Shutter driving device of locomotive cooling system

A cooling system and driving device technology, applied to locomotives, etc., can solve problems such as high failure rate, backwardness, gas contained in oil and exhaust, etc., and achieve the effect of low failure rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

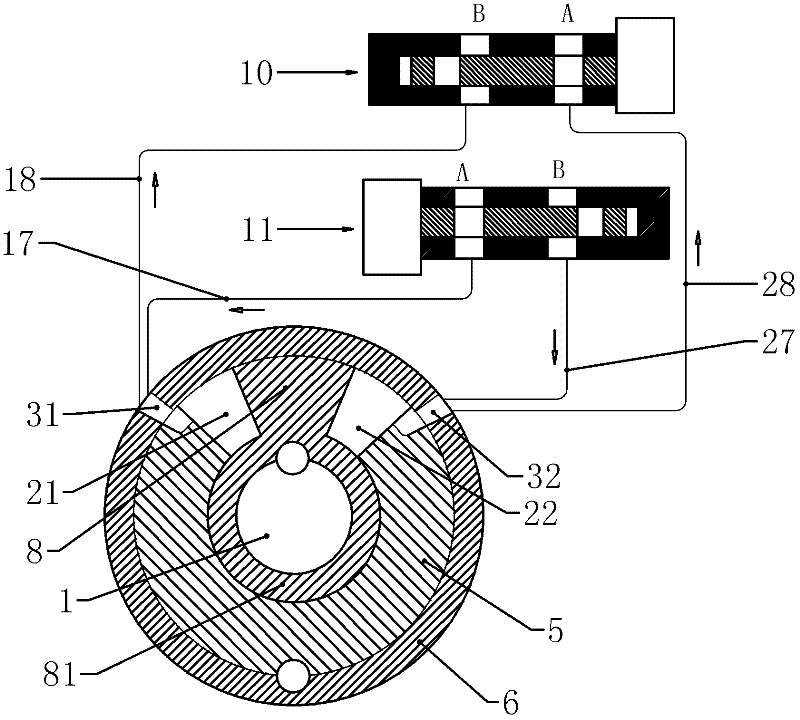

[0021] The working principle of the locomotive cooling system louver driving device of the present invention is to drive the pneumatic two-position rotary angle valve 12 through the wind pressure of the locomotive braking system to drive the louver to open and close.

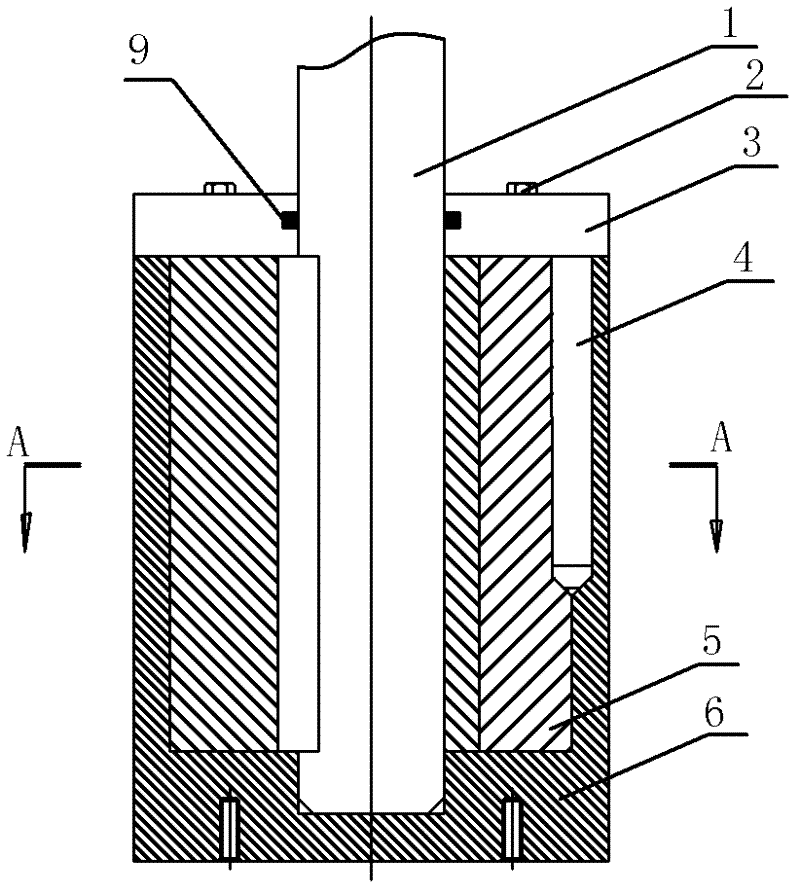

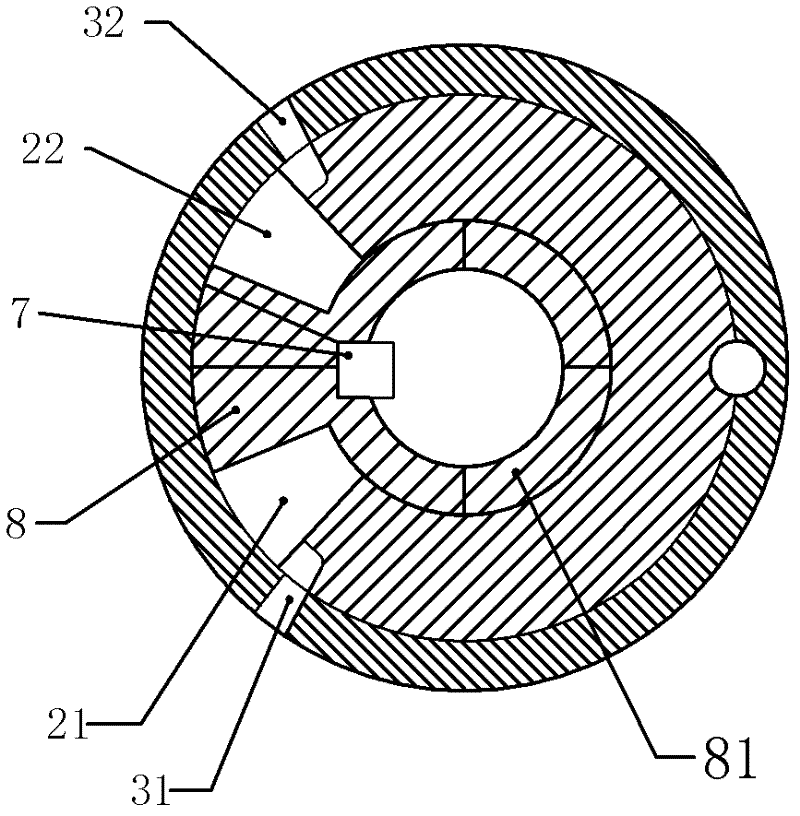

[0022] First, the structure and action principle of the pneumatic two-position rotary valve 12 are as follows. Such as figure 1 , figure 2 As shown, the pneumatic two-position rotary valve 12 includes a valve body, a drive shaft 1 at the center, and a drive vane 8 fixedly connected to the drive shaft 1. The valve body has a fan-shaped cavity, and the drive vane 8 moves in the fan-shaped cavity. The cavity is divided into the first air chamber 21 and the second air chamber 22 which are respectively sealed. The first air hole 31 corresponding to the position of the first air chamber 21 and the corresponding hole 31 to the position of the second air chamber 22 are opened on the valve body. The second air hole 32...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap