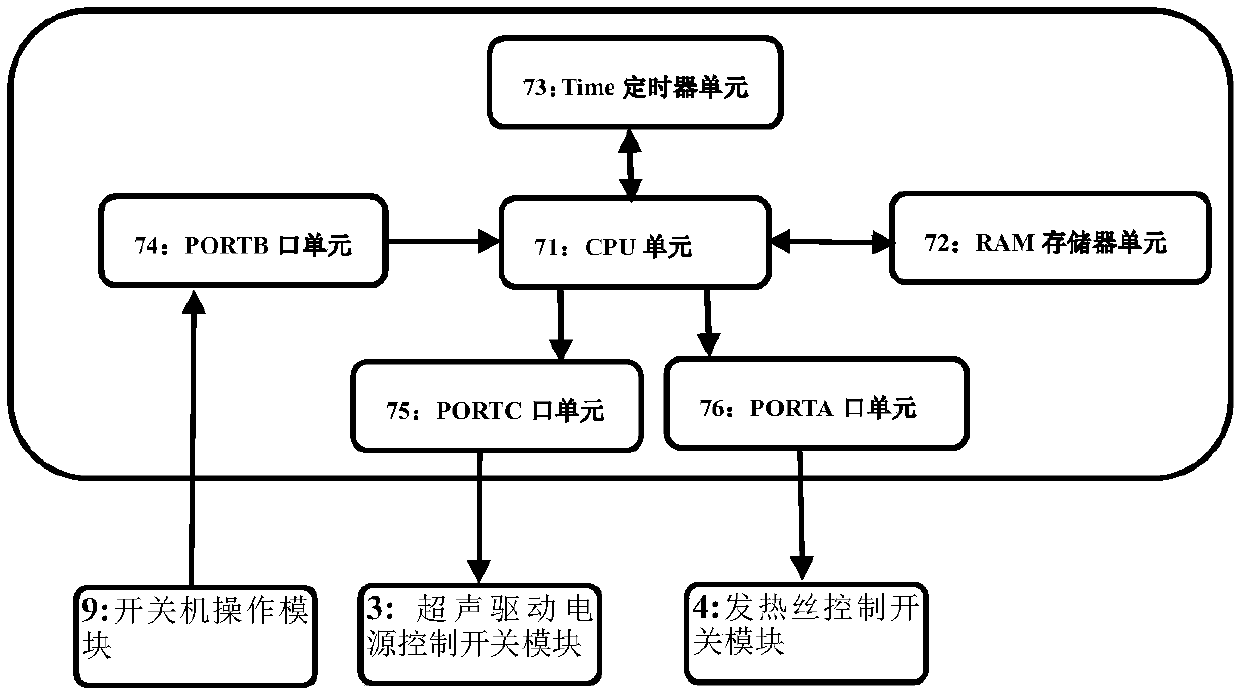

Method and circuit for ultrasonic atomization electronic cigarette control

The invention discloses a method and a circuit for ultrasonic atomization electronic cigarette control. The method comprises: starting an ultrasonic atomizing sheet to work, recording working time H1of the ultrasonic atomizing sheet; comparing downtime T0 and set downtime t0; if T0>=t0, a heating wire atomizing tobacco tar in full power, recording working time T1 of the heating wire; if T0<t0, calculating output power P1 of the heating wire; the heating wire working in the output power P1; comparing the working time T1 of the heating wire with a preset working time t1 of the heating wire, ifT1>=t1, the heating wire stopping work, the ultrasonic atomizing sheet continuing to work; comparing the working time H1 of the ultrasonic atomizing sheet with preset excessive smoking protection timeH, if H1>=H, the ultrasonic atomizing sheet stopping work, and an electronic cigarette stopping work. When the circuit is started, working state of a high-frequency ultrasonic atomizing sheet when auser smokes last time is determined to decide whether the heating wire should be started this time, and output power of the heating wire makes power utilization of the whole electronic cigarette in higher efficiency, and smoke amount of the electronic cigarette more uniform.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Infusion device and driving mechanism for same

ActiveUS20050240167A1Small thickness dimensionMinimize traumaPositive displacement pump componentsPharmaceutical delivery mechanismEngineeringBiological activation

A drive mechanism for delivery of infusion medium has a coil and an armature is moveable toward a forward position, in response to the electromagnetic field produced by activation of the coil. A piston is moveable axially within a piston channel to a forward position, in response to movement of the armature to its forward position. The armature and piston are moved toward a retracted position, when the coil is not energized. In the retracted position of the piston, a piston chamber is formed between the piston and a valve member and is filled with infusion medium. As the piston is moved to its forward position, the piston chamber volume is reduced and pressure within the piston chamber increases to a point where the pressure moves the valve member into an open position through an outlet.

Owner:MEDTRONIC MIMIMED INC

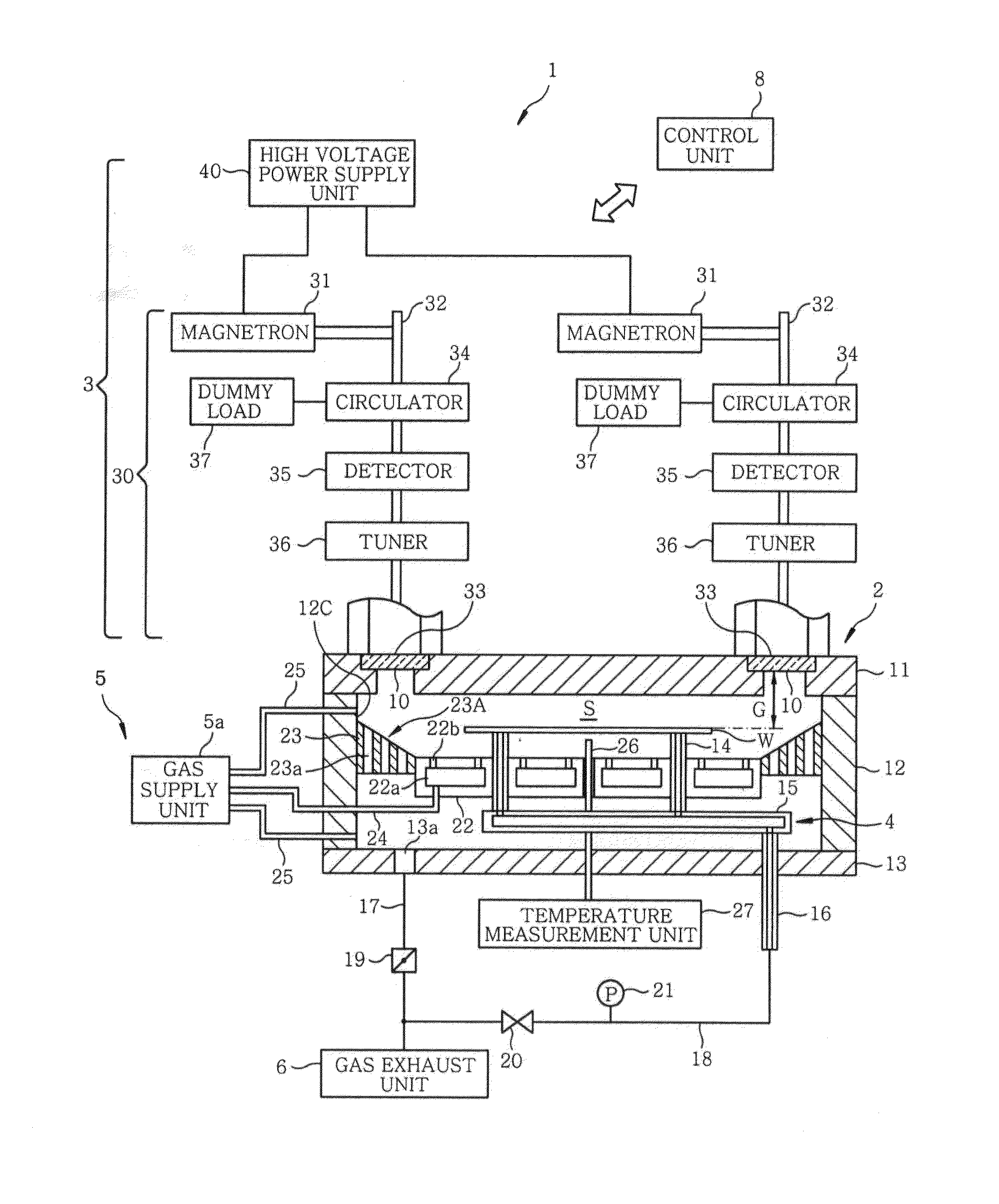

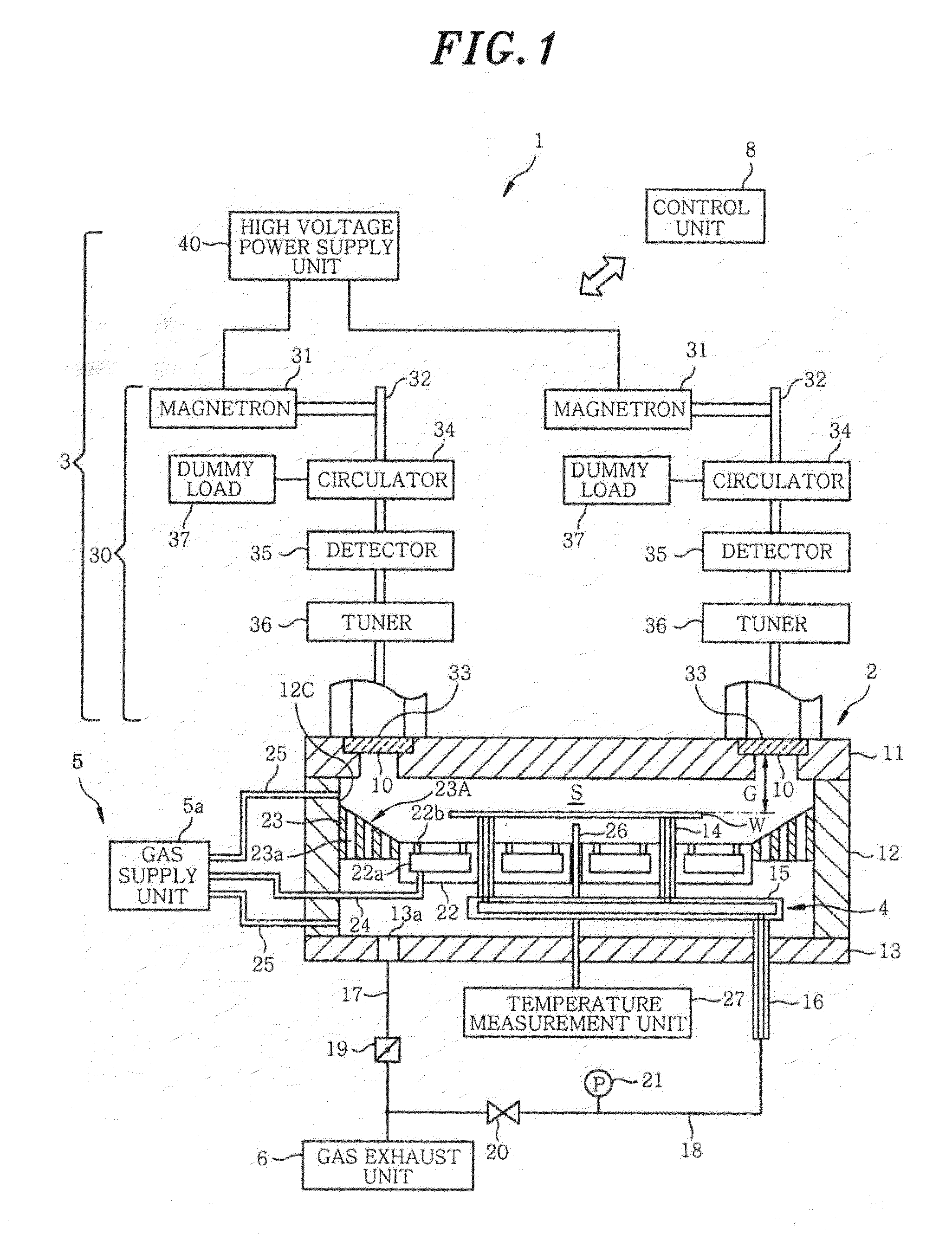

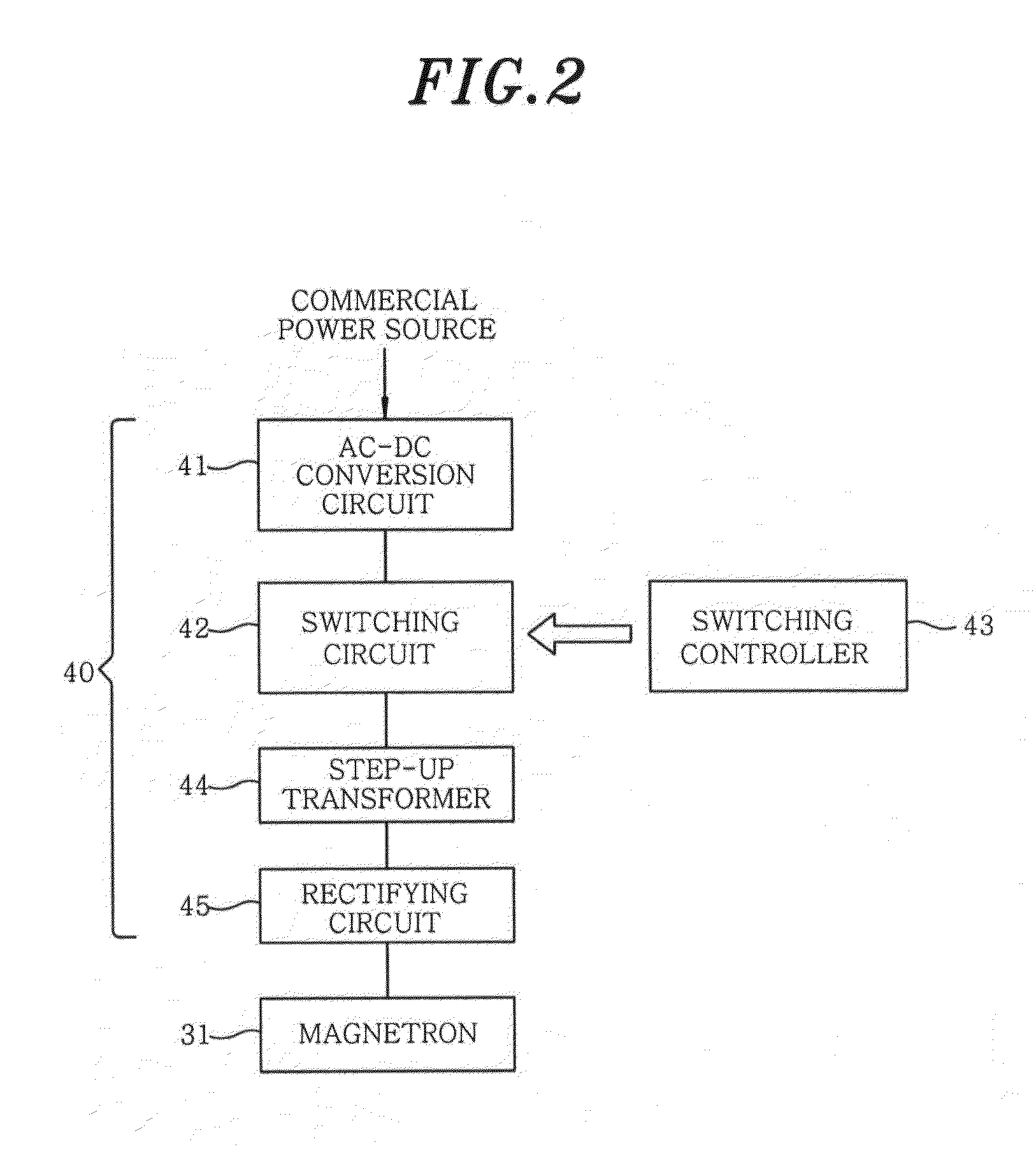

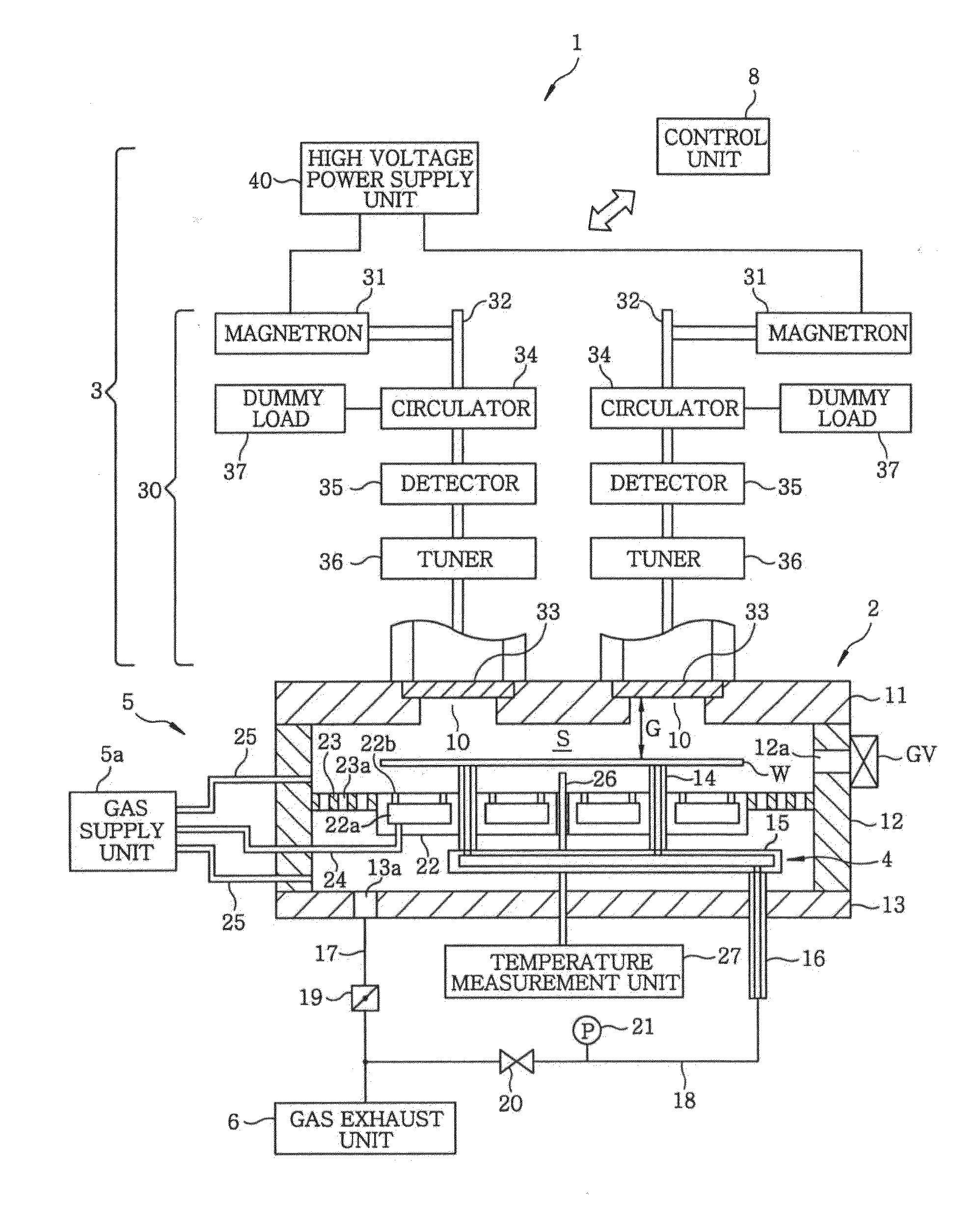

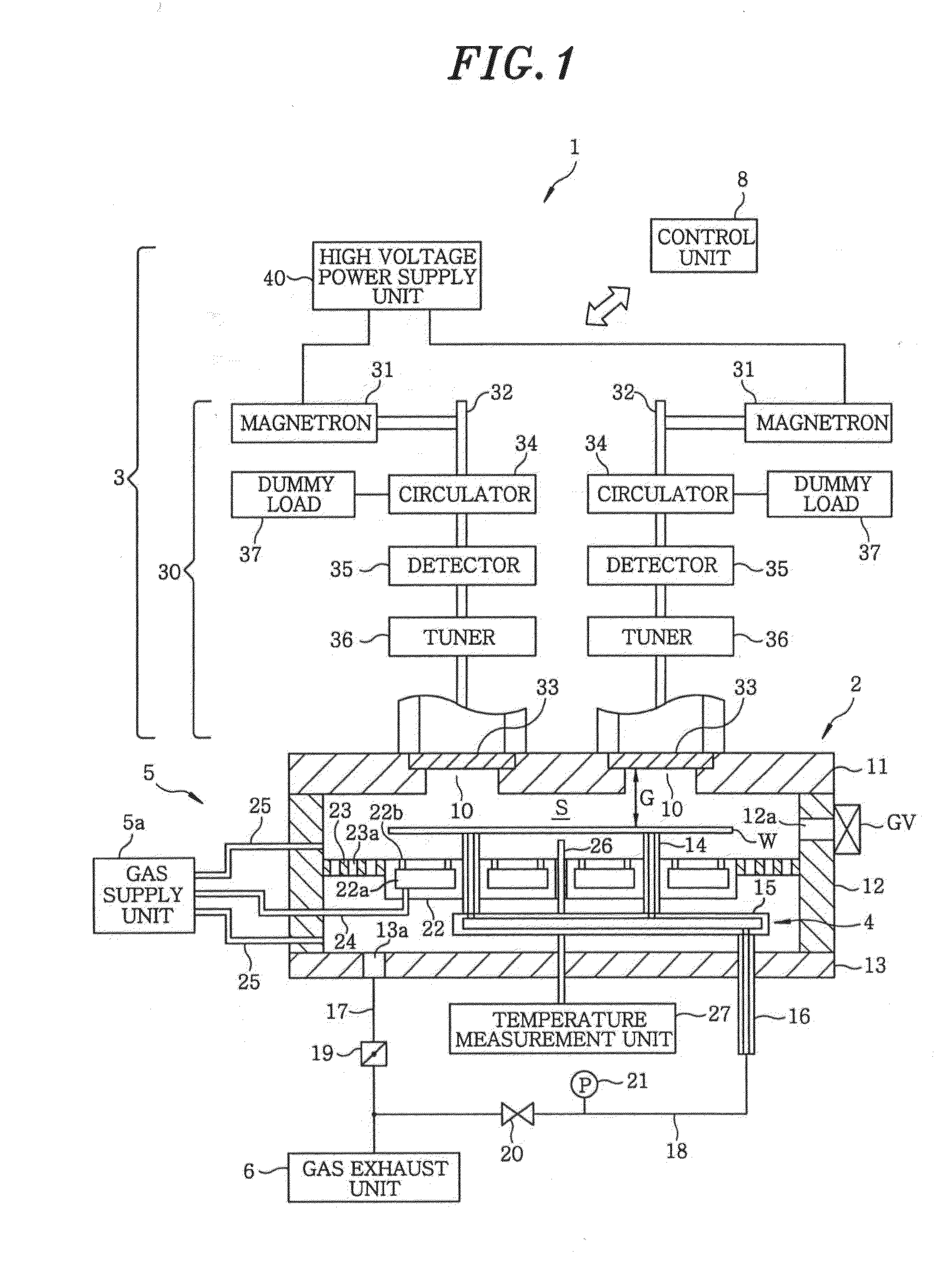

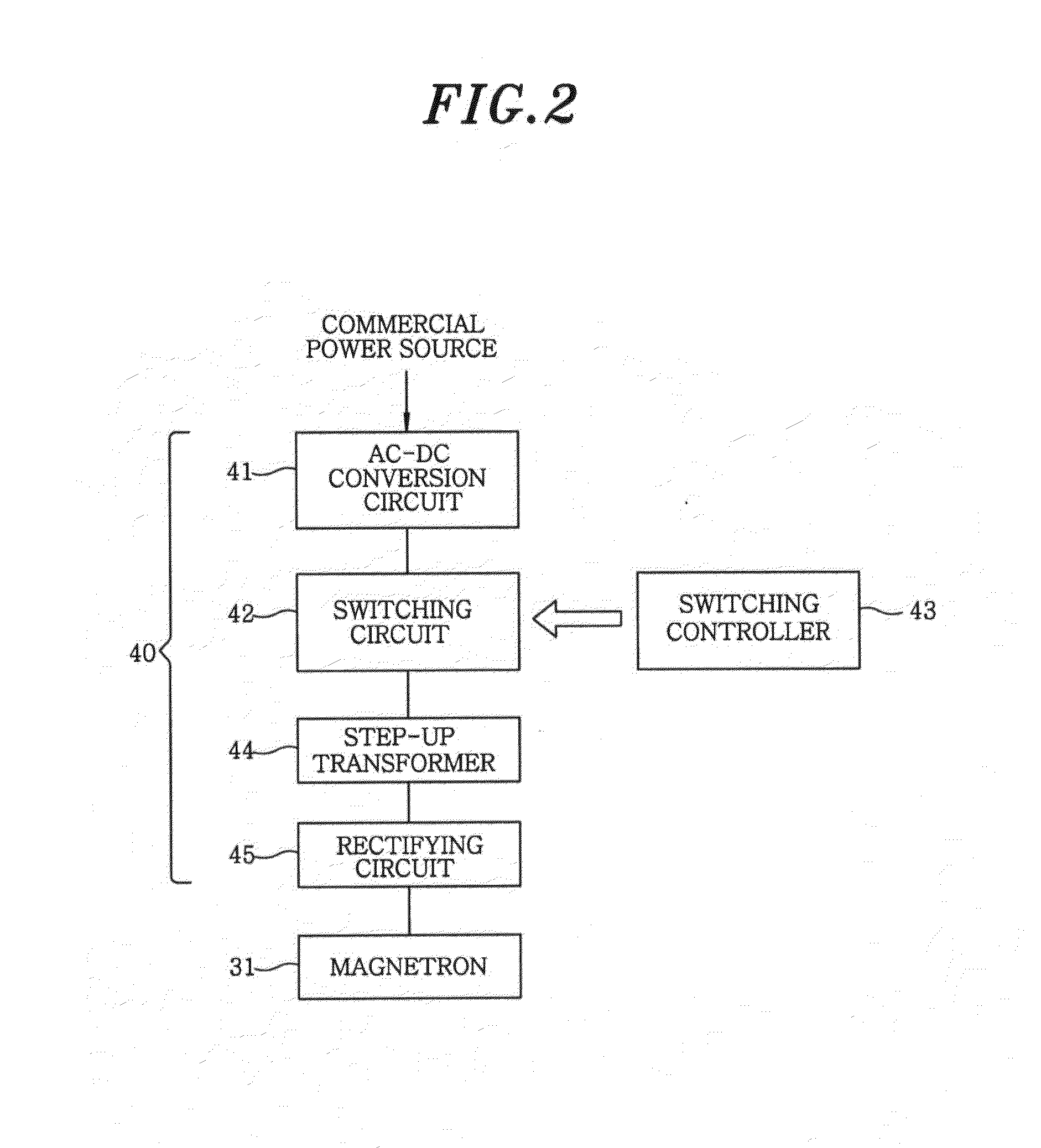

Microwave heating apparatus and processing method

InactiveUS20130168389A1Uniform processingImprove efficiencySemiconductor/solid-state device manufacturingMicrowave heatingMicrowaveElectrical and Electronics engineering

Four microwave introduction ports are arranged to deviate from directly above a wafer in such a way that the long sides thereof are in parallel to at least one of the four straight sides. The top surface of a rectifying plate which surrounds the wafer is inclined so as to be widened from the side of the wafer (inner side) toward the side of a sidewall portion (outer side) to form an inclined portion. The inclined portion is disposed to face the four microwave introduction ports in a vertical direction.

Owner:TOKYO ELECTRON LTD

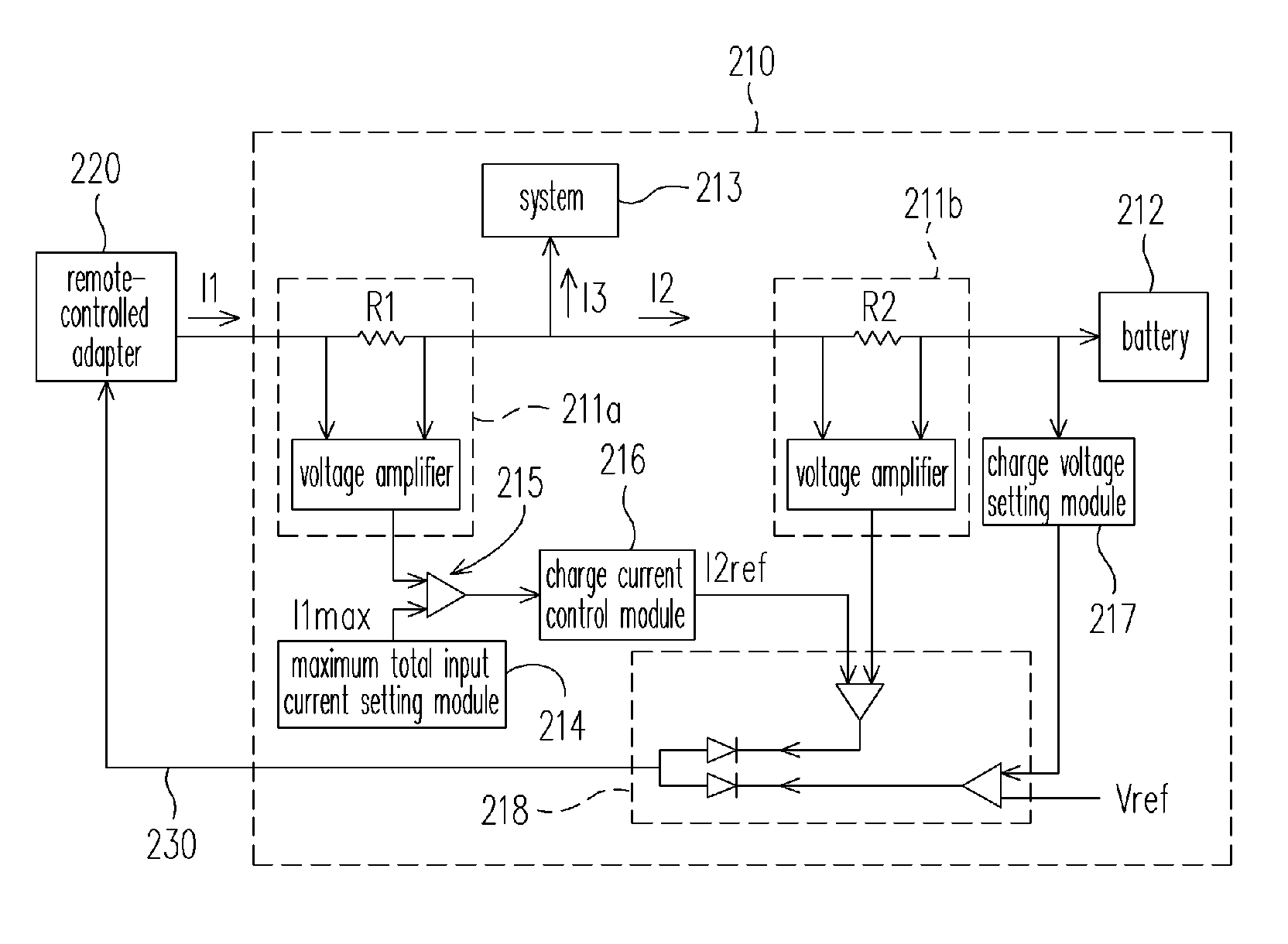

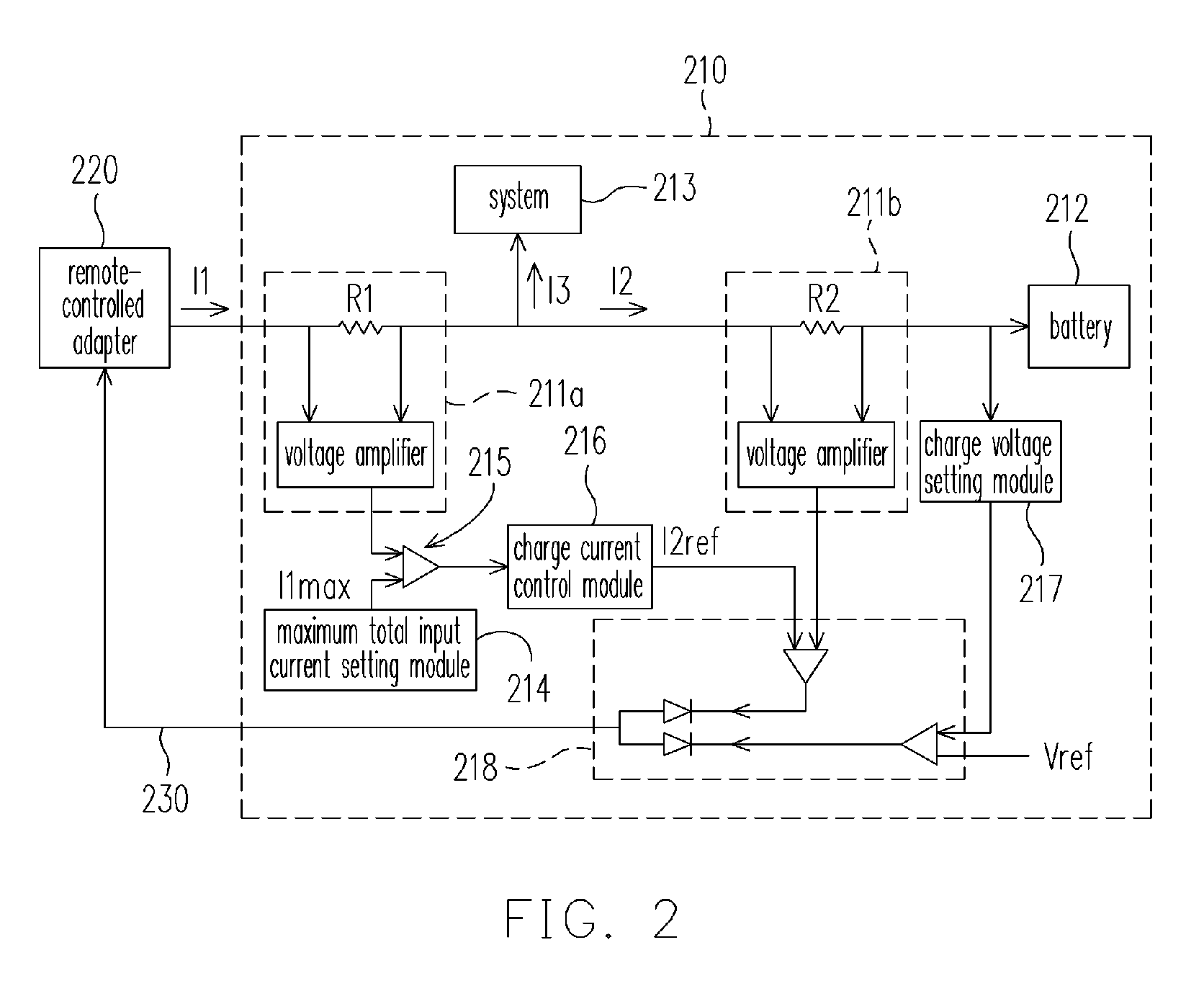

Power control apparatus

ActiveUS7692403B2Ensure safetyEfficient use of powerElectric powerBattery load switchingCharge currentRemote control

A power control apparatus and method for an electronic device is provided, which utilizes a charge current control module and a feedback signal control module to transfer the power control signal to a remote-controlled adapter through a feedback circuit, to control the output voltage of the remote-controlled adapter so as to adjust the charge current until the total input current supplied by the remote-controlled adapter is equal to the highest total input current. Therefore, the system of the electronic device can be provided with sufficient power to process needed procedures in a safe condition. Besides, according to the power required by the system of the electronic device, the controller can distribute the power for both the system and the battery in order to improve the efficiency of power use.

Owner:COMPAL ELECTRONICS INC

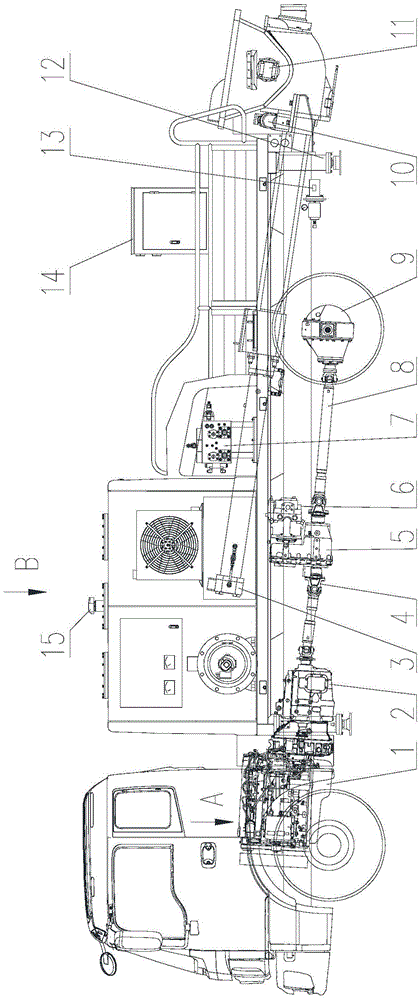

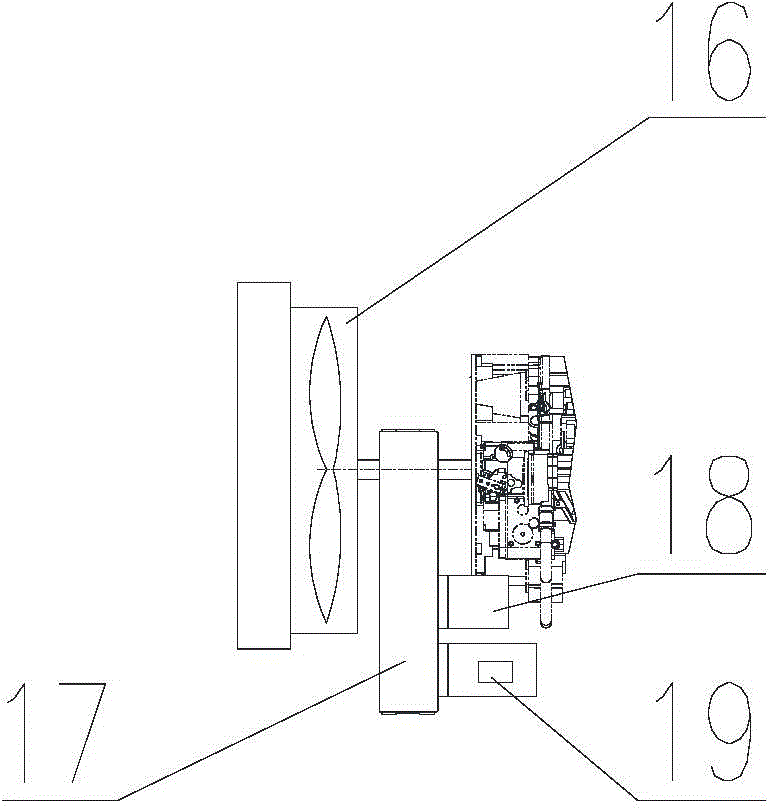

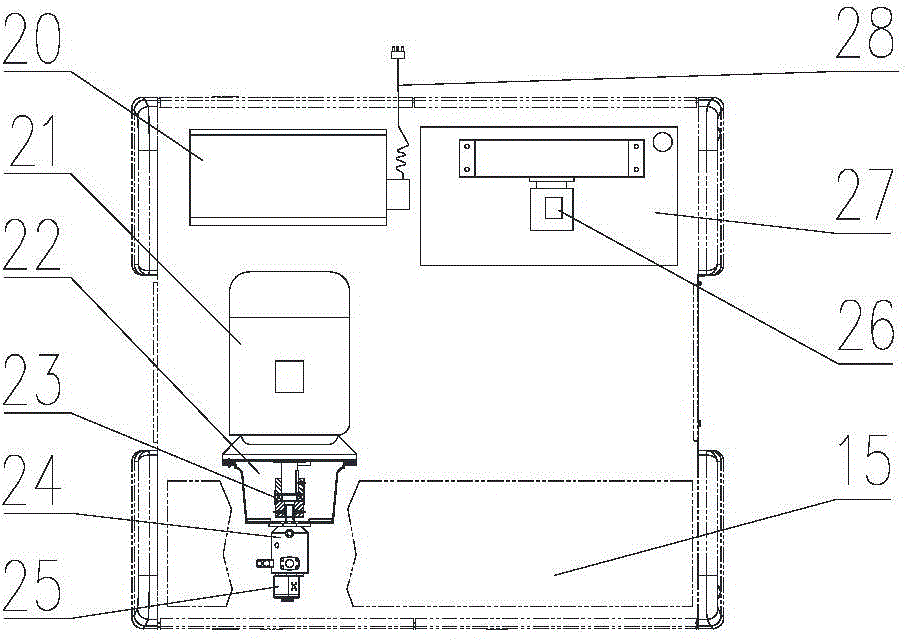

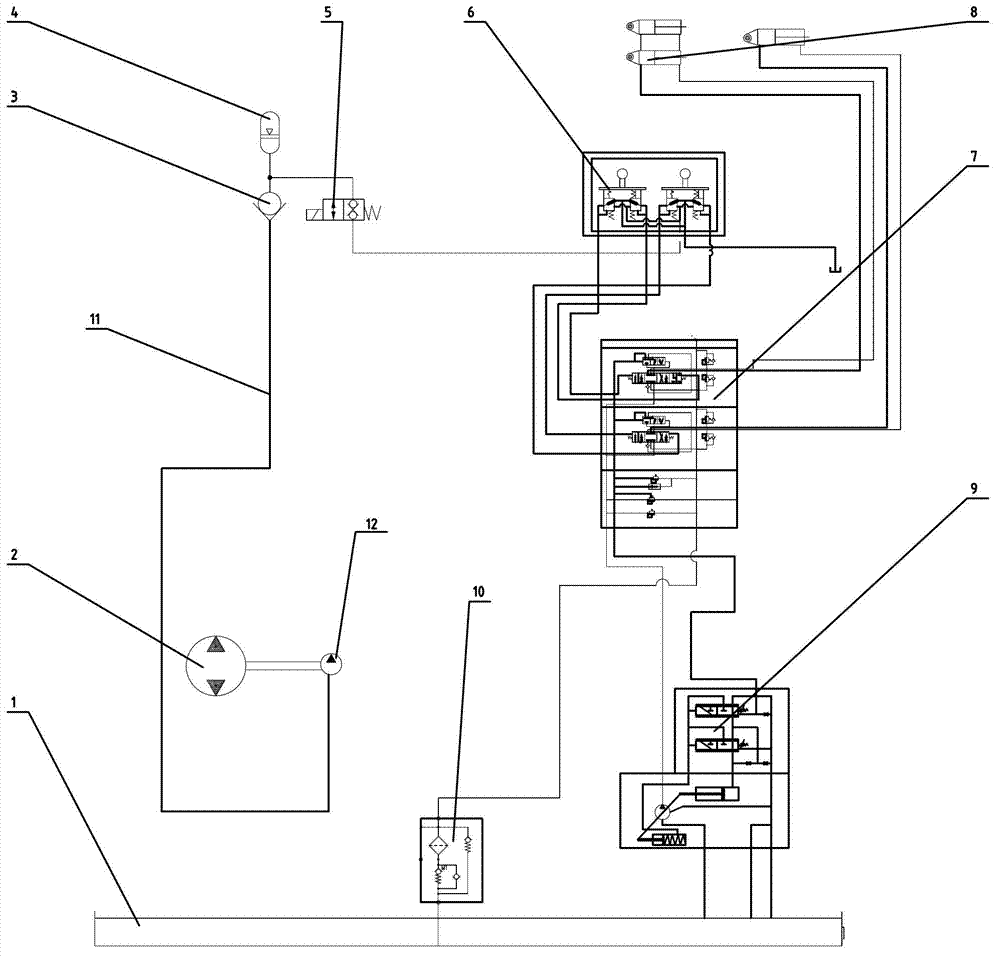

Vehicle-mounted concrete pump truck

InactiveCN104827903AExtended service lifeReduce pollution dischargeAuxillary drivesDistribution systemEngineering

The invention provides a vehicle-mounted concrete pump truck, which comprises an engine, a power supply system, a feeding system, a distribution system and a stirring system, wherein the feeding system is connected with the engine and pumps material under driving of the engine; the distribution system is connected with the power supply system and distributes material under driving of the power supply system; and the stirring system is connected with the power supply system and stirs material under driving of the power supply system.

Owner:BEIQI FOTON MOTOR CO LTD

Microwave heating apparatus and processing method

ActiveUS20130168390A1Efficient use of powerImprove heating efficiencySemiconductor/solid-state device manufacturingMicrowave heatingMicrowaveElectrical and Electronics engineering

In the microwave heating apparatus, four microwave introduction ports are arranged at positions spaced apart from each other at an angle of about 90° in a ceiling portion of a processing chamber in such a way that the long sides and the short sides thereof are in parallel to inner surfaces of four sidewalls. The microwave introduction port are disposed in such a way that each of the microwave introduction ports are not overlapped with another microwave introduction port whose long sides are in parallel to the long sides of the corresponding microwave introduction port when the corresponding microwave introduction port is moved in translation in a direction perpendicular to the long sides thereof.

Owner:TOKYO ELECTRON LTD

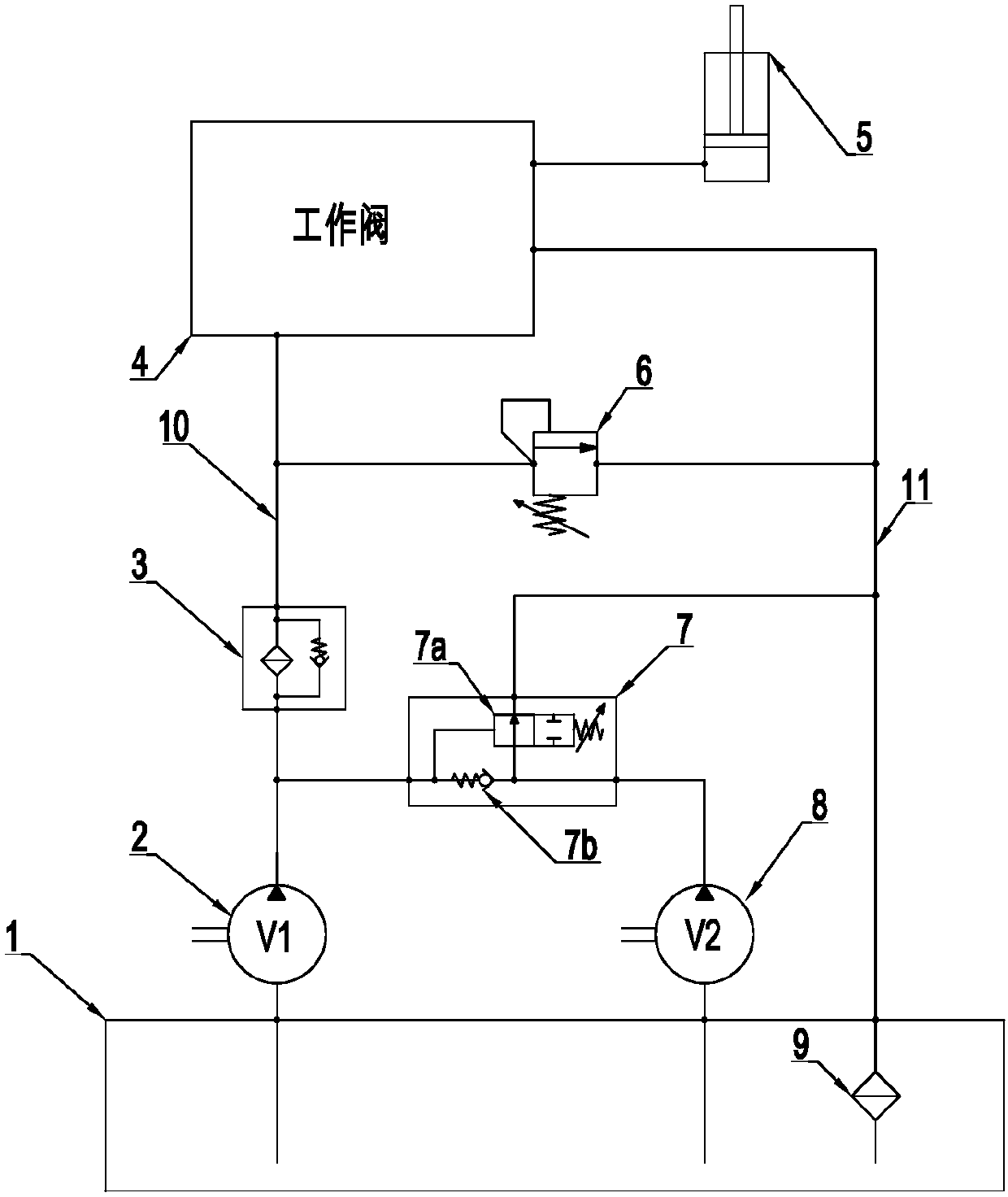

Load-sensitive operation system of loading machine

ActiveCN103114624AControl temperature riseEfficient use of powerSoil-shifting machines/dredgersPlunger pumpEngineering

The invention relates to a loading machine, in particular to a load-sensitive operation system of the loading machine. An oil outlet of a travelling plunger pump is connected with a first pipeline, an energy accumulator and a two-position two-way electromagnetic reversing valve are connected at one end of the first pipeline in parallel, and the other end of the two-position two-way electromagnetic reversing valve is connected into an oil inlet of a pilot operated valve. A control oil port of the piloted operated valve is connected with a control port of a load-sensitive multi-path valve through a pipeline, an oil outlet of the pilot operated valve is connected with an oil tank, and a feedback oil port of the load-sensitive multi-path valve is connected with a feedback oil port of a working plunger pump. Control oil of the pilot operated valve in the load-sensitive operation system of the loading machine is supplied by an oil compensating pump in the travelling plunger pump, and one conventional pilot pump for supply oil is omitted and substituted. The working plunger pump adjusts pressure-flow output via the feedback oil port of the load-sensitive multi-path valve according to load changes, engine power is effectively utilized, temperature rise of hydraulic oil is controlled, and energy saving and environment friendliness are realized.

Owner:WUXI KIPOR MACHINERY CO LTD

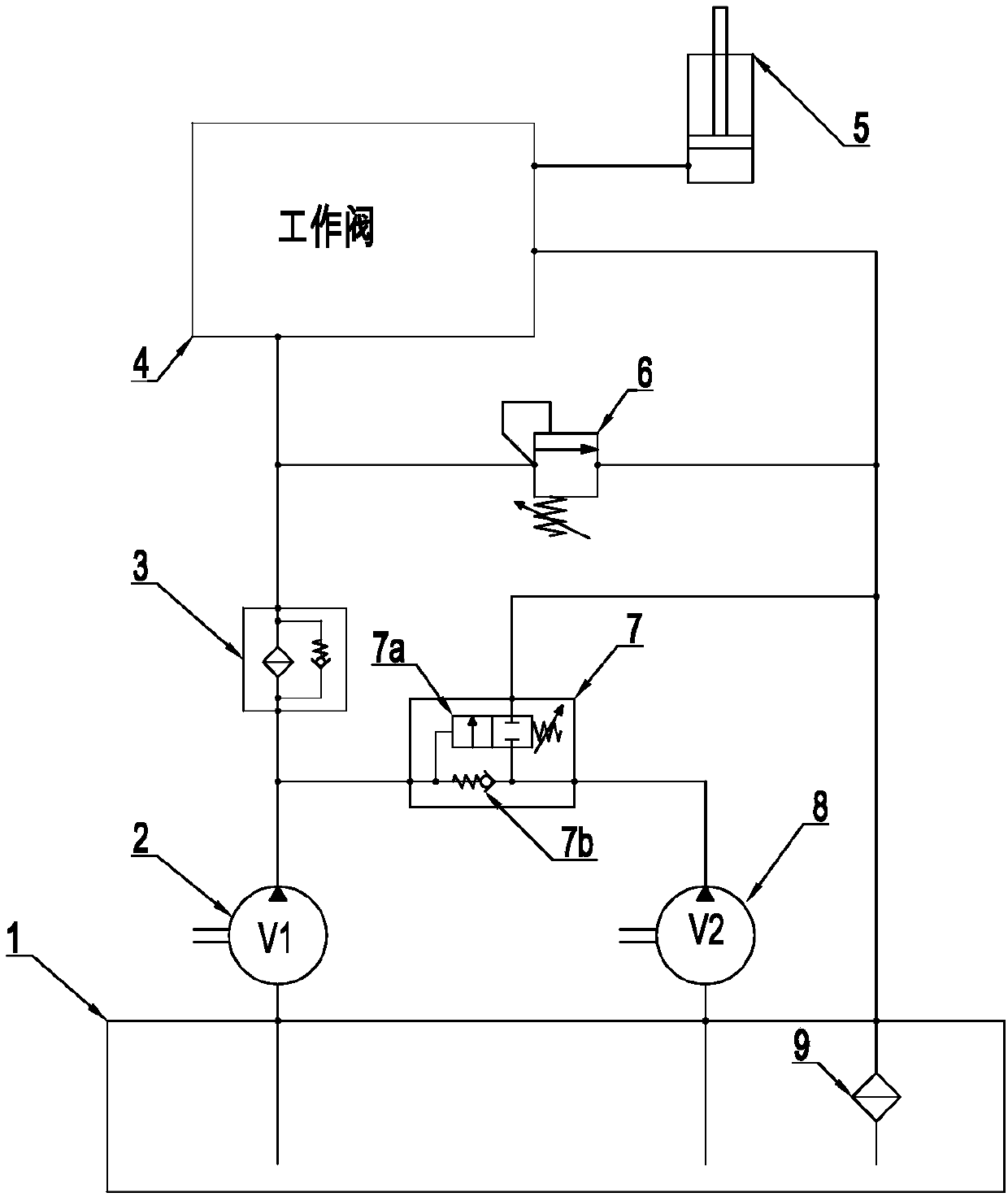

Hydraulic system and control method capable of providing suitable performance for load

ActiveCN107725504AMeet the performance needs of high load conditionsEfficient use of powerServomotor componentsServomotorsHydraulic pumpEngineering

The invention discloses a hydraulic system and control method capable of providing suitable performance for a load. The hydraulic system comprises a working valve of an industrial machine or an engineering machine and further comprises at least one first hydraulic pump, at least one second hydraulic pump and a control valve. The working valve is connected with an execution mechanism; the first hydraulic pumps are configured to provide pressure oil for the working valve; the second hydraulic pumps are configured to provide the pressure oil for the working valve when the working oil pressure ofthe working valve is smaller than a set value; and the control valve is used for controlling the second hydraulic pumps to provide the oil for the working valve or not provide the oil for the workingvalve, and the control valve is connected in the position, between an oil outlet of one of the second hydraulic pumps and an oil inlet of the working valve, of an oil way. The suitable hydraulic performance can be provided for the actual load; the performance requirement of a forklift under the high-load working condition can be met, and the performance requirement of the forklift under the low-load working condition can be further met; and the power of an engine can be utilized effectively.

Owner:LINDE CHINA FORKELEVATOR TRUCK CORP

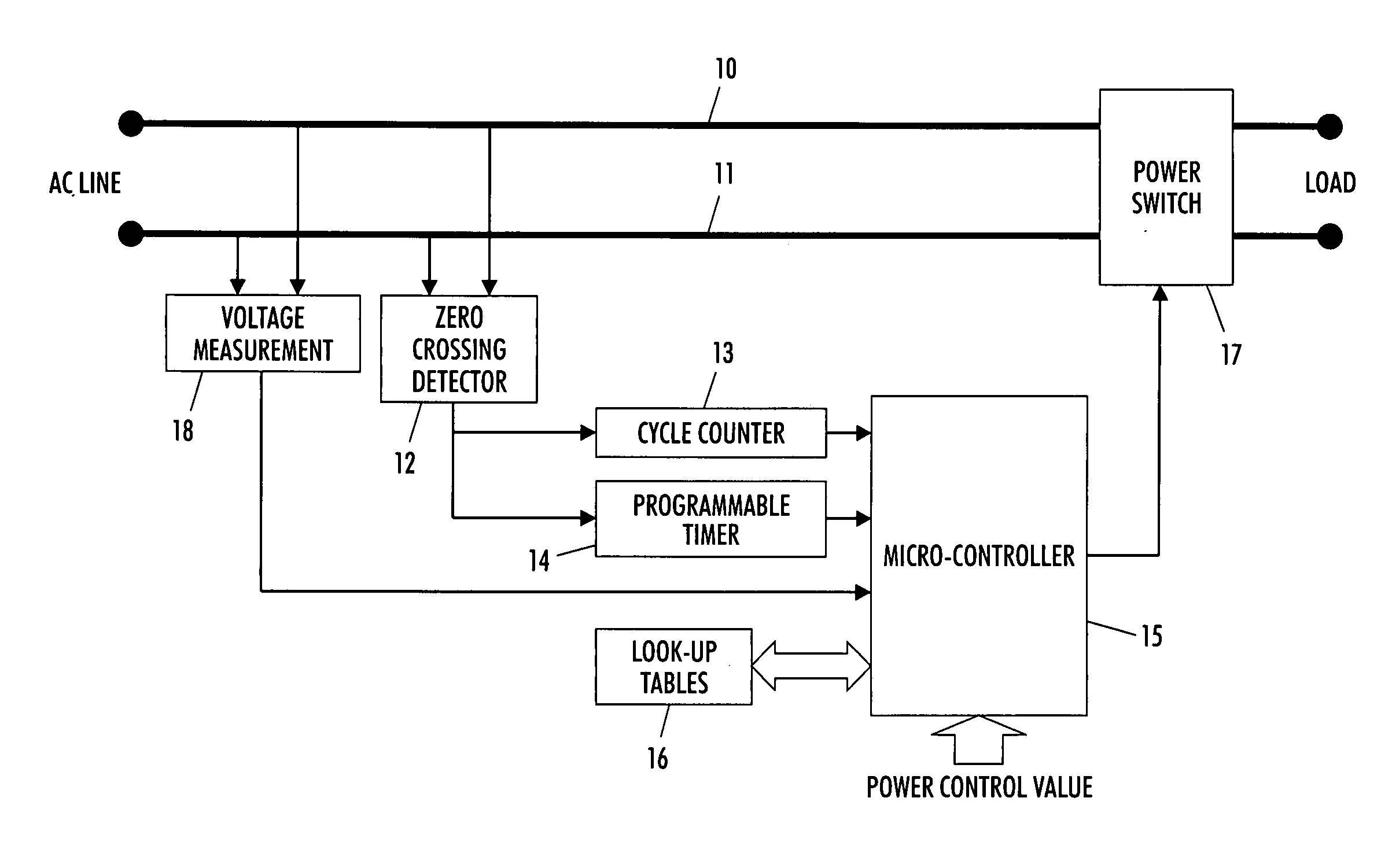

Power control using at least 540 degrees of phase

InactiveUS20060097758A1Minimize signal artifactConvenient power controlMultiple input and output pulse circuitsDc network circuit arrangementsHarmonicEngineering

An electrical alternating current power signal and a circuit and method for generating the same in which the alternating current signal is dropped once at a non-zero crossing point in every 540 plus N degrees, where N is a non-negative number. This manner of controlling power to a device enables wide ranges of power control while generating acceptable levels of power line harmonics and while conforming to existing international regulations governing voltage variations.

Owner:XEROX CORP

Charging methods for battery powered devices

ActiveUS8080976B2Accurate balanceEfficient use of powerCharge equalisation circuitSecondary cells charging/dischargingBattery chargeChemical composition

Owner:TOWER SEMICONDUCTOR

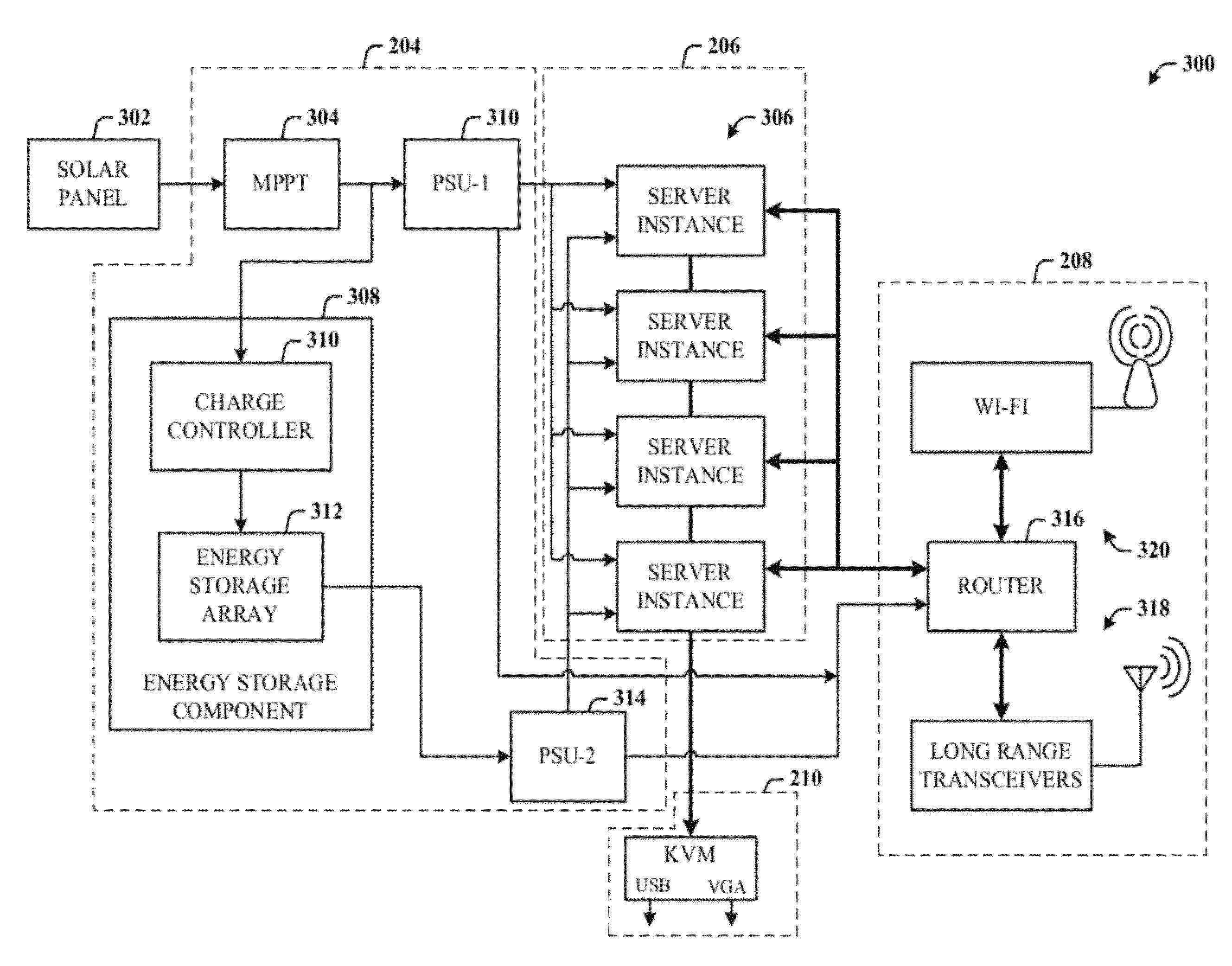

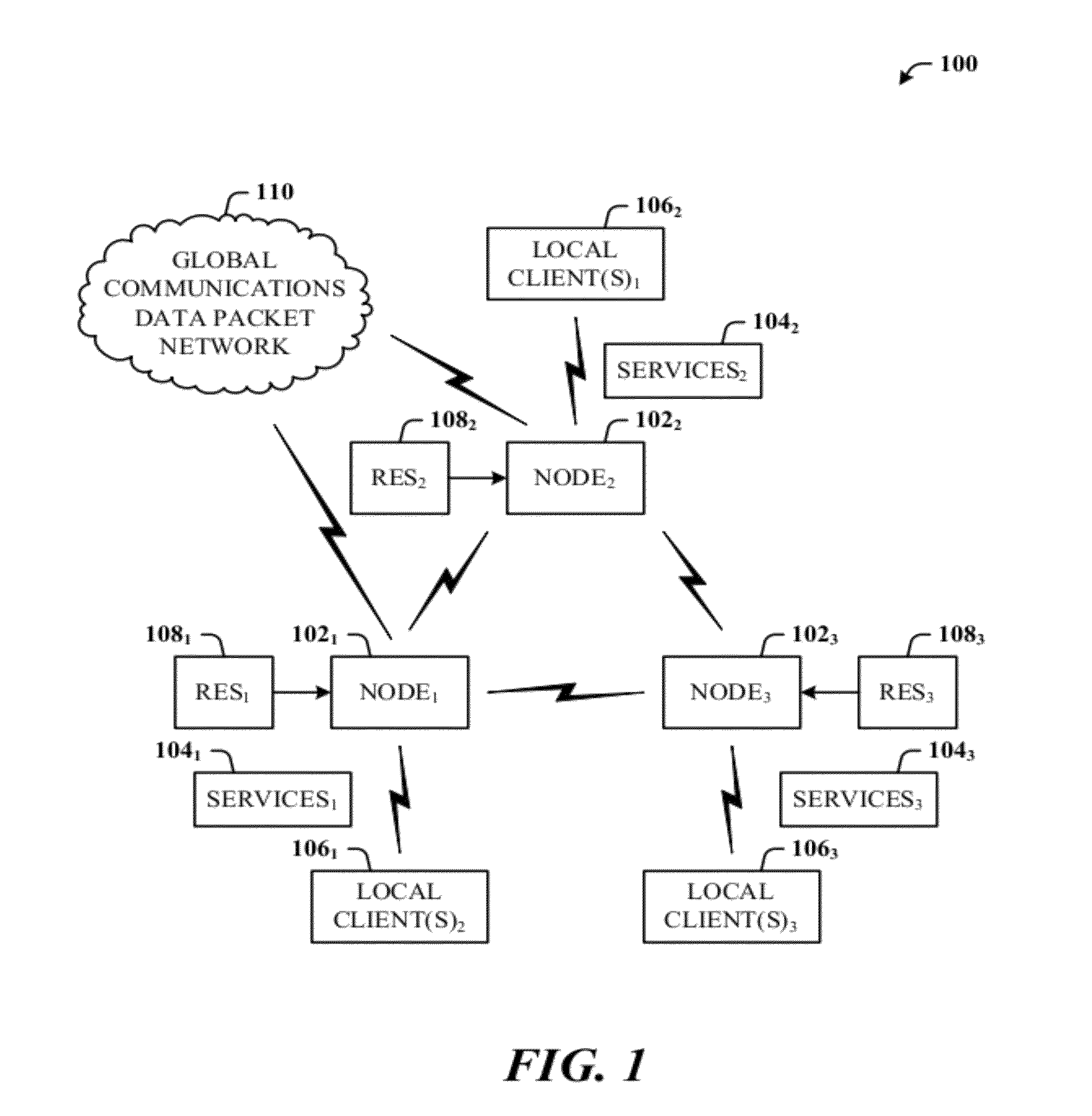

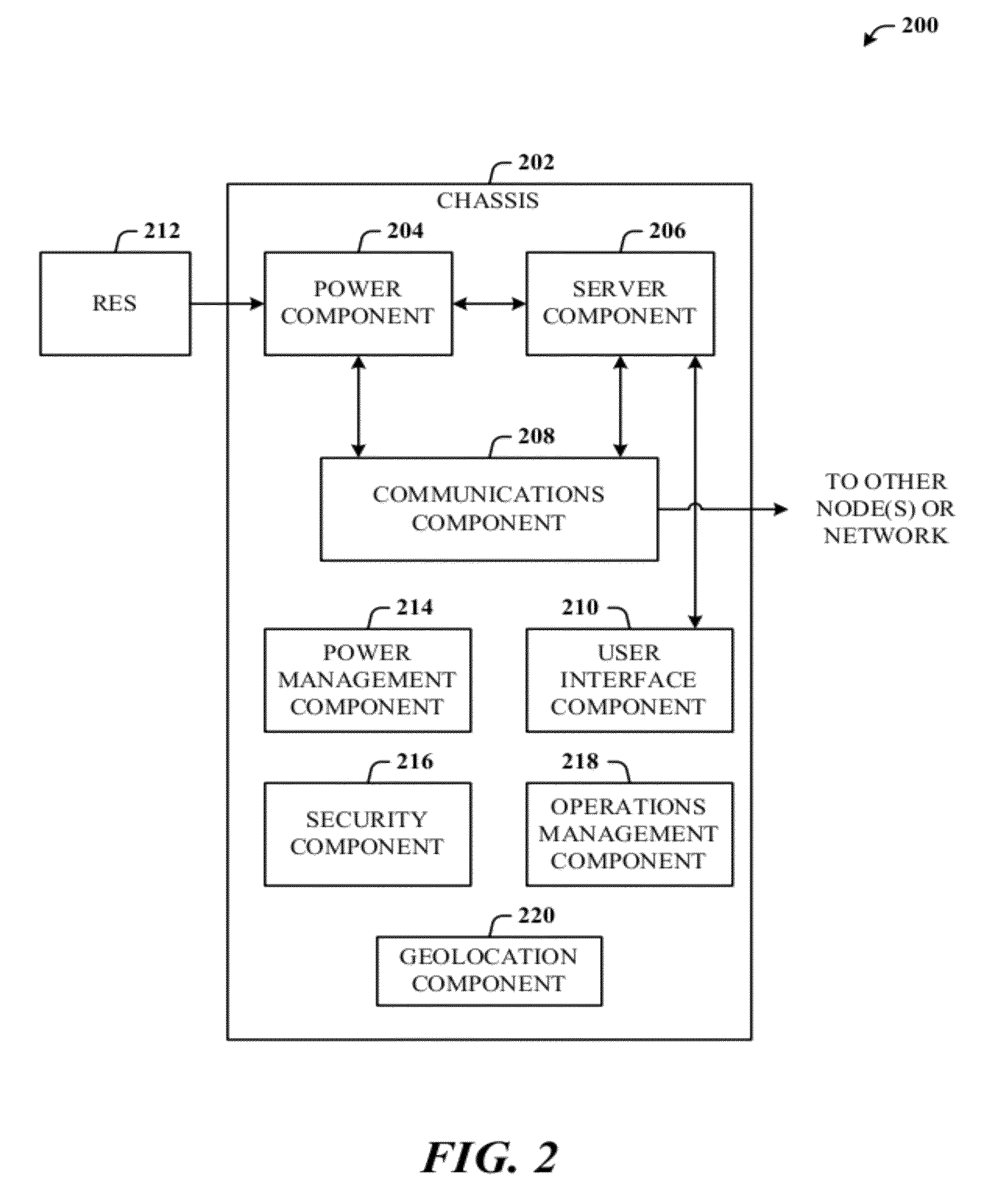

Wireless cloud-based computing for rural and developing areas

A framework that enables a local computing cloud infrastructure for rural (and third world) populations with the ability to connect into the global cloud. The framework include is a low cost architecture of long distance, wireless based, renewable energy powered, and small datacenter (DC) (referred to as a pico-DC) nodes that can fully operate off-grid, both power-wise and Internet connection-wise at a very low cost. Additionally, the framework includes power management and storage techniques that effectively enable low power and efficient power use. Thus, systems are self-sufficient, low maintenance and weather proof with no need for power or data connections.

Owner:MICROSOFT TECH LICENSING LLC

Distribution apparatus

ActiveUS9553467B2Efficient use of powerEfficient powerElectric power distributionPower installationsElectric power systemActuator

Disclosed herein is an invention of a power system including a distal distributor, an electric actuator which receives a supply of power from the distal distributor, and a relay device. Regenerative power generated by the electric actuator is output to a storage battery.

Owner:NABLESCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com