System for maintaining brake device of elevator

A braking device and elevator technology, applied in the directions of transportation, packaging, elevators, etc., can solve problems such as it is difficult to detect abnormal braking characteristics, evaluation of braking characteristics, etc., to achieve the effect of maintenance work and maintenance of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

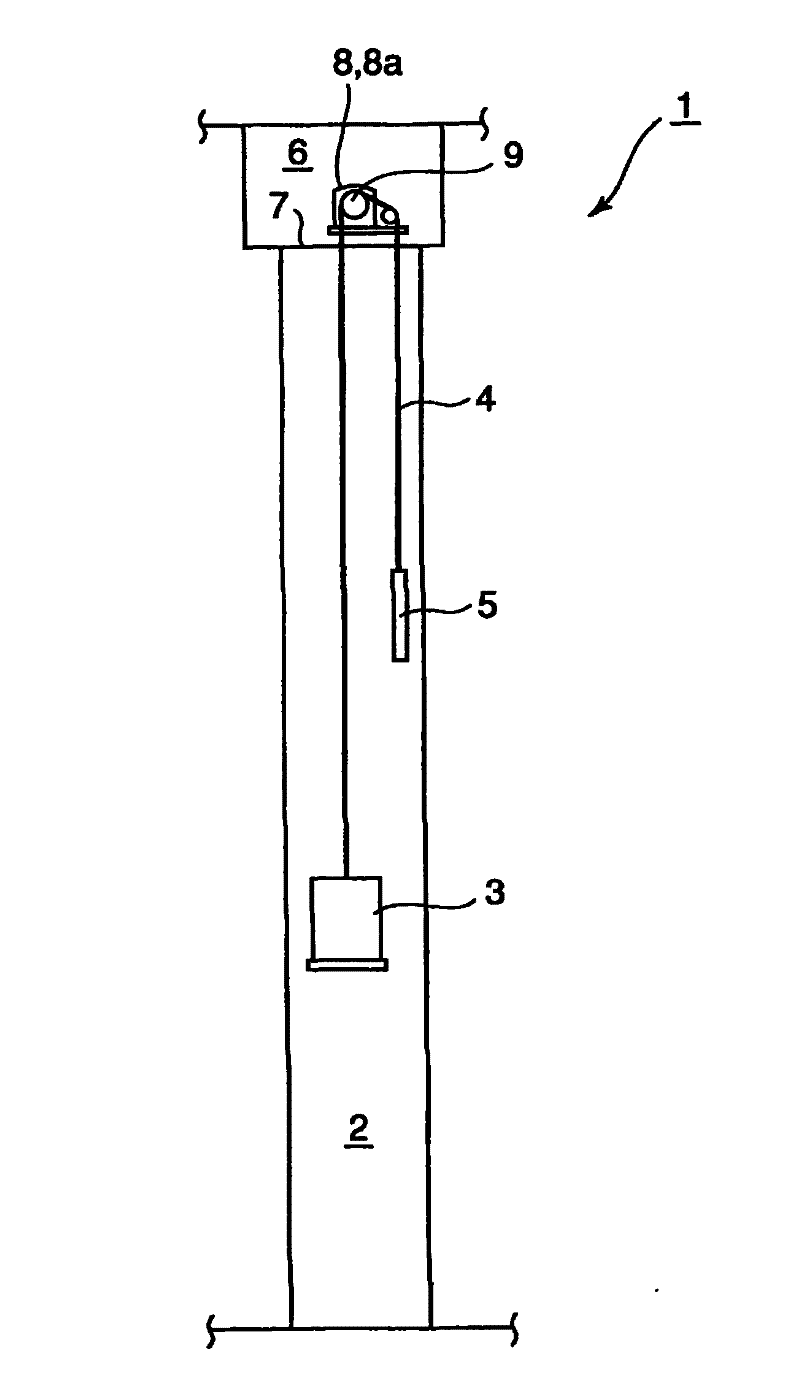

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings. here, Figure 1 ~ Figure 4 It is a figure which shows the brake device inspection system for elevators concerning 1st Embodiment of this invention.

[0033] First, through figure 1 The overall configuration of the elevator system 1 will be described. like figure 1 As shown, the elevator system 1 includes: a car 3 ascending and descending in the hoistway 2; a main rope 4 connected to the car 3 at one end to lift the car 3; Further, above the hoistway 2, a machine room bottom 7 defining the machine room 6 is provided, and a hoist 8 for driving the main rope 4 is provided on the machine room bottom 7. As shown in FIG. In addition, the hoist 8 is connected to a pulley 9 around which the main rope 4 is wound, and is connected to a braking device 10 ( figure 2 see) link.

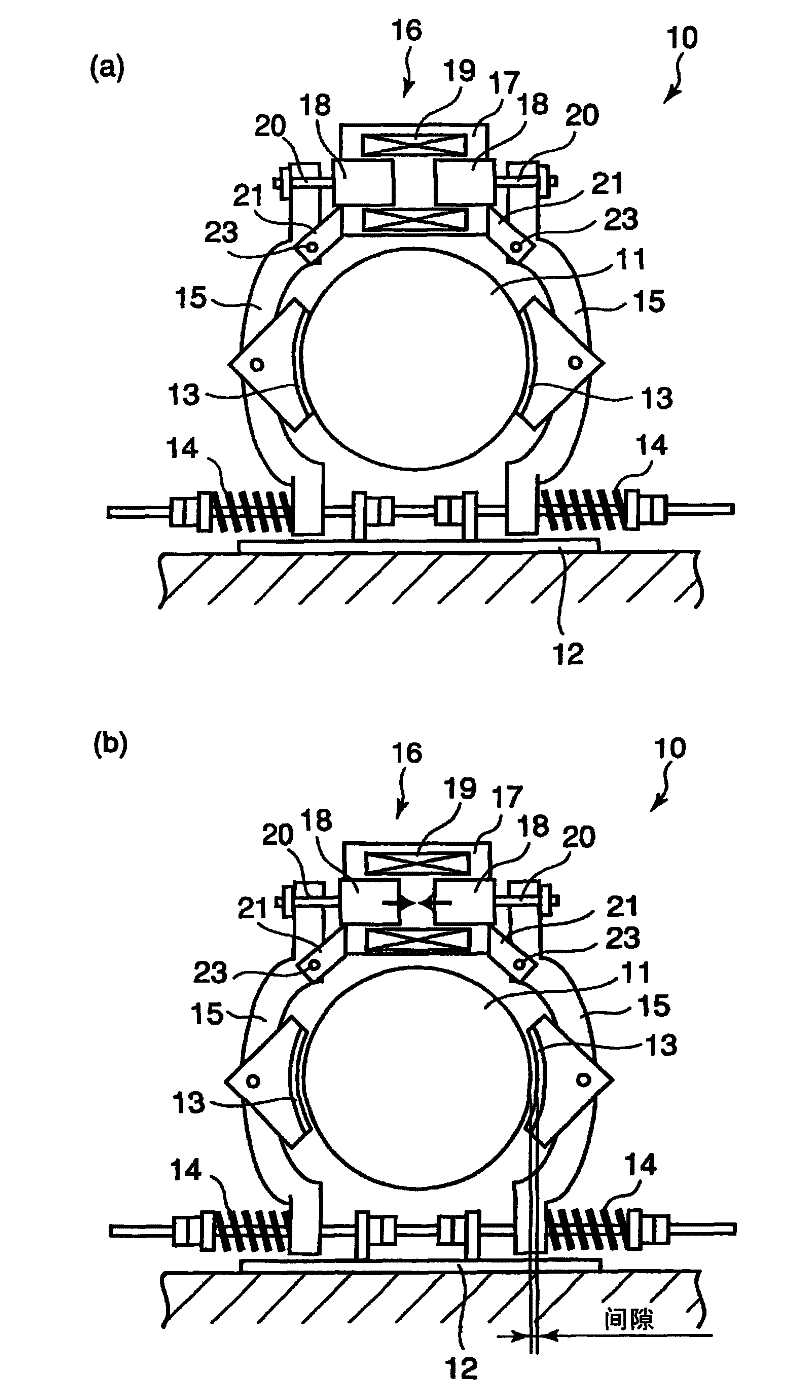

[0034] Next, use figure 2 (a), figure 2 (b) The brake device 10 will be described. figure 2 (...

no. 2 Embodiment approach

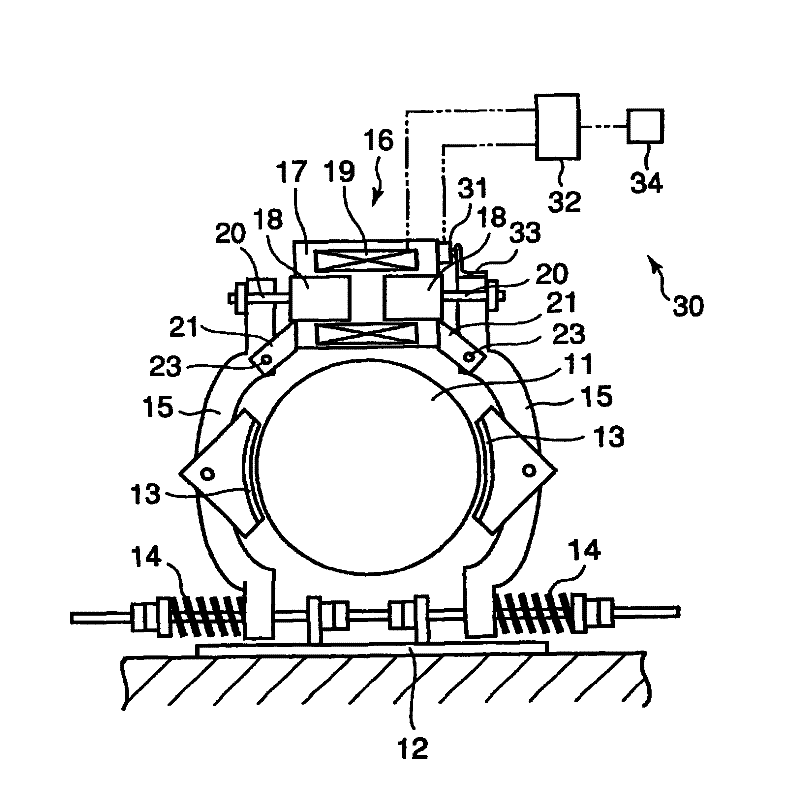

[0058] Next, refer to Figure 5 as well as Image 6 , the elevator braking device inspection system according to the second embodiment of the present invention will be described.

[0059] exist Figure 5 as well as Image 6 In the second embodiment shown, the brake device inspection system switches for elevators are respectively provided corresponding to the pair of arms of the brake device, which is mainly different in this point, and other configurations are the same as Figure 1 ~ Figure 4 The first embodiment shown is substantially the same. In addition, in Figure 5 as well as Image 6 in, for with Figure 1 ~ Figure 4 The same reference numerals are assigned to the same parts as those in the first embodiment shown, and detailed description thereof will be omitted.

[0060] In addition, a first switch 31a is provided corresponding to one lining 13 of the pair of linings 13 for detecting that the one lining 13 in contact with the brake drum 11 is separated from the ...

no. 3 Embodiment approach

[0071] Next, refer to Figure 7 , an elevator braking device inspection system according to a third embodiment of the present invention will be described.

[0072] exist Figure 7 (a), Figure 7 In the third embodiment shown in (b), in the brake device inspection system for elevators, the position measuring unit for measuring the position of the lining is provided on the base of the brake device, which is mainly different in this point, and the other Consists of Figure 1 ~ Figure 4 The first embodiment shown is substantially the same. In addition, in Figure 7 in, for with Figure 1 ~ Figure 4 The same reference numerals are assigned to the same parts as those in the first embodiment shown, and detailed description thereof will be omitted.

[0073] exist Figure 7 (a), Figure 7In the elevator braking device inspection system 30 shown in (b), a pair of linear gauges (linear gauges) (position measuring means) for measuring the position of the front end of each arm 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com