Touch control display panel and manufacture method thereof

A technology of touch display panel and touch panel, which is applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

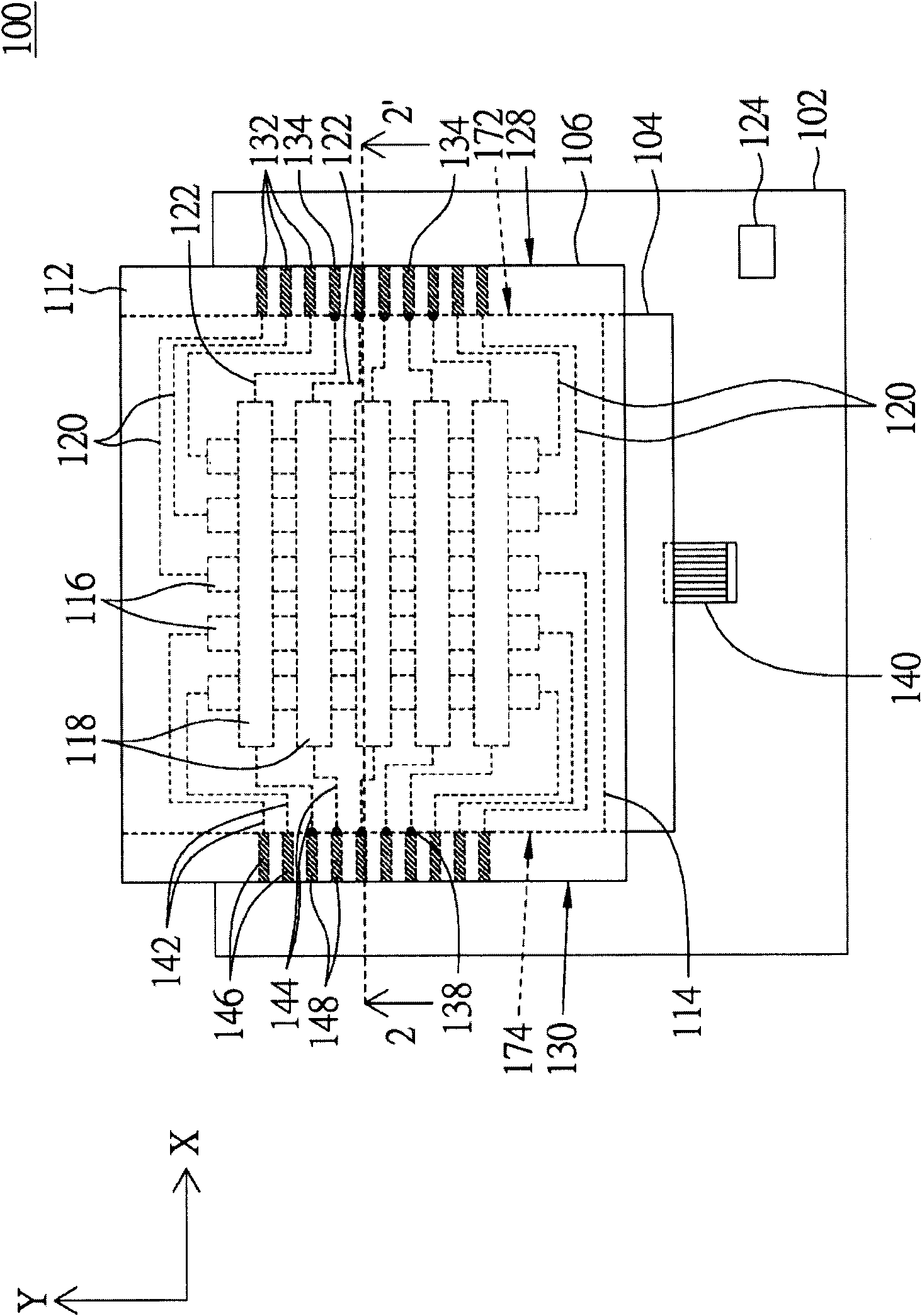

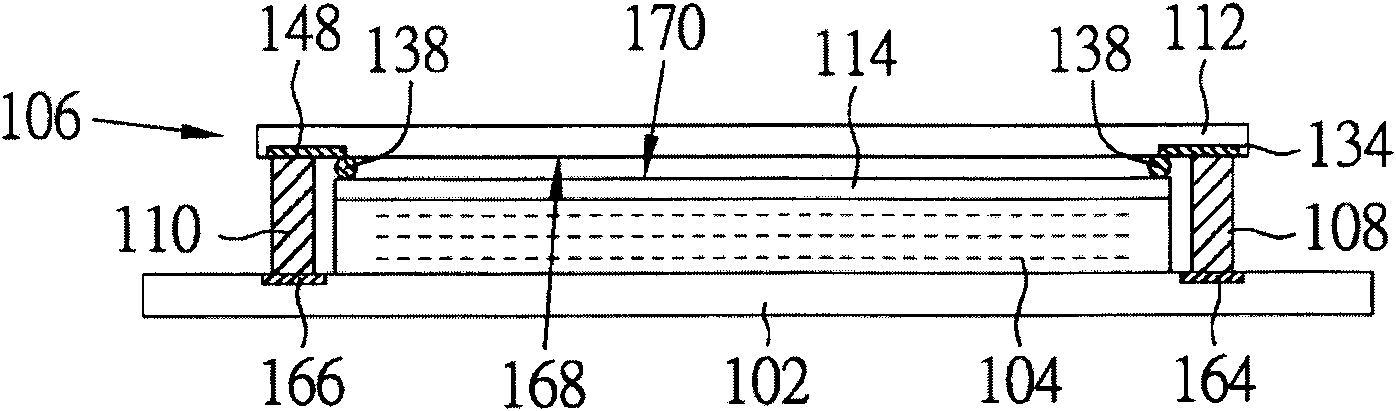

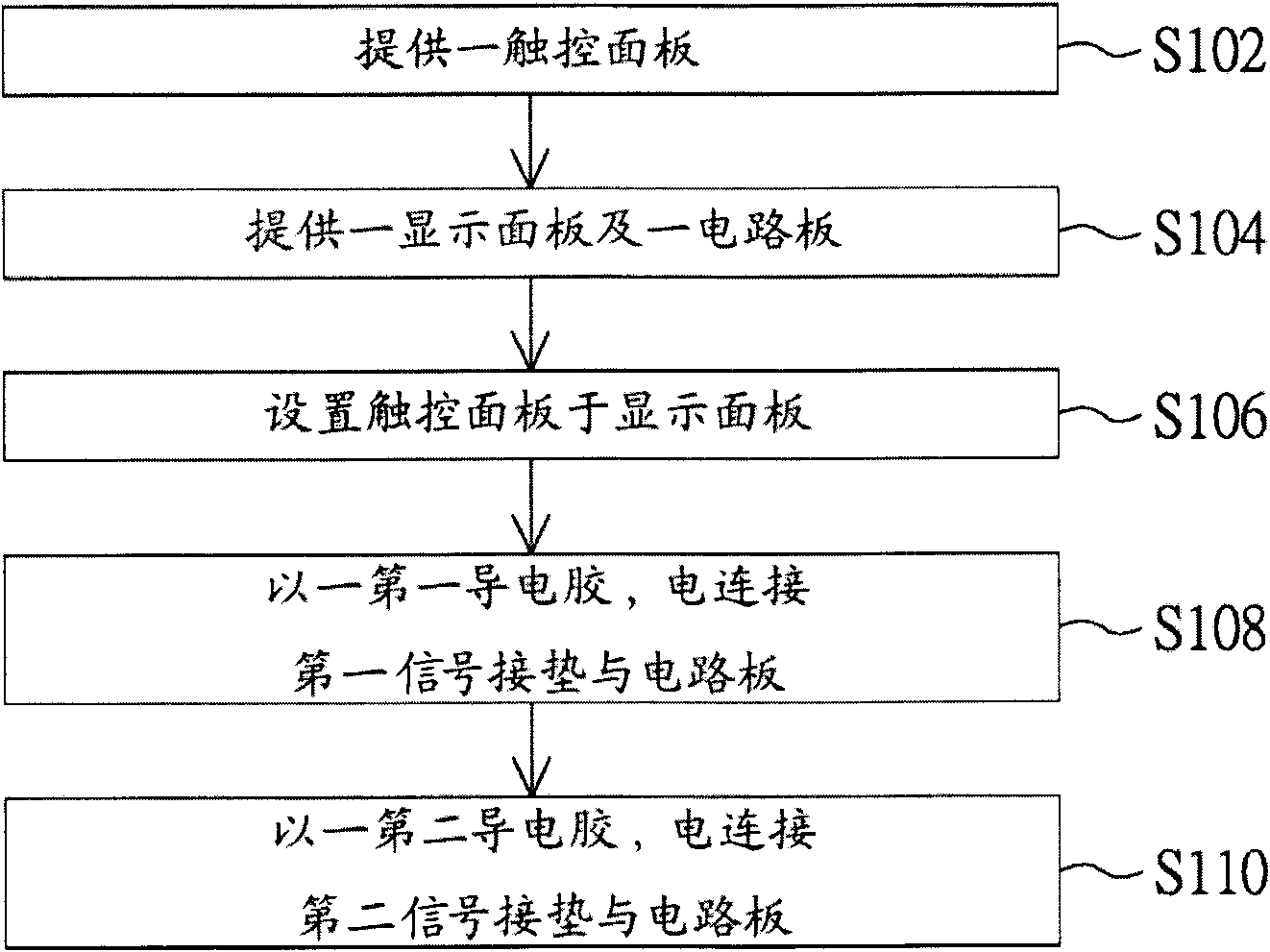

[0051] Please refer to figure 1 and figure 2 , figure 1 It shows the top view of the touch display panel according to the first embodiment of the present invention, figure 2 draw figure 1 Sectional view of 2-2' in the middle direction.

[0052] like figure 1 As shown, the touch display panel 100 includes a circuit board 102, a display panel 104, a touch panel 106, a first conductive glue 108 and a second conductive glue 110 (the first conductive glue 108 and the second conductive glue 110 are shown in figure 2 ). Wherein, the touch panel 106 is a resistive touch panel.

[0053] The touch panel 106 includes a plurality of signal lines and a first substrate 112 and a second substrate 114 disposed opposite to each other. The signal lines include several first signal lines 120 , several second signal lines 122 , several third signal lines 142 and several fourth signal lines 144 .

[0054] The first substrate 112 includes a plurality of first sensing lines 116 , a plural...

no. 2 example

[0080] Please refer to Figure 4 , which is a schematic diagram of a display touch panel according to a second embodiment of the present invention. The parts in the second embodiment that are the same as those in the first embodiment use the same reference numerals, which will not be repeated here. The display touch panel 200 of the second embodiment is different from the display touch panel 100 of the first embodiment in that the signal pads of the display touch panel 200 are disposed corresponding to four sides of the first substrate.

[0081] The touch panel 206 of the display touch panel 200 is, for example, a resistive touch panel, which includes a plurality of signal lines 262 and a first substrate 212 and a second substrate 214 disposed opposite to each other.

[0082] The first substrate 212 includes a plurality of first sensing lines 116 , a plurality of first signal pads 254 , a plurality of second signal pads 256 , a plurality of third signal pads 258 and a plurali...

no. 3 example

[0088] Please refer to Figure 5 and Image 6 , Figure 5 It shows the top view of the touch display panel according to the third embodiment of the present invention, Image 6 draw Figure 5 Sectional view of 6-6' in the middle direction. The parts in the third embodiment that are the same as those in the first embodiment use the same reference numerals, which will not be repeated here. The touch display panel 300 of the third embodiment is different from the touch display panel 100 of the first embodiment in that the sensing lines of the touch panel 306 of the touch display panel 300 are formed on a single substrate.

[0089] The touch panel 306 is, for example, a capacitive touch panel, which includes a plurality of signal lines 362 and a substrate 312 . The substrate 312 includes a plurality of first sensing lines 316 and a plurality of second sensing lines 318 . The first sensing line 316 , the second sensing line 318 and the signal line 362 are all formed on the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com