Draining pump of washing machine

A technology for drainage pump and washing machine, which is applied to washing machine appliances, other washing machines, pumps, etc., can solve the problems of shortening the service life of the motor, increasing the load of the motor, and complex structure of the impeller and pump cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

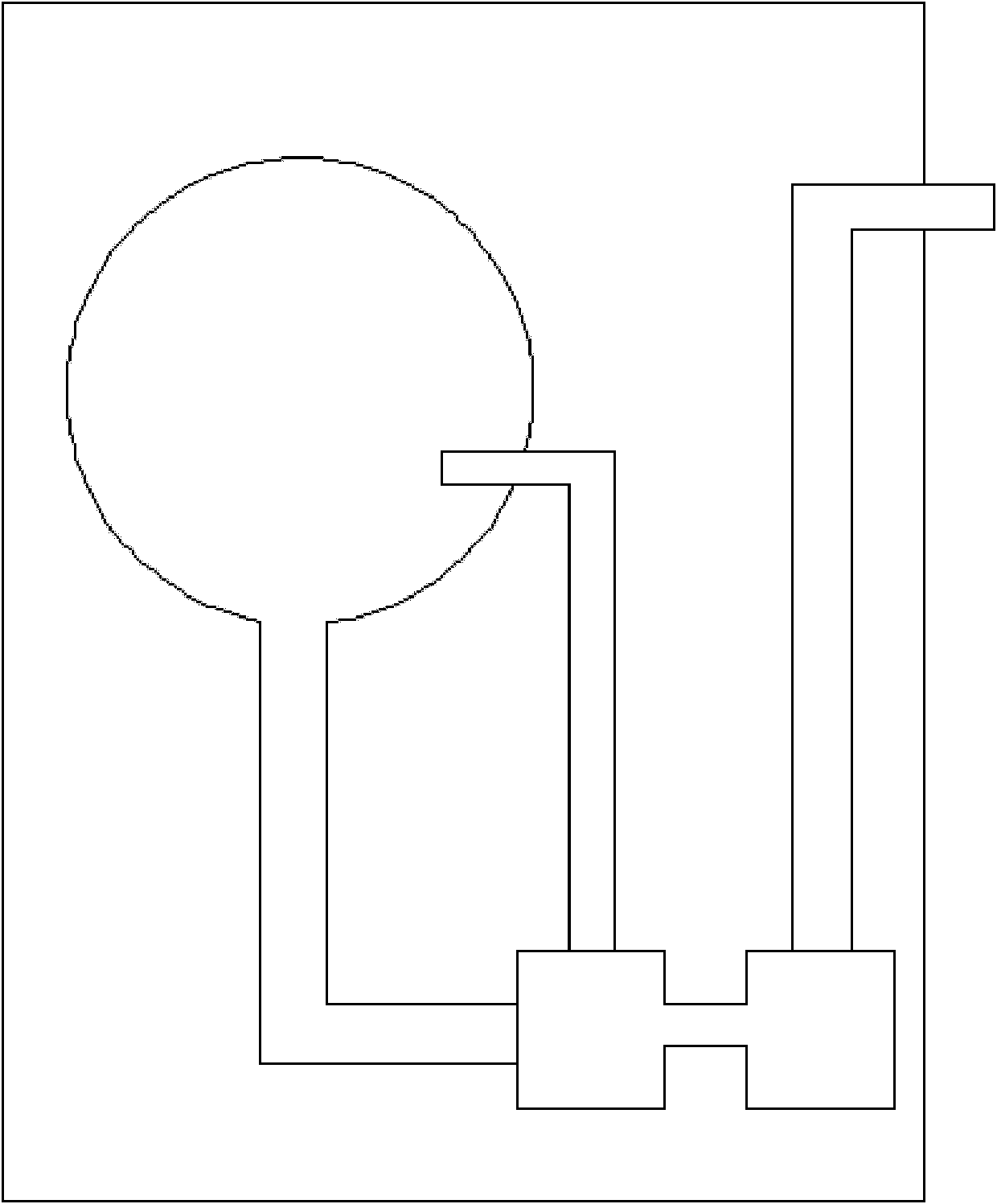

Image

Examples

Embodiment 1

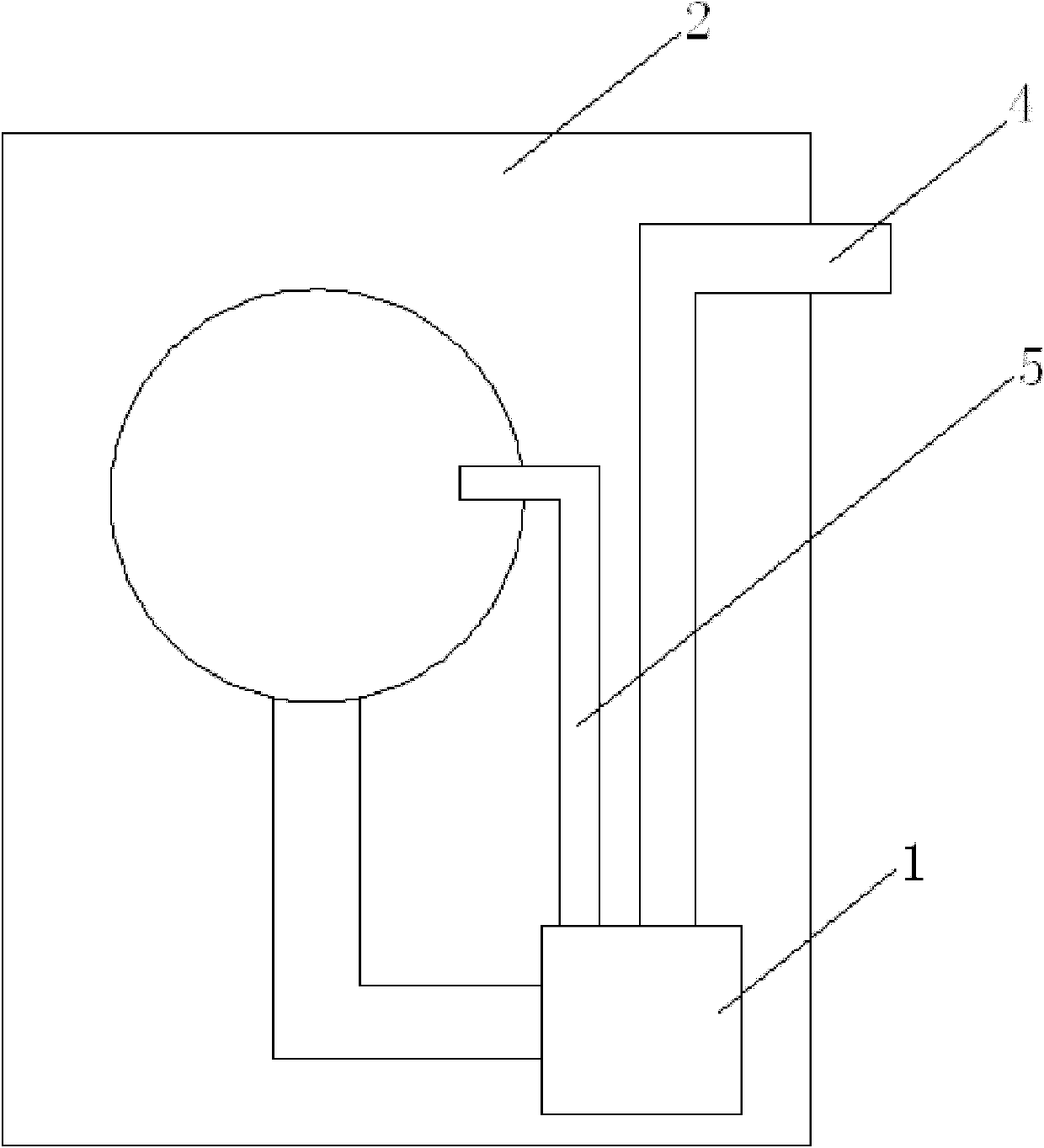

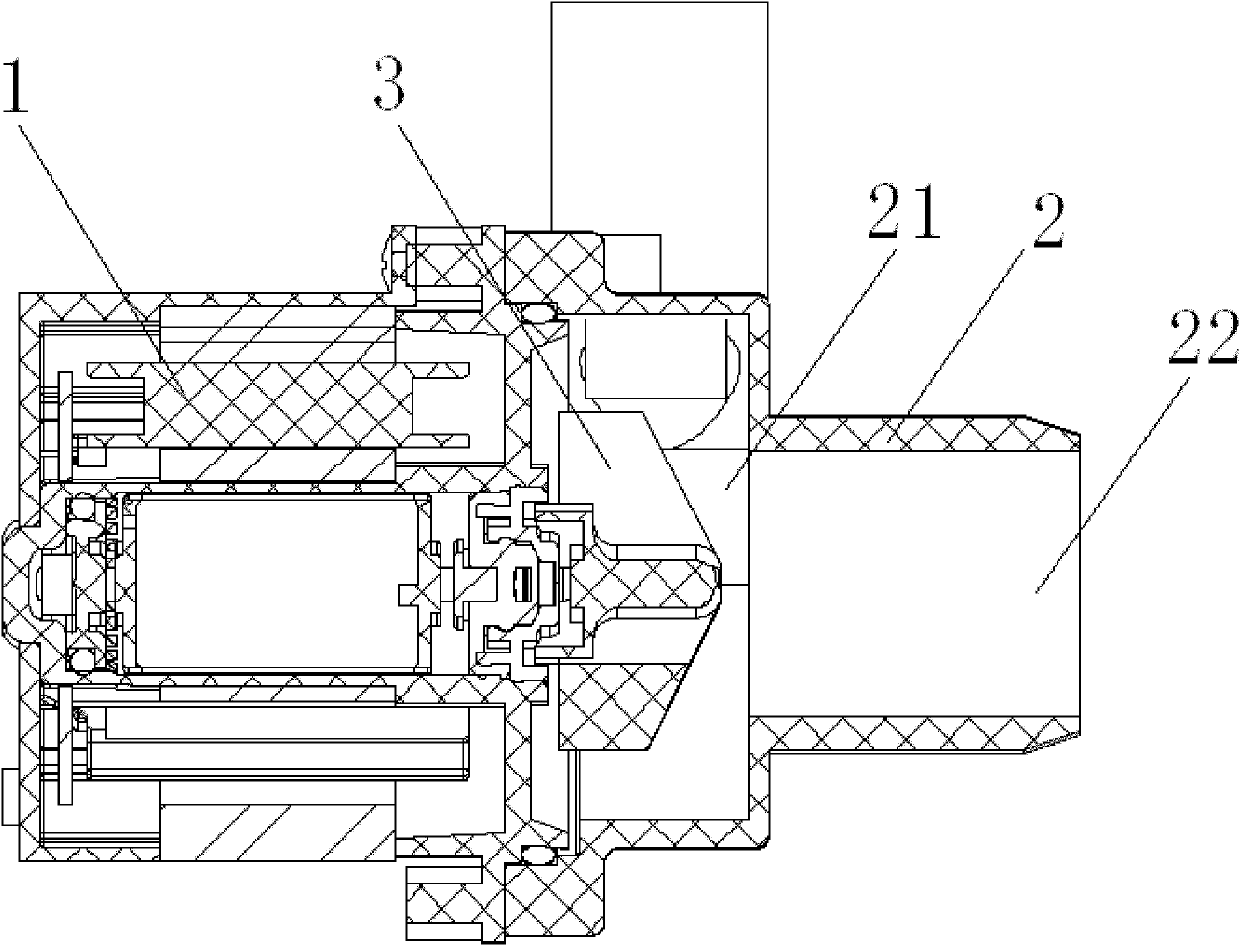

[0020] See figure 2 and image 3 , This embodiment includes a motor 1, a pump casing 2, an impeller 3, a drainage pipe 4, a circulation pipe 5 and an arc stopper 6.

[0021] The motor 1 is a brushless permanent magnet DC motor capable of forward and reverse rotation. The motor 1 is fixed on the bottom of the pump casing 2 . The lower part of the pump casing 2 is a pump chamber 21 , and the upper part is a water inlet 22 . The impeller 3 is located in the pump cavity 21 of the pump casing 2 and is fixed on the motor shaft of the motor 1 . The drainage pipe 4 and the circulation pipe 5 are arranged in the same direction, and are respectively fixed on both sides of the pump casing 2 , and both are tangent to the inner wall of the pump chamber 21 . The arc-shaped stopper 6 is fixed at the intersection of the drain pipe 4 and the inner wall of the pump chamber 21 .

[0022] See Figure 4 When the washing machine drains water, the impeller 3 rotates clockwise under the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com