Elevator winch mounting method

An installation method, hoist technology, applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of using the same supplies, use restrictions, and large parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

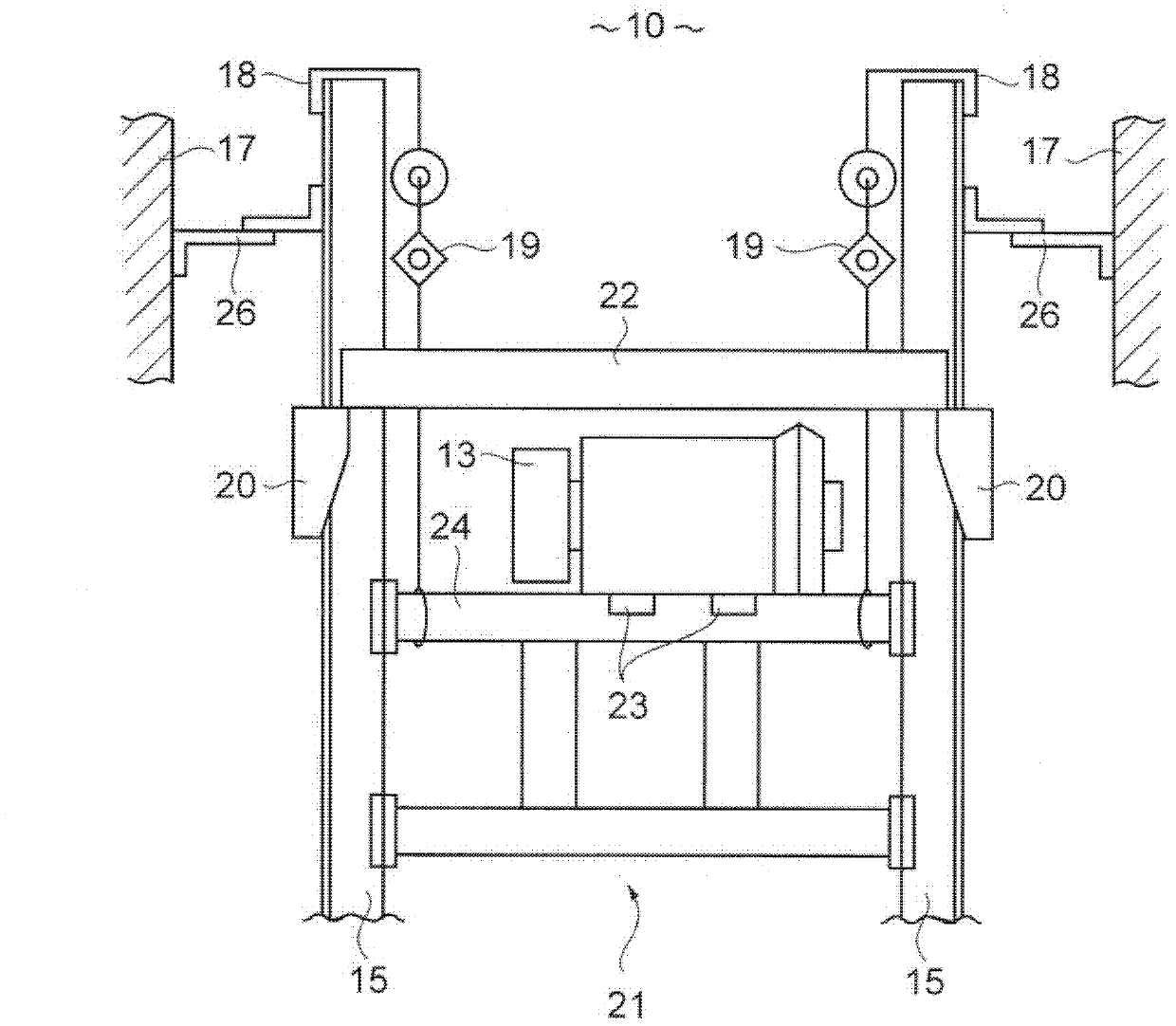

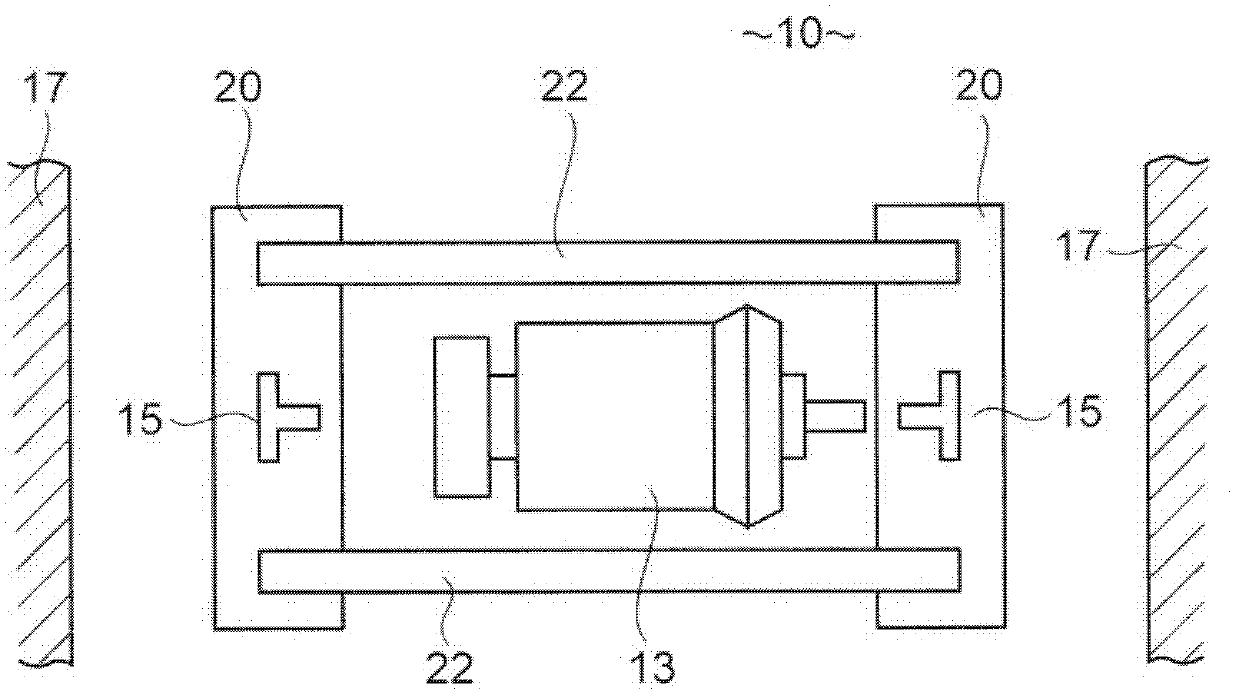

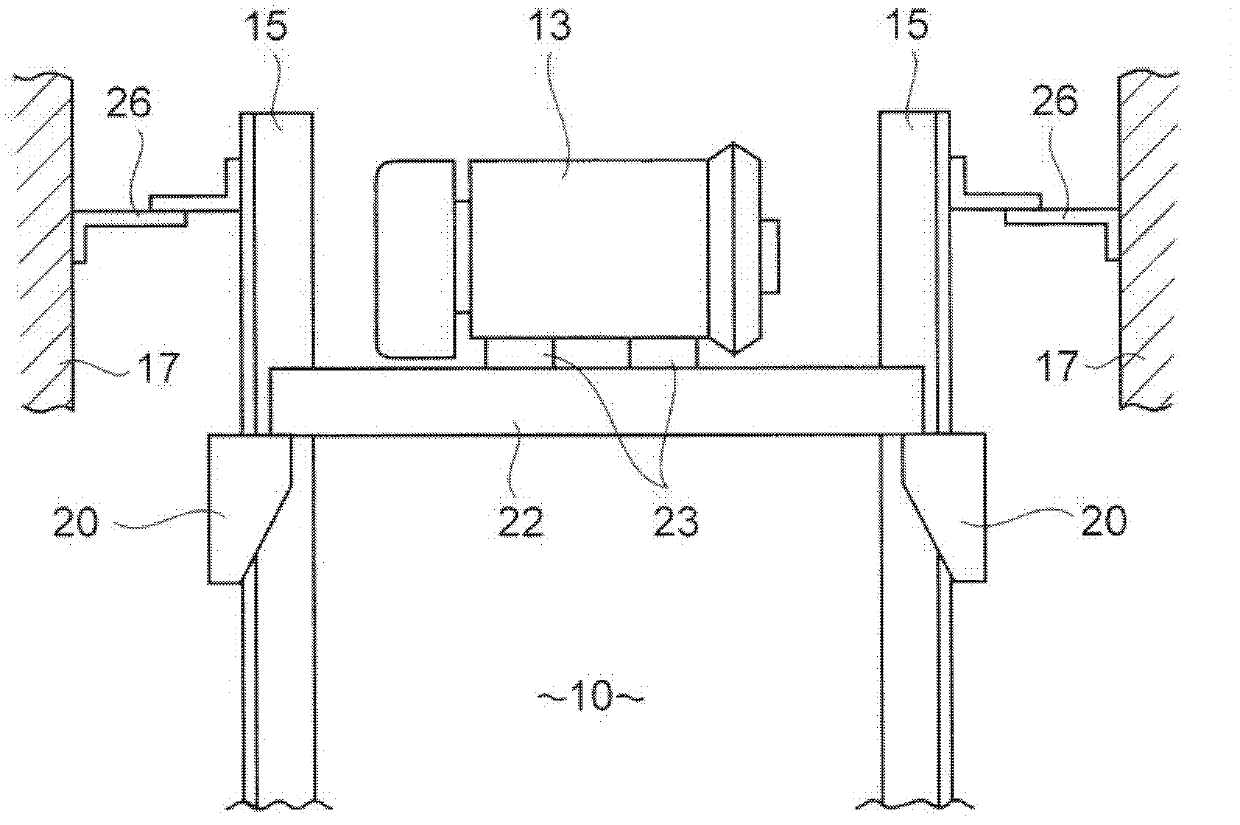

[0012] Embodiments of the elevator hoist installation method of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a schematic elevational view showing the state in the middle of a lifting step in one embodiment of the method for installing an elevator hoist according to the present invention. figure 2 yes means figure 1 A top view of the state. image 3 yes means figure 1 A schematic elevational view of the situation after the installation of the hoist of the elevator according to the embodiment of the present invention is completed. Figure 4 It is a flowchart showing the operation procedure of one embodiment of the elevator hoist installation method of the present invention.

[0013] In the elevator apparatus of this embodiment, a hoist 13 , a car and a counterweight (not shown) are arranged in the hoistway 10 . The car and the counterweight are suspended by ropes (not shown), and the ropes are wound up or unwound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com