Press board for folder

A technology for folder and cardboard, applied in the field of cardboard, can solve the problems such as hindering the user's operation of the folder, the outer contour lines are not beautiful and elegant, and the overall structure of the cardboard is uncoordinated, etc. The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

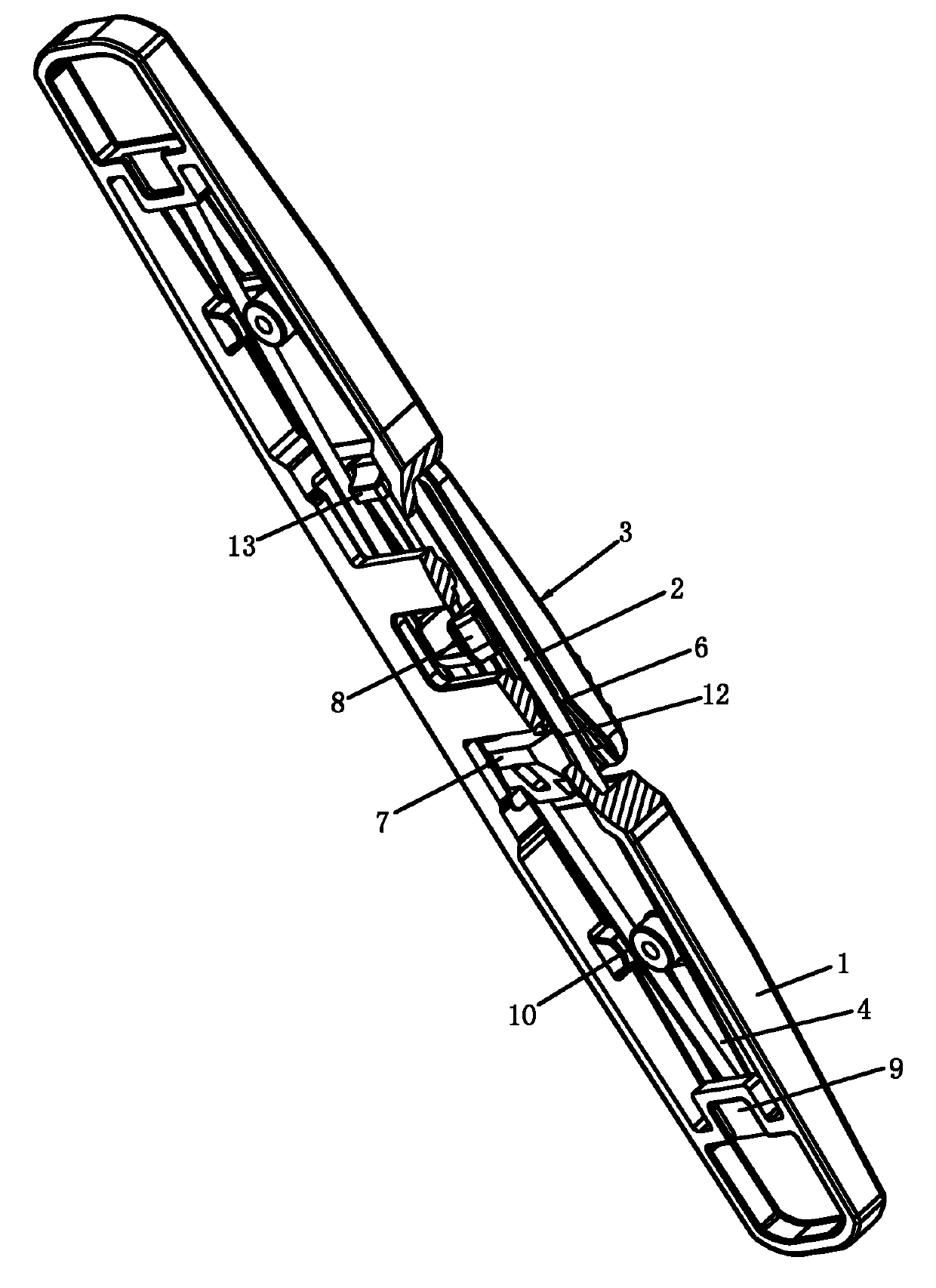

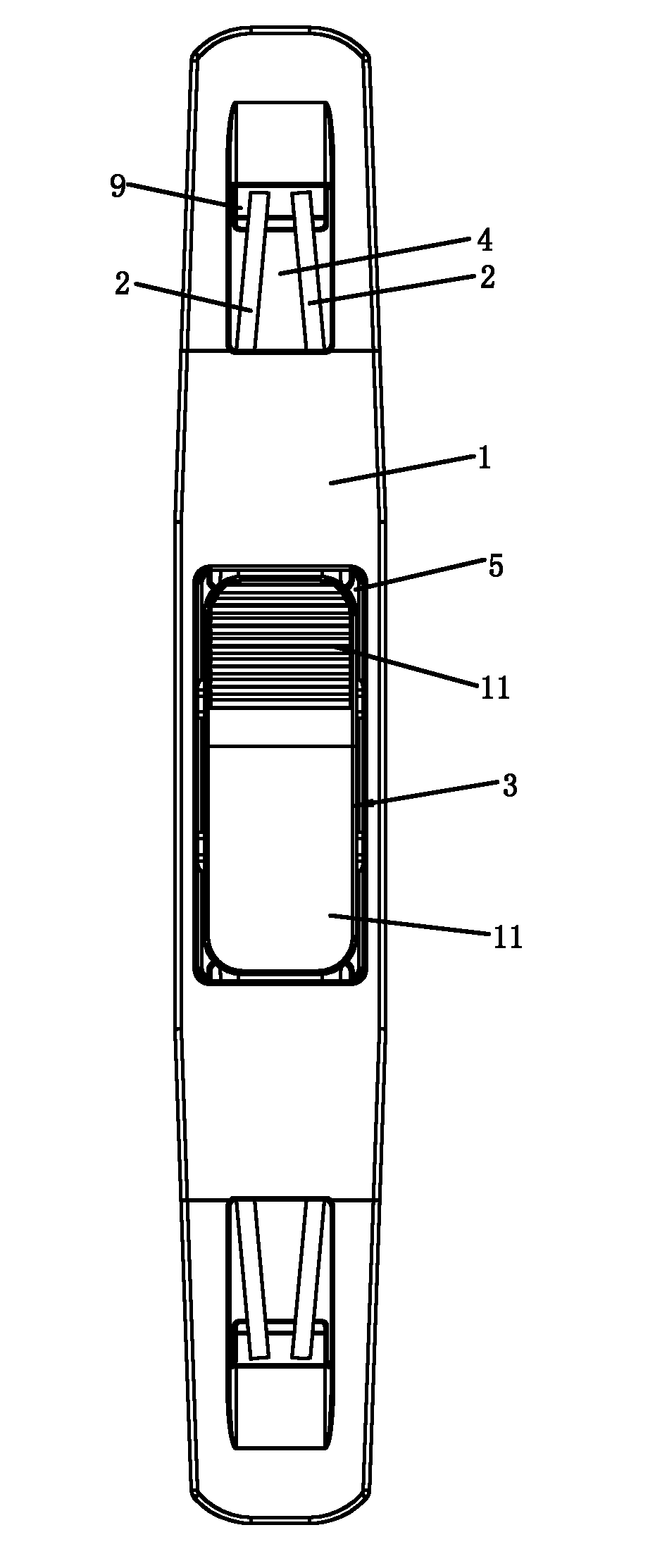

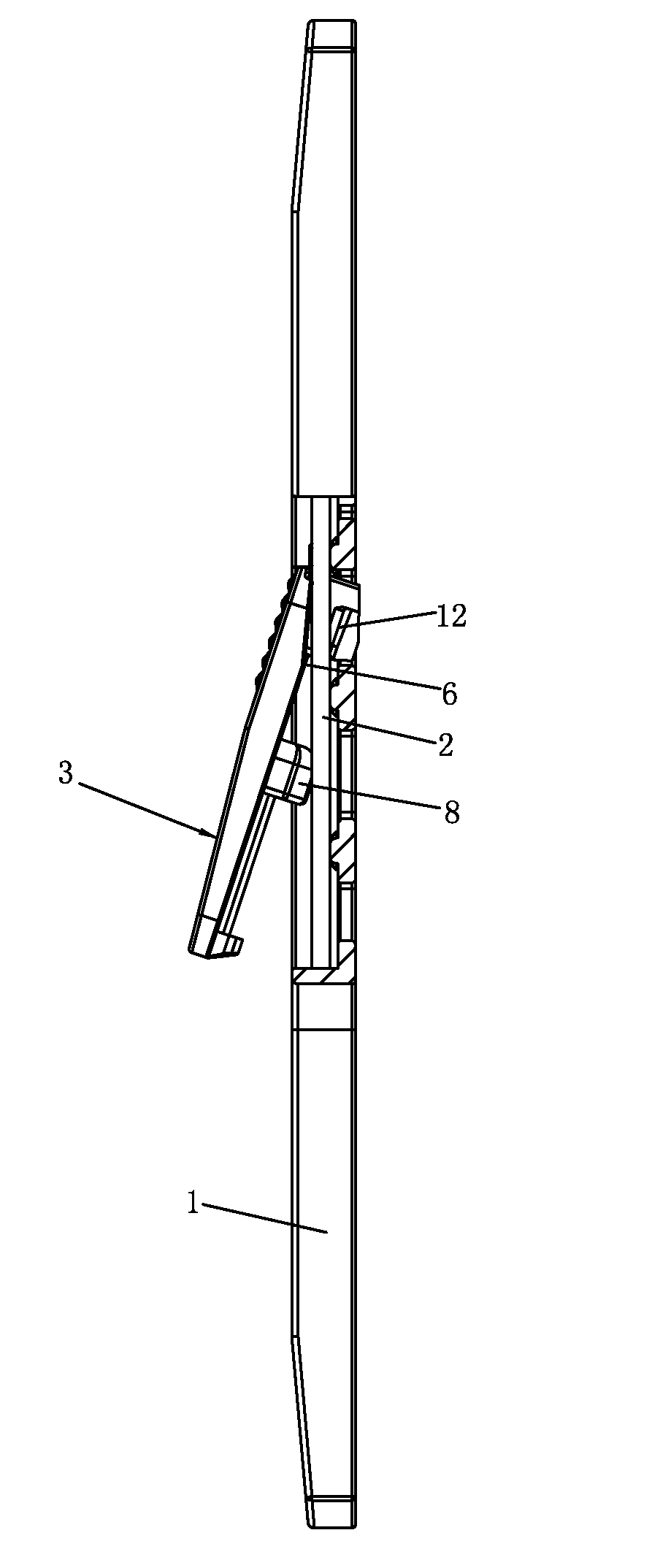

[0033] An embodiment of a pressboard used in folders of the present invention is as follows: Figure 1 to Figure 9 As shown, it includes a bottom plate 1, two elastic steel wires 2 and a pressing handle 3. The two sides of the bottom plate 1 are respectively provided with windows 4 for the needle body of the file folder to pass through. The first side of the bottom surface of the pressing handle 3 is provided with a The first side of the handle 3 is clamped to the clamping part 7 of the two elastic steel wires 2 and the clamping part 8 for clamping the pressing handle 3 on the two elastic steel wires 2, and the clamping part 7 of the pressing handle 3 is clamped On two elastic steel wires 2.

[0034] In a preferred embodiment, two elastic steel wires 2 pass through the bottom of the bottom plate 1 . This design is especially suitable for pressboards comprising a bottom plate 1 made of metal material.

[0035] In another preferred embodiment, the bottom plate 1 is provided wi...

Embodiment 2

[0056] An embodiment of a pressboard used in folders of the present invention is as follows: Figure 10 to Figure 16 As shown, the main structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here. The difference is that the top surface of the bottom plate 1 is hollowed out, and the two sides of the handle receiving cavity 5 on the bottom plate 1 are respectively The windows 4 on both sides of the base plate 1 are communicated.

[0057] This embodiment is especially suitable for the bottom plate 1 made of plastic materials. The top surface of the bottom plate 1 adopts a full hollow design, which further reduces the amount of materials used, further reduces the production cost, and reduces the thickness of the pressboard, making the pressboard lighter, thinner and more compact , the space occupied by the pressboard is smaller, and the file folder configured with the pressboard of the present invention can hold more paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com