Exhaust gas treatment system and exhaust gas treatment method

A technology for waste gas treatment and waste gas, which is applied in separation methods, chemical instruments and methods, and solid waste removal, etc., and can solve the problems of insufficient and excessive fly ash treatment agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, specific embodiments of the present invention will be described in detail, but the present invention is not limited to any of the following embodiments, and can be appropriately modified within the scope of the purpose of the present invention.

[0024]

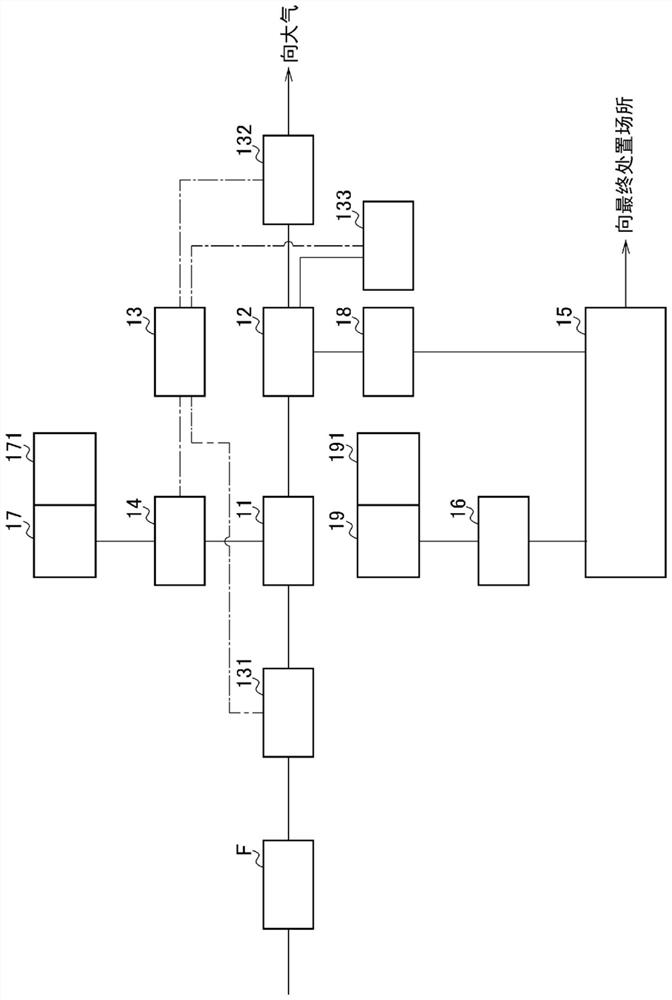

[0025] figure 1 A schematic flowchart of a construction example of the exhaust gas treatment system according to the present embodiment is shown. In addition, in figure 1 In , the solid line among the lines connecting the blocks represents the flow of objects, and the dotted line represents the flow of information.

[0026] The exhaust gas treatment system 1 involved in this embodiment is mainly composed of an exhaust gas treatment unit 11, a fly ash recovery unit 12, an exhaust gas treatment agent addition management unit 13, an exhaust gas treatment agent supply unit 14, a fly ash treatment unit 15, and a fly ash treatment agent supply unit. 16 and a fly ash treatment agent storage unit 19 constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com