Liquid supply system and liquid consumption apparatus with same

A technology of a liquid consumption device and a liquid supply system, which is applied in printing and other directions, and can solve problems such as multiple replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, in order to clarify the contents of the present invention described above, examples will be described in the following order.

[0057] A. Device composition:

[0058] A-1. Composition of inkjet printer:

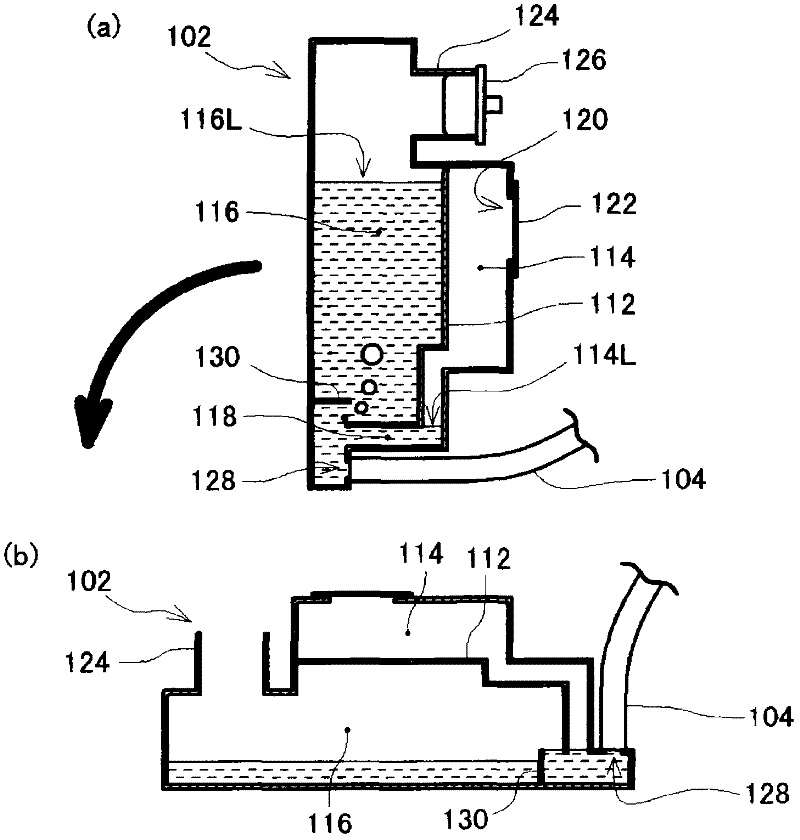

[0059] A-2. The composition of the ink tank;

[0060] A-3. The composition of the tank:

[0061] B. Variations:

[0062]A. Device composition:

[0063] A-1. Composition of inkjet printer:

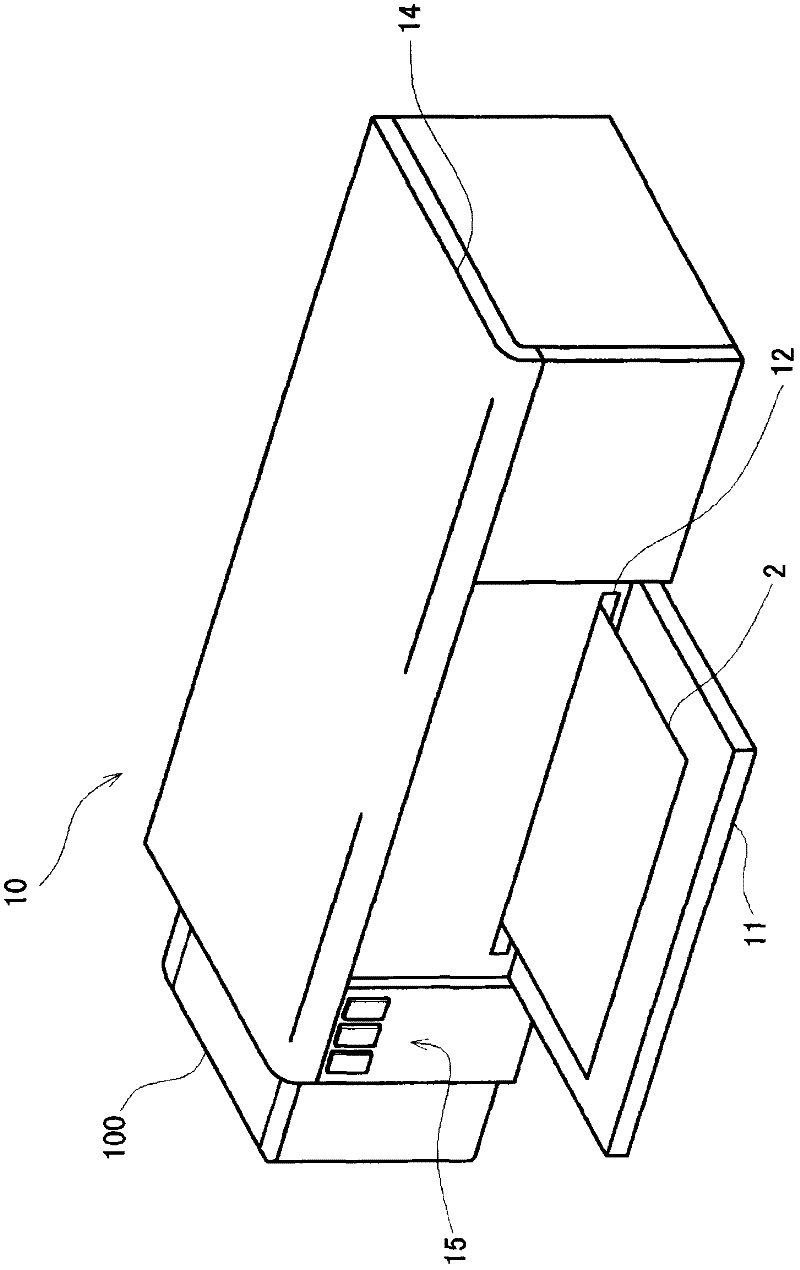

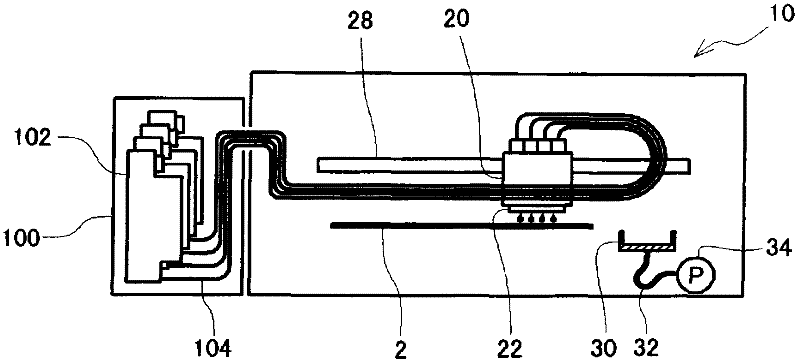

[0064] figure 1 It is an explanatory diagram illustrating an inkjet printer 10 as a liquid consuming device of this embodiment. The illustrated inkjet printer 10 has a generally box-shaped appearance, a front cover 11 is provided at a substantially central position of the front surface, and a plurality of operation buttons 15 are provided adjacent to the left side of the front cover. The front cover 11 is pivotally supported on the lower end side, and when the upper end side is brought down to the front side, the elongated paper discharge opening 12 through which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com