Method and circuit for ultrasonic atomization electronic cigarette control

An ultrasonic atomization and control circuit technology, applied in the field of electronic cigarettes, can solve the problems of high output power, cracking into carbon monoxide, affecting human health, etc., to achieve uniform smoke output, reduce the formation of harmful substances, and efficiently utilize power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

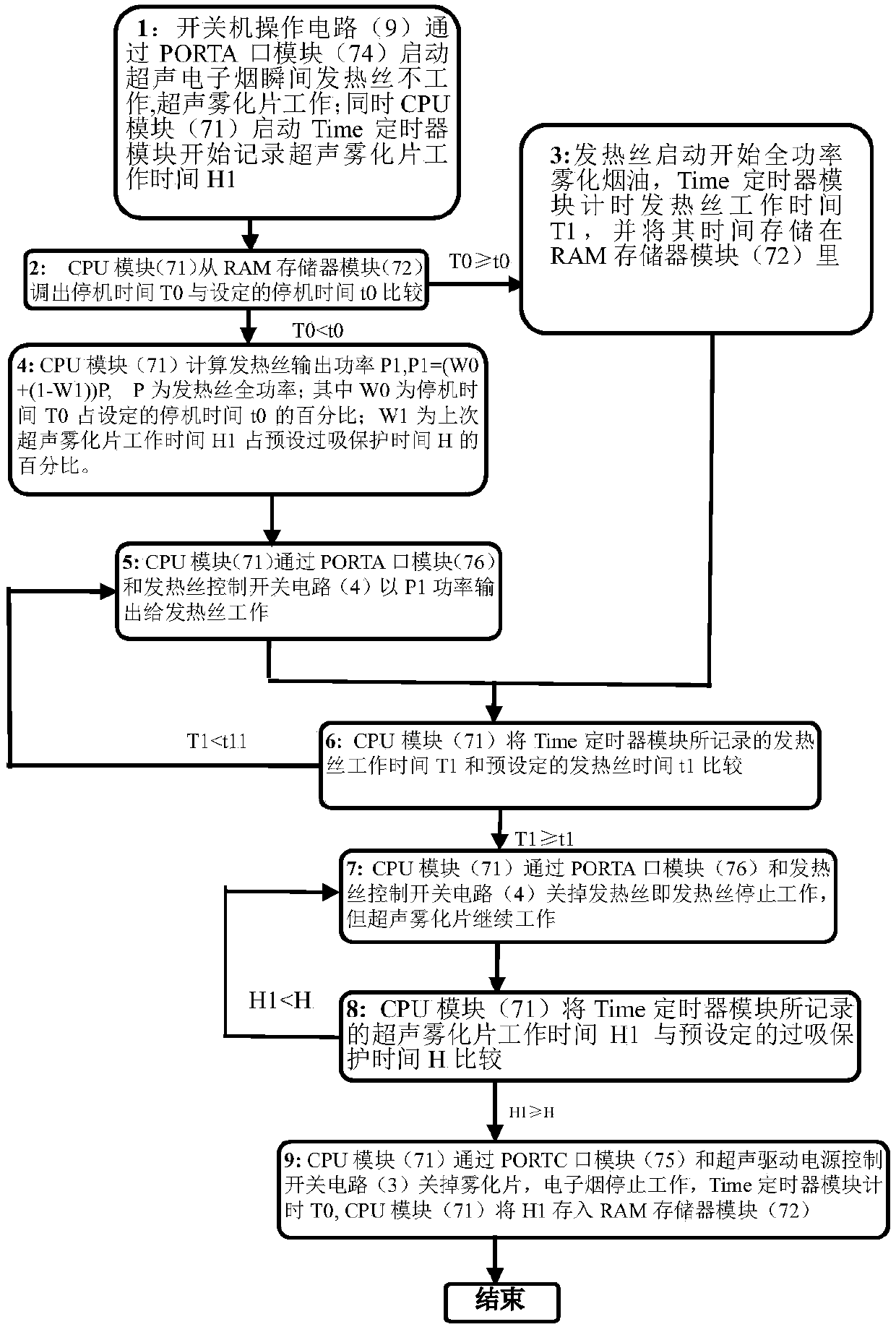

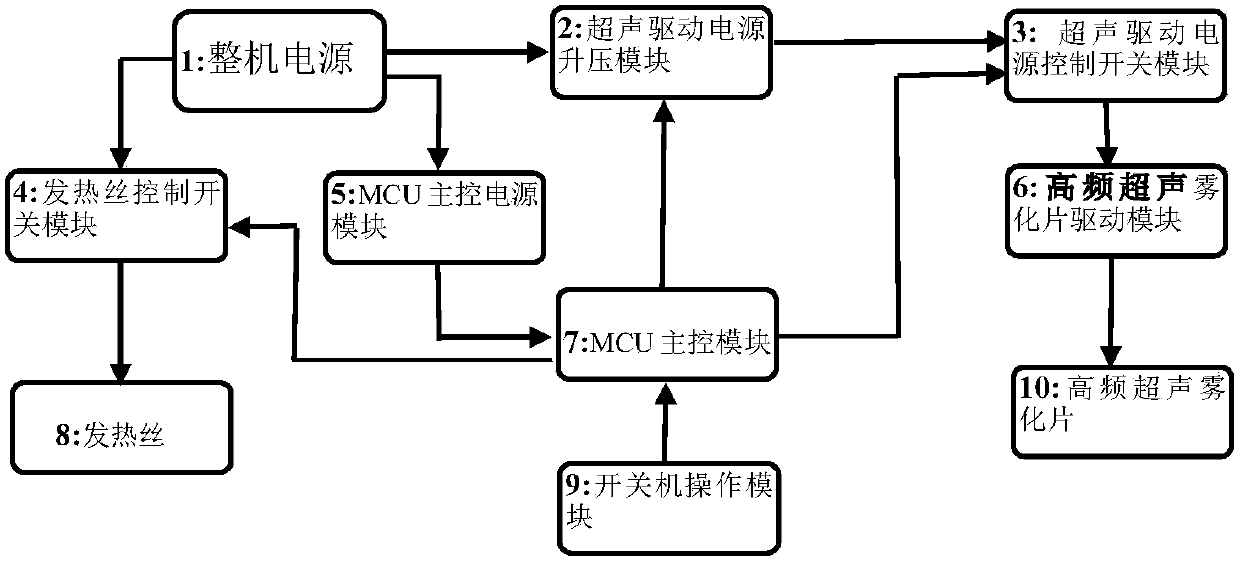

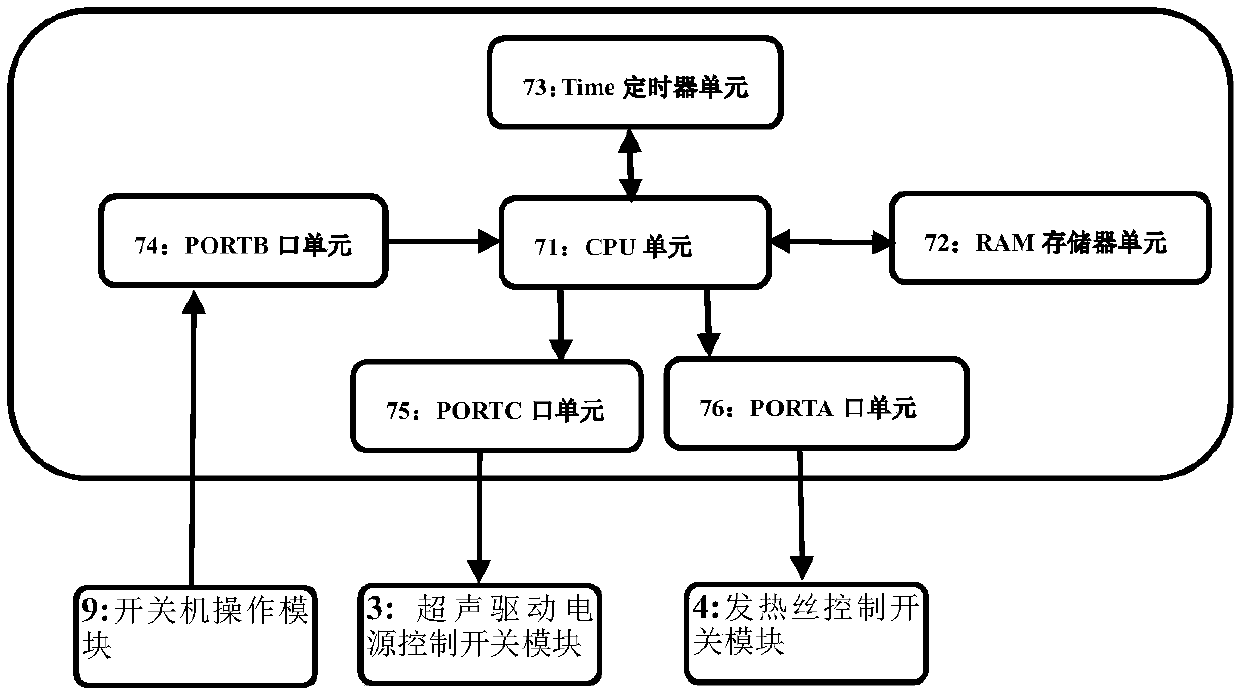

[0042] Such as figure 1 , the method steps of the present invention are as follows:

[0043] 1) Start the work of the ultrasonic atomizer, and record the working time H1 of the ultrasonic atomizer at the same time;

[0044] 2) Compare the downtime T0 with the set downtime t0; if T0≥t0, the heating wire atomizes the e-liquid at full power, records the working time T1 of the heating wire, and enters step 5); if T0<t0, enters Step 3); The preset shutdown time is 0.5<t0<5min, preferably 0.5<t0<1.5min;

[0045] 3) Calculate the heating wire output power P1 according to the formula P1=(W0+(1-W1))*P; where P is the full power of the heating wire (namely the rated power), and W0 is the percentage of downtime T0 in the set downtime t0 ; W1 is the percentage of the working time H1 of the last ultrasonic atomization tablet to the overabsorption protection time H.

[0046] 4) The heating wire works with output power P1;

[0047] 5) Compare the working time T1 of the heating wire with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com